Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Reduce production quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

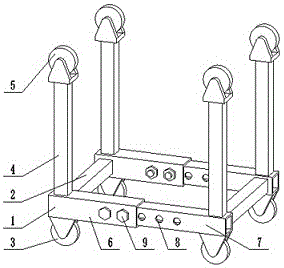

Intelligent bottle transport vehicle

InactiveCN106004948AEasy to moveReduce production quantityHand carts with multiple axesDrive wheelStructural engineering

The invention discloses an intelligent bottle transport vehicle, and belongs to the technical field of transport vehicles. The intelligent bottle transport vehicle comprises a bracket, the bracket is of a rectangular frame structure formed by connecting two transverse beams with two longitudinal beams, four corners of the bottom of the bracket are each provided with a driving wheel, four corners of the upper portion of the bracket are each provided with a support beam, and each support beam is provided with a supporting wheel; the transverse beams comprise the first transverse beam and the second transverse beam, the first transverse beam is of a tubular structure, and one end of the second transverse beam stretches into the first transverse beam; a control box is arranged on the longitudinal beams, and a temperature sensor, a central processing unit, a memory and an air conditioner infrared emitter are arranged in the control box. According to the transport vehicle, bottles can be conveniently and quickly carried, the functional defects of an existing transport vehicle are overcome, and it can be guaranteed that people are always in a suitable environment.

Owner:MAANSHAN JINCHAO RUBBER TECH R&D TECH CO LTD

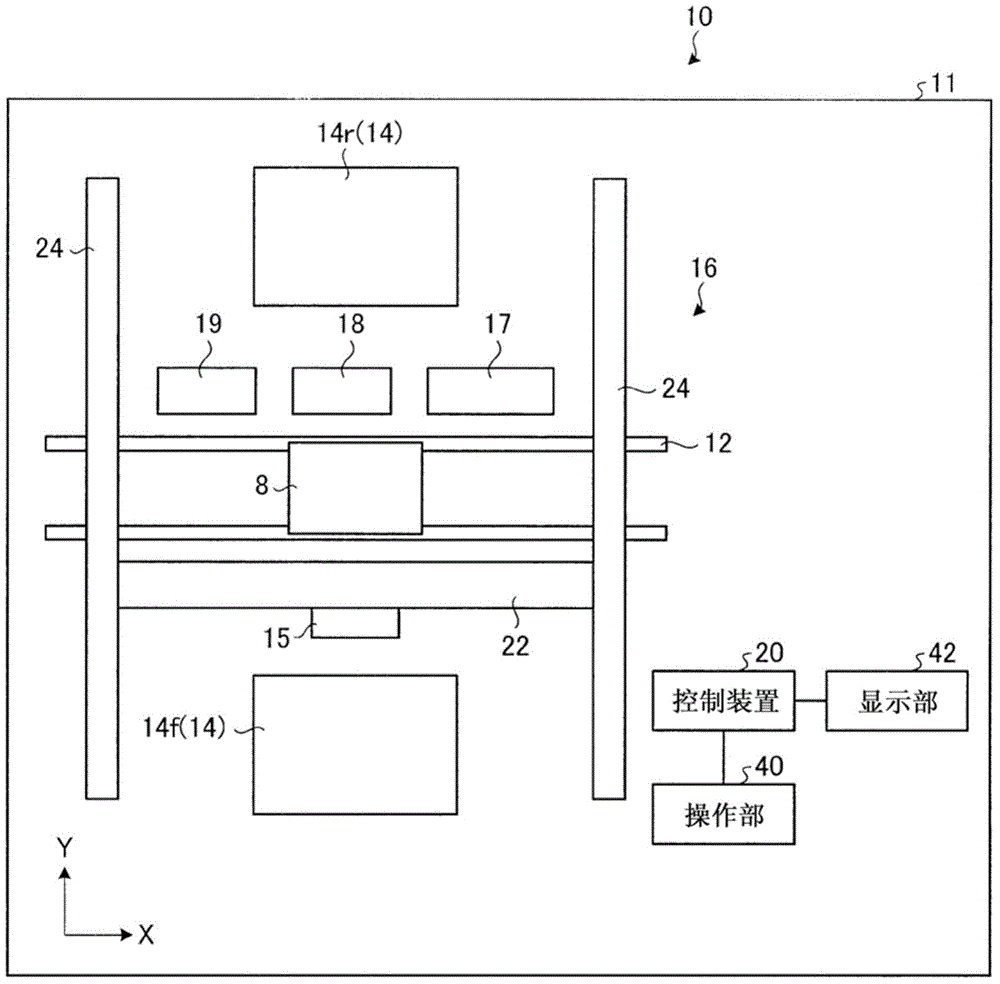

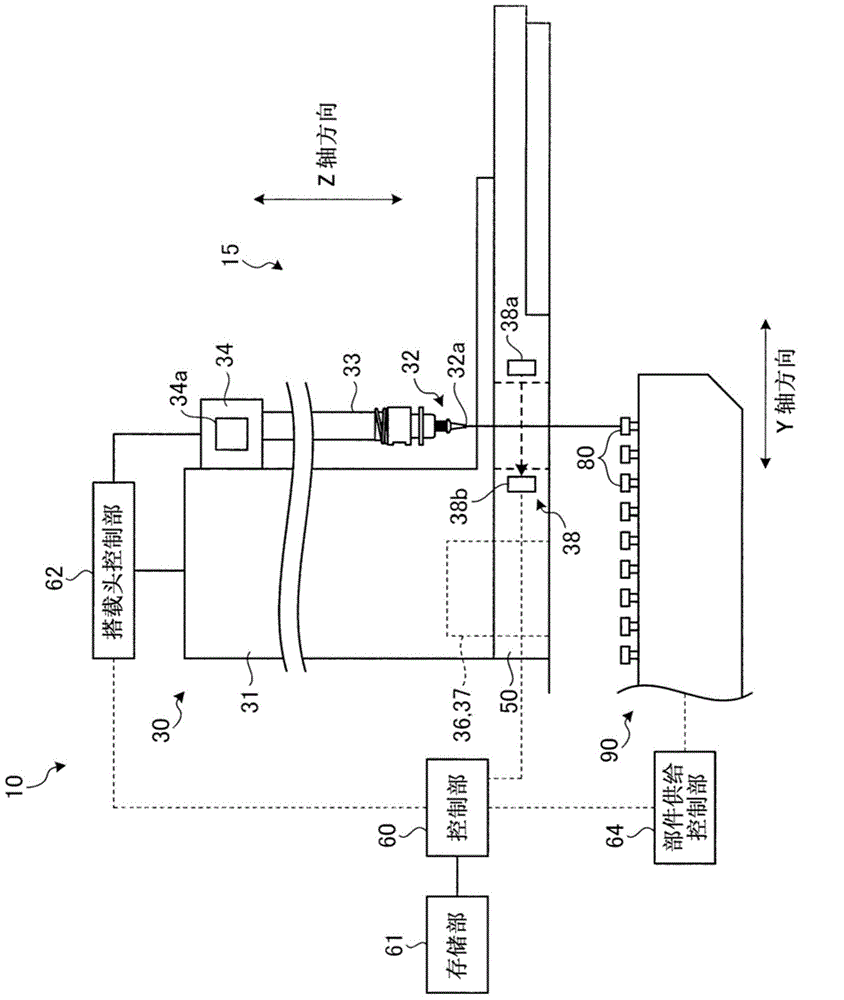

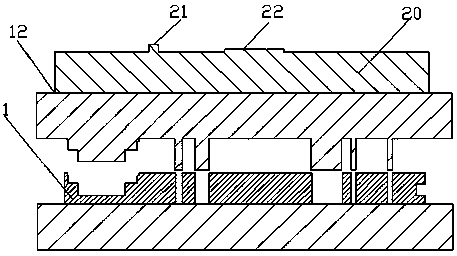

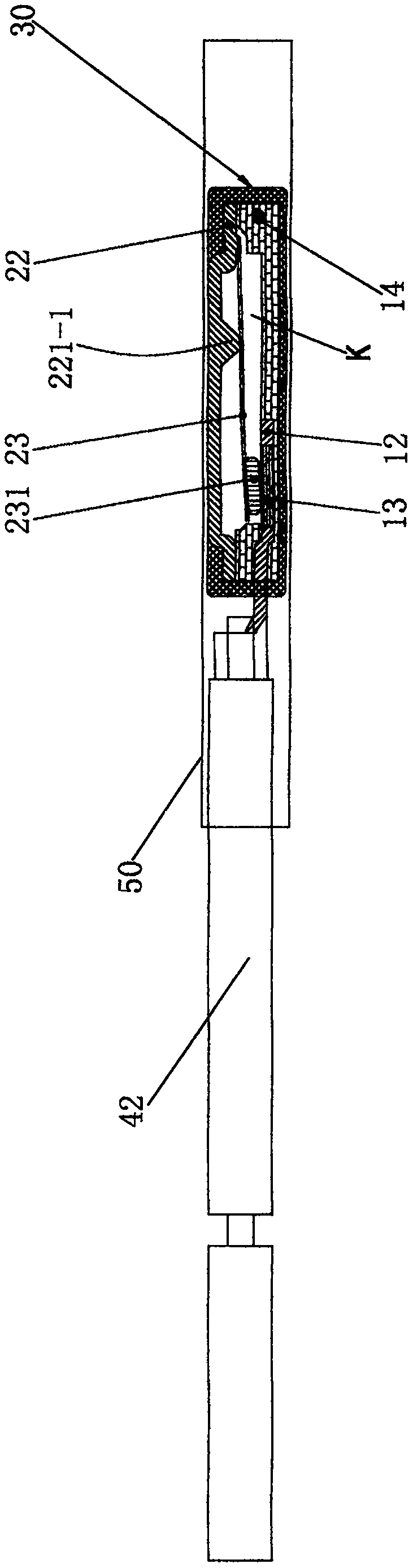

Electronic Part Installing Device And Electronic Part Installing Method

ActiveCN103917079ASuppression of production volume reductionReduce production quantityElectrical componentsEngineering

Owner:JUKI CORP

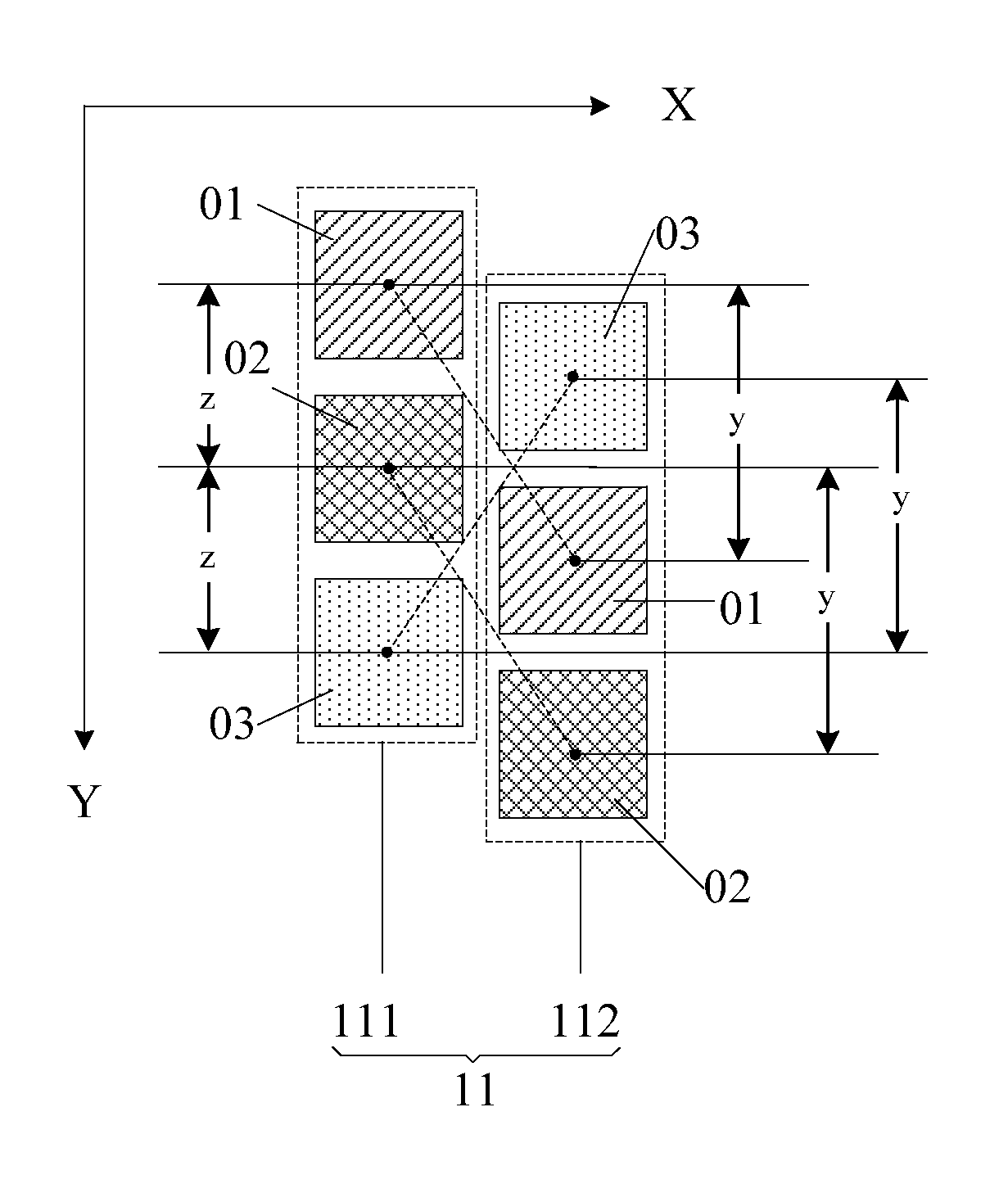

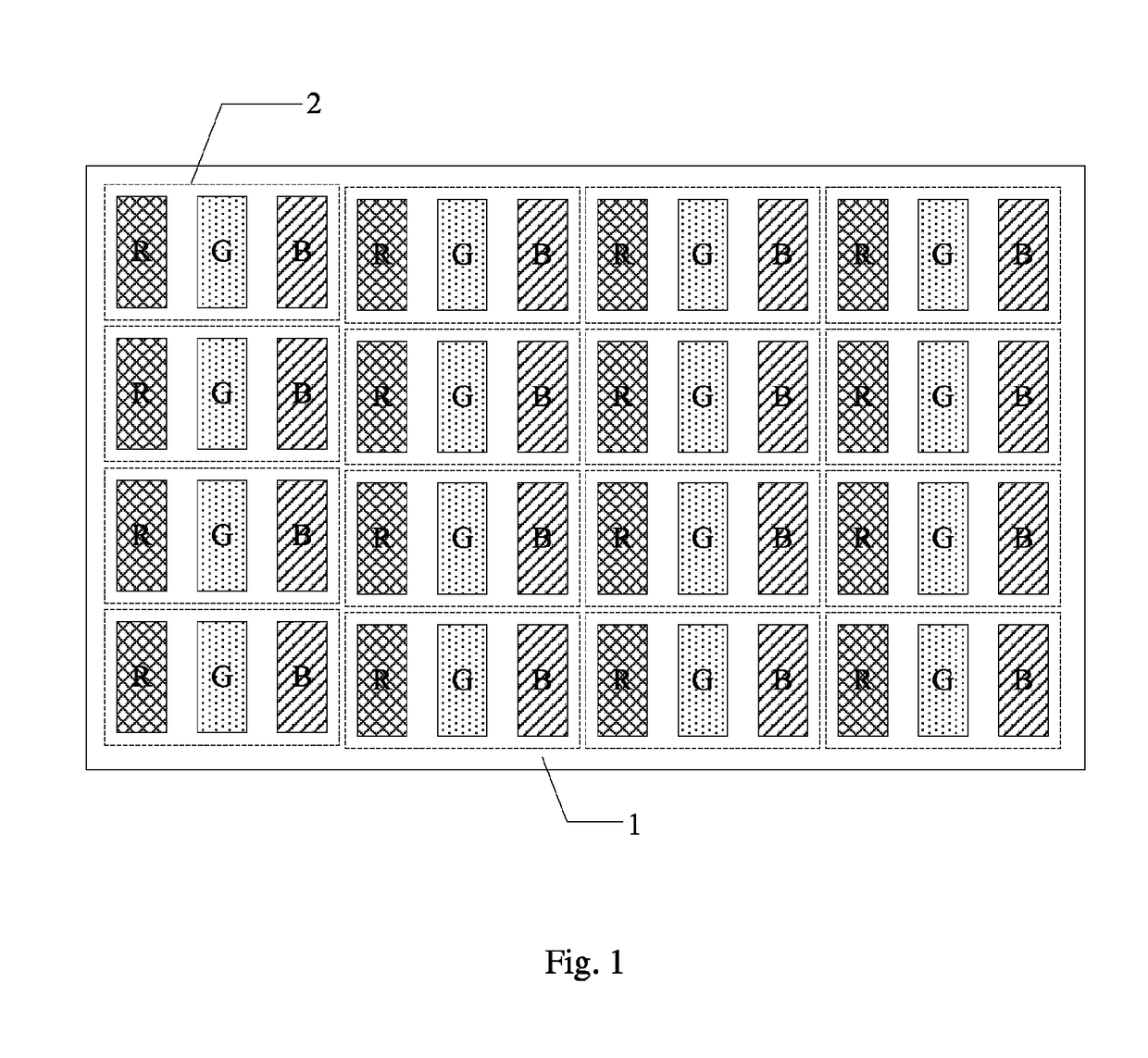

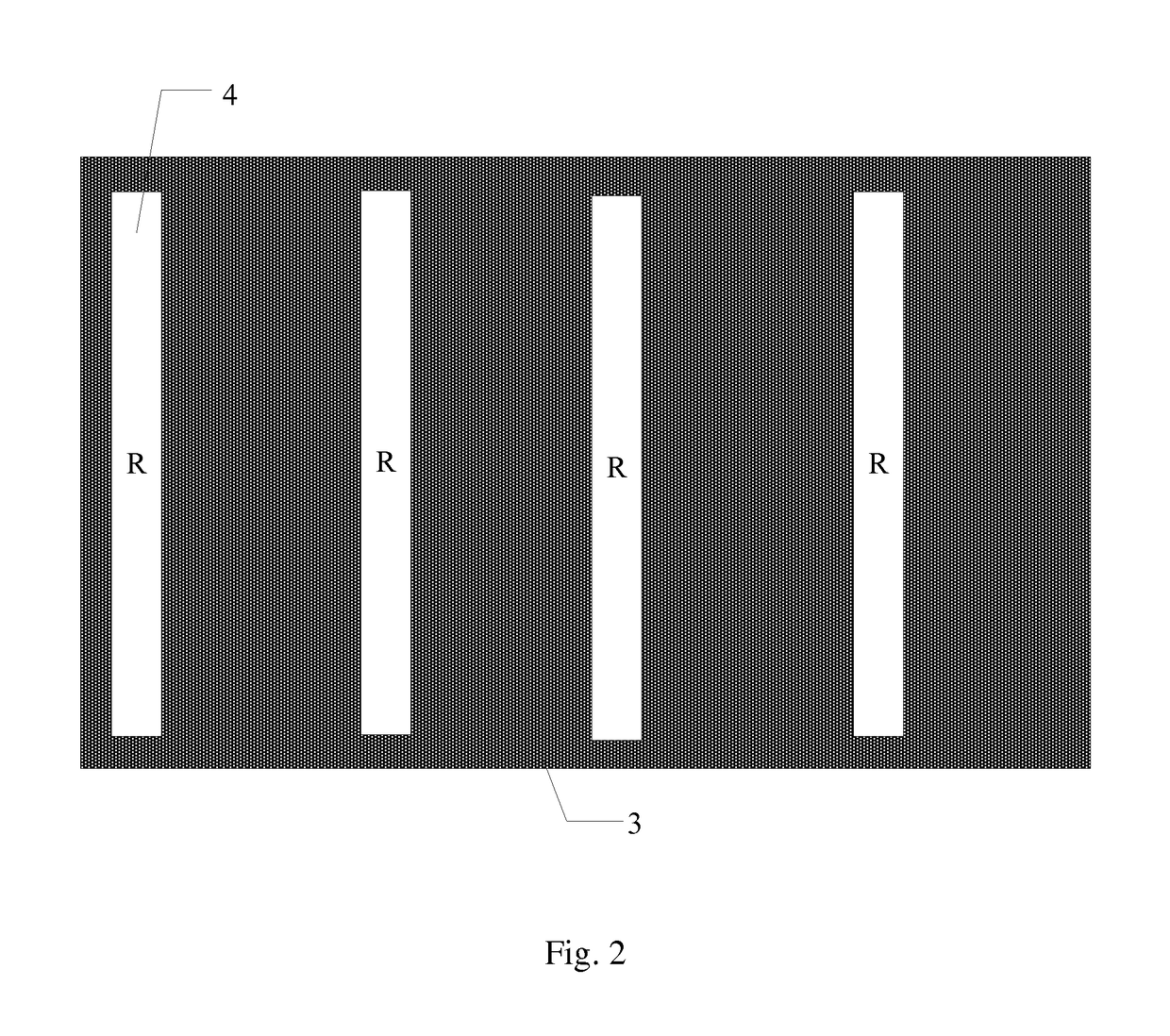

Organic electroluminescent display device, driving method thereof

ActiveUS20160253972A1High strengthImprove display deviceStatic indicating devicesImage resolutionOptoelectronics

