Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Improve Surface Treatment Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

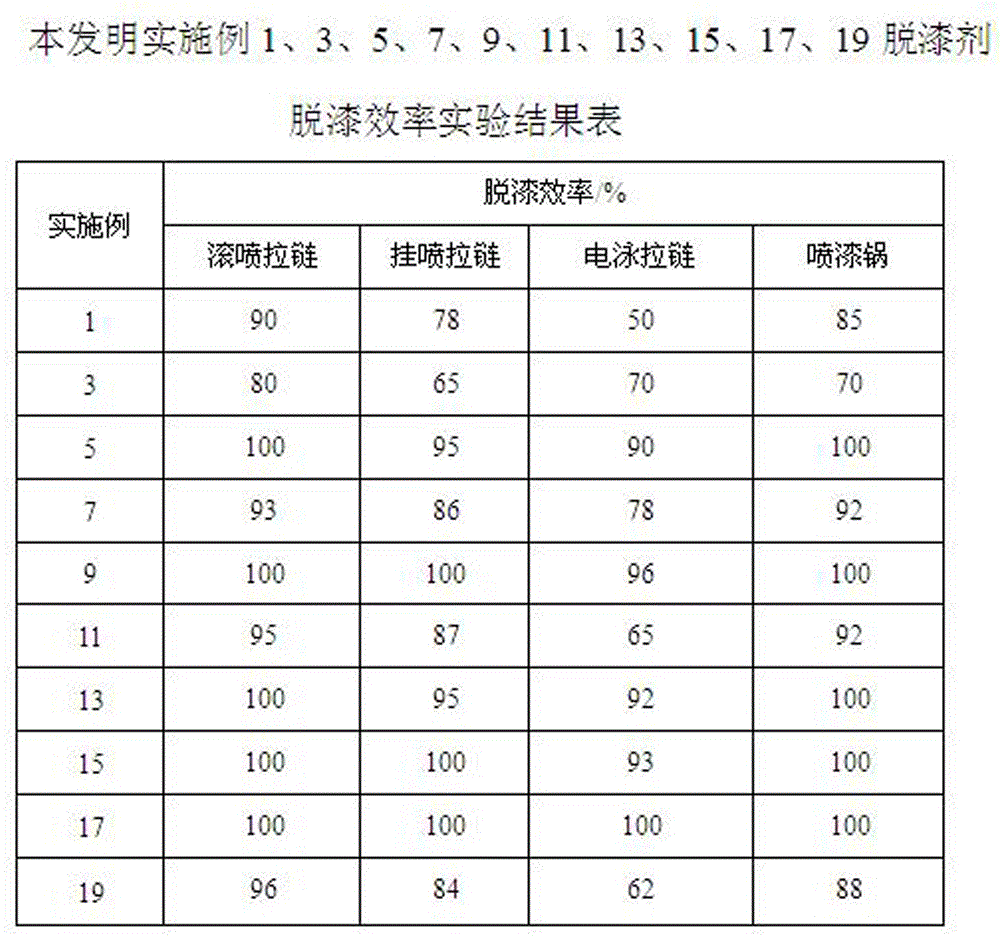

Water-based paint remover applied to zipper production and preparation method thereof

InactiveCN106590142ASuitable for cleaningStrong paint removal abilityChemical paints/ink removersWater basedBenzaldehyde

The invention discloses a water-based paint remover applied to zipper production and a preparation method thereof, and belongs to the technical field of paint cleaning. The water-based paint remover is characterized by consisting of the following components in parts by mass: 20-30 parts of a main solvent, 25-35 parts of a cosolvent, 10-20 parts of an activating agent, 3-5 parts of an emulsifying agent, 8-10 parts of a penetrating agent, and 20-25 parts of deionized water, wherein the main solvent is one of or a combination of two or more of the solvents including N-methyl-2-pyrrolidone, butylcellosolve, propylene carbonate, dimethyl sulfoxide, benzaldehyde, and methyl methacrylate; the cosolvent is one of or a combination of two or more of the solvents including Y-butyrrolactone, benzyl alcohol, ethanol, and propanetriol; and the activating agent is one of formic acid, acetic acid, oxalic acid and salicylic acid. The water-based paint remover disclosed by the invention can remove paint on a zipper paint spraying pot and a zipper head at a normal temperature, is noncorrosive to equipment, does not pollute the environment and generate wastewater, and can be used repeatedly.

Owner:义乌市中科院兰州化物所功能材料中心

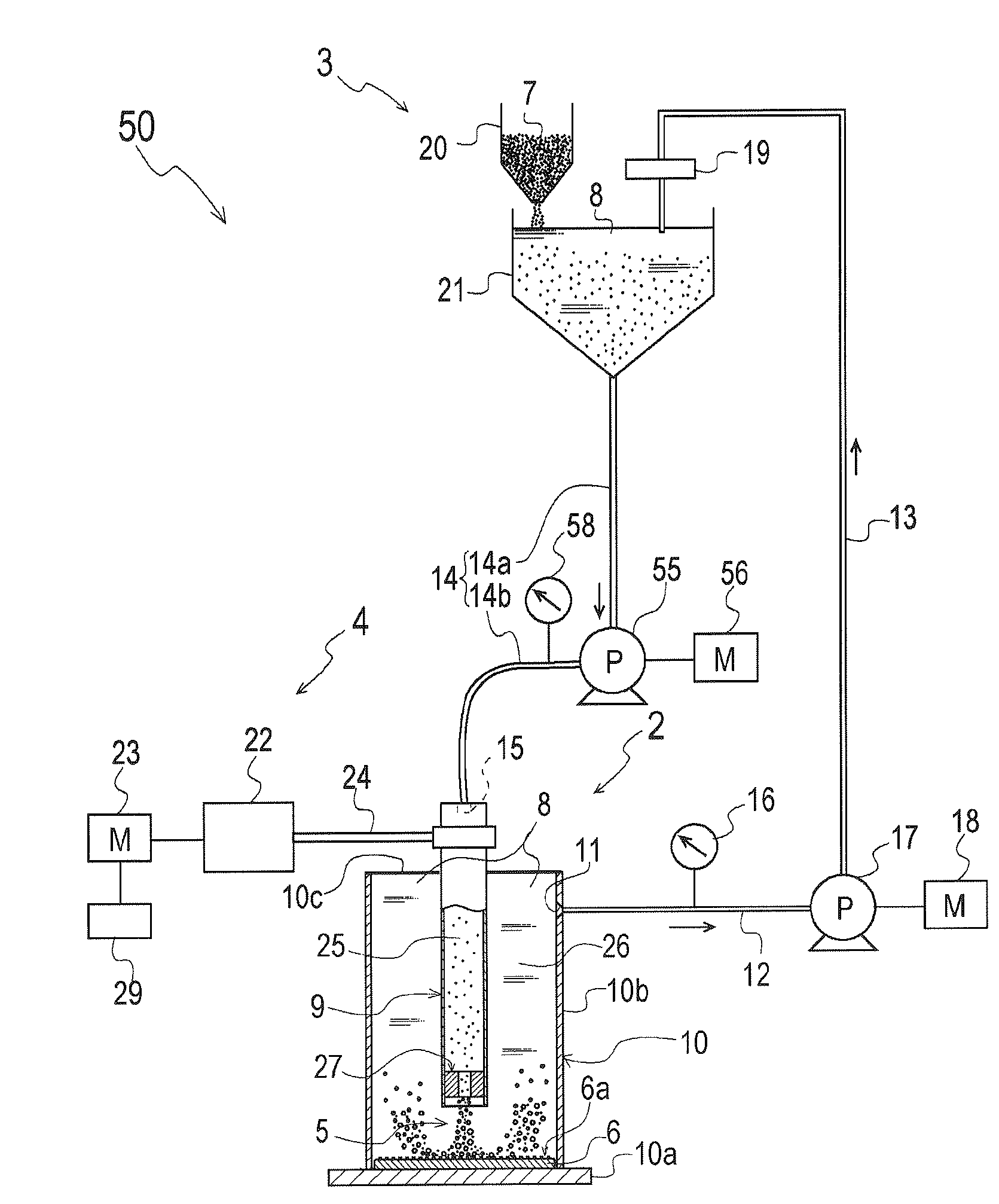

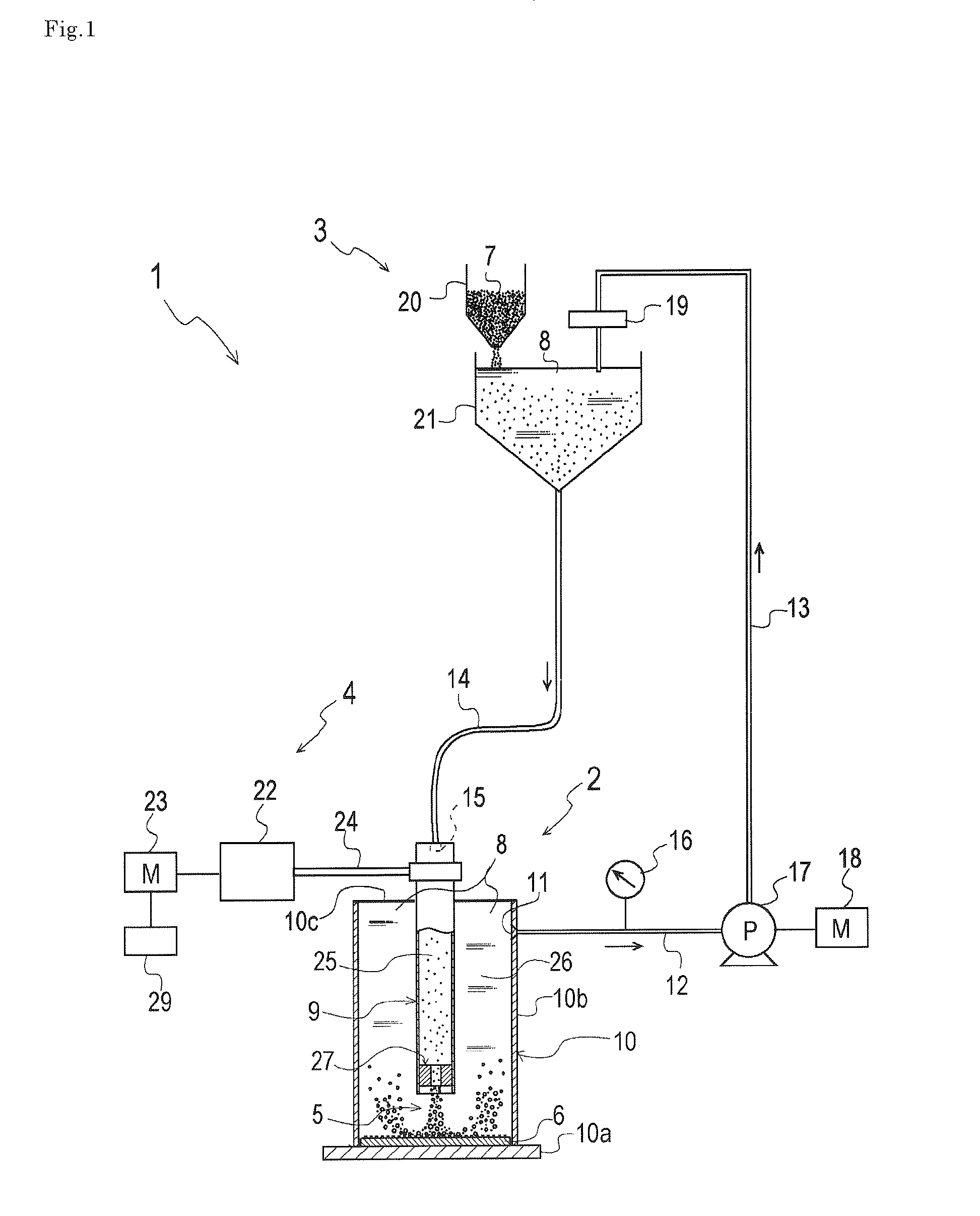

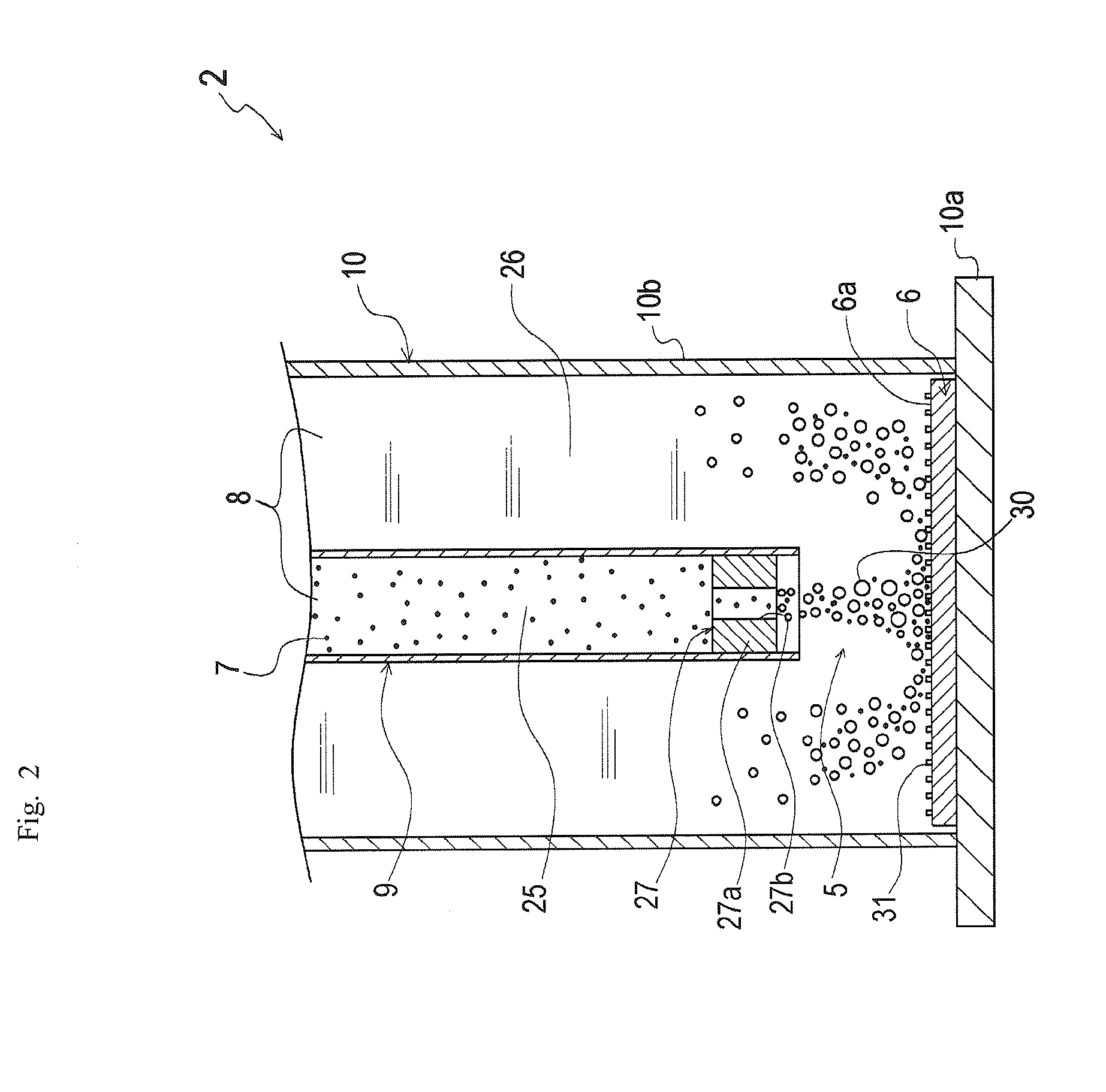

Surface Treating Method and Device Thereof

InactiveUS20100255759A1Improve machining accuracyEnlarge treating sizeAbrasive machine appurtenancesGrain treatmentsEngineeringCavitation flow

