Manufacturing method of thermal protector

A technology of thermal protector and manufacturing method, which is applied to electrical components, electrical switches, circuits, etc., can solve the problems of poor sealing performance of thermal protectors, poor pressure resistance of housings, and malfunction of thermal protection, and achieves excellent sealing performance, resistance to Strong pressure ability, avoids the effect of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

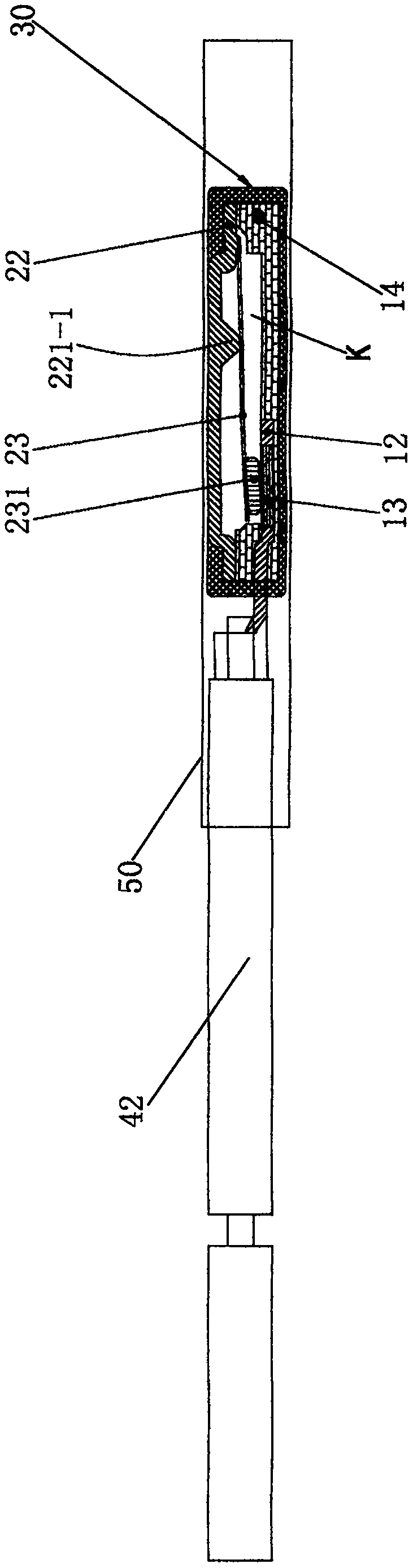

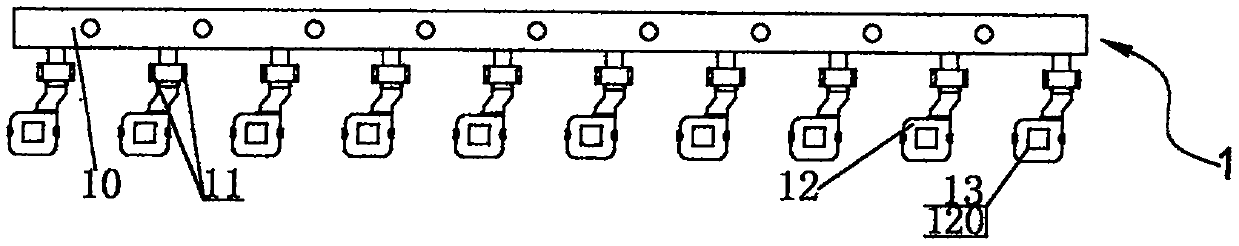

[0051] see figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, a method for manufacturing a thermal protector, the method includes the following manufacturing steps:

[0052] S1. Integral forming process of the static sheet group with static contact, the cold-rolled steel strip in the coil and the static contact strip in the coil are fed into the press synchronously and continuously, and the segments with the static contact are cut into segments when the material is discharged Static sheet group 1, wherein the cold-rolled steel strip is punched and formed into a transition bridging section a 10, a plurality of static sheets 12 arranged at intervals, a plurality of line cards a11 connecting the transition bridging section a 10 and the static sheet 12, and the static The multiple pieces of static contacts 13 cut from the contact strip material are pressed and fixed in the punching holes 120 of the corresponding static pieces 12 one by one.

[0053] The specifications o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com