The embodiments of the present invention provide an organic electroluminescent display device, a driving method thereof and a display device. Due to the regular staggered arrangement of sub pixels with the same color on the basal substrate, during the manufacture of a metal mask plate, the distance between adjacent openings corresponding to the sub pixels with the same color in the metal mask plate can be relatively large, improving the strength of the metal mask plate; this is beneficial for manufacturing small-sized sub pixels, thereby further improving the resolution of the organic electroluminescent display device.

Owner:BOE TECH GRP CO LTD +1

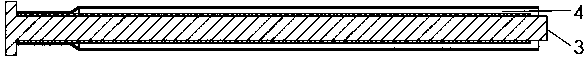

Heat pipe, manufacturing method of heat pipe and equipment comprising heat pipe

InactiveCN109764708AFlexible approachRich technical meansIndirect heat exchangersWaste productEnergy consumption

The invention discloses a heat pipe, a manufacturing method of the heat pipe and equipment comprising the heat pipe, mainly relates to a capillary core of the heat pipe and a manufacturing method of the capillary core, and belongs to the technical field of heat conduction. According to the manufacturing method, a positioning tool and a metal net are mainly used, metal powder is arranged and limited in a specific space position in a pipe shell, and the technical problems that in the sintering process in which a traditional method is adopted, the metal powder is bonded with a core rod, when thecore rod is pulled out after sintering, the capillary core is prone to damage, and even a waste product occurs, and the technical problems that core rod is used for separating the reducing atmospherefrom the metal powder, so that the reducing effect is poor, secondary sintering is generally needed, and the energy consumption and the thermal pollution are large can be comprehensively or correspondingly solved; and the technical situations that the capillary core of the sintered layer is damaged due to the deformation processes of bending, flattening and the like can be relieved or avoided, andthe process route in which bending is carried out first, and then sintering is carried out can be realized. The method is applied to manufacturing of the heat pipes (including hot columns and ultra-thin heat pipes). The heat pipe is applied to equipment or a device requiring heat transfer or heat dissipation through the heat pipe.

Owner:刘康

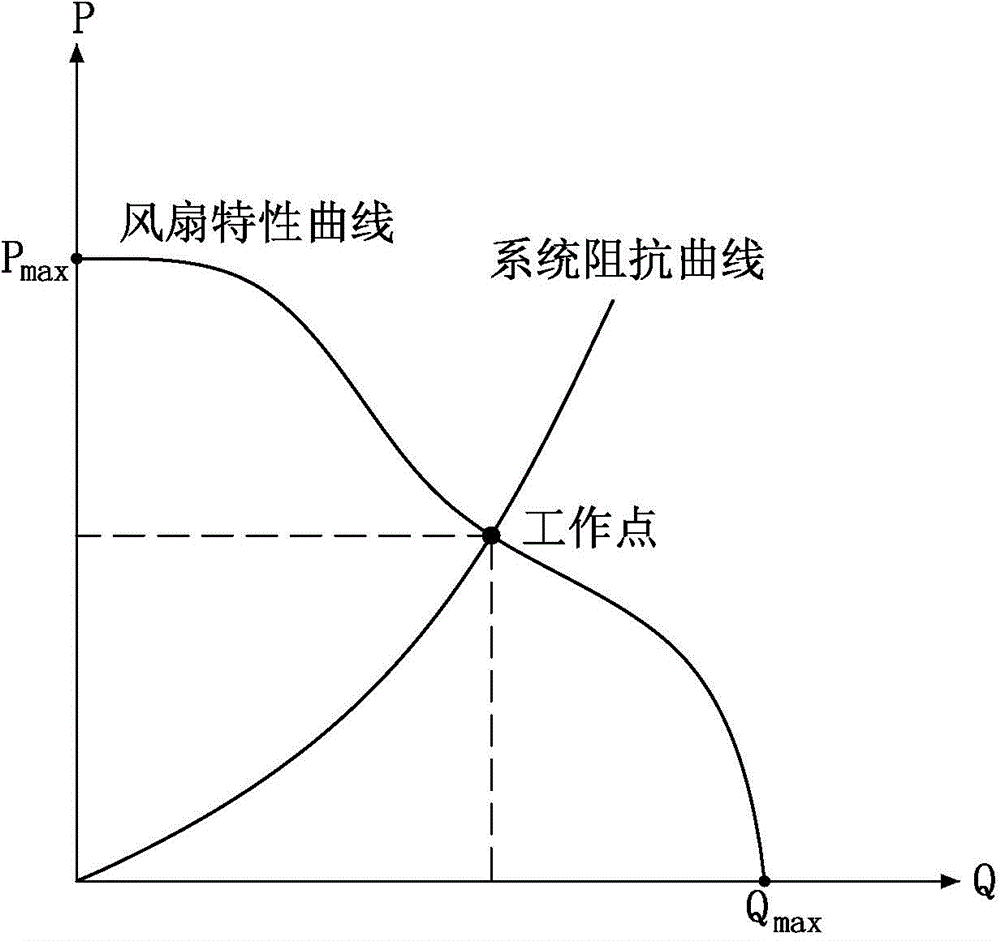

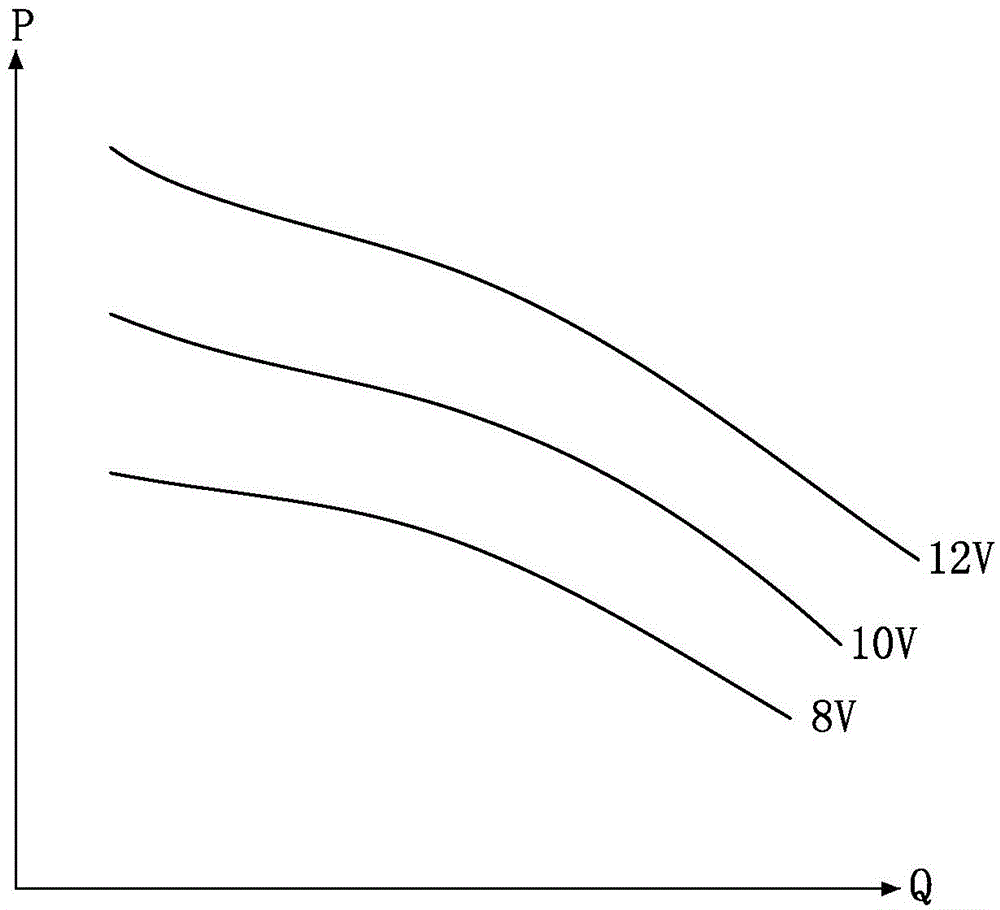

Matching method of cooling module of passenger vehicle

ActiveCN105987817AReduce production quantityReduce dependenceVehicle testingComputer moduleMatching methods

The invention relates to a matching method of a cooling module of a passenger vehicle. The method comprises: fan feature curves of a reference fan under different voltages are obtained; when a vehicle is driven at a certain speed in a testing cabin, total-impedance curves of the vehicle at different vehicle speeds are obtained by fitting; a rotating speed and a torque value that are needed by an engine of a checking vehicle type on a typical condition for checking are obtained by simulation; corresponding engine cooling demanding quantities of the engine at different rotating speeds under different loads are obtained by bench testing, so that a cooling demand quantity of the checking vehicle on the typical condition for checking is obtained; a fan feature curve of a matched fan under a rated voltage is obtained by processing; and according to the total-impedance curves and the fan feature curve of the matched fan under the rated voltage, a cooling capacity that can be provided by a matched cooling module is calculated, and then the cooling capacity provided by the matched cooling module is compared with the cooling demand quantity of the checking vehicle on the typical condition for checking to determine whether the matched cooling module matches the cooling demand of the checking vehicle type.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

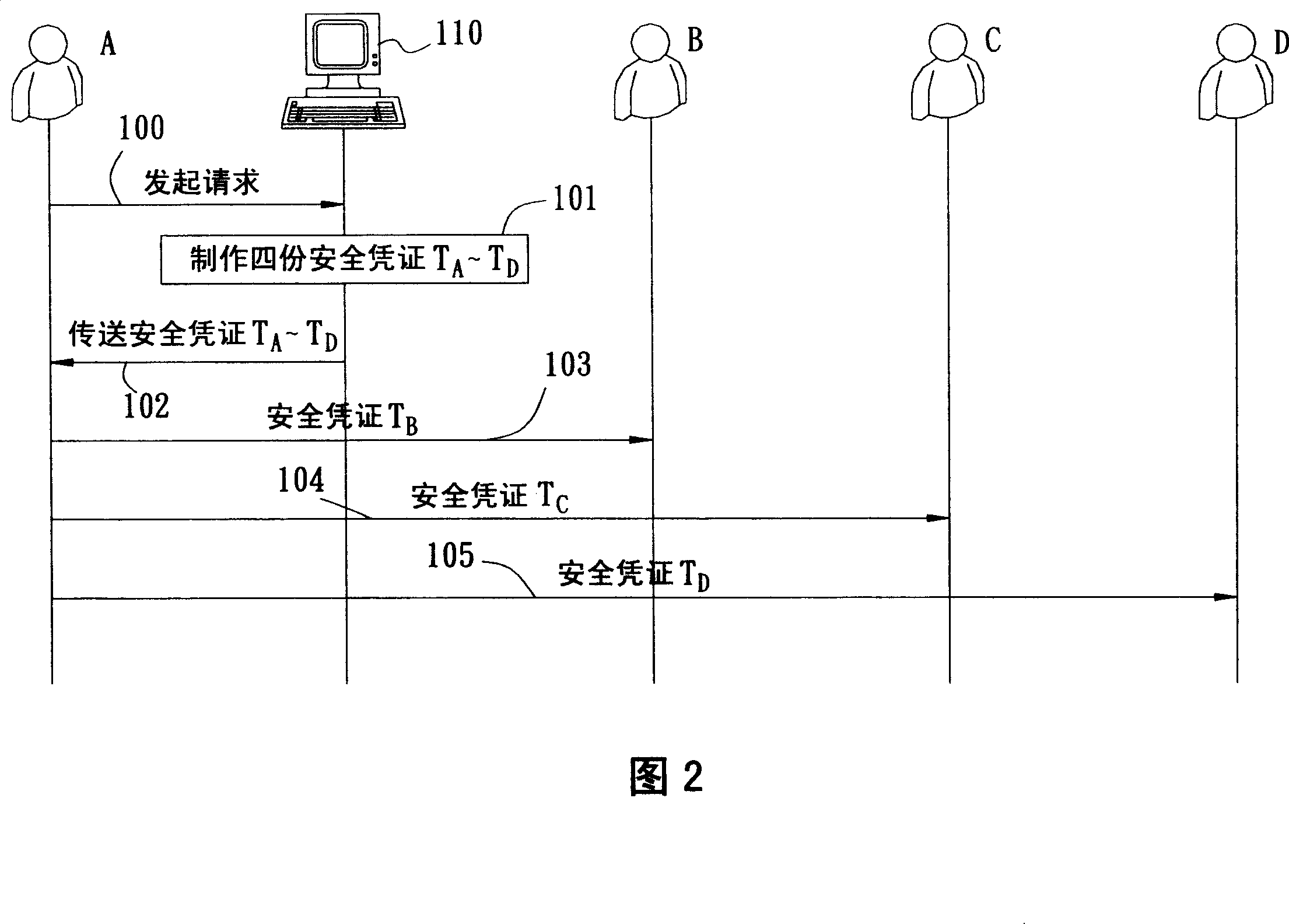

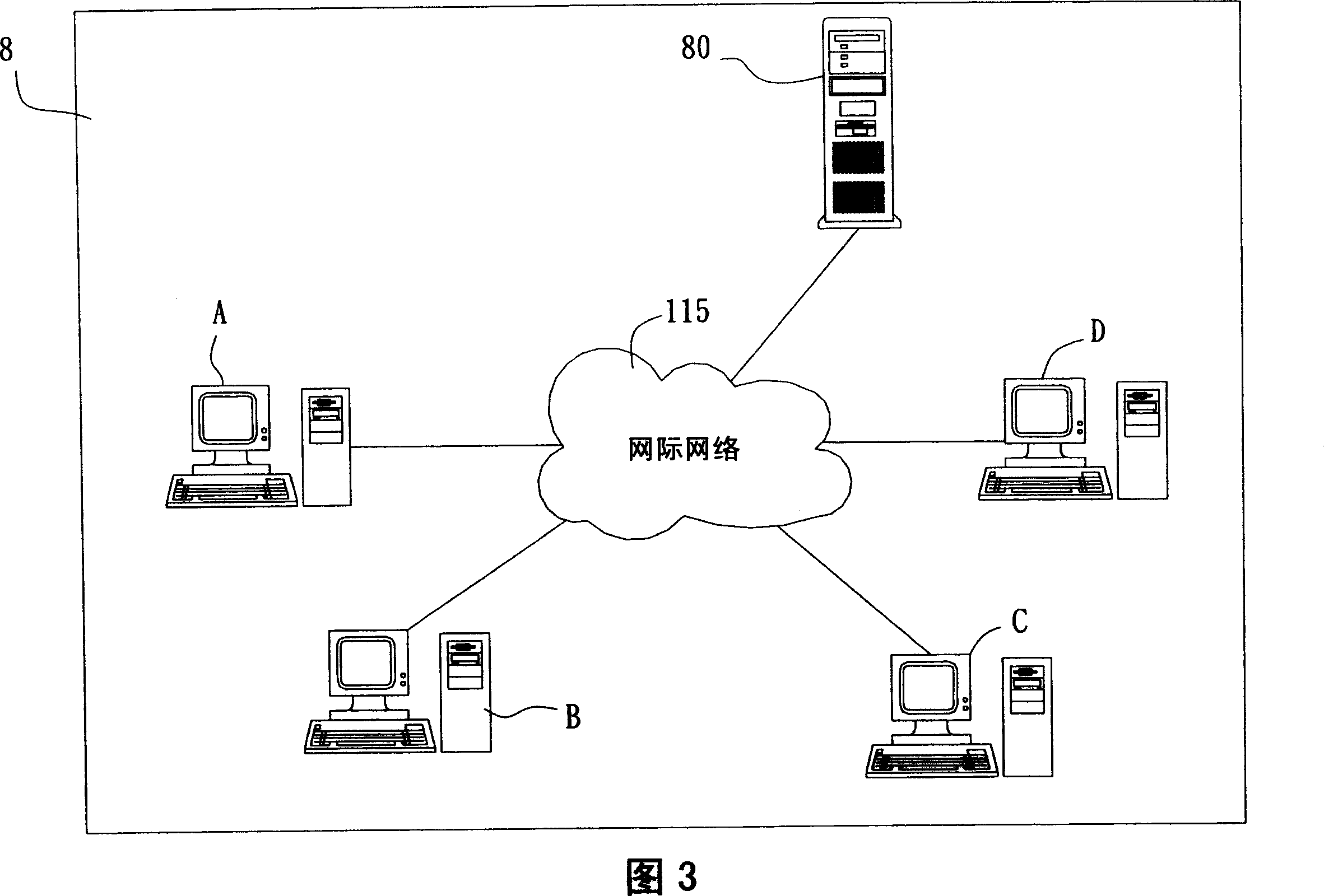

A new safety group safety certificate generating method, communication method, and network system

InactiveCN101060398AReduce production quantityReduce computationSpecial service provision for substationKey distribution for secure communicationNetworked systemComputer security

The disclosed security receipt generation method for new group comprises: when original group changes, such as new one adds or leaves, the central service center is notified to find out the minimal key in new group, generates relative security receipt with the key of the new group, and enciphers the receipt to send all members in new group. This invention reduces system loading.