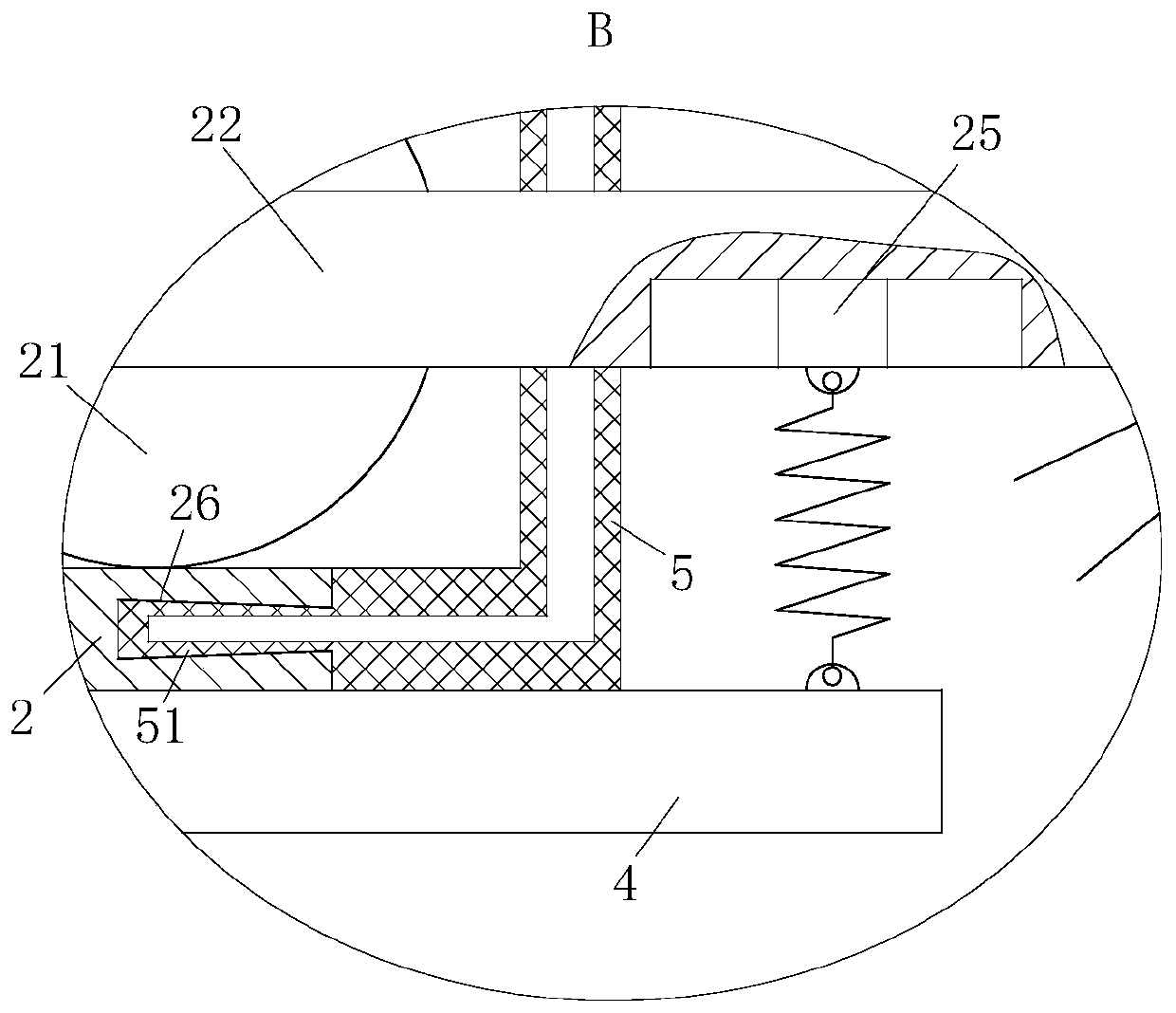

In a surface treating method of the present invention, a fluid suction passage 26 communicating with a fluid supply passage 25 via only a narrowed portion 27 is provided, so as to approximately concentrically surround the periphery of the fluid supply passage 25 having the narrowed portion 27 at one end thereof, and the sucking cavitation flow 5 is generated at the direct downstream of the narrowed portion 27, by sucking the processing fluid 8 into the fluid suction passage 26 using a suction pump 17, as well as a surface treating is performed on the treated surface 6a, by crushing the sucking cavitation flow 5 approximately perpendicular to the treated surface 6a.

Owner:UNIV OKAYAMA

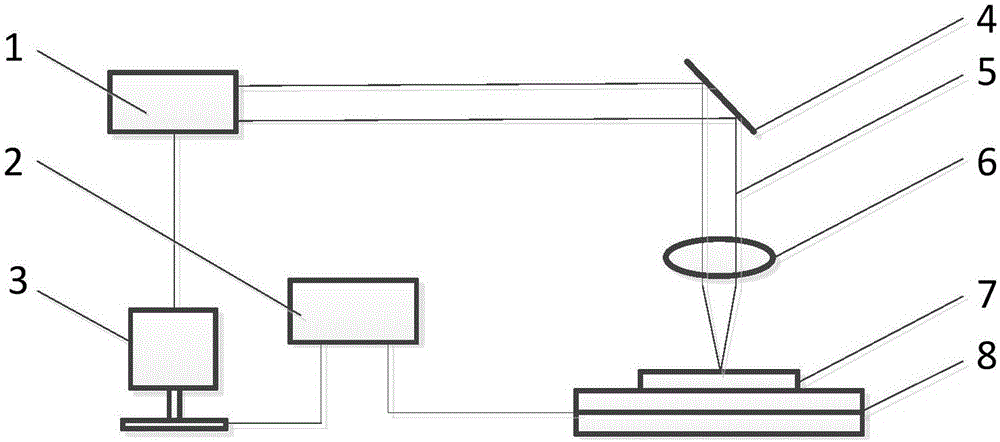

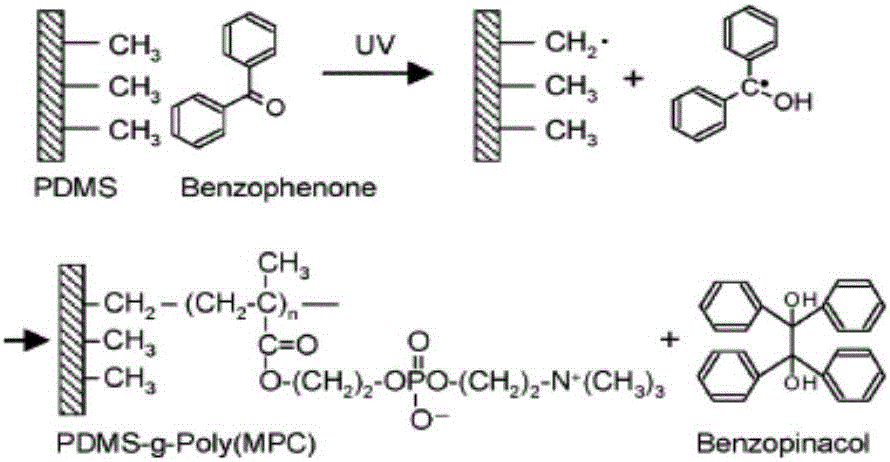

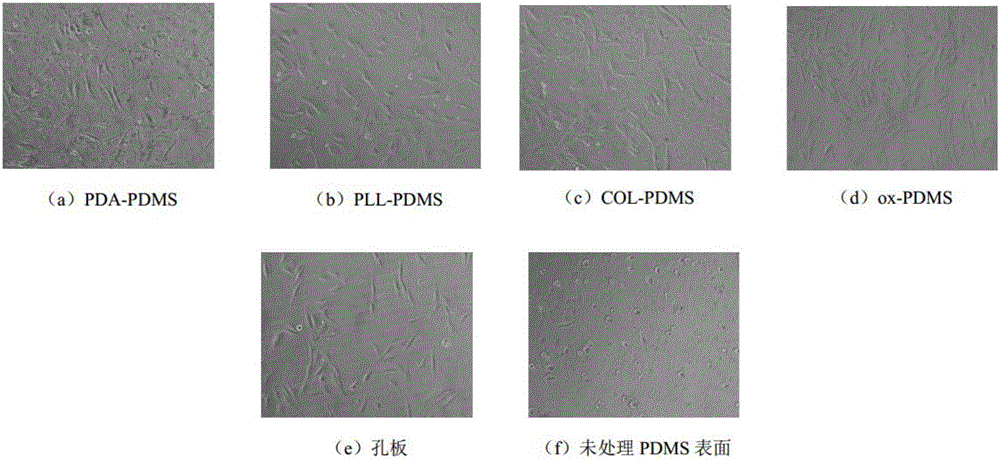

Method for quickly improving biological adhesiveness of laser patterned PDMS surface

The invention discloses a method for quickly improving biological adhesiveness of a laser patterned PDMS surface. A microstructure can be formed on the PDMS surface after laser action, so that a good environment is provided for cell adhesion and growth; or the PDMS surface after laser action is chemically modified or structurally modified, so that biological adhesiveness is improved; the microstructure can fix protein, cell growth factors, enzyme and nucleic acid; a laser device generates high-energy pulse laser beams which focus to the PDMS surface through a convex lens after going through a reflection mirror, and under action of high energy and impact force caused by radiation of the high-energy pulse laser beams, the PDMS surface occurs photothermal action and photochemical action and is instantly vaporized or splashes so as to form the microstructure on the PDMS surface. Laser action is utilized for material surface modification or forming the surface microstructure, modification step of the PDMS surface is simplified without having influence on a non-modified area surface, and the PDMS surface is patterned, so that preparation efficiency is improved greatly.

Owner:GUANGDONG UNIV OF TECH

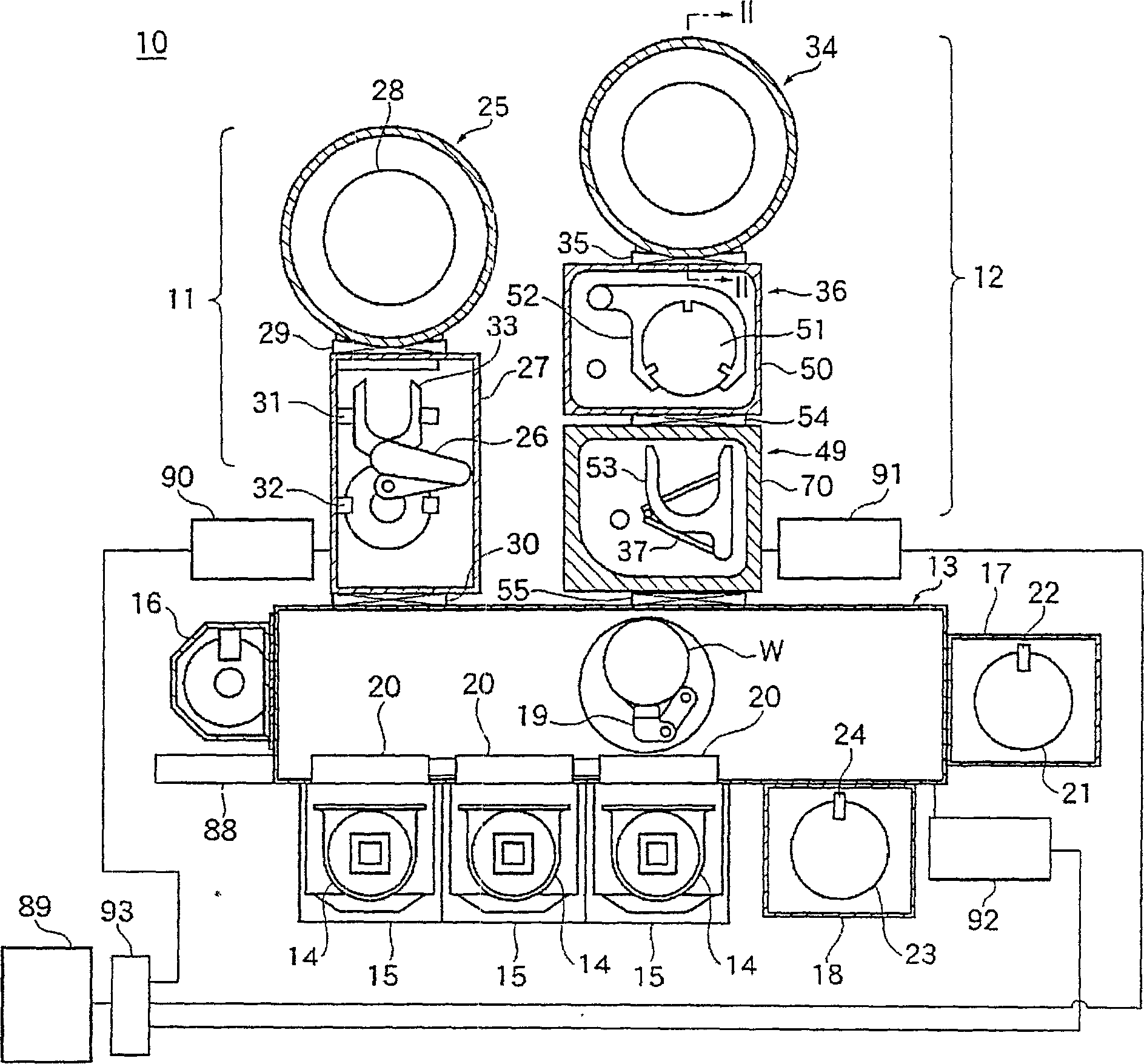

Method of processing and cleaning substrate, and method of and program for manufacturing electronic device

InactiveCN1822327AInhibit deteriorationAvoid destructionSemiconductor/solid-state device manufacturingLow-k dielectricCompound (substance)

A method of processing a substrate which enables a surface damaged layer and polishing remnants on the surface of an insulating film to be removed, and enable the amount removed of the surface damaged layer and polishing remnants to be controlled easily. An insulating film on a substrate, which has been revealed by chemical mechanical polishing, is exposed to an atmosphere of a mixed gas containing ammonia and hydrogen fluoride under a predetermined pressure. The insulating film which has been exposed to the atmosphere of the mixed gas is heated to a predetermined temperature.