Owner:PANASONIC CORP

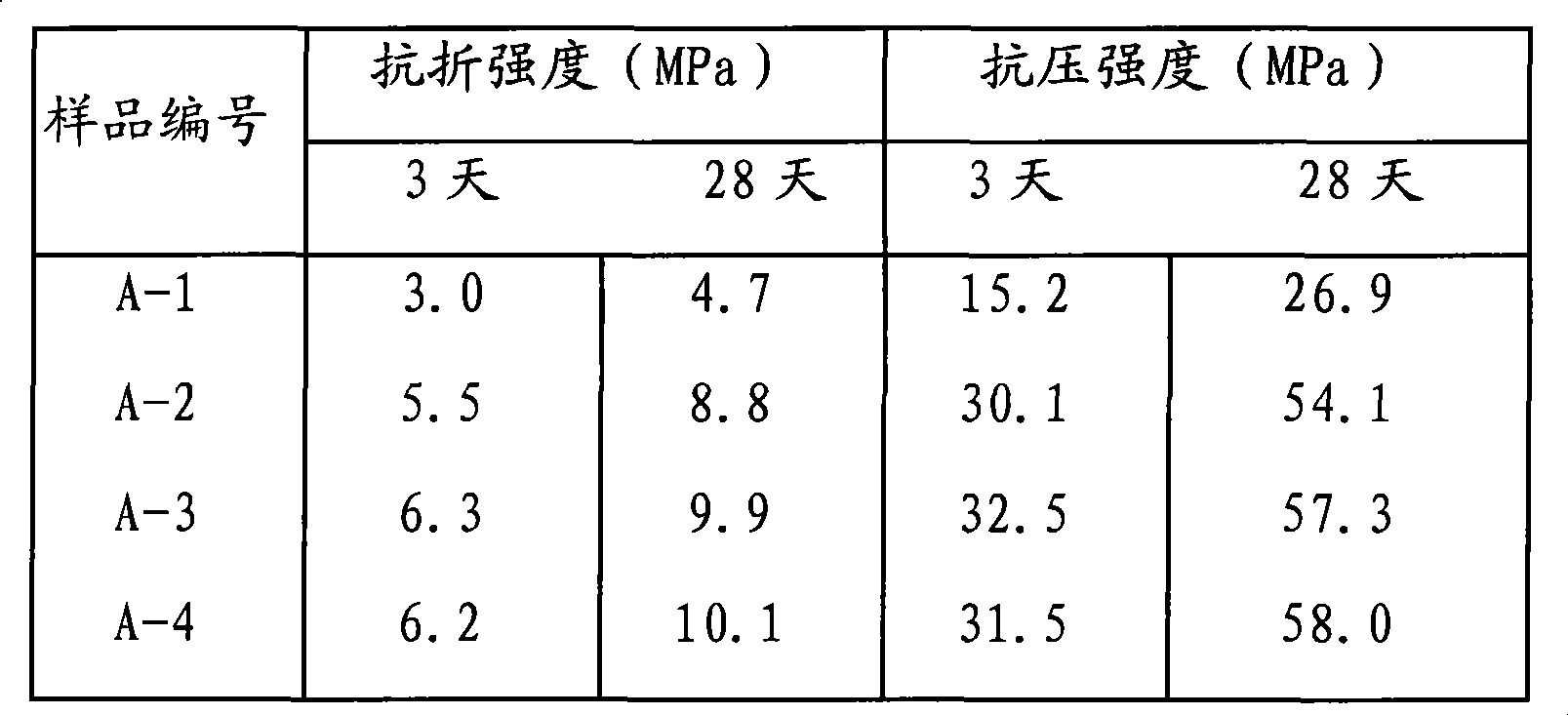

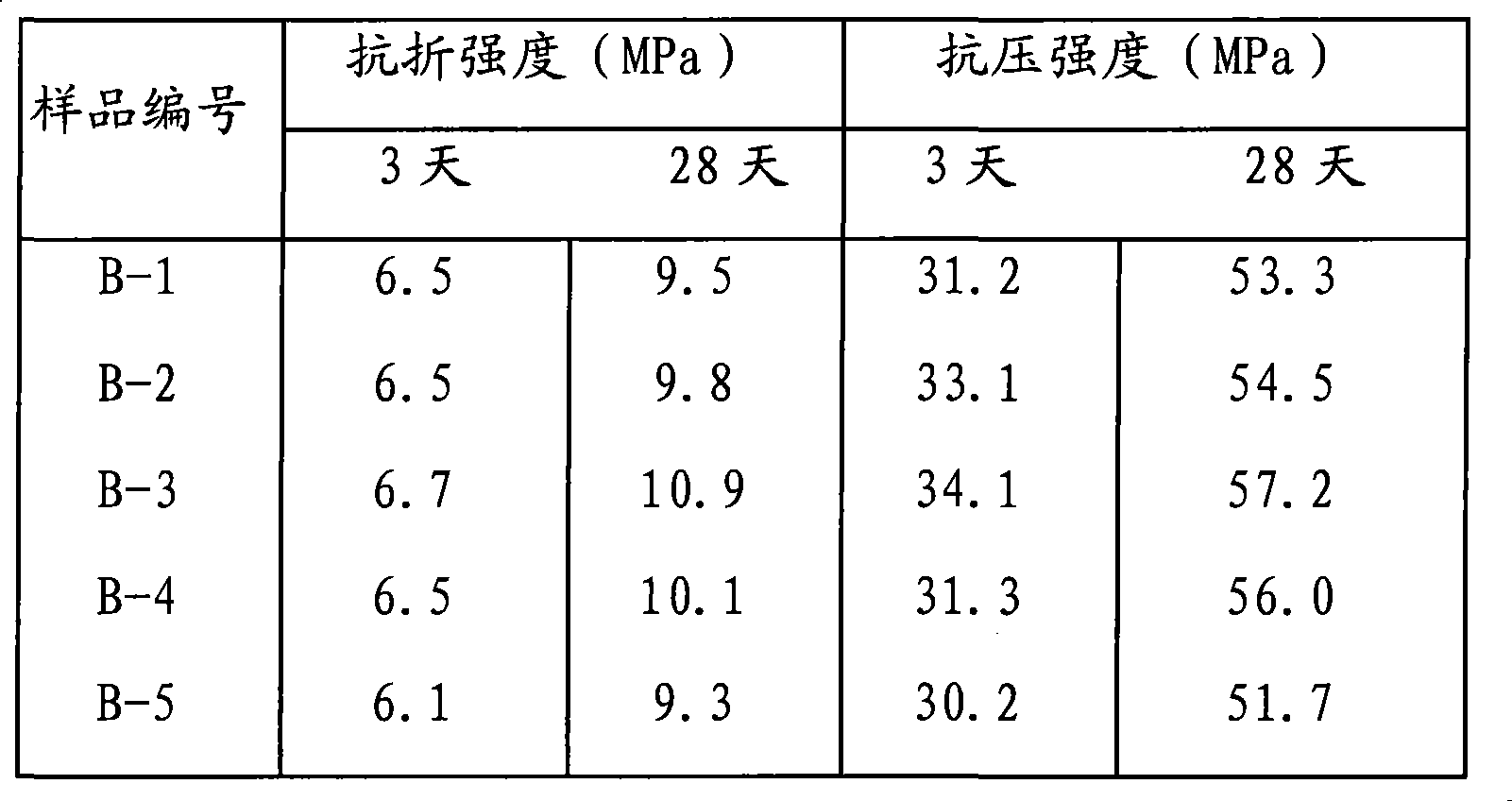

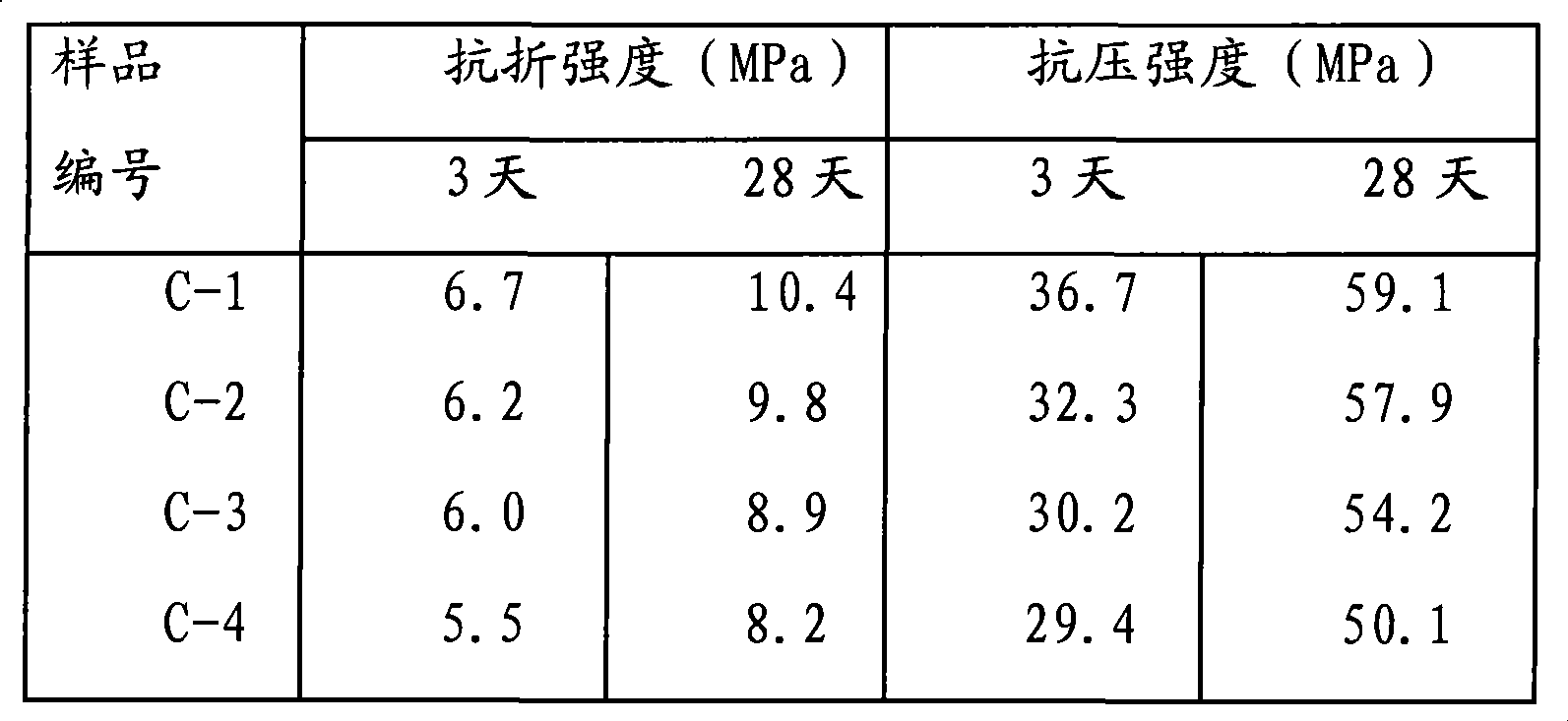

Silicon-aluminum polymeric material and preparation thereof

InactiveCN101412596AIncrease added valueConvenient sourceSolid waste managementCement productionSlagChemical corrosion

The invention discloses a silicon-aluminum polymeric material, which comprises 60 to 90 weight percent of calcined bauxite tailing powder, 40 to 10 weight percent of slag powder, and 20 to 80 percent of water glass of the total weight of calcined bauxite tailing and slag. The invention also discloses a preparation method for the material, which comprises the following steps: a. calcining the bauxite tailing, and grinding the calcined bauxite tailing to obtain the calcined bauxite tailing powder; b. mixing 40 to 10 weight percent of the slag powder and 60 to 90 weight percent of the calcined bauxite tailing powder evenly, and preparing powder material; and c. adding 20 to 80 percent of the water glass of the weight of the powder material in step b, and preparing the silicon-aluminum polymeric material, wherein the calcining temperature is between 800 and 1,000 DEG C, and the calcining time is between 0.5 and 10 hours. The material has the advantages of excellent mechanical performance, chemical corrosion resistance and volume stability; and the preparation method is simple, uses industrial wastes as raw materials, has low cost, not only can solve stockpiling problem of wastes, but also achieves comprehensive utilization of resources.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

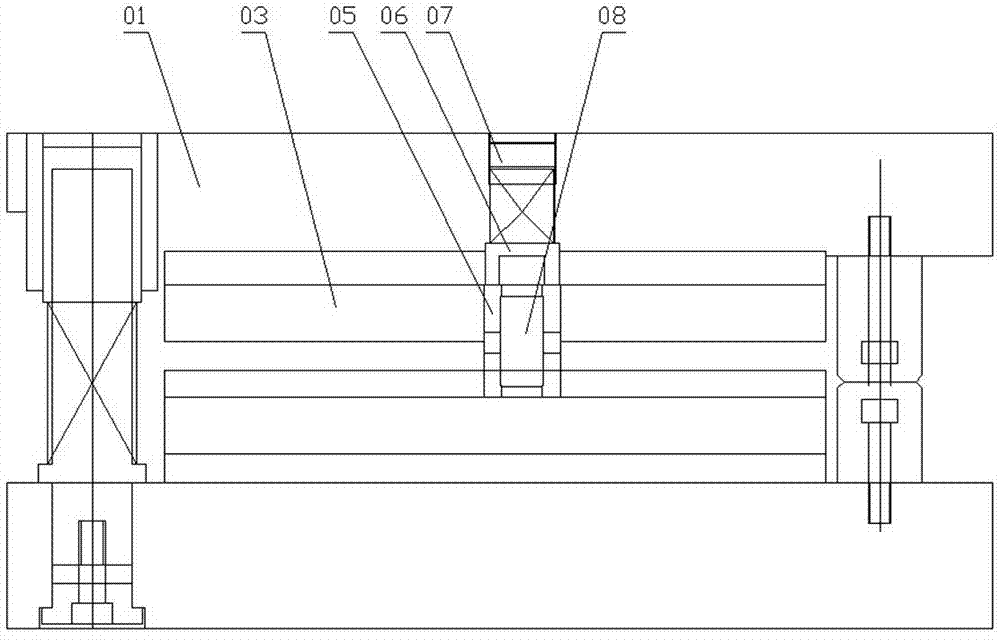

Size-adjustable prefabricated laminated floor slab combination die

PendingCN110103322AReduce production quantitySimple structureMouldsMould fastening meansFloor slabMechanical engineering

The invention discloses a size-adjustable prefabricated laminated floor slab combination die. The size-adjustable prefabricated laminated floor slab combination die comprises an integral die block, wherein the integral die block is formed by fixedly connecting a front adjusting die block, a rear adjusting die block, a left adjusting die block and a right adjusting die block, each adjusting die block comprises a fixed die, fastening blocks are fixed on one end portions of the fixed dies, movable blocks which can move are arranged in the fixed dies, locking blocks which are used for being connected and fixed to the fastening blocks are connected on the movable blocks, and the adjacent adjusting die blocks are connected and fixed through the corresponding fastening blocks and locking blocks.According to the size-adjustable prefabricated laminated floor slab combination die, the single-side length is adjusted by adjusting the positions of the movable blocks, so that the size-adjustable prefabricated laminated floor slab combination die is suitable for various square prefabricated laminated floor slabs with different sizes, the manufacturing number of single-side dies is reduced, one set of die is repeatedly used for multiple times, so that the production cost is reduced, and the size-adjustable prefabricated laminated floor slab combination die has quite high practicability.

Owner:电联工程技术股份有限公司

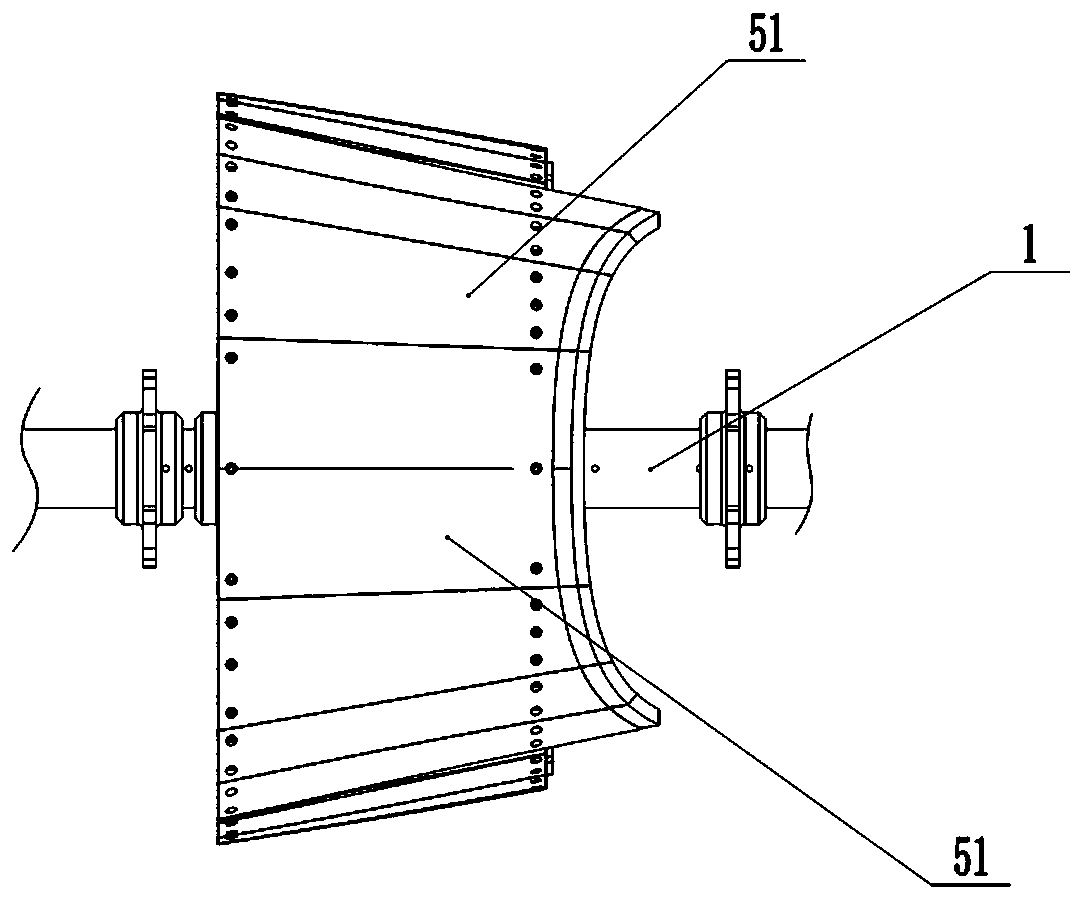

Integrated adjustable rack

InactiveCN102251093AHigh strengthImprove high temperature deformation resistanceFurnace typesHeat treatment furnacesContinuous annealingMechanical engineering

The invention relates to an integrated adjustable rack used for hoisting in a continuous annealing furnace between dense charging and processing of metal plates, belts, foil and other products. The integrated adjustable rack comprises a rack body, wherein the rack body comprises a rectangular underpan; the underpan comprises an upper underpan and a lower underpan; the upper underpan is composed of parallel top cross beams and top longitudinal beams connected with one end of each top cross beam; the lower underpan is composed of parallel cross beams and parallel longitudinal beams which are crossed; the joint of each cross beam and each longitudinal beam between the upper underpan and lower underpan is provided with a column; a top longitudinal beam is arranged between the other ends of every two parallel top cross beams of the upper underpan; a movable cross beam is arranged between every two columns connecting the top cross beams on the left and right sides of the rack body, and positioned between the upper underpan and lower underpan; both ends of the movable cross beam are provided with a U chute which is matched with the column; axis pin holes are distributed on the column; an axis pin which is inserted into the axis pin hole is arranged below the U chute; the movable cross beams on the left and right sides of the rack body are provided with symmetrical slide block seats; and a coil core tube is arranged between the symmetrical slide block seats.

Owner:柳燕明

Cutting method of chips at different sizes

InactiveCN109449119ASolve problems such as edge collapseReduce production quantitySemiconductor/solid-state device manufacturingWafer fabricationEngineering

The invention discloses a cutting method of chips at different sizes. The cutting method comprises the steps of firstly, forming a mask of a target region on a wafer, wherein the target region can beat an arbitrary size and in an arbitrary shape; fixing the processed wafer on an operating table; performing dry etching to form a deep groove, and removing a part which is not covered with the mask;removing the mask; taking out the water with the deep groove, and filling the deep groove with a substitute material; grinding a back surface of the wafer until the substitute material of the groove is exposed; and removing the substitute material, and completing chip cutting. Cutting of the chips at different sizes and in different shapes is achieved on the same wafer, and the problems of chip edge breakage and the like are solved; the method is simple and efficient, separation of all chips in one time can be achieved, the wafer production number is reduced, the cost is reduced, the wafer manufacturing time is reduced, and the development progress is also accelerated; and meanwhile, the separation of the chips at the different sizes and in the different shapes is achieved, and the problemof wafer breakage probably occurring in the cutting process is prevented.

Owner:镇江微芯光子科技有限公司

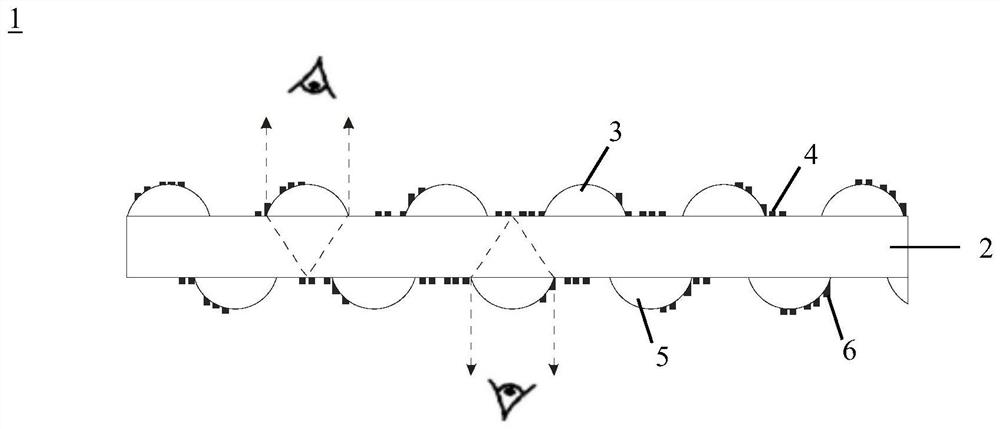

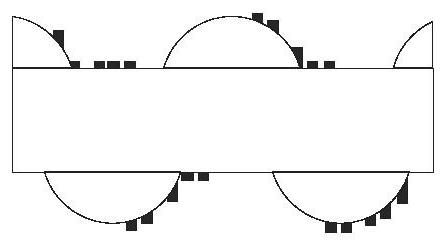

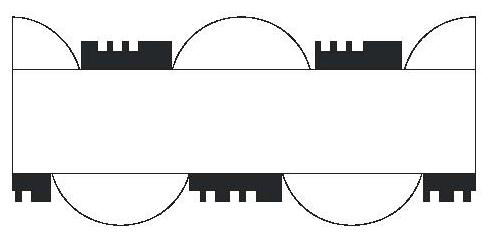

Optical anti-counterfeiting element and anti-counterfeiting product

ActiveCN111619262AImprove anti-counterfeiting effectImprove visual effectsInformation cardsMagnificationMicro lens array

The embodiment of the invention provides an optical anti-counterfeiting element and an anti-counterfeiting product, and belongs to the field of optical anti-counterfeiting. The optical anti-counterfeiting element comprises a base material, a first micro-relief structure and a second micro-relief structure, wherein the base material comprises a first surface and a second surface opposite to each other; the first surface is at least partially covered with the first micro-relief structure, the first micro-relief structure comprises a first micro lens array and a first micro-image-text array; thesecond surface is at least partially covered with the second micro-relief structure, the second micro-relief structure comprises a second micro-lens array and a second micro-image-text array, the first micro-lens array can perform sampling synthesis on the second micro-image-text array so as to form a first reproduction image, the second micro lens array can perform sampling synthesis on the firstmicro-image-text array so as to form a second reproduction image. The reappeared images after sampling magnification can be observed from both sides of the base material respectively.

Owner:ZHONGCHAO SPECIAL SECURITY TECH +1

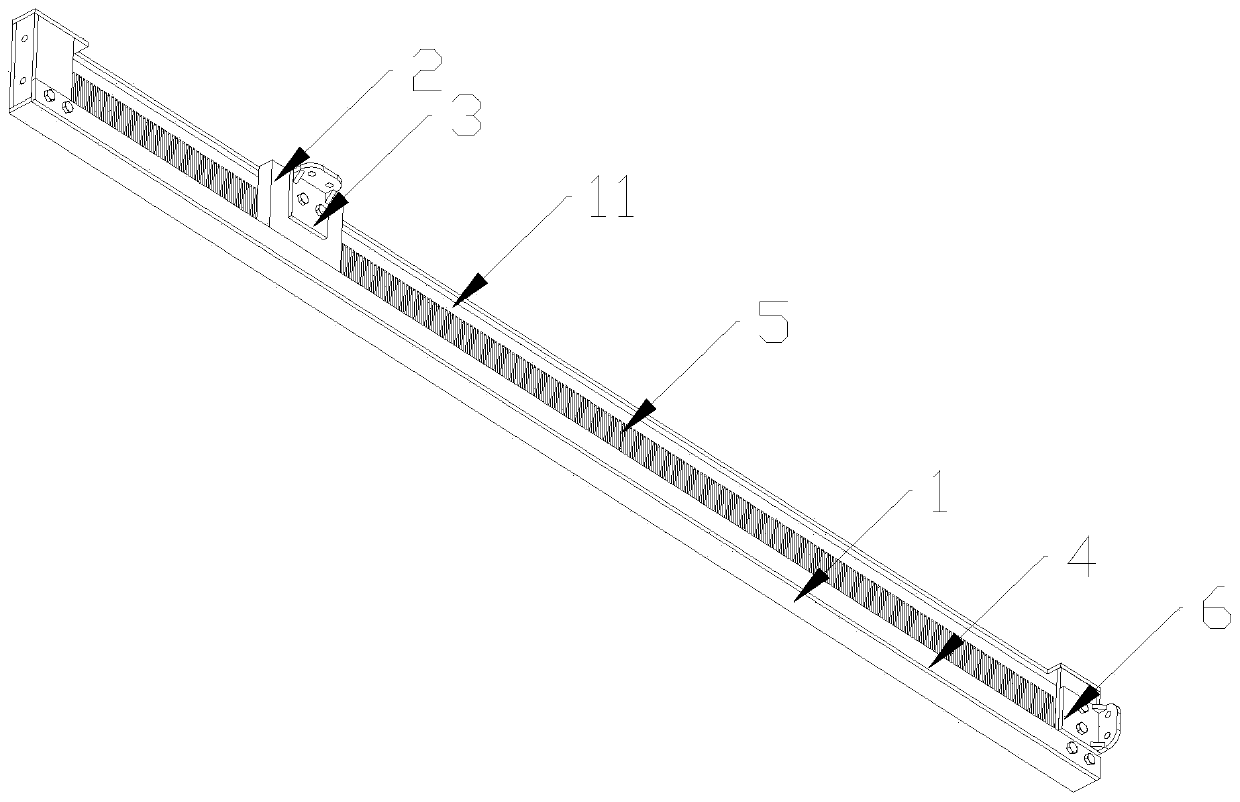

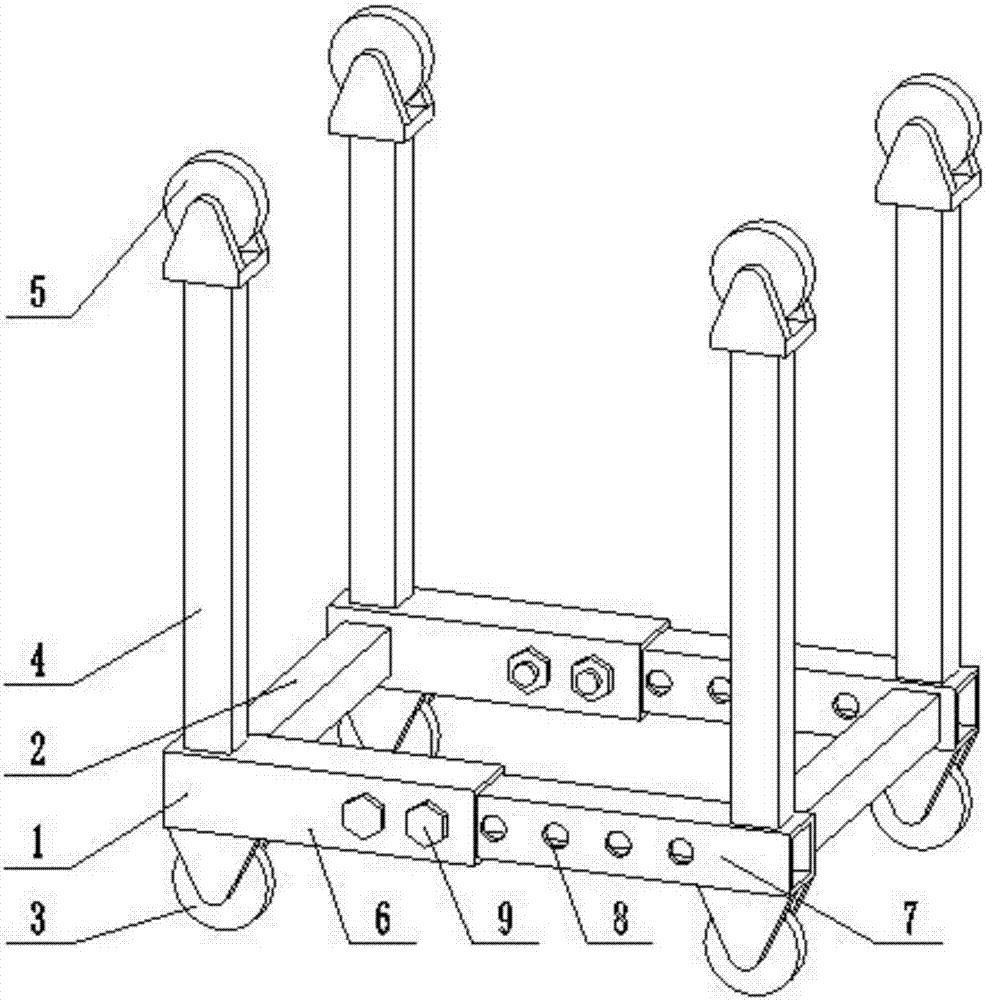

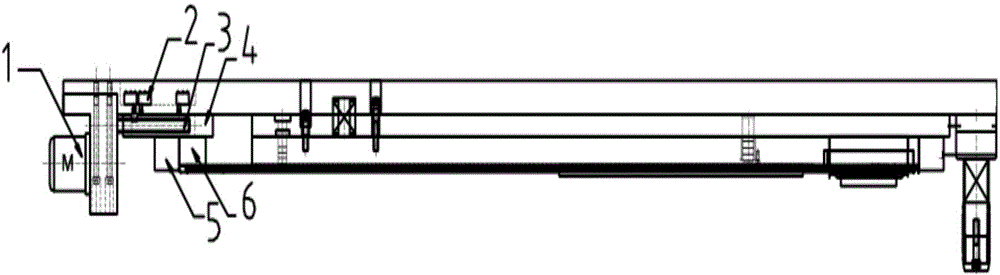

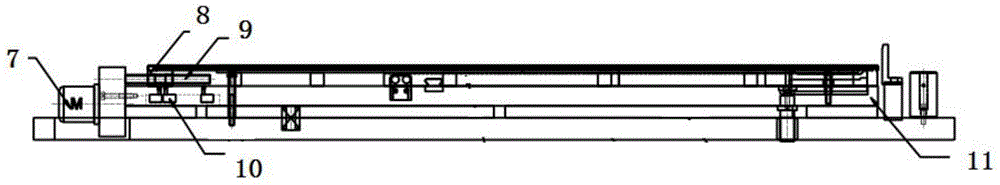

Telescopic bottle body transport vehicle

InactiveCN107310603AEasy to carryReduce production quantitySledgesHand carts with multiple axesEngineeringBottle

The invention discloses a telescopic bottle body transport vehicle and belongs to the technical field of transport vehicles. The telescopic bottle body transport vehicle comprises a bracket. The bracket is of a rectangular frame structure formed by connecting of two cross beams and two longitudinal beams. Travelling wheels are arranged at the four corners of the bottom of the bracket correspondingly. Supporting beams are arranged at the four corners of the upper portion of the bracket correspondingly. A supporting wheel is mounted on each supporting beam. Each cross beam comprises a first cross beam body and a second cross beam body, wherein the first cross beam body is of a tubular structure, and one end of the second cross beam body stretches into the first cross beam body. According to the telescopic bottle body transport vehicle, bottle bodies can be conveniently and rapidly transported, the labor amount is less, efficiency is high, and safety is high; and meanwhile, the telescopic bottle body transport vehicle is adaptive to transporting of the bottle bodies of different specifications, adaptability is high, universality is good, the number of the transport vehicles is decreased, the production cost is reduced, and space is saved.