Owner:TOKYO ELECTRON LTD

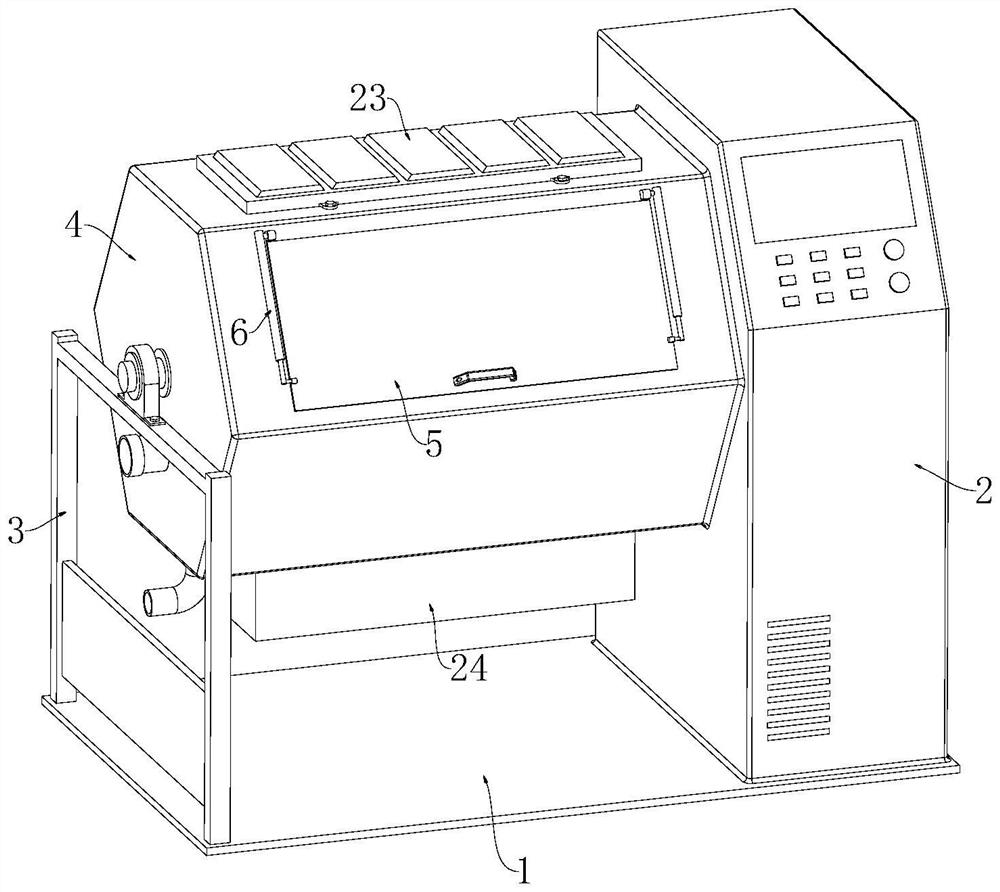

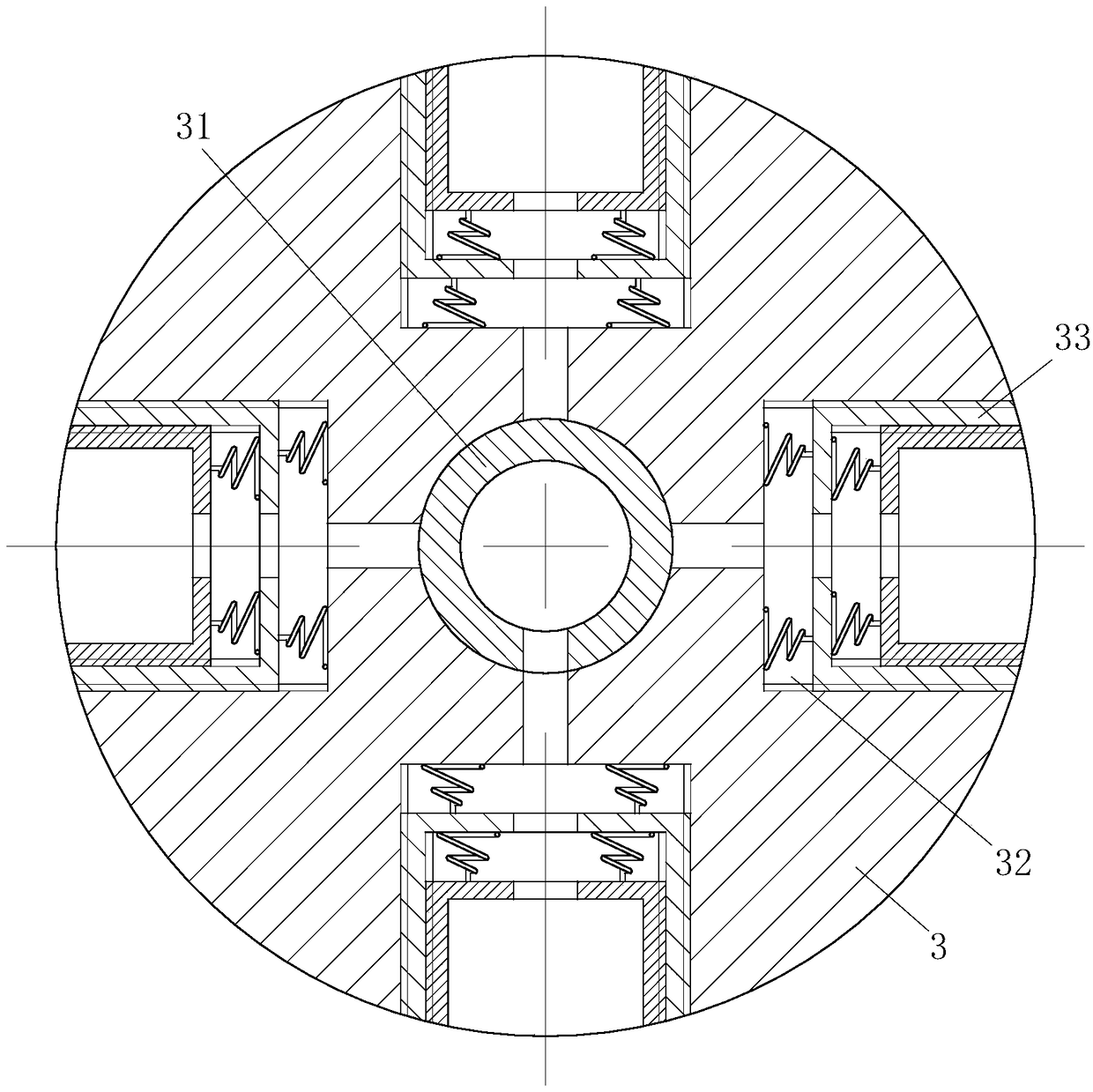

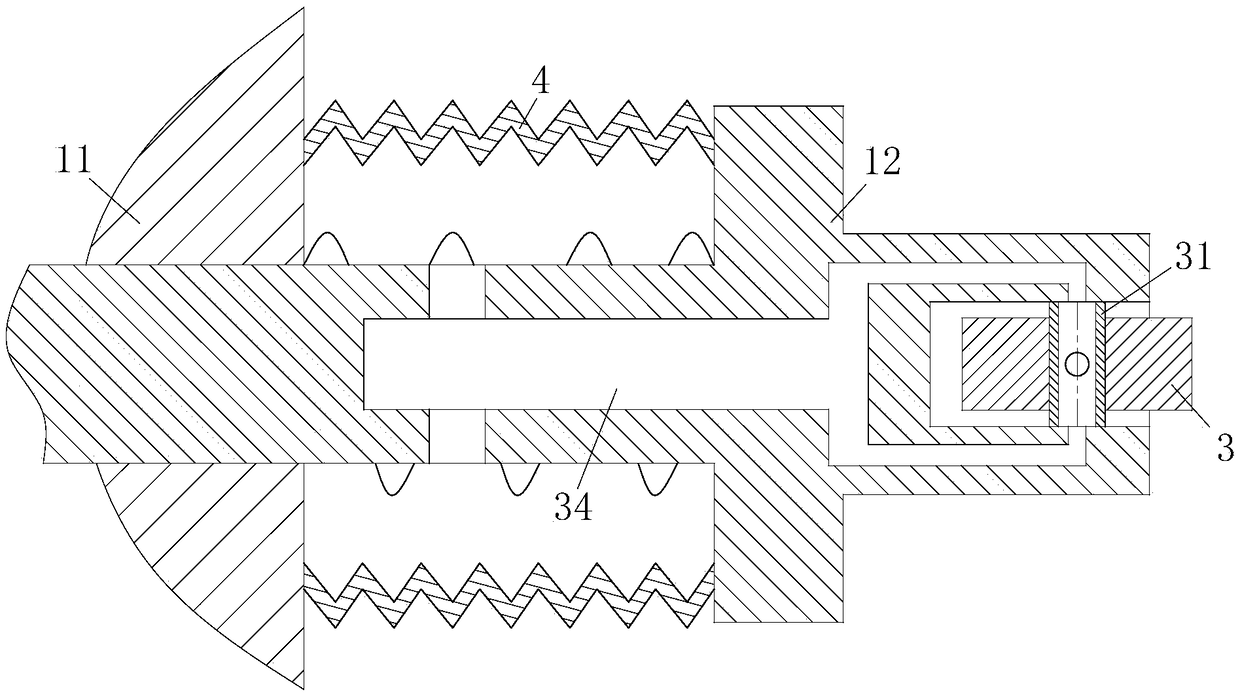

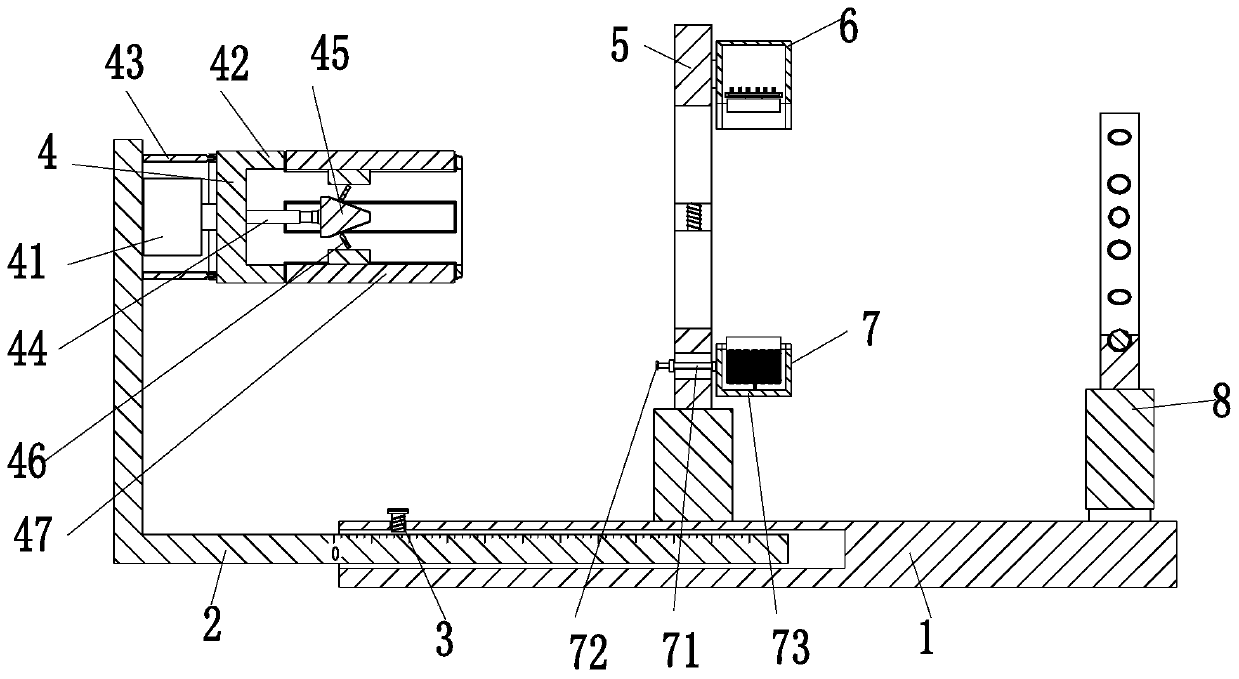

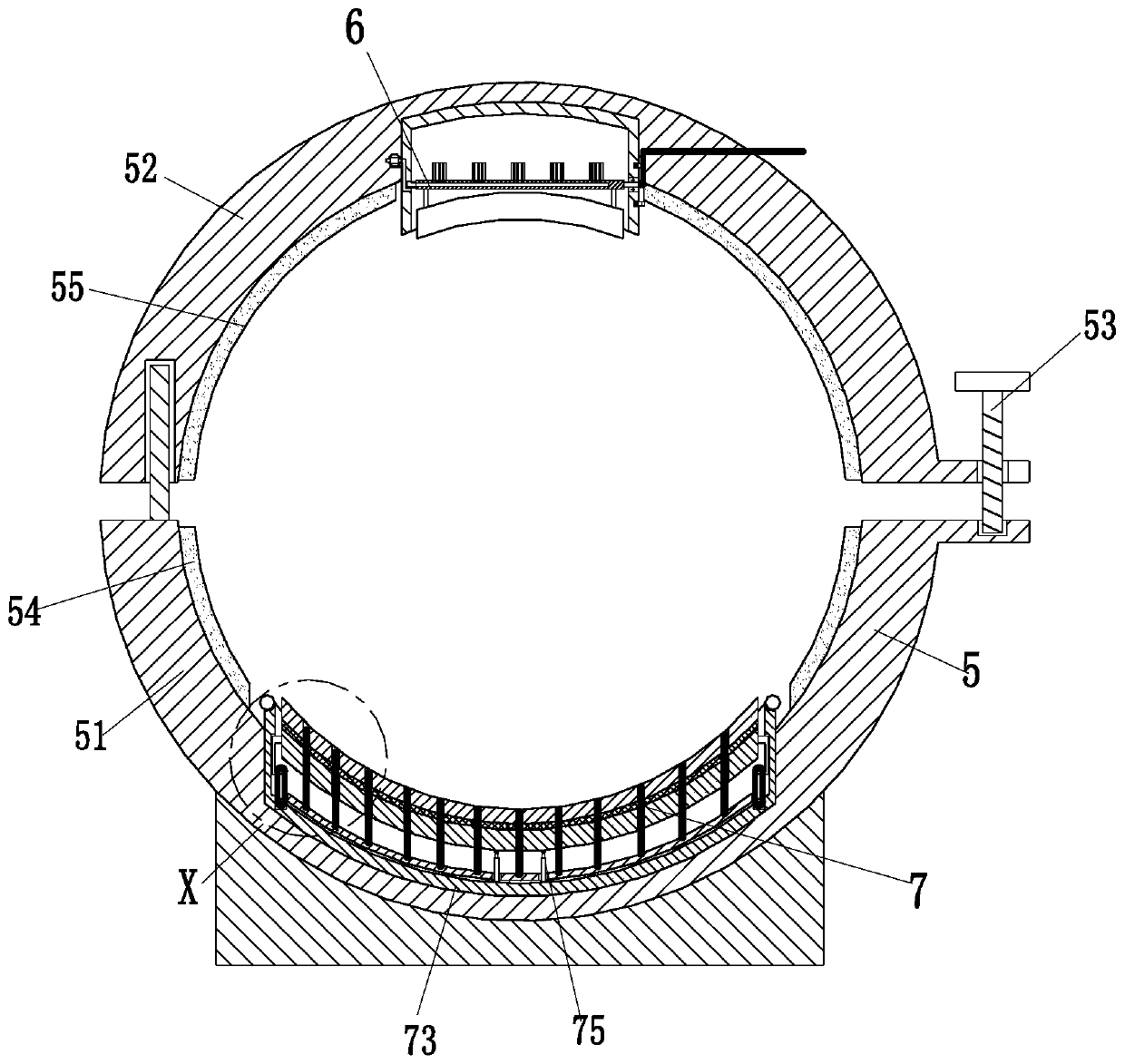

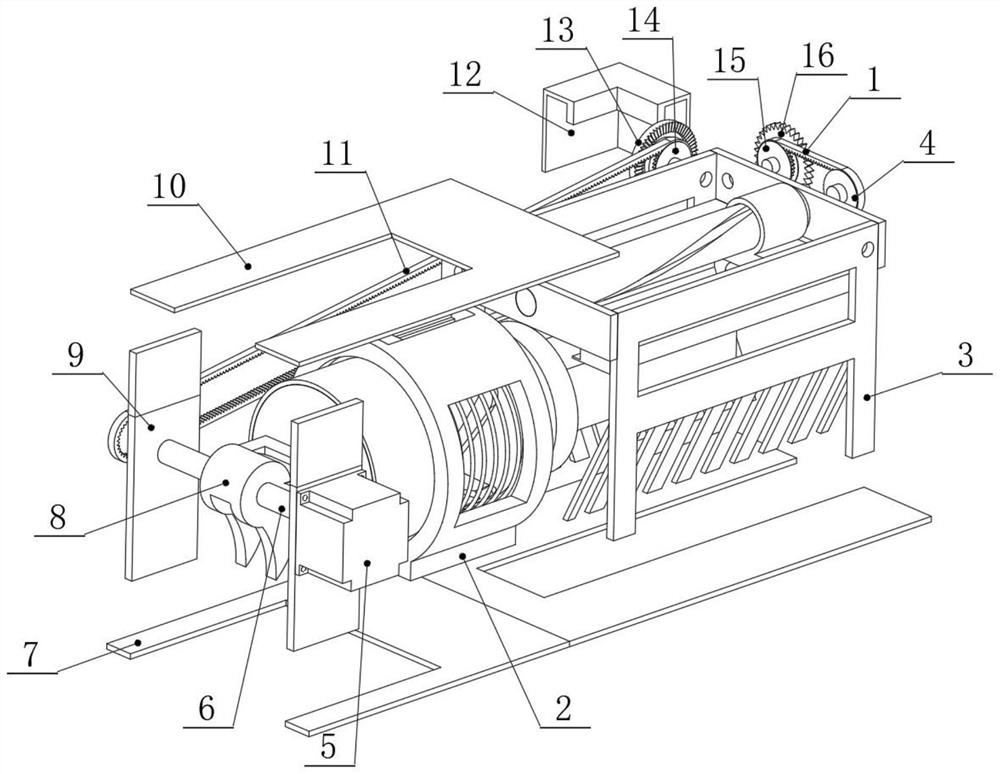

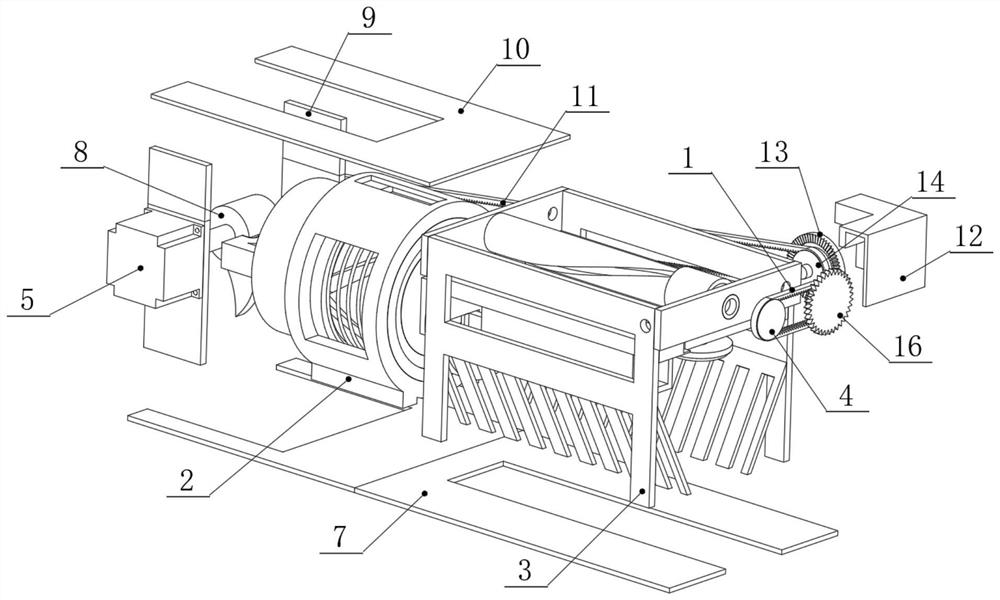

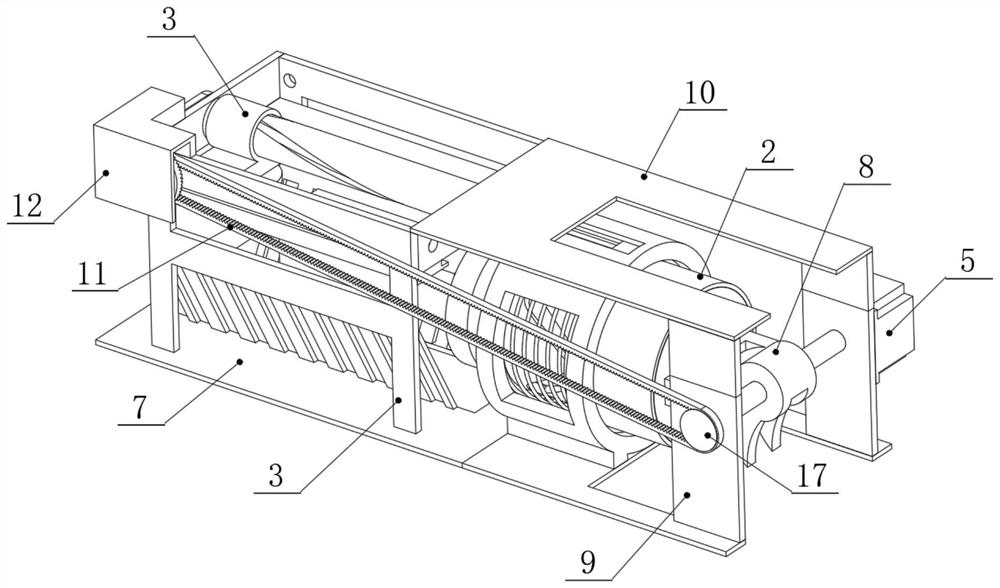

Precision treatment system for surface of split blade of aircraft engine and treatment process of precise treatment system

ActiveCN114131499AImprove uniformityCompact structureEdge grinding machinesPolishing machinesGrindingAirplane

The invention discloses an aircraft engine folio blade surface precision treatment system and a treatment process thereof.The aircraft engine folio blade surface precision treatment system comprises a base, a control box and a support are arranged on the two sides of the top of the base correspondingly, a through driving shaft is arranged in a barrel, and a plurality of connecting bases which are annularly and evenly distributed are arranged on the outer wall of the center of the driving shaft; driving parts are arranged on the two sides of the connecting base, each driving part is composed of a clamping mechanism and a guiding mechanism, and an upper magnetic pole mechanism and a lower magnetic pole mechanism are arranged on the upper side and the lower side of the barrel correspondingly. According to the invention, the driving part is arranged in the barrel body to drive the blade to move, the relative movement modes between the blade and the grinding material are diversified through the mutual cooperation of the fixed magnetic pole and the movable magnetic pole, and the module in the grinding material can always rub the surface of the blade with larger pressure by increasing the disorder of the movement; and the surface of the blade is completely treated, and meanwhile, the surface treatment efficiency is improved.