Owner:安徽省三山汽车制造有限公司

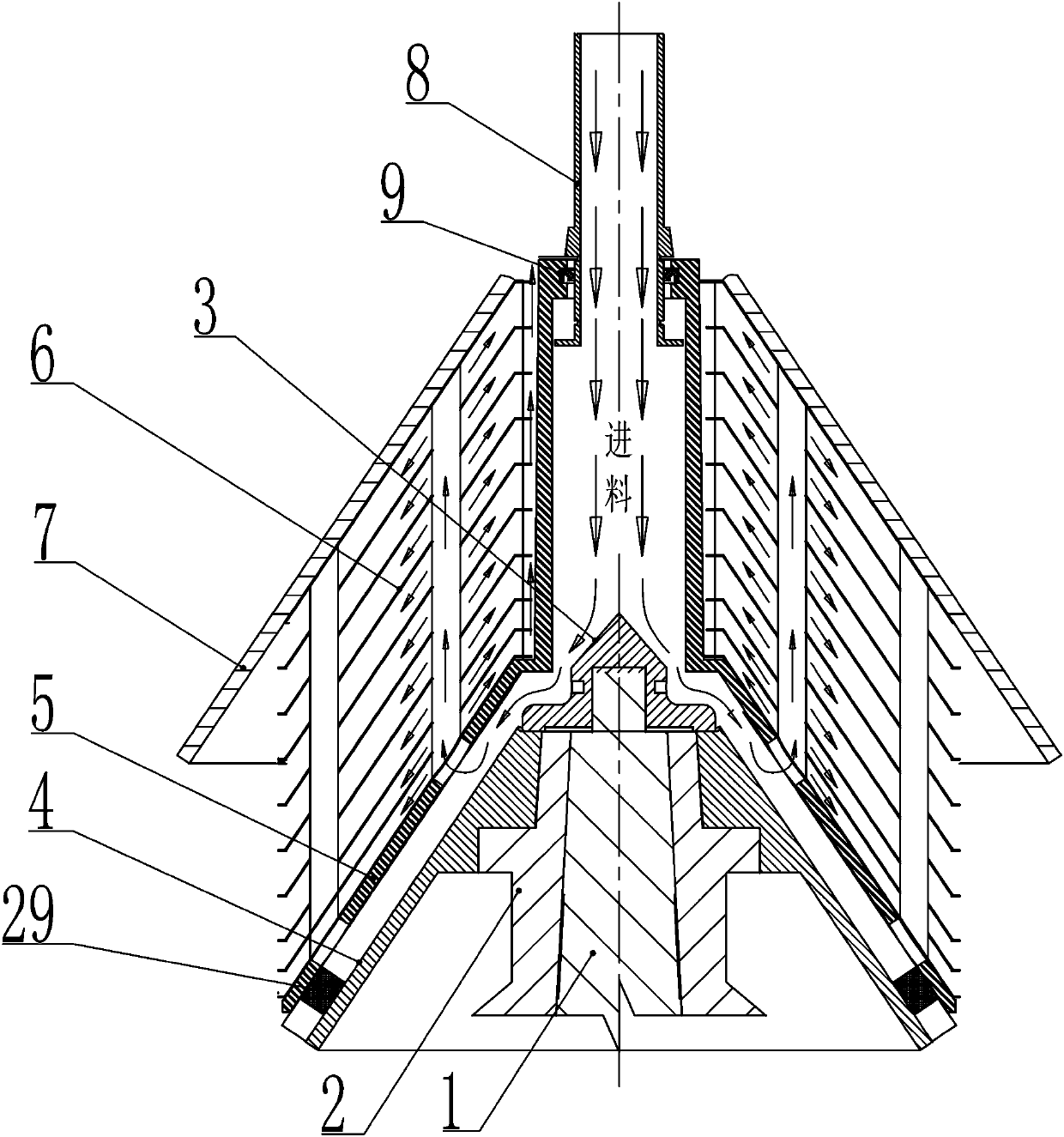

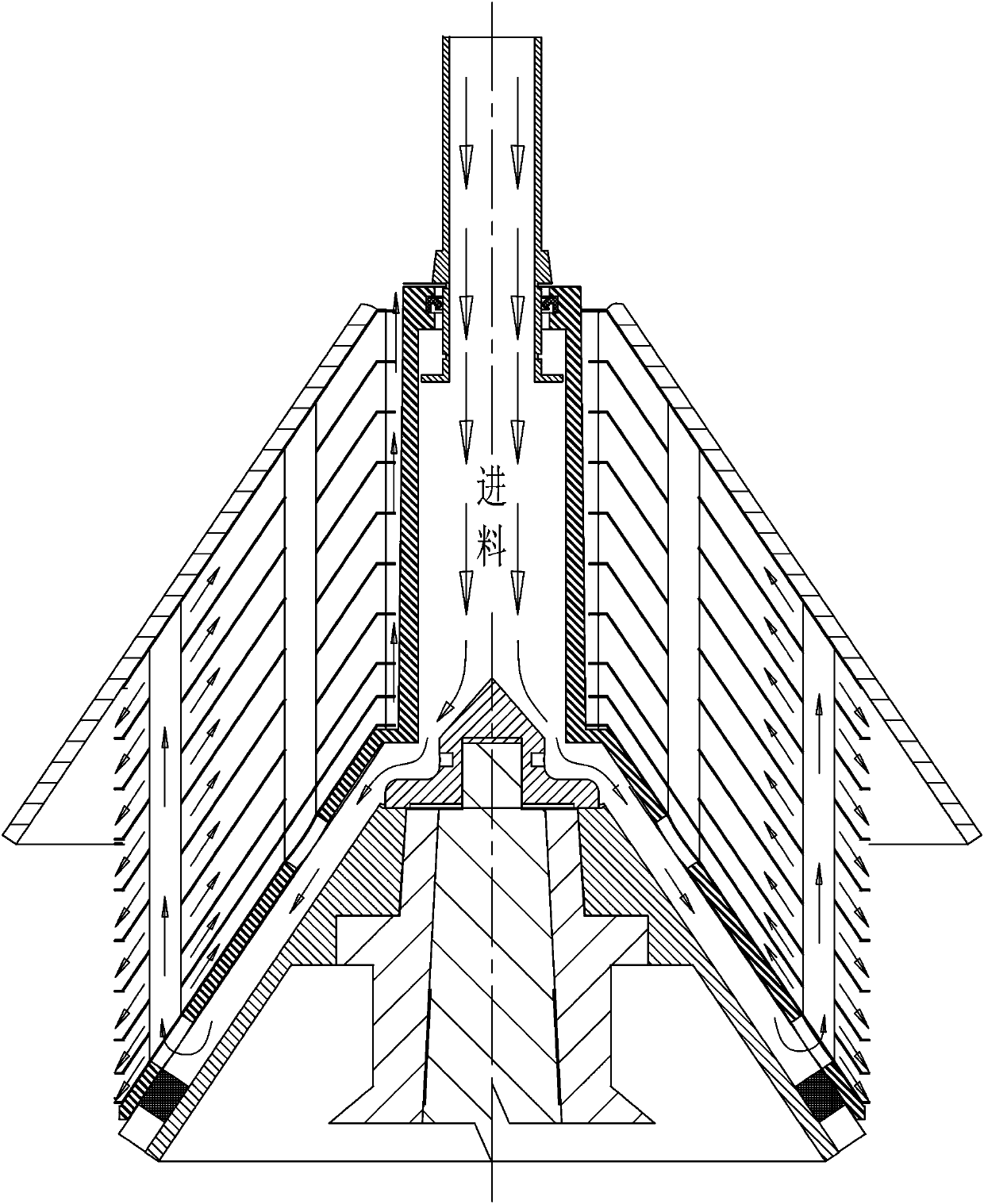

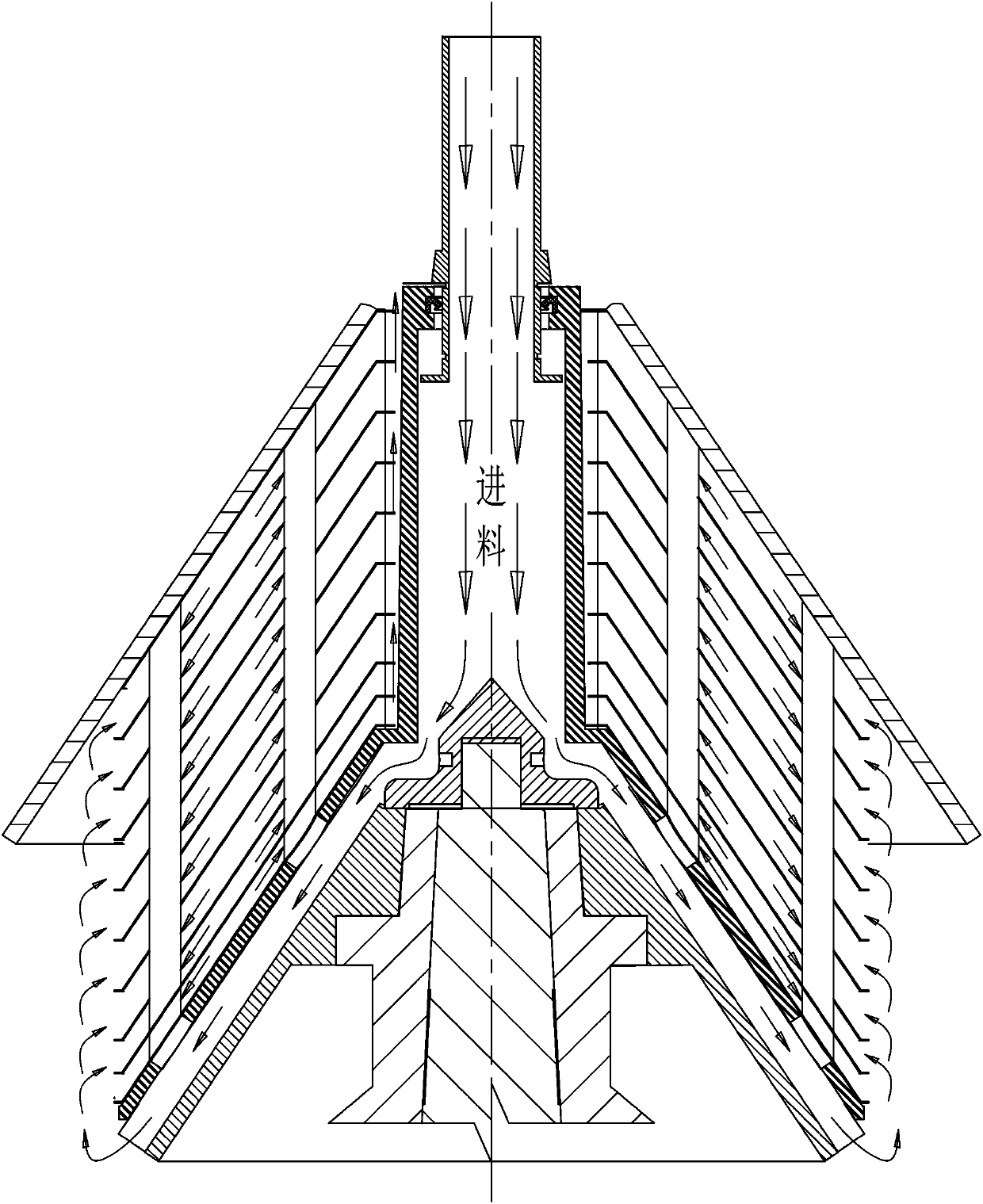

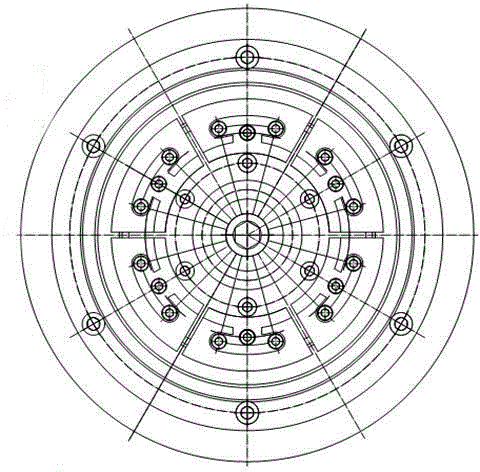

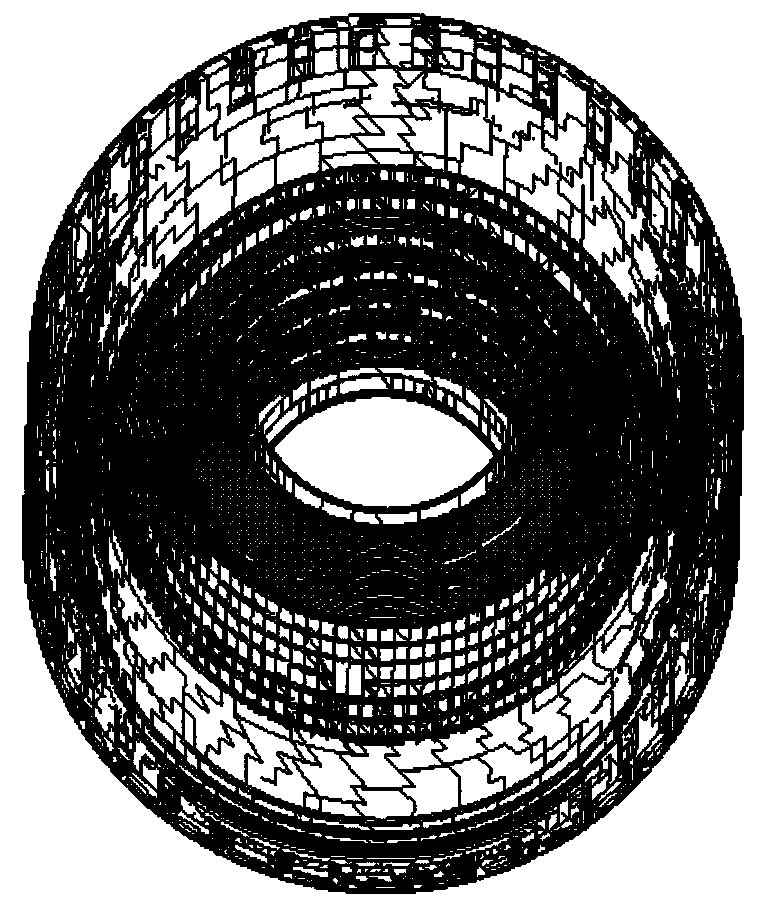

Changeable flow channel structure of multifunctional disc type separator capable of changing multiple flow channels

The invention relates to a changeable flow channel structure of a multifunctional disc type separator capable of changing multiple flow channels. A locking screw cap is positioned at the upper end ofa disc bracket base, is screwed on the external threads at the top of a center shaft, and is pressed on the disc bracket base; the disc bracket base is pressed on the outer conical surface of the lower body of a rotating drum in a sleeving manner; the lower body of the rotating drum is pressed on the outer conical surface of the top of the central shaft in the sleeving manner; the upper side of the disc bracket base is matched with a disc bracket; a plurality of flow channels are enclosed between the disc bracket base and the disc bracket; a detachable plug is fixed to the lower end of each flow channel; a plurality of layers of discs with gaps therebetween are arranged on the disc bracket in a sleeving manner; the discs are compressed through a disc pressing cap on the uppermost side; thedisc bracket is provided with double rows of lower cone through holes; and each disc is provided with a single row of upper through holes or a single row of lower through holes which communicate withthe lower cone through holes of the disc bracket or is not provided with the through holes. According to the changeable flow channel structure of the multifunctional disc type separator capable of changing the multiple flow channels, a variety of flow channels can be realized.

Owner:SHENYANG POLYTECHNIC UNIV

Modularized intelligent reconstruction general work stair platform

The invention discloses a modularized intelligent reconstruction general work stair platform having a plurality of liftable work stairs. A work area for airplane assembling is enclosed by the plurality of work stairs. The modularized intelligent reconstruction general work stair platform is characterized in that each work stair is a shearing hydraulic elevating work stair; a buried-in groove is arranged on the ground; a pedestal of the work stairs is fixed in the buried-in groove; when expansion amount of the work stairs at a non-work state is zero, the stair platform surfaces of the work stairs are in a seamless connection to form a plane; and the plane is on the same level as the work area ground. Space can be fully utilized by the use of the work stair platform, so use area of a factory plant is increased and low cost and convenience can be achieved for airplane assembling; relative reconstructions can be achieved based on various products by the use of the modularized general work stair platform, so an assembling demand for various reconstructions via one work stair platform can be achieved; and numbers of specific work stairs can be reduced, so manufacturing cost can be lowered.

Owner:SHENYANG AIRCRAFT CORP

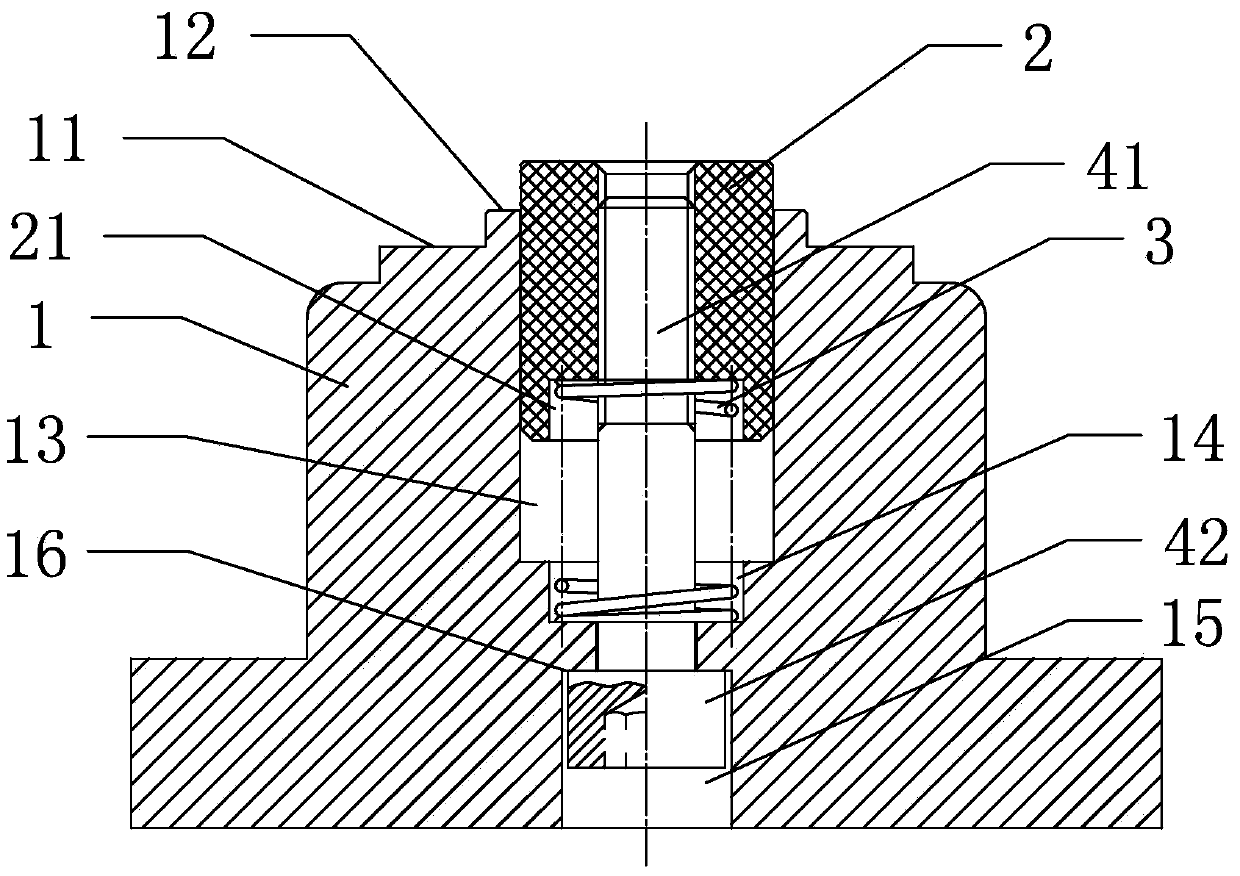

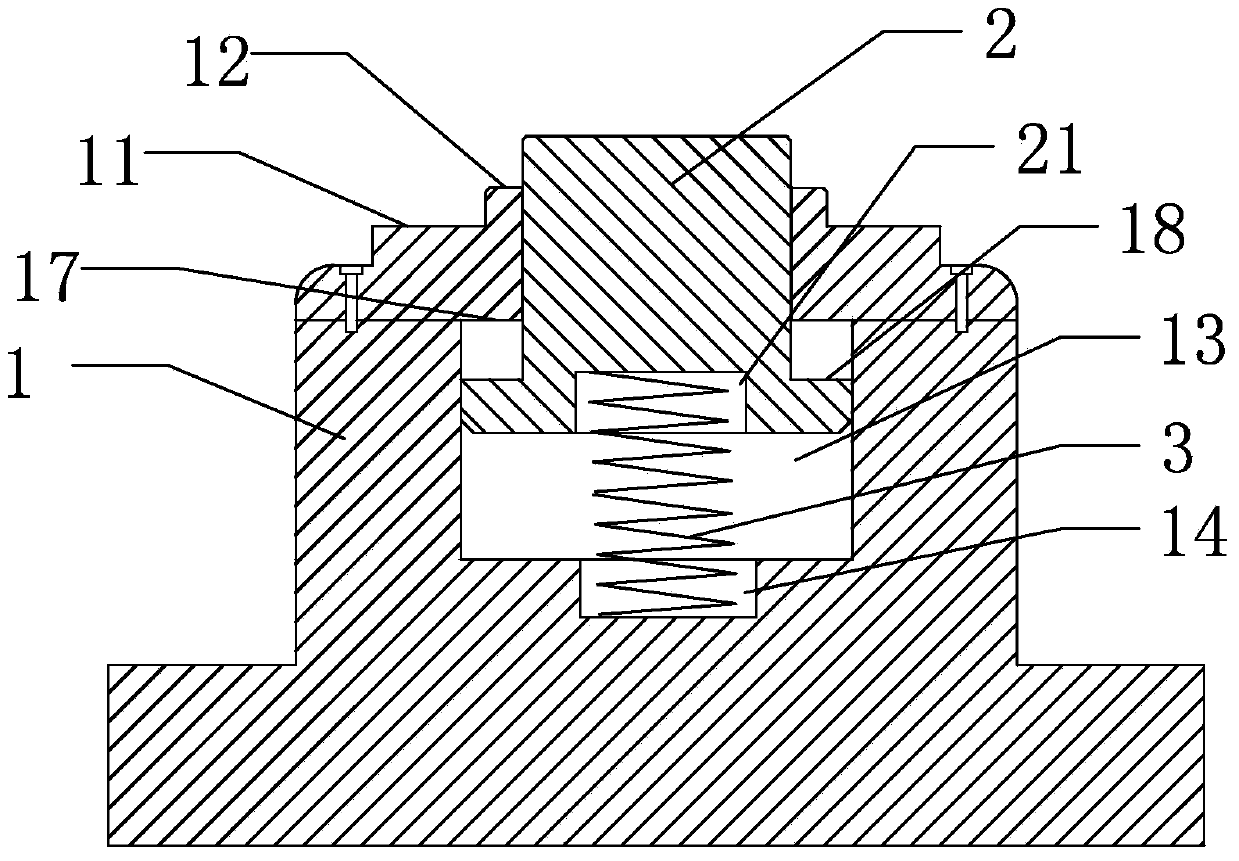

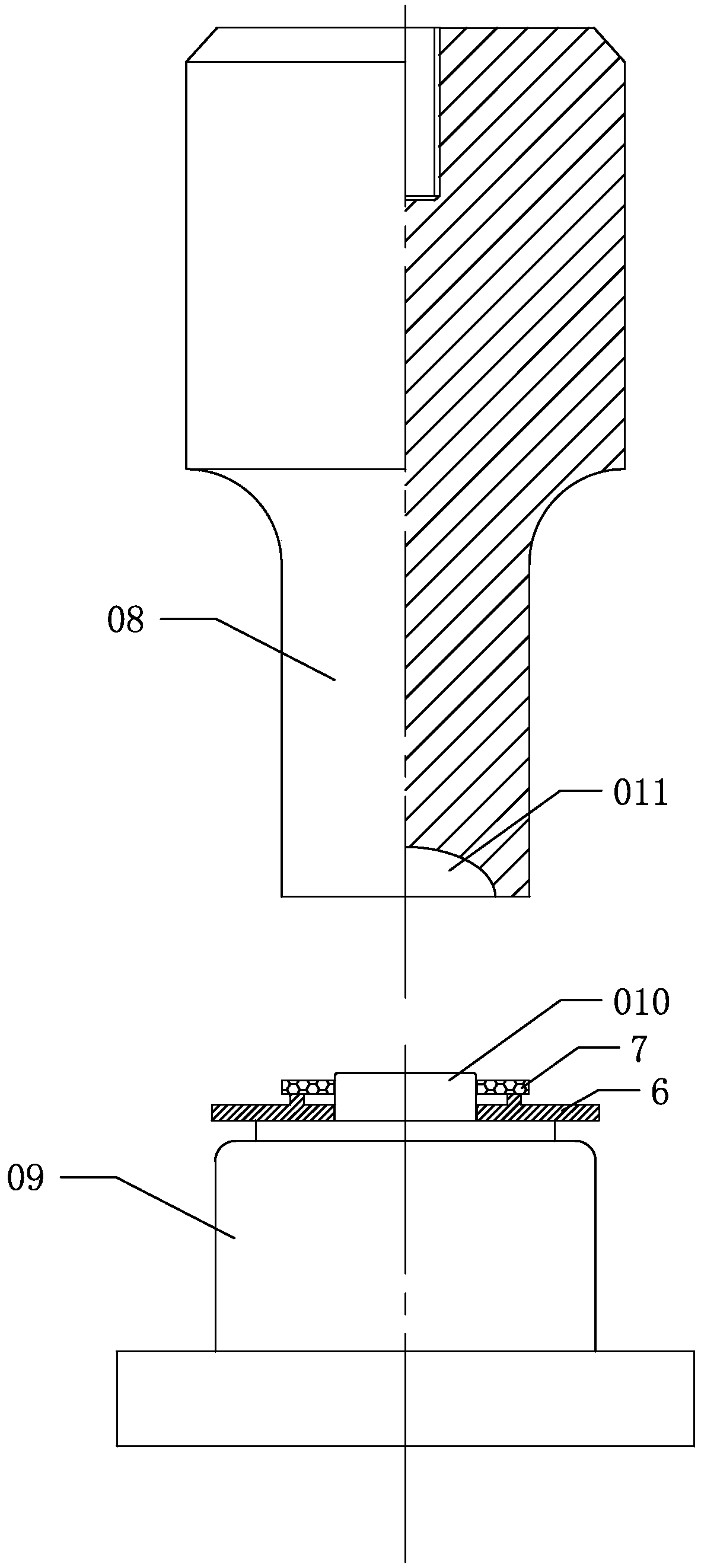

Telescopic ultrasonic welding fixture base and ultrasonic welding fixture

ActiveCN104084689AReduce production quantitySave adjustment timeNon-electric welding apparatusEngineeringUltrasound

The invention provides a telescopic ultrasonic welding fixture base and an ultrasonic welding fixture. The telescopic ultrasonic welding fixture base comprises a base main body, wherein a placing surface is arranged at the top of the base main body, a hollow cavity is formed in the base main body, an opening is formed in the top of the hollow cavity, the placing surface surrounds the opening in the top of the hollow cavity, a center shaft is sleeved in the hollow cavity, a spring used for ejecting the center shaft to the outside of the opening in the top of the hollow cavity is arranged in the hollow cavity, and a support part which supports the spring is arranged in the hollow cavity. Meanwhile, the invention provides the ultrasonic welding fixture. The base disclosed by the invention is manufactured to be a telescopic structure relying on the spring, when a product model is replaced, an ultrasonic base is only required to be replaced, so that the structure greatly reduces the production number of welding heads, furthermore, the replacement frequency of the welding heads is greatly lowered, the service life of an ultrasonic machine is prolonged, and the stability of the product welding quality is improved.

Owner:ZHEJIANG WEITAI AUTOMOBILE PARTS

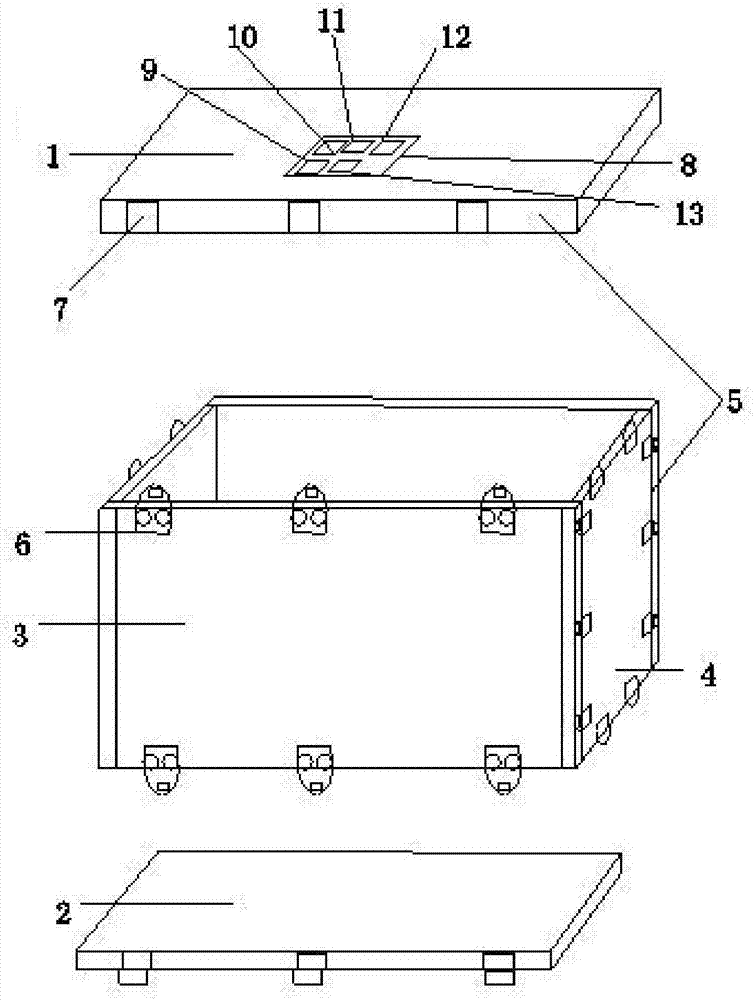

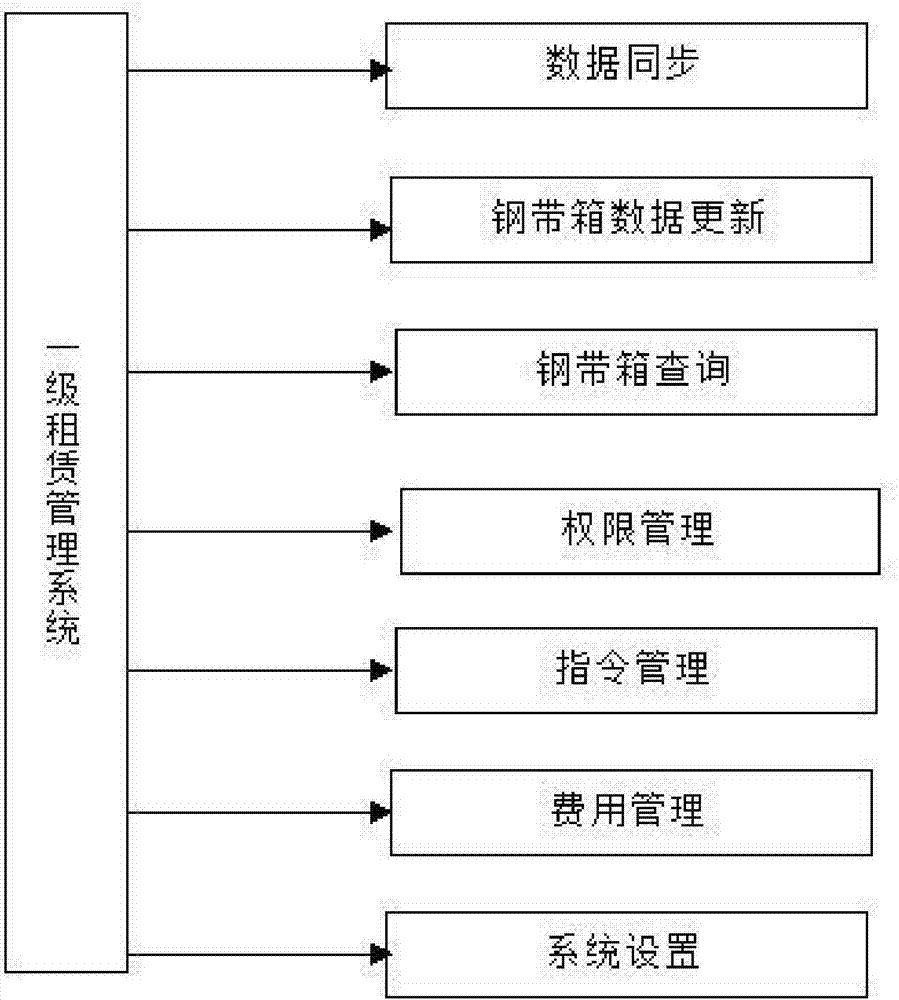

Steel belt box lease management system and control method thereof

InactiveCN107123018AEffective management statusEasy to useBuying/selling/leasing transactionsLogisticsData managementEngineering

The present invention belongs to the steel belt box field and relates to a steel belt box lease management system and a control method thereof. The lease management system includes a warehouse, a steel belt box, a cloud end, a management center and a mobile terminal, wherein the steel belt box is provided with an intelligent lock and an electronic device connected with the intelligent lock. The control method of the steel belt box lease management system includes a lease step, a use step, a returning step, an inquiring step and a data management step. With the steel belt box lease management system adopted, the states of steel belt boxes in a whole nation can be managed effectively; limited steel belt box resources can be utilized reasonably and efficiently through a lease means; customers can lease and transport the steel belt boxes, and therefore, product packaging and transportation costs can be greatly decreased; and the customers can return the steel belt boxes at different places, and therefore, the customers can conveniently use the steel belt boxes, the number of packaging boxes can be decreased, and energy saving and environment protection can be facilitated.

Owner:广州泰柯实业有限公司

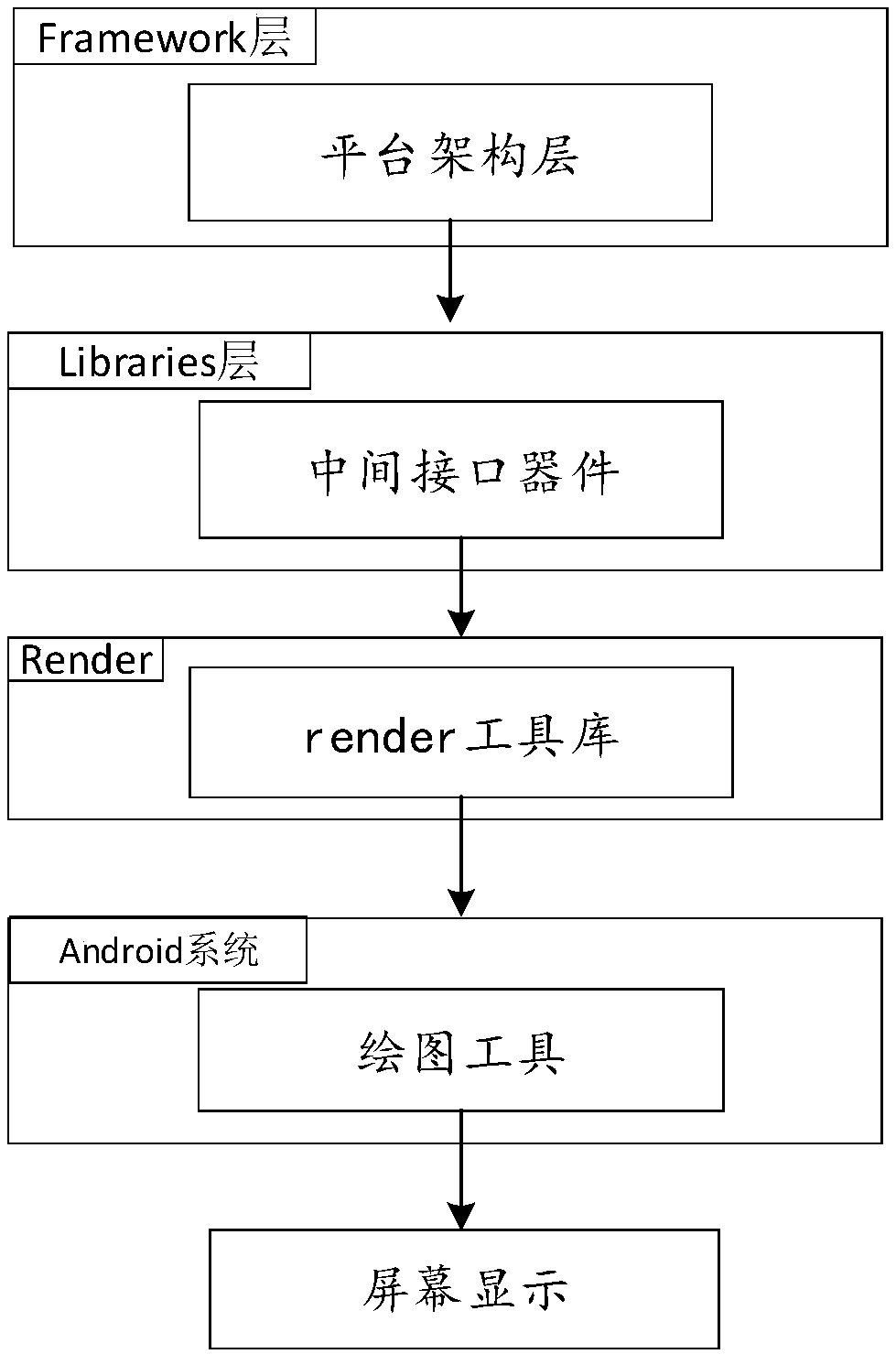

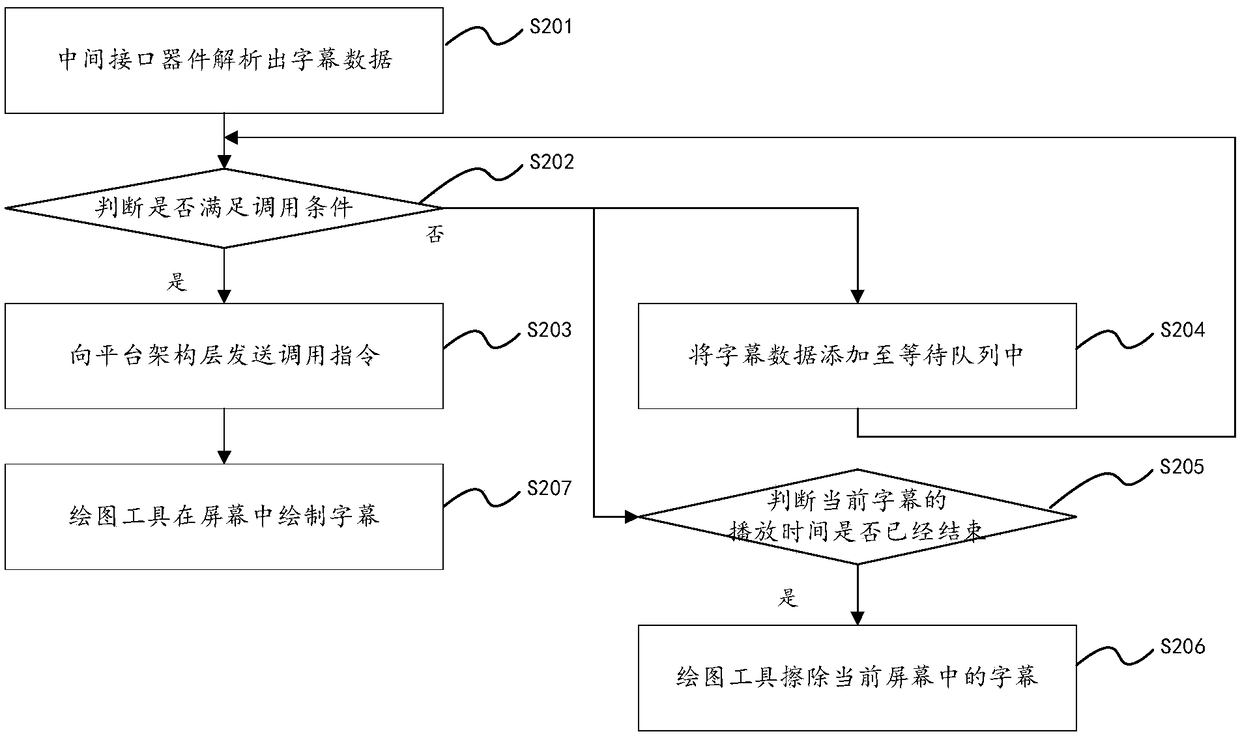

Caption display method and device compatible with different platforms

ActiveCN109151609AReduce production quantityReduce manufacturing costSelective content distributionTechnology of televisionComputer engineering

The invention relates to a caption display method and device compatible with different platforms, and belongs to the technical field of intelligent televisions. The method comprises that an intermediate interface device is driven to obtain a caption file, and the caption file is parsed to obtain caption data; the intermediate interface device is driven send a calling instruction to a platform configuration layer; a new container is created, and the caption data is sent to the platform configuration layer via the container; and the platform configuration layer calls a tool library packaged witha drawing toll according to the calling instruction, the caption data is sent to the drawing tool for processing, and caption is obtained by drawing. The caption display method is not limited by a chip platform, and can be applied to different chip platforms, one caption file can be applied to multiple chip platforms, it is required to make fewer caption files, the making cost is reduced, and development of digital electronic equipment in the different system platforms is helped.