Owner:CHENGDU HONGXIA TECH CO LTD

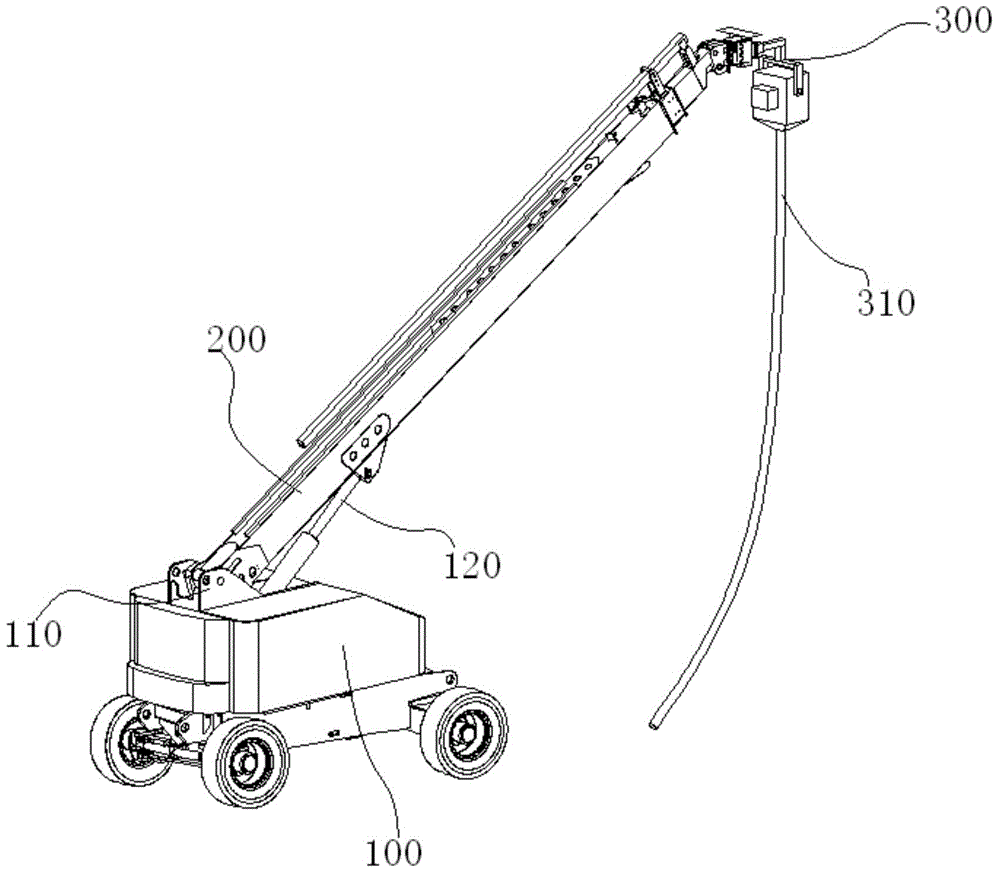

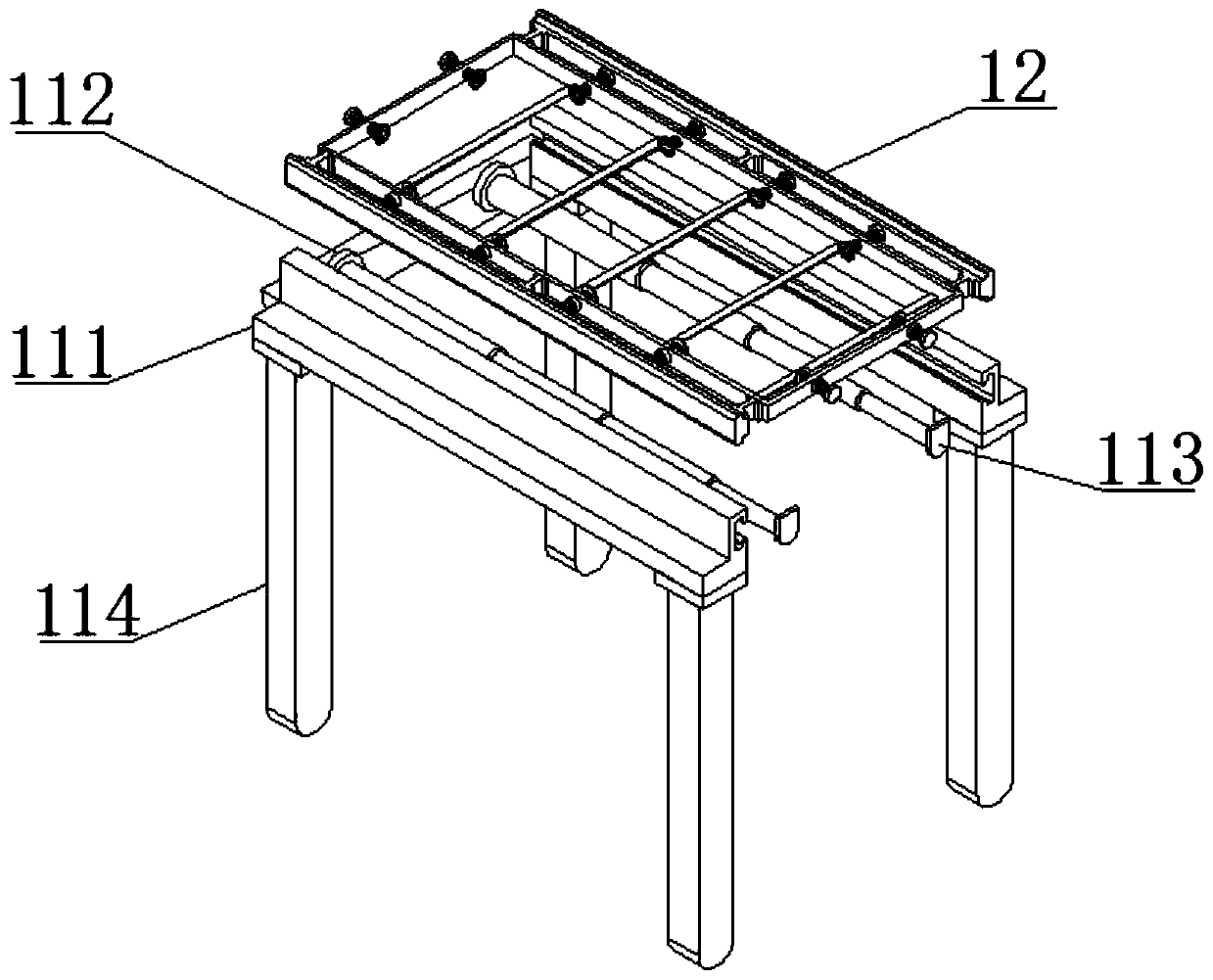

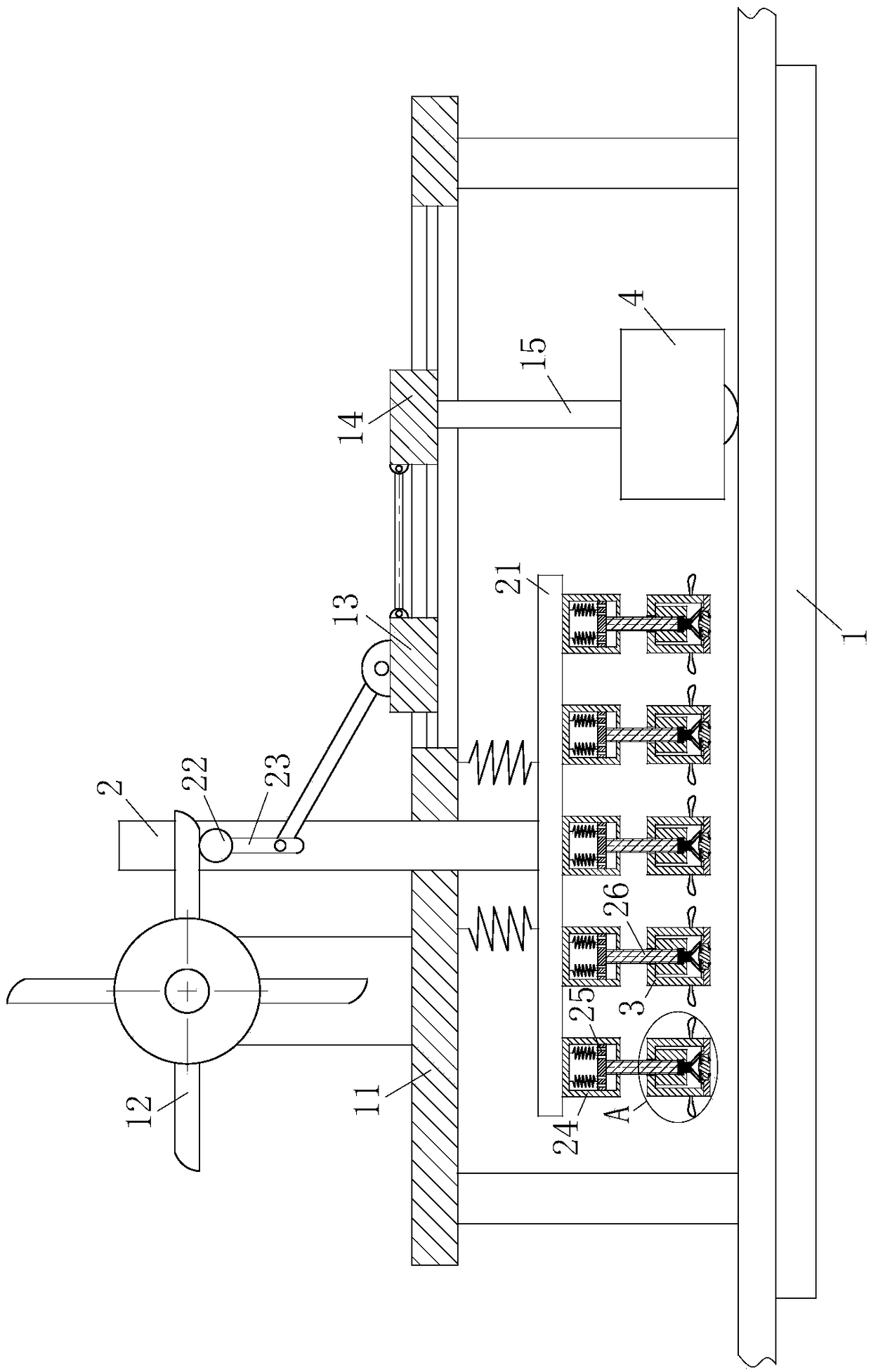

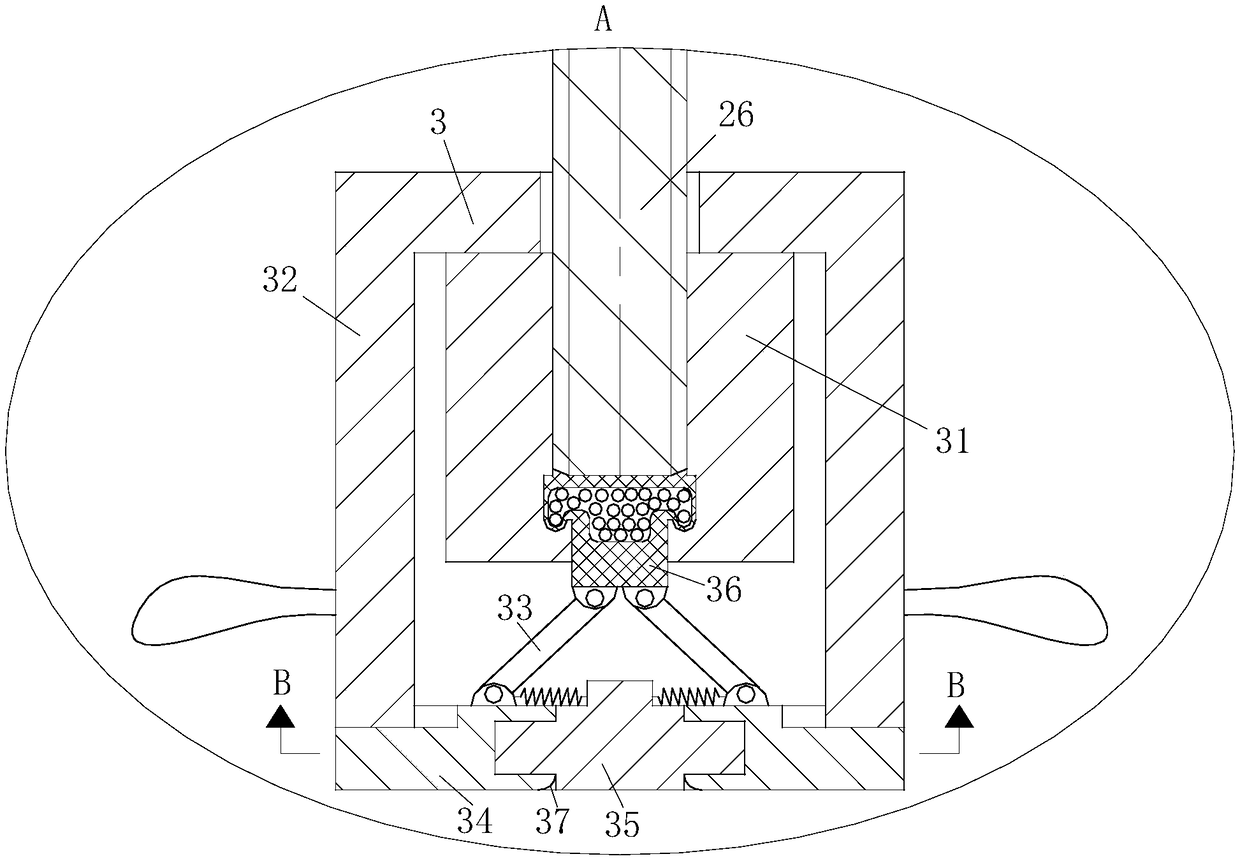

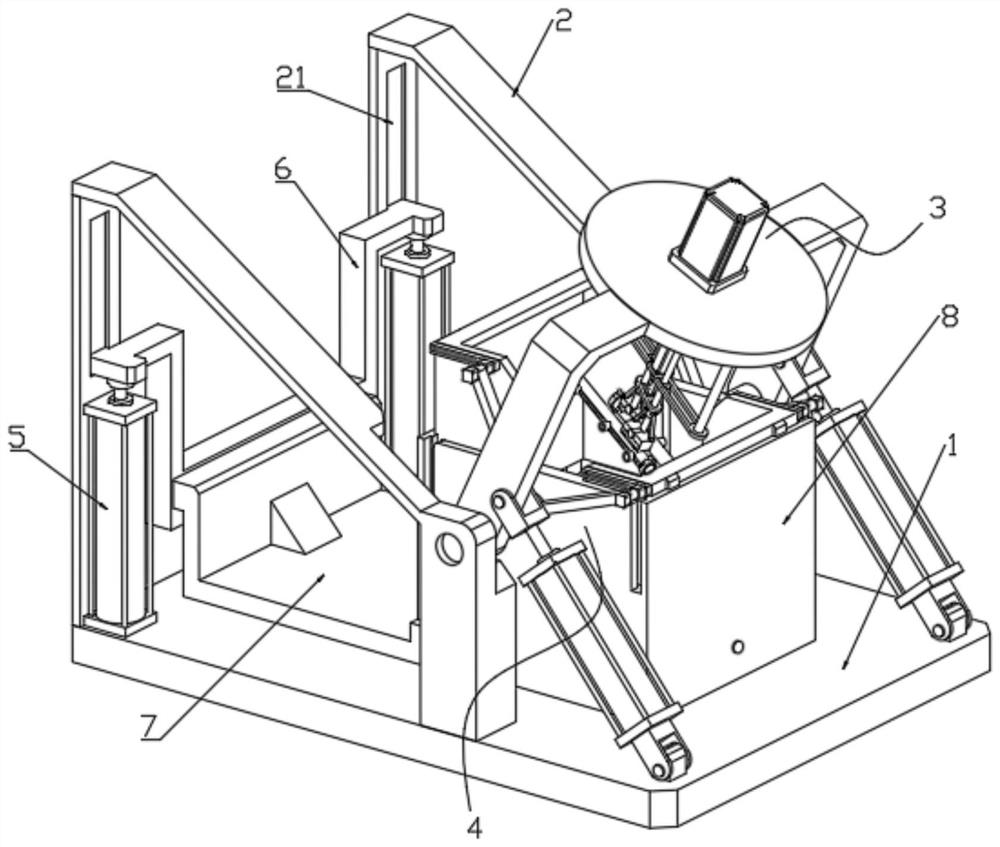

Automatic sand blasting system for ship outer wall

InactiveCN105171619AImprove Surface Treatment EfficiencySimple structureAbrasive machine appurtenancesAbrasive blasting machinesMarine engineeringSand blasting

The invention discloses an automatic sand blasting system for a ship outer wall. The automatic sand blasting system for the ship outer wall comprises a vehicle body, a mechanical arm, a sand blasting mechanical arm and a control switch. A mechanical arm installing end is arranged at the top end of the vehicle body. One end of the mechanical arm is detachably installed at the mechanical arm installing end, and the mechanical arm can stretch out and draw out on the vehicle body. The sand blasting mechanical arm is arranged at the other end of the mechanical arm, and provided with a spray gun, and the sand blasting mechanical arm can drive the spray gun to swing. The control switch is in matched connection with the vehicle body, the mechanical arm and the sand blasting mechanical arm. The automatic sand blasting system is simple in structure and convenient to operate, the surface processing efficiency of the ship outer wall is greatly improved, and the labor force is saved.

Owner:上海广成涂装技术工程有限公司

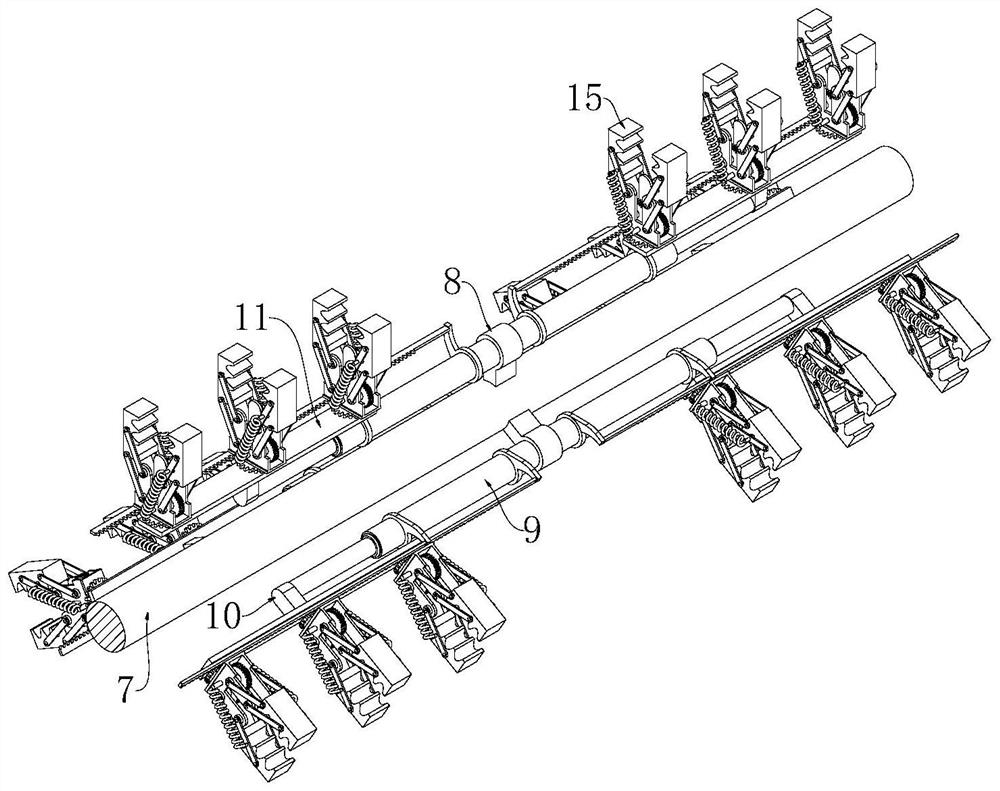

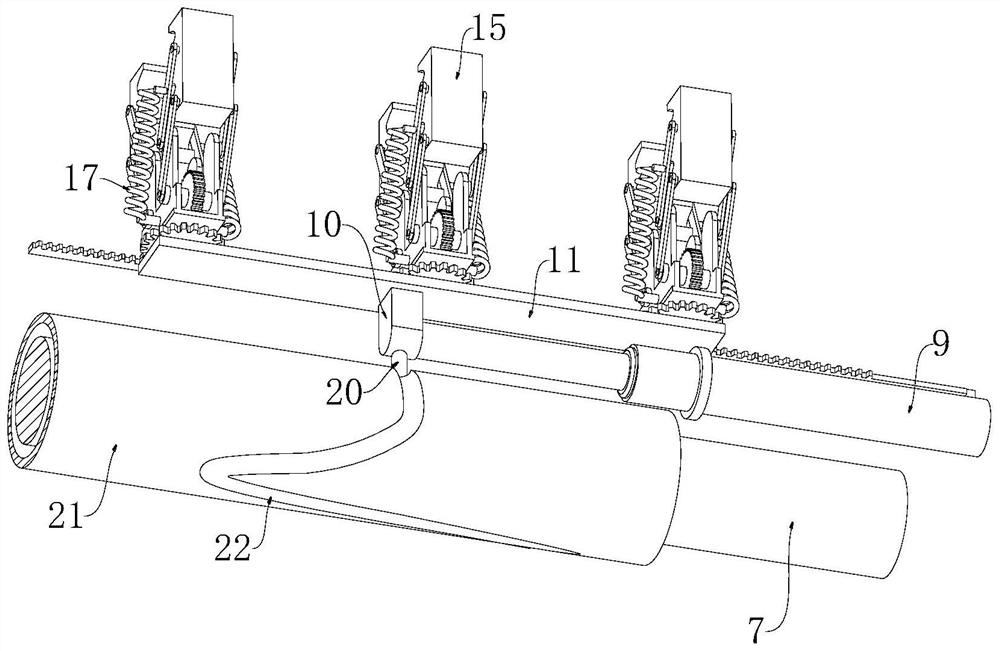

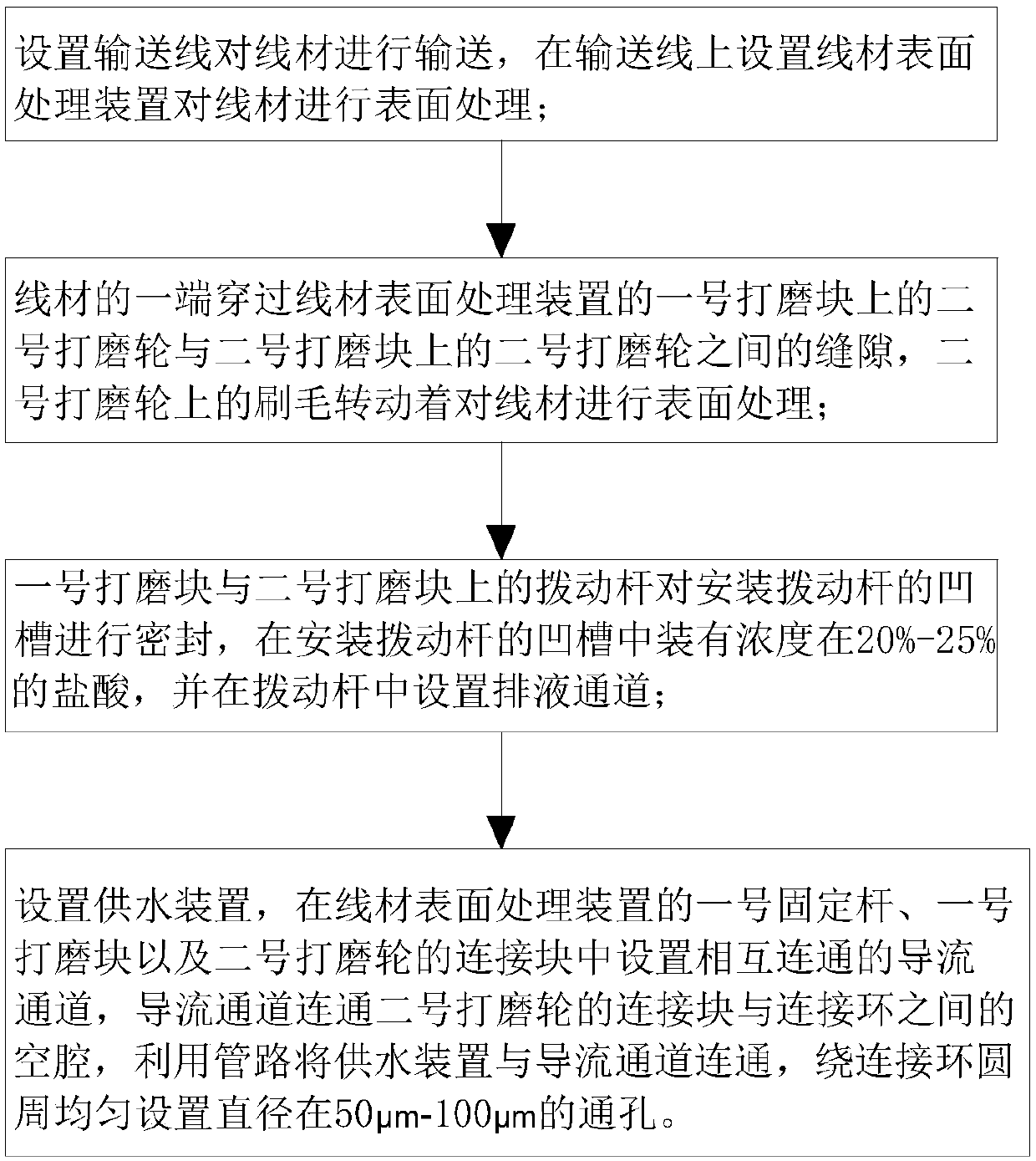

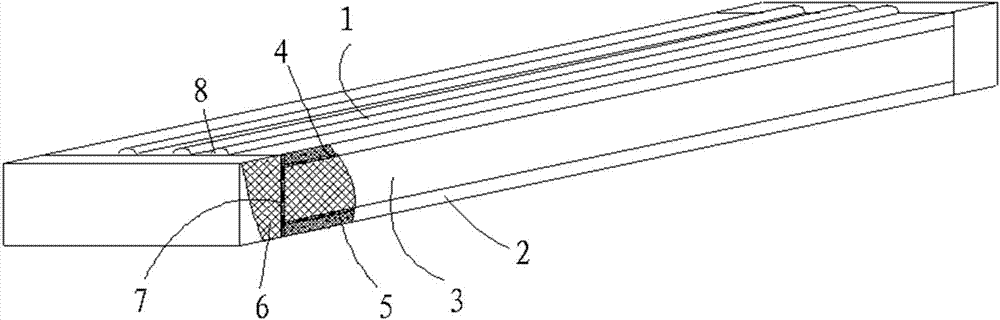

Wire surface treatment process

ActiveCN109623524AImprove Surface Treatment EfficiencyImprove the rotation effectRevolution surface grinding machinesGrinding drivesFlow diversionEngineering

The invention belongs to the technical field of wire surface treatment, and particularly relates to a wire surface treatment process. The wire surface treatment process comprises the following steps that a transporting line is arranged to transport the wire, and a wire surface treatment device is arranged on the conveying line to carry on the surface treatment on the wire; one end of the wire penetrates through the gap between a second polishing wheel on a first polishing block and a second polishing wheel on a second polishing block on the wire surface treatment device; poking rods on the first polishing block and the second polishing block seal grooves for mounting the poking rods, the grooves are loaded with hydrochloric acid with the concentration being 20-25%, and a liquid dischargingchannel is arranged in each poking rod; and a water supply device is arranged, flow diversion channels communicating with one another are arranged in a first fixed rod, the first polishing block of the wire surface treatment device and a connecting block of the second polishing wheel, the flow diversion channels communicate with a cavity between the connecting block and a connecting ring of the second polishing wheel, the water supply device communicates with the flow diversion channels through a pipeline, and through holes with the diameter of 50-100 [mu]m are evenly formed in the peripheryof the connecting ring.

Owner:佛山市开源林辉五金实业有限公司

Method for preparing anti-wear hydraulic pump part

ActiveCN110468259AImprove wear resistanceMitigation of physical performance differencesVacuum evaporation coatingSputtering coatingCarbide coatingGas phase

The invention belongs to the technical field of hydraulic pump manufacturing, and particularly relates to a method for preparing an anti-wear hydraulic pump part. After hydraulic pump part base material is subjected to quenching, high-temperature tempering and rough and finish machining, an ion plating method is adopted for carburizing treatment, and a HfCrWSiC multielement complex carbide coatingon the surface is deposited through an ion plating and magnetron sputtering combined method. According to the method for preparing the anti-wear hydraulic pump part, the HfCrWSiC carbide coating, a physical vapor deposition method and the carburizing technology are combined, physical performance differences between the HfCrWSiC multielement complex carbide coating and the hydraulic pump part base material can be relieved, the surface hardness and supporting function of the base material can be improved, and high surface hardness and core toughness are achieved. According to the method, the adhesion performance of the coating and the base material can be enhanced by 100% or above, the surface hardness can be improved by two times or more, the surface treatment time can be shortened by 90%or above, the service life of a hydraulic pump can be prolonged by one time or more, and the maintenance cost of the hydraulic pump can be reduced by 70% or above.

Owner:JINING UNIV

Solid wood floor production and processing technology

InactiveCN111002421AImprove Surface Treatment EfficiencyReduce complicated proceduresWood working apparatusSolid woodDust control

The invention discloses a solid wood floor production and processing technology comprising the steps: S1, raw material screening; S2, cutting and drying; S3, polishing treatment; S4, spraying; S5, drying; and S6, cutting. A polishing device comprises a polishing structure. The polishing structure is composed of a bracket, a fixing structure, a grinding structure and a dust removal structure. The fixing structure is horizontally mounted on the bracket in a sliding manner; the polishing structure is mounted on the top end surface of the bracket; the dust removal structure is mounted on the lowerend surface of the bracket; the dust removal structure and the grinding structure are connected in a penetrating mode. The complex procedures of traditional polishing and grinding can be reduced, thesurface treatment efficiency of logs is improved, meanwhile, smoke dust and wood chips generated in polishing are recycled, and the situation that the wood chips and dust drift in air, pollute the working environment easily and harm the health of workers is prevented.

Owner:湖州联科粘合剂有限公司

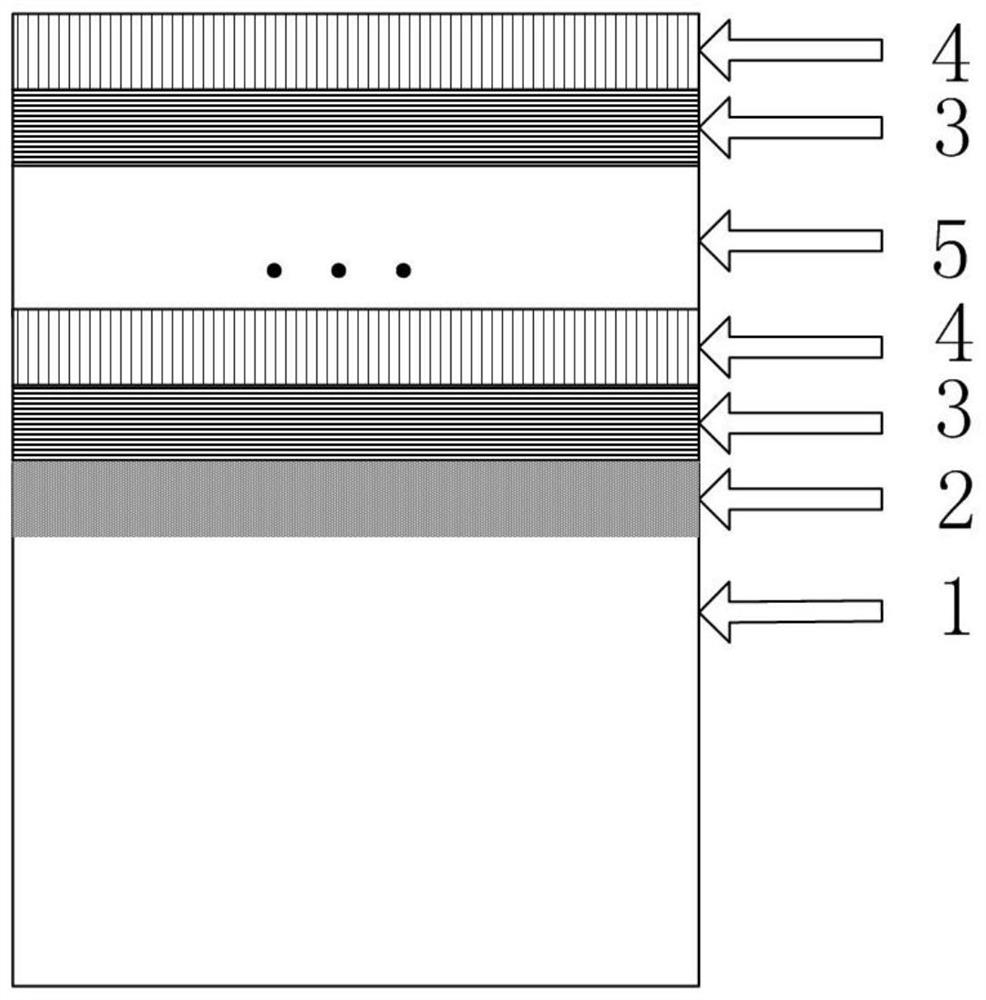

Composite phenolic resin sandwich panel

ActiveCN103802413AIncrease roughnessIncrease bonding areaSynthetic resin layered productsEngineeringRough surface

The invention discloses a composite phenolic resin sandwich panel which comprises a first panel and a second panel, wherein a sandwich layer is arranged between the first panel and the second panel; the first panel and the second panel are made of phenolic resin panels; the inner surfaces of the first panel and the second panel are rough surfaces; two sides of the sandwich layer are respectively adhered to the rough surfaces of the first panel and the second panel through an epoxy resin adhesive. According to roughening treatment on the adhesion surface, the roughness of the adhesion surface is improved, the adhesion area between the adhesion surface and the sandwich layer is enlarged, the adhesion strength is improved, and by adoption of the phenolic resin, the composite phenolic resin sandwich panel is low in compressive strength, high in ageing resistance, light in weight and good in fireproof performance and is particularly suitable for occasions with high comprehensive requirements such as fire resistance.

Owner:山东桑园塑胶股份有限公司

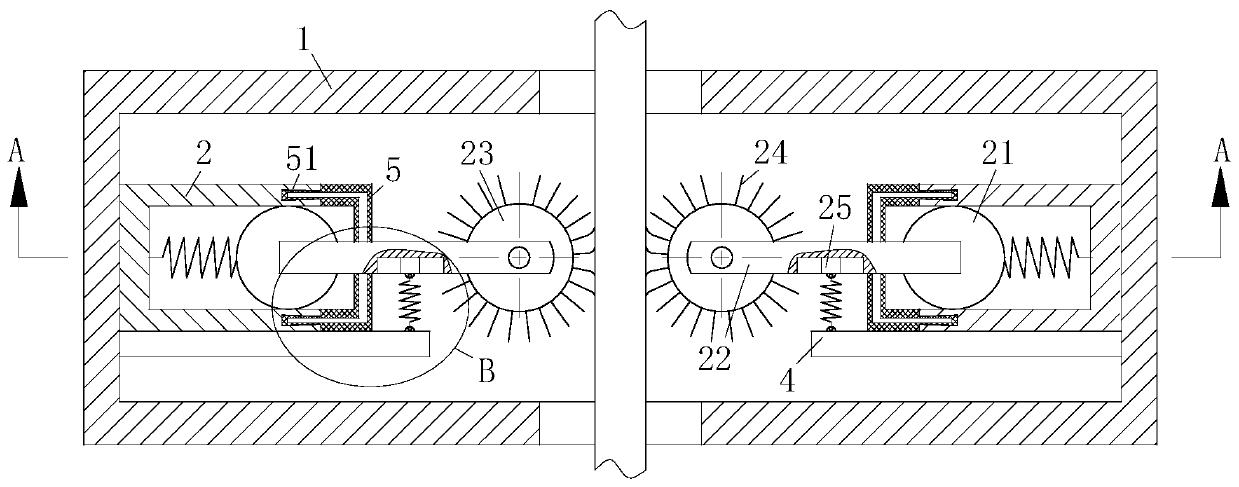

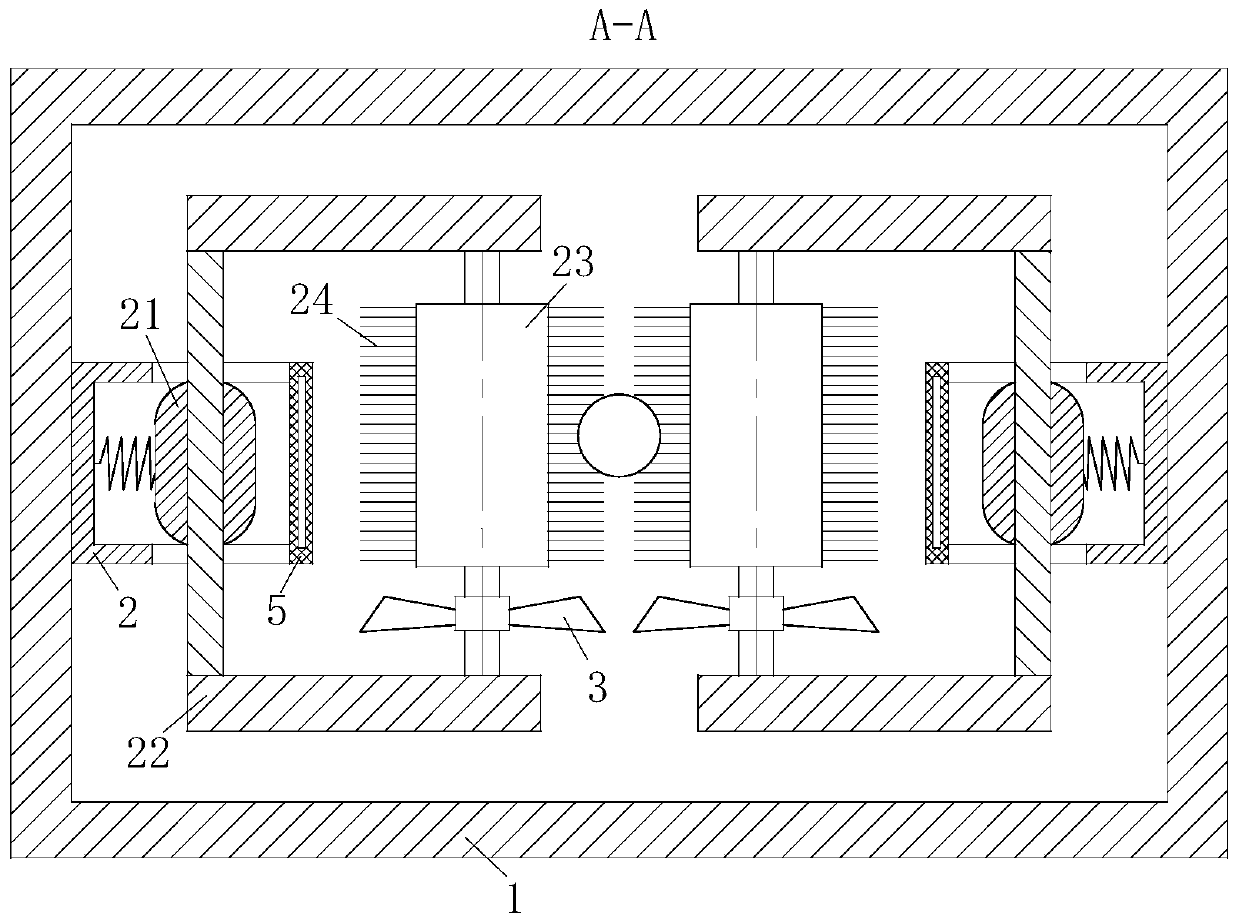

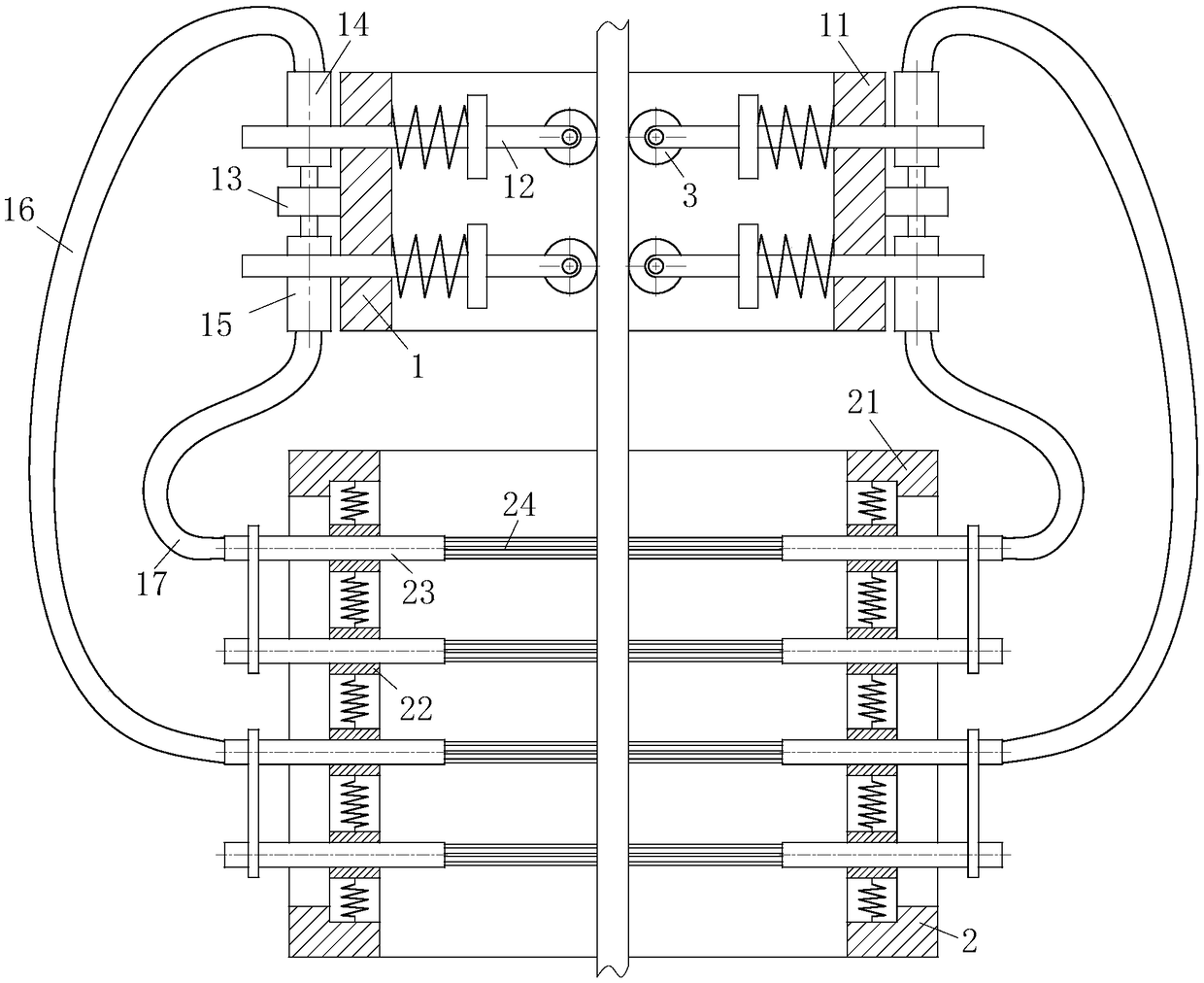

Steel wire surface treatment device

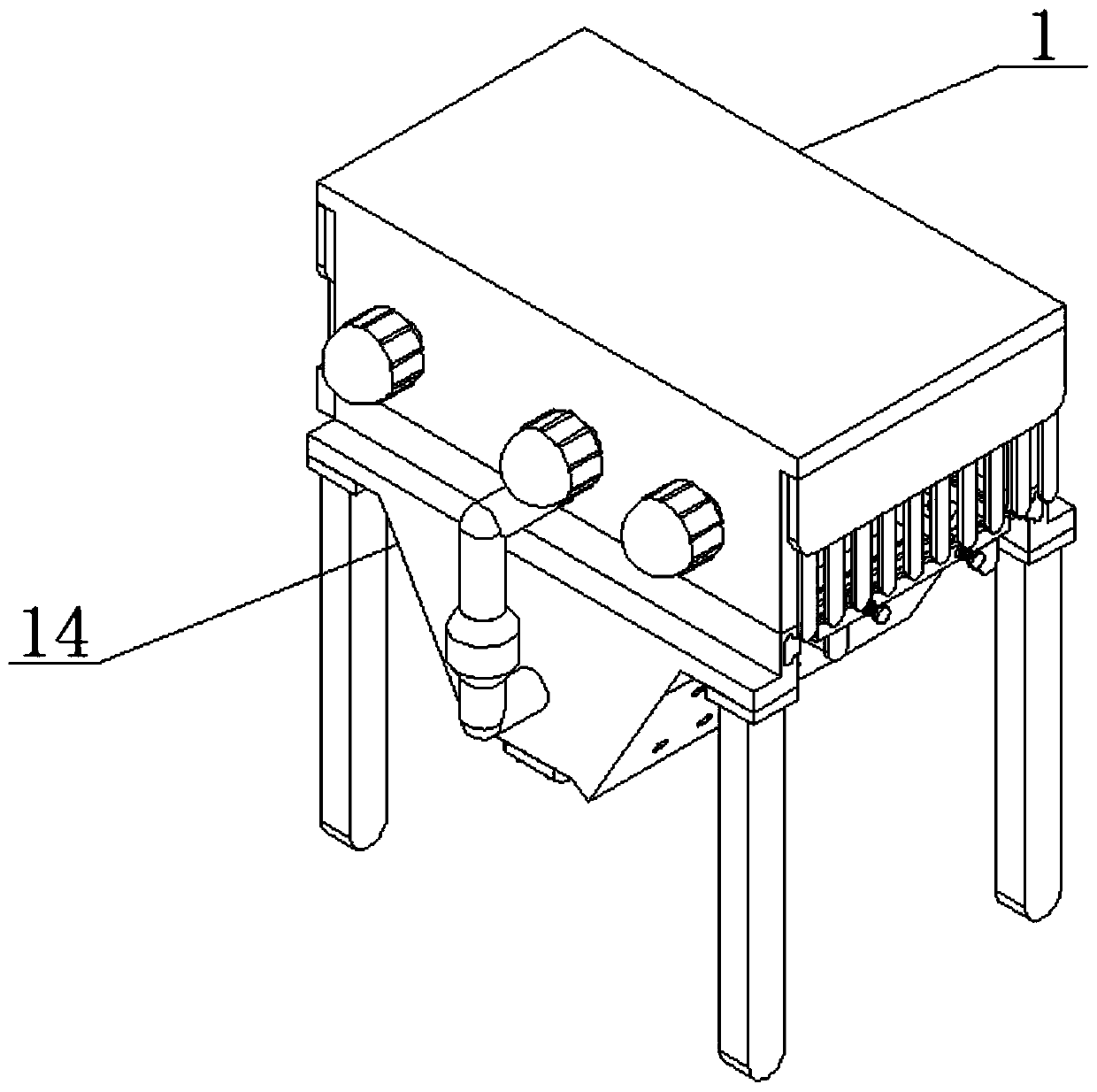

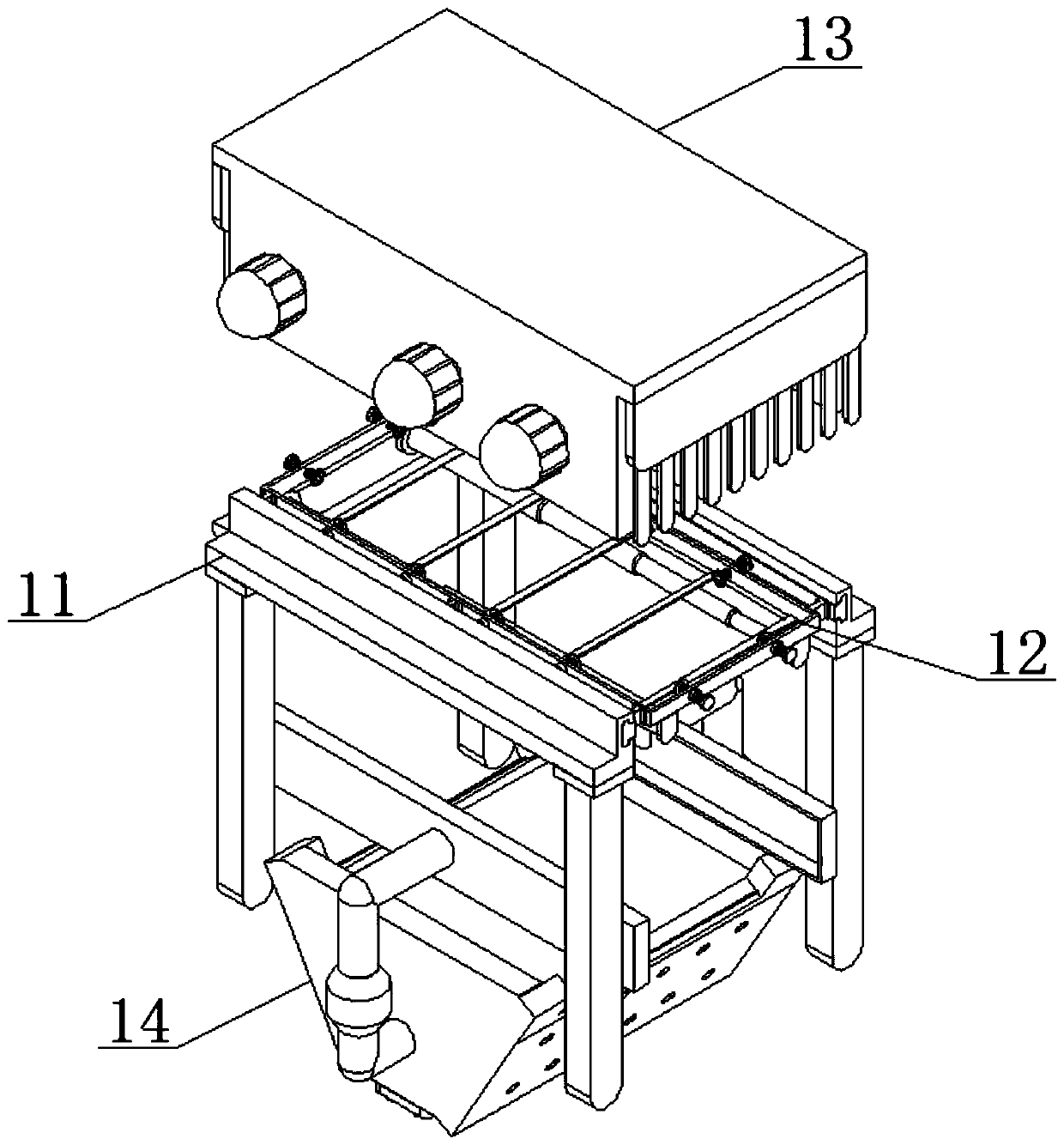

ActiveCN109719158AImprove Surface Treatment EfficiencyQuality improvementCleaning using toolsExtrusion cleaning devicesFixed frameEngineering

The invention belongs to the technical field of metal wire surface treatment, and particularly discloses a steel wire surface treatment device. The device comprises a shell, channels are formed in thefront and back walls of the shell, fixed frames are arranged on the left and right inner walls of the shell, piston blocks are arranged in the fixed frames, springs are arranged in the fixed frames,one ends of the springs are fixedly connected to the inner walls of the fixed frames, the other ends of the springs make contact with the piston blocks, sliding grooves are formed in the upper and lower walls of the fixed blocks, sliding rods are arranged in the piston blocks, mounting plates are fixedly connected to the upper and lower ends of the sliding rods, the sliding rods can slide in the sliding grooves, rollers are rotatably arranged on the mounting plates through rotating shafts, brushes are arranged on the rollers, and the brushes are used for brushing away foreign bodies on a steelwire. The steel wire surface treatment speed can be effectively improved, and the quality of the steel wire with the treated surface is good.