Owner:HISENSE VISUAL TECH CO LTD

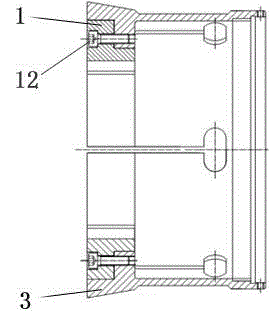

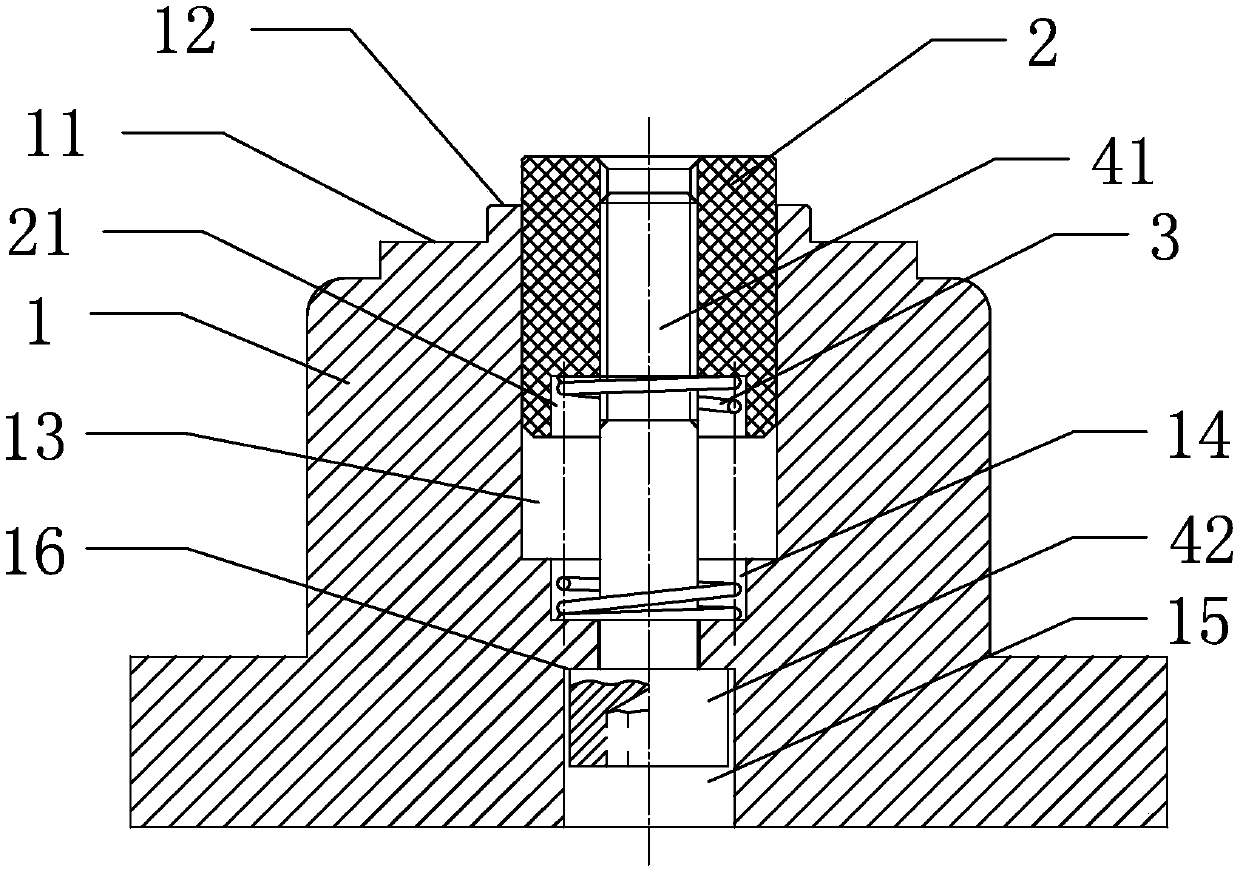

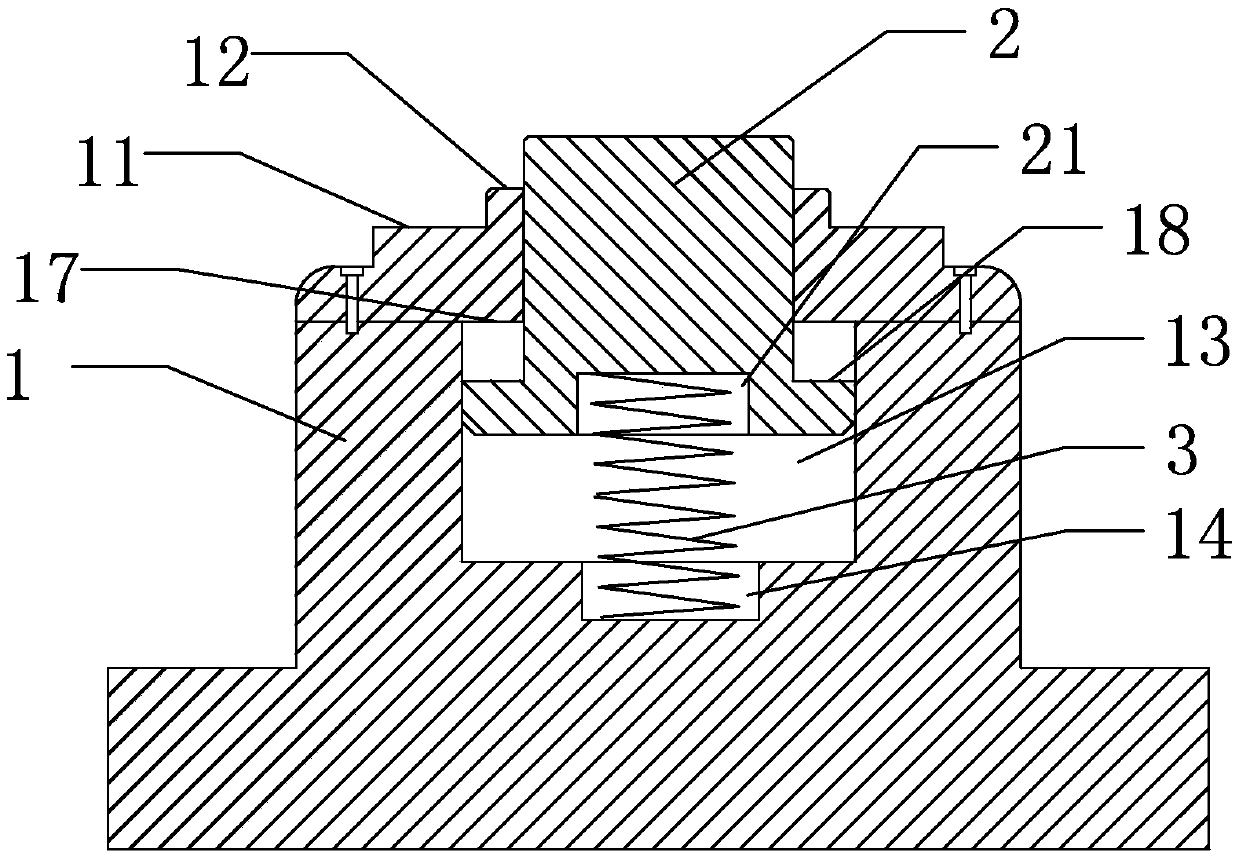

Short large-aperture inlaid centering fixture

ActiveCN104551797AInterchangeableEasy to operateChucksPositioning apparatusEngineeringLarge aperture

The invention provides a short large-aperture inlaid centering fixture which can ensure radial and axial locating precision, has interchangeability and is convenient to operate and high in generalization degree. The short large-aperture inlaid centering fixture comprises a flange and is characterized in that a transition disk is supported on the flange; a fixture body is supported on the transition disk; the guide opening of the flange is provided with a tensioning disk; the center of the tensioning disk is connected with a draw rod; a chuck body is provided with a connecting disk; the fixture body is internally provided with multiple clip spring bases and elastic clip springs; spigot matching structures are arranged between the clip springs and the clip spring bases, between the fixture body and the connecting disk and between the transition disk and the flange; the upper parts of the inner walls of the clip springs are provided with T-shaped grooves; the upper parts of insert blocks are provided with clamping platforms which extend inwards; the clamping platforms are clamped in the corresponding T-shaped grooves, and the clamping platforms and the T-shaped grooves are connected and pressed by screws; the internal guide surface of the upper opening of the fixture body is in conical surface contact with the external side surfaces of the upper parts of the clip springs; the clip spring bases, the connecting disk and the tensioning disk are connected by virtue of guide posts.

Owner:JINZHOU RIYILONG IND FACILITIES & EQUIP +1

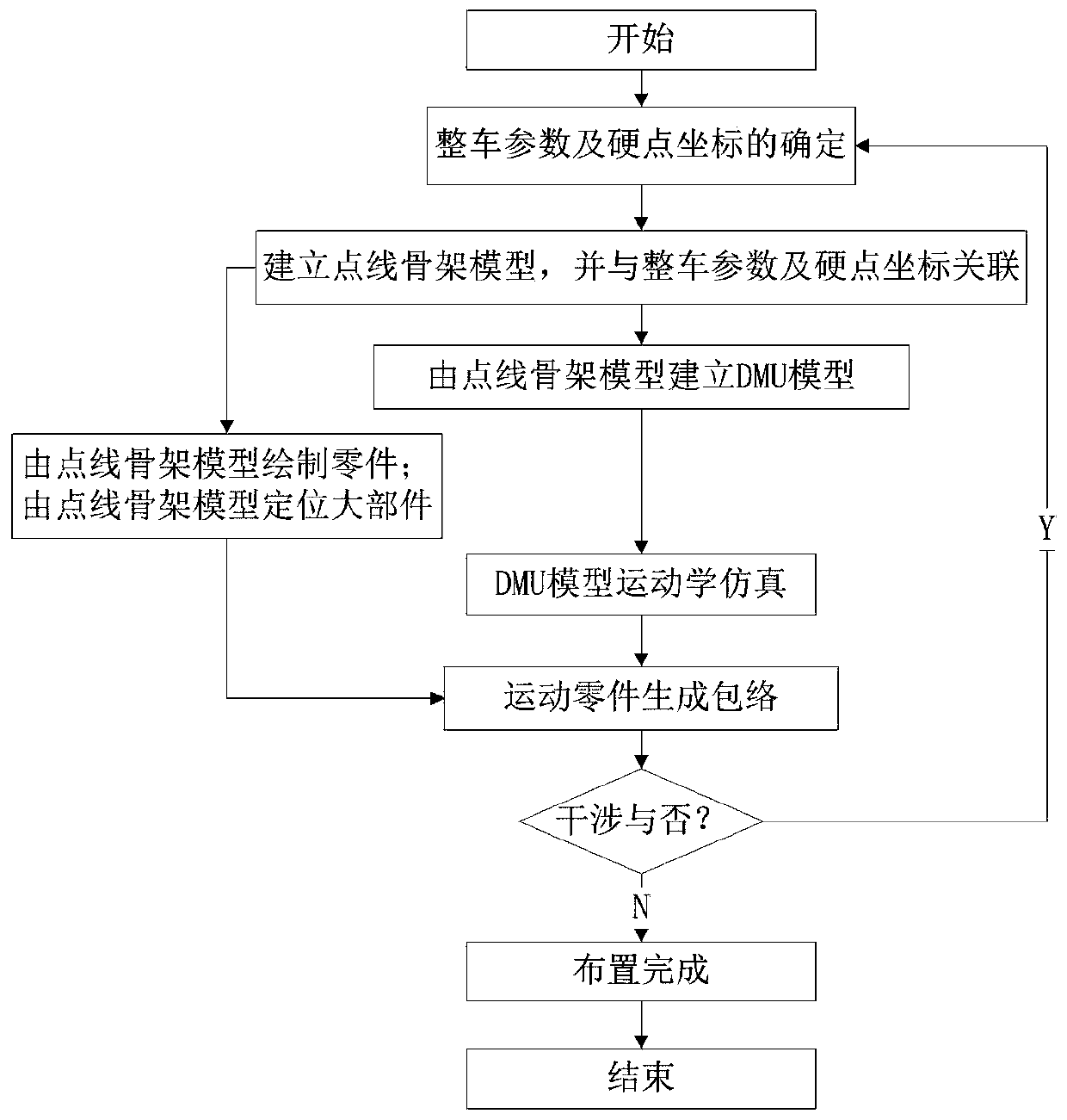

Heavy truck general arrangement method

PendingCN109800471AEliminate interferenceReduce production quantitySpecial data processing applicationsStructural engineeringTruck

The invention belongs to the technical field of vehicle total arrangement, and particularly relates to a top-down heavy truck total arrangement method based on a parameterized skeleton model. According to the method, complete forward design from top to bottom is adopted, and top layer planning is established and serves as a design criterion to be transmitted downwards step by step; The modification is very convenient, only corresponding parameters or hard point coordinates need to be modified, the point-line skeleton model, the part model and the large part are positioned, the point-line DMU model can be automatically modified, and the part motion envelope can be automatically generated; The method is suitable for a series of vehicle types of the same platform, and the requirements can bemet only by establishing one-time vehicle parameters and hard point coordinates, a one-time point line skeleton model and a one-time point line DMU model and simply modifying other vehicle types. Theworkload is greatly reduced, the sample production quantity is reduced, the product development cost is reduced, and the product development period is shortened.

Owner:BEIBEN TRUCKS GRP

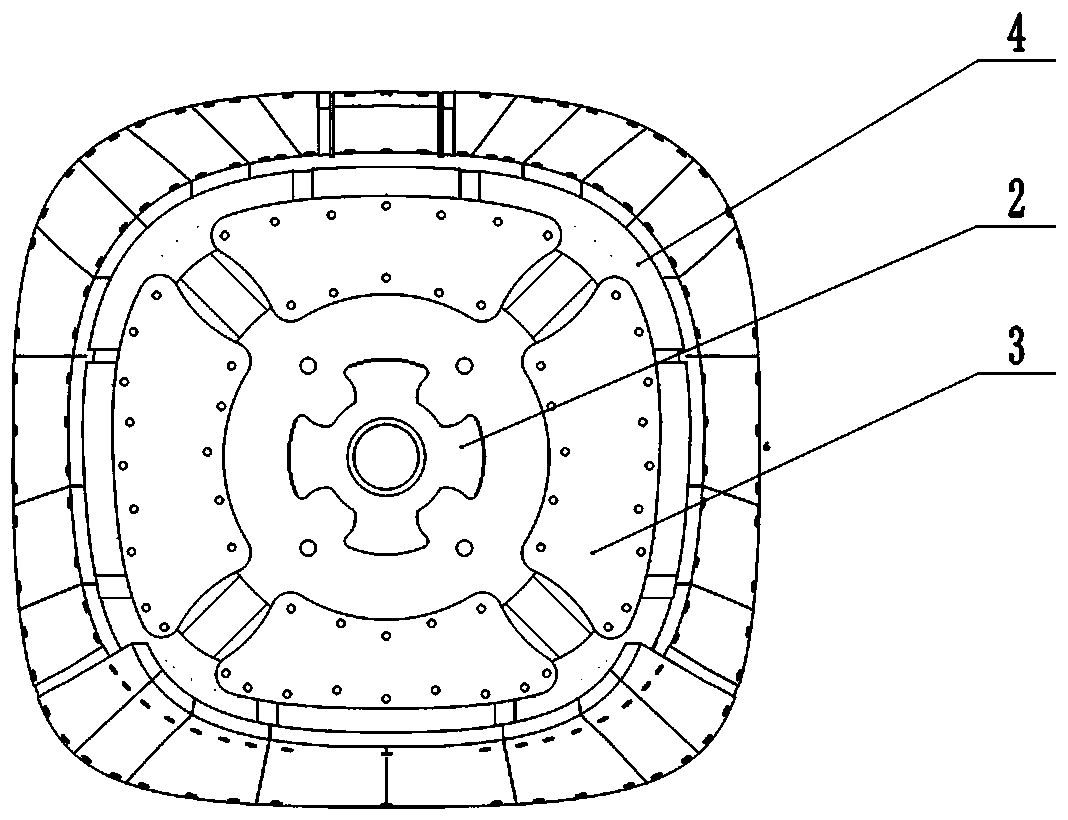

Small combined molding die for aircraft skin

ActiveCN108248890AQuick combinationLow production costWeight reductionAircraft assemblyEconomic benefitsCrush injury

The invention discloses a small combined molding die for aircraft skin. The molding die comprises a central spindle, at least two rotating plates fixed to the central spindle, a filter plate connectedwith the rotating plates through quick-release pins, a connecting frame connected with the filter plate through a quick-release pin and die outer skin connected with the connecting frame through a bolt. All the components are connected through the quick-release pins, assembling and disassembling are convenient, and the needed aircraft skin production die can be rapidly assembled according to theproduction requirement. After manufacturing, disassembling work can be performed directly inside a product, scratches, crush injuries, internal cracks and the like caused by direct die release are greatly avoided, the using risk can be lowered, and the product quality is improved. All the components can be repeatedly and alternately used, the production cost of the aircraft skin is lowered, and economic benefits of a production plant are improved.