Owner:杭州华生合金材料有限公司

Automatic product surface treatment process method

ActiveCN108723598AImprove Surface Treatment EfficiencyProcess realizationLaser beam welding apparatusSurface finishingRough surface

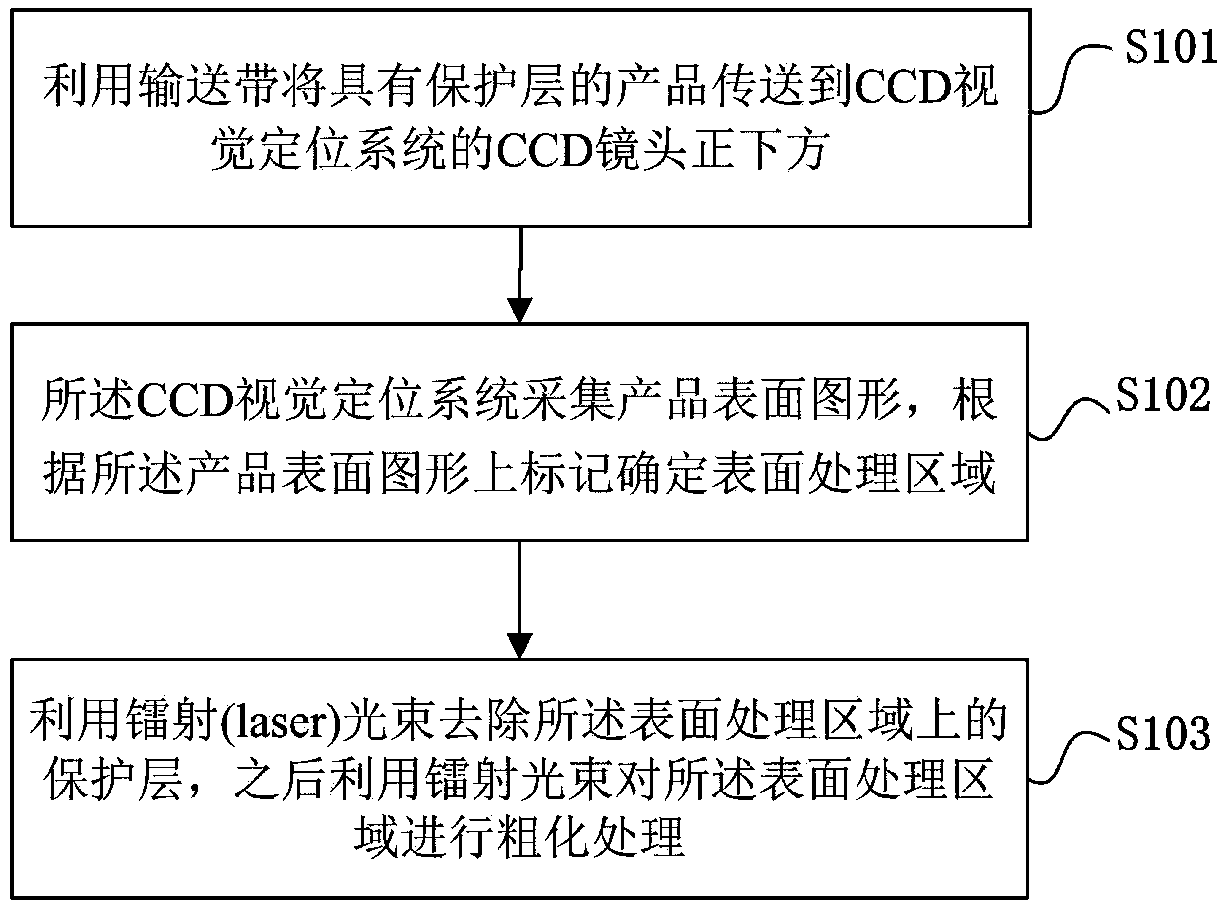

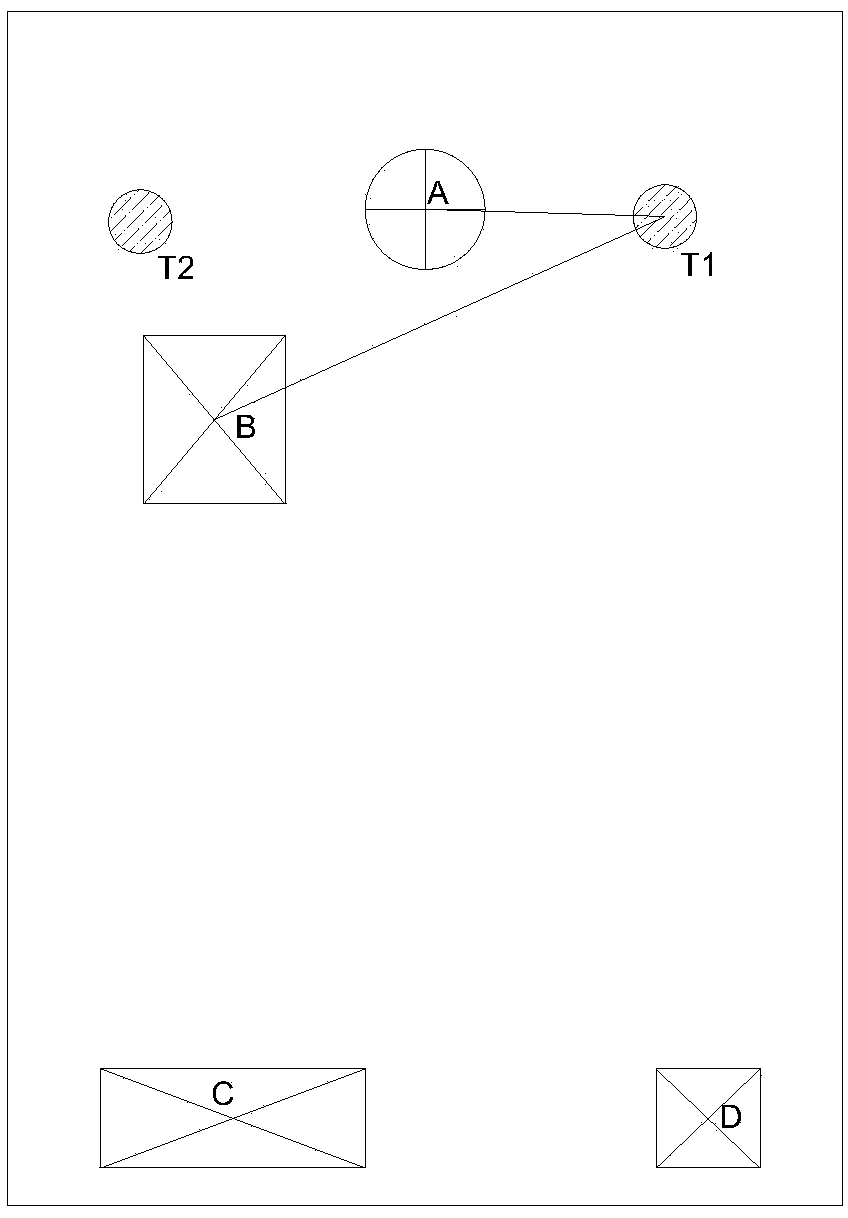

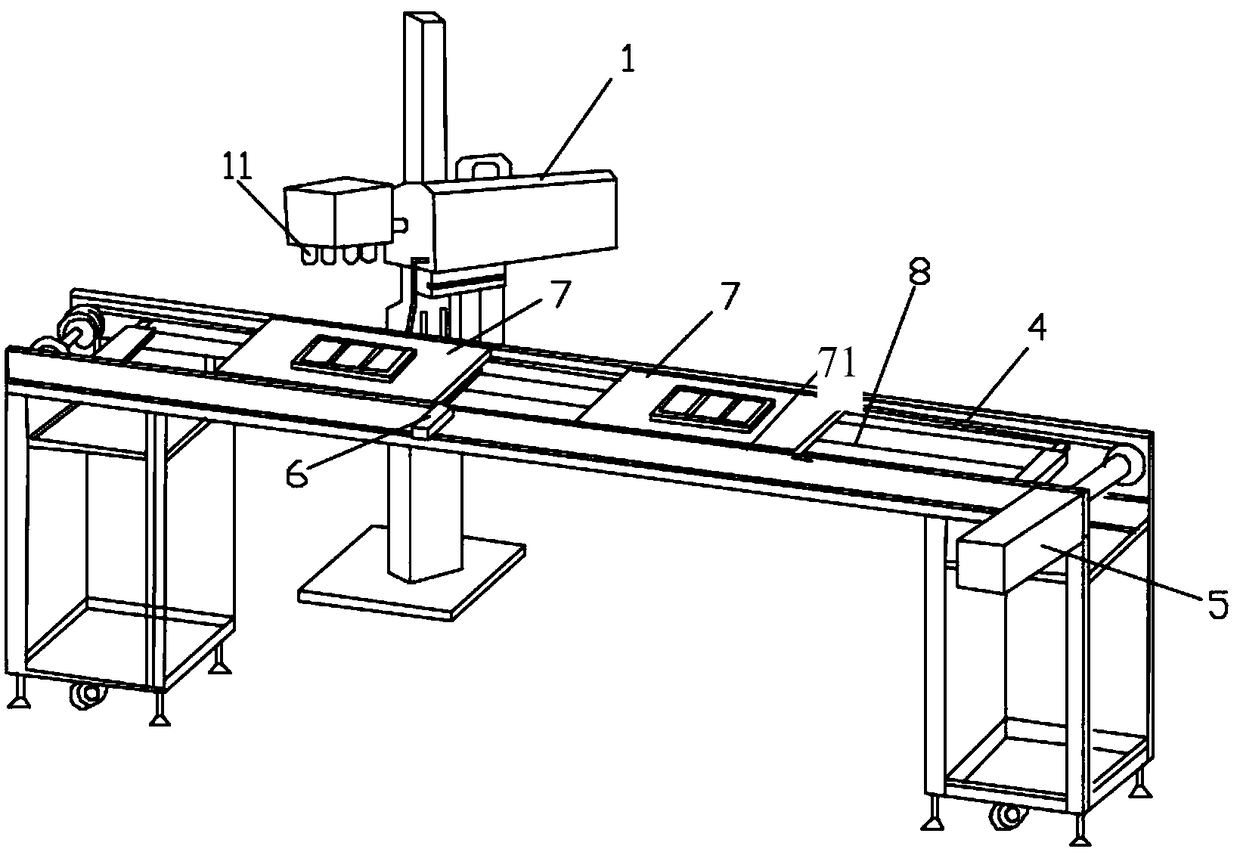

The invention discloses an automatic product surface treatment process method. The method comprises the following steps that products with protective layers are conveyed to the portions under CCD lenses of a CCD visual positioning system by using a conveying belt; the CCD visual positioning system collects surface images of the products and determines the surface treatment areas according to markson the surface images of the products; and laser beams are used to remove the protective layers on the surface treatment areas, and then the laser beams are used to coarsen the surface treatment areas. According to the automatic product surface treatment process method, the protective layers of the products are removed through the conveying belt, the CCD visual positioning system and a laser engraving device, and the areas requiring surface treatment are coarsened through the laser beams, that is, the rough surface texture is formed; and the processing technology of the surface treatment areas can be automatically realized by adopting a servo motor, no manual intervention is needed, and the products can be clamped and fixed without a precision jig, so that the surface treatment efficiencyis greatly improved.

Owner:DONGGUAN GOOD VIEW TECH CO LTD

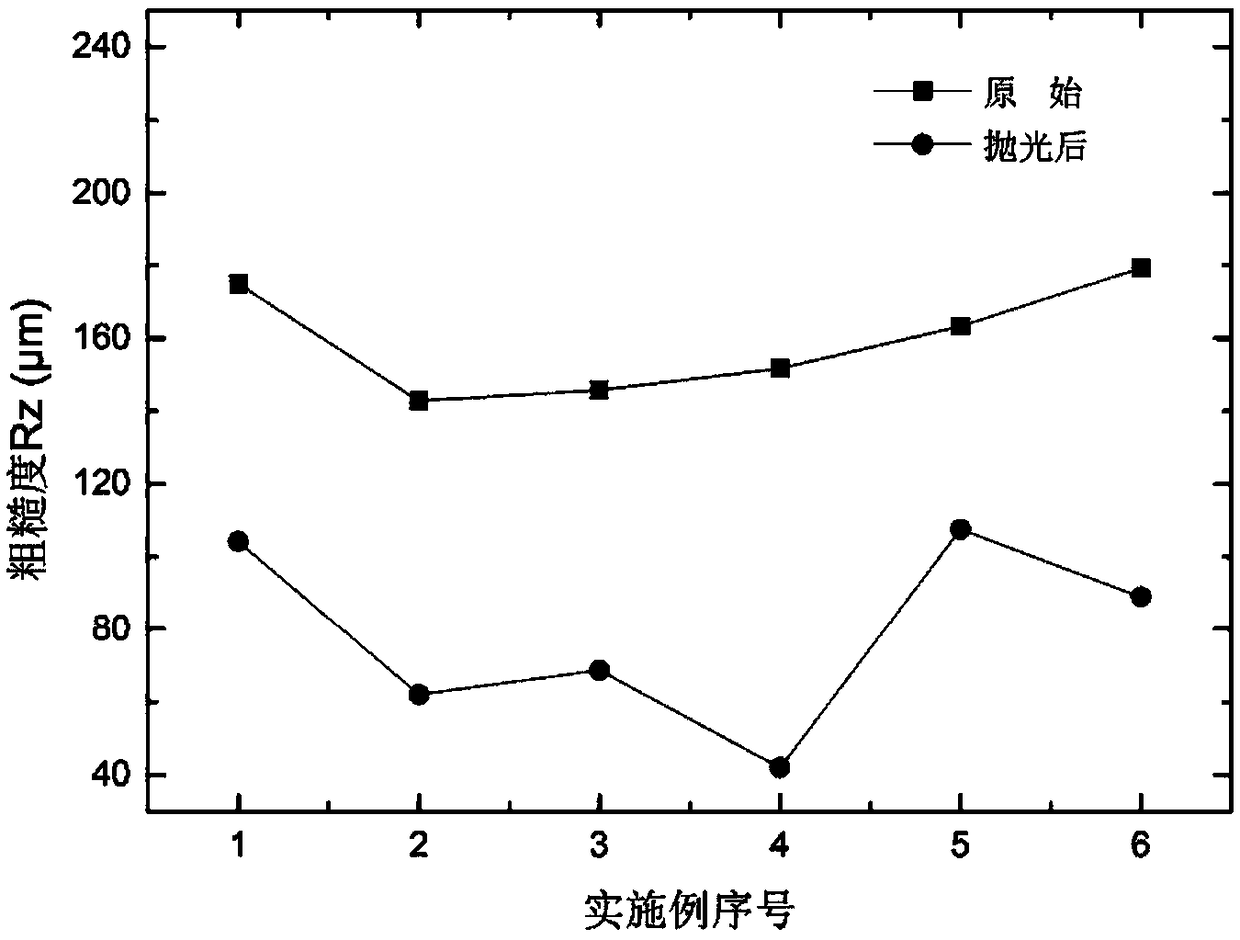

Cylindrical-component grinding device, and workpiece advancing apparatus and grinding method thereof