Owner:石家庄飞机工业有限责任公司

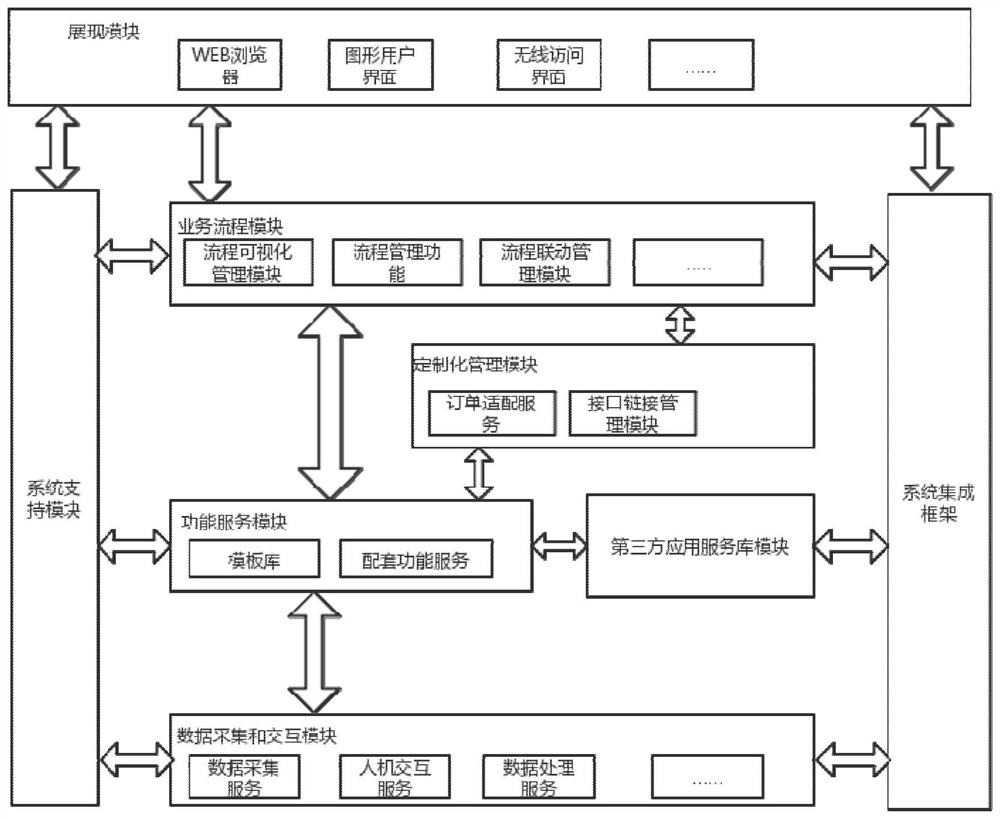

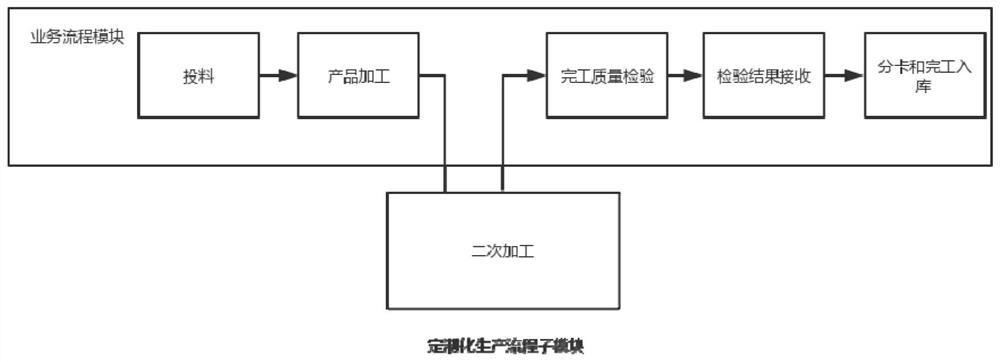

Cloud system for supporting customized industrial process production management and method thereof

ActiveCN112418820AThe total amount of orders is largeReduce production quantityOffice automationExecution paradigmsProcess engineeringBusiness process

The invention provides a cloud system for supporting customized industrial process production management and a method thereof, and the system comprises a function service module, a business process module, and a customized management module which are connected with one another in pairs. The customized management module is used for inserting a customized interface into any one or more links of thebusiness process module and externally hanging a customized production process sub-module through the customized interface; when the business process is executed to the link where the customized interface is inserted, the customized production process sub-module is automatically triggered through the customized interface, production management is executed according to the sub-process in the customized production process sub-module, and the customized production process sub-module customizes the business processes to meet order requirements according to the attribute characteristics oriented tothe corresponding order. According to the system, the characteristics that the total quantity of intelligently manufactured orders is large and the production quantity of each order is small can be met, and meanwhile, the system has high flexibility in production.

Owner:蒲惠智造科技股份有限公司

Flexible fixture for surface milling and drilling of fan bracket and clamping and positioning method

ActiveCN113199269ASimple clamping methodEasy to adjustWork clamping meansWind energy generationStructural engineeringMachining

The invention discloses a flexible fixture for surface milling and drilling of a fan bracket and a clamping and positioning method. The flexible fixture comprises a bottom plate, and the bottom plate is provided with a first positioning pressing block assembly capable of moving in the X direction, a second positioning pressing block assembly capable of being adjusted in the Y direction, a third positioning pressing block assembly capable of being adjusted in the X direction and the Y direction respectively, and at least three height-adjustable support positioning pin assemblies. The first positioning pressing block assembly is used for actively positioning and clamping a positioning point on the first side face of the fan bracket, the second positioning pressing block assembly is used for passively positioning and clamping two positioning points on the second side face of the fan bracket, and the third positioning pressing block assembly is used for pre-tightening, positioning and clamping a positioning point on the third side face of the fan bracket. When the flexible fixture is used for surface milling and datum hole drilling of fan bracket products, quick clamping switching of machining of different types of products can be achieved, the manufacturing number of fixtures in the product sample stage is reduced, the sample development period is shortened, and the development cost before product shaping and mass production is reduced.

Owner:东风汽车动力零部件有限公司

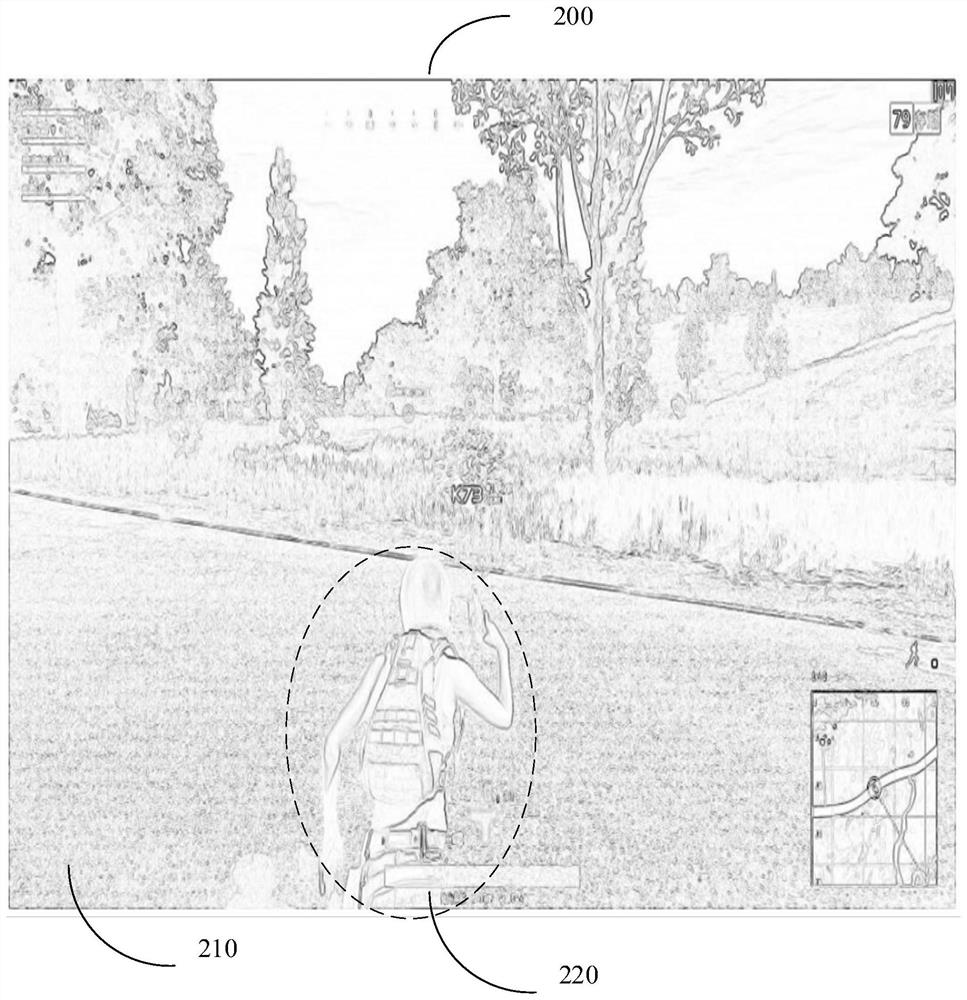

Plot animation playing method, generating method, terminal, device and equipment

The invention provides a plot animation playing method, a generating method, a terminal, a device and equipment. After plot animation playing is triggered, an animation skeleton model which is pre-constructed in a plot animation and is provided with hooking anchor points is adopted, and based on the plot animation needing to be played, a plurality of role model structure components comprising skeletons and appearances are selected and copied from a game role model in a game scene; and the plurality of role model structure components arehookedon the animation skeleton model according to corresponding hooking anchor points, and a target animation role model of which the appearance and the skeleton are the same as those of the game role model is generated in the plot animation, and the configured plot animation is played based on the target animation role model at the moment. For different game roles, the appearance of the animation skeleton model and the appearance of the game role model in the game scene are always kept consistent in the plot animation, the playing effect of the plot animation is improved, and the efficiency of making the plot animation is increased.

Owner:BEIJING ZITIAO NETWORK TECH CO LTD

Organic electroluminescent display device, driving method thereof

ActiveUS9767741B2Increase productivityEasy to manufactureStatic indicating devicesSolid-state devicesImage resolutionOptoelectronics

The embodiments of the present invention provide an organic electroluminescent display device, a driving method thereof and a display device. Due to the regular staggered arrangement of sub pixels with the same color on the basal substrate, during the manufacture of a metal mask plate, the distance between adjacent openings corresponding to the sub pixels with the same color in the metal mask plate can be relatively large, improving the strength of the metal mask plate; this is beneficial for manufacturing small-sized sub pixels, thereby further improving the resolution of the organic electroluminescent display device.

Owner:BOE TECH GRP CO LTD +1

Control arm flanging stamping die

The invention discloses a control arm flanging stamping die. The control arm flanging stamping die includes a control arm, a front panel, a main hole, a secondary hole, a back panel, a half hole, a semi arc, a stamping die body, an upper stamping plate, and a lower stamping plate, the front panel is arranged on the control arm, the main hole is formed in the surface of the front panel, the secondary hole is formed above the main hole, and the secondary hole and the main hole are fixedly connected with the front panel; and the hale hole is formed in the surface of the back panel, the semi arc is arranged above the half hole, the semi arc and the half hole are fixedly connected with the back panel, the stamping die body is arranged on the outer side of the control arm, the upper stamping plate is arranged on the stamping die body, and the lower stamping plate is fixedly arranged below the upper stamping plate. According to the control arm flanging stamping die, by arranging the stampingdie body with the upper stamping plate and the lower stamping plate, the production quantity of the flanging stamping die body is conveniently reduced, the storing and using are conveniently conducted, and the control arm flanging stamping die is simple in structure and easy to achieve.

Owner:镇江罗氏模具设计有限公司

Sheet metal part common stamping die

The invention provides a sheet metal part common stamping die comprising a lower template and an upper template matched with the lower template; one side of the lower template is fixedly provided with a first deceleration motor through a mounting base; a pair of first slide rails are fixed in front of the first deceleration motor; the first slide rails are provided with a transversely mobile lower template mobile flanging male die; the lower template mobile flanging male die is in drive connection with the rotary shaft of the first deceleration motor through a first screw rod; one side of the upper template is fixedly provided with a second deceleration motor through a mounting base; a pair of second slide rails are fixed in front of the second deceleration motor; the second slide rails are provided with a transversely mobile upper template mobile flanging female die through a movable pad; the rotary shaft of the second deceleration motor is in drive connection with the movable pad through a second screw rod; the lower template mobile flanging male die and the upper template mobile flanging female die are matched; the sheet metal part common stamping die is energy saving and consumption reduction, can reduce die manufacture quantity, thus reducing cost, and improving production efficiency.

Owner:苏州工业园区金鑫模具制造有限公司

Elastic discharging device in high-speed precise punching die for automobile terminals

ActiveCN103752719AReduce production quantitySimple structureStripping-off devicesPunchingEngineering

The invention discloses an elastic discharging device in a high-speed precise punching die for automobile terminals. The elastic discharging device comprises an upper die and a male die fixing plate, an elastic discharging block is arranged on the upper die, a blanking male die is arranged on the male die fixing plate and comprises a first working end face and a second working end face, a large waste discharging hole is formed in the first working end face, and a small waste discharging hole is formed in the second working end face. The elastic discharging block is matched with the first working end face, and connected with the upper die via a screw plug which is arranged on the upper die and penetrates an elastic part. Compared with the prior art, the elastic discharging device has the advantages that the requirements on part production of the two waste discharging holes of different models are met by one discharging block, and the device is simple in structure and convenient to use; production number of the elastic discharging block is reduced effectively, so that production cost is lowered; working procedures are decreased, time and labor are saved, and production efficiency is improved.

Owner:HENAN THB ELECTRIC

A scalable ultrasonic welding tool base and ultrasonic welding tool

ActiveCN104084689BReduce production quantitySave adjustment timeNon-electric welding apparatusUltrasonic weldingMechanical engineering

The invention provides a telescopic ultrasonic welding fixture base and an ultrasonic welding fixture. The telescopic ultrasonic welding fixture base comprises a base main body, wherein a placing surface is arranged at the top of the base main body, a hollow cavity is formed in the base main body, an opening is formed in the top of the hollow cavity, the placing surface surrounds the opening in the top of the hollow cavity, a center shaft is sleeved in the hollow cavity, a spring used for ejecting the center shaft to the outside of the opening in the top of the hollow cavity is arranged in the hollow cavity, and a support part which supports the spring is arranged in the hollow cavity. Meanwhile, the invention provides the ultrasonic welding fixture. The base disclosed by the invention is manufactured to be a telescopic structure relying on the spring, when a product model is replaced, an ultrasonic base is only required to be replaced, so that the structure greatly reduces the production number of welding heads, furthermore, the replacement frequency of the welding heads is greatly lowered, the service life of an ultrasonic machine is prolonged, and the stability of the product welding quality is improved.

Owner:ZHEJIANG WEITAI AUTOMOBILE PARTS

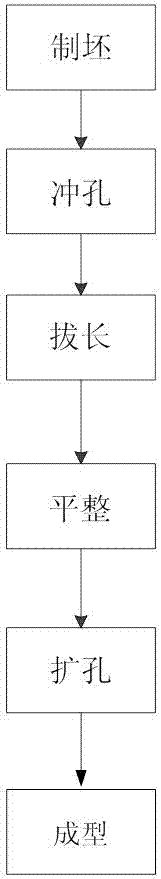

A method for forging special-shaped forgings of the filter screen main body of a thermal power unit

The invention discloses a forging method of a special-shaped forged piece of a thermal power unit filter screen main body. The method comprises the following steps: 1) blank manufacturing, including feeding material according to the requirement of the thermal power unit filter screen main body, manufacturing a forged piece blank at normal temperature, and upsetting and drawing the forged piece blank at 1,050 DEG C; 2) punching, drawing and shaping, including performing high-pressure punching of the upset blank, drawing the forged piece according to the special shape requirement of the filter screen main body, and then shaping the side wall of the forged piece; 3) leveling, including integrally leveling the end surface of the forged piece once; and 4) reaming forming, including reaming the forged piece with a special-shaped core rod to obtain the finished special-shaped forged piece. In the reaming process of the method, the dedicated special-shaped core rod is used to form the forged piece once, and turning machining is omitted, so that blank waste is waste, the machining time is shortened, and the metal flow in the forged piece is integral so as to enhance the strength and toughness of the forged piece.

Owner:四川民盛特钢锻造有限公司

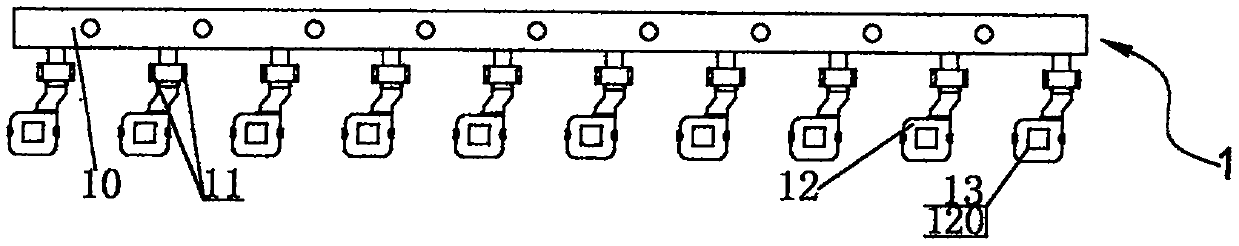

Manufacturing method of thermal protector

PendingCN109817479ARealize continuous mass productionEfficient processingElectric switchesWork in processMechanical engineering

The invention discloses a method for manufacturing a thermal protector, which comprises the following steps of: a steel strip and a static contact strip material are fed and cut into sections, and a static sheet group with static contacts is discjarged, wherein the static sheet group comprises a transition bridging section, a plurality of static sheets and the static contacts pressed on the staticsheets; the static sheet group is subjected to injection molding to obtain a static sheet seat assembly; the steel strip is continuously fed, the cut support group is discharged, the support group comprises a transition bridging segment and a plurality of supports, one surface of each support is provided with a groove, and the other surface of each support is provided with a boss with a temperature adjusting concave point; a bimetallic strip which is fixedly provided with a contact and is pressed with a constant temperature ring is fixed in the support to obtain a movable sheet support assembly; the two assemblies are integrally injection-molded after being overlapped to obtain a thermal protector packaging piece, and the temperature adjusting concave point is exposed out of the insulating resin block; the two transition bridging segments are cut to obtain a single thermal protector semi-finished product; the needle of the constant-temperature machine is aligned with the temperature adjusting concave point to extrude the constant-temperature ring to reach the process action temperature; and the wire is clamped to the wire clamp and installing the insulating sheath to obtain a finished product. The method is few in procedure, good in sealing performance, rapid and preset, and capable of calibrating the action temperature.

Owner:嵊州市甘霖王氏热保护器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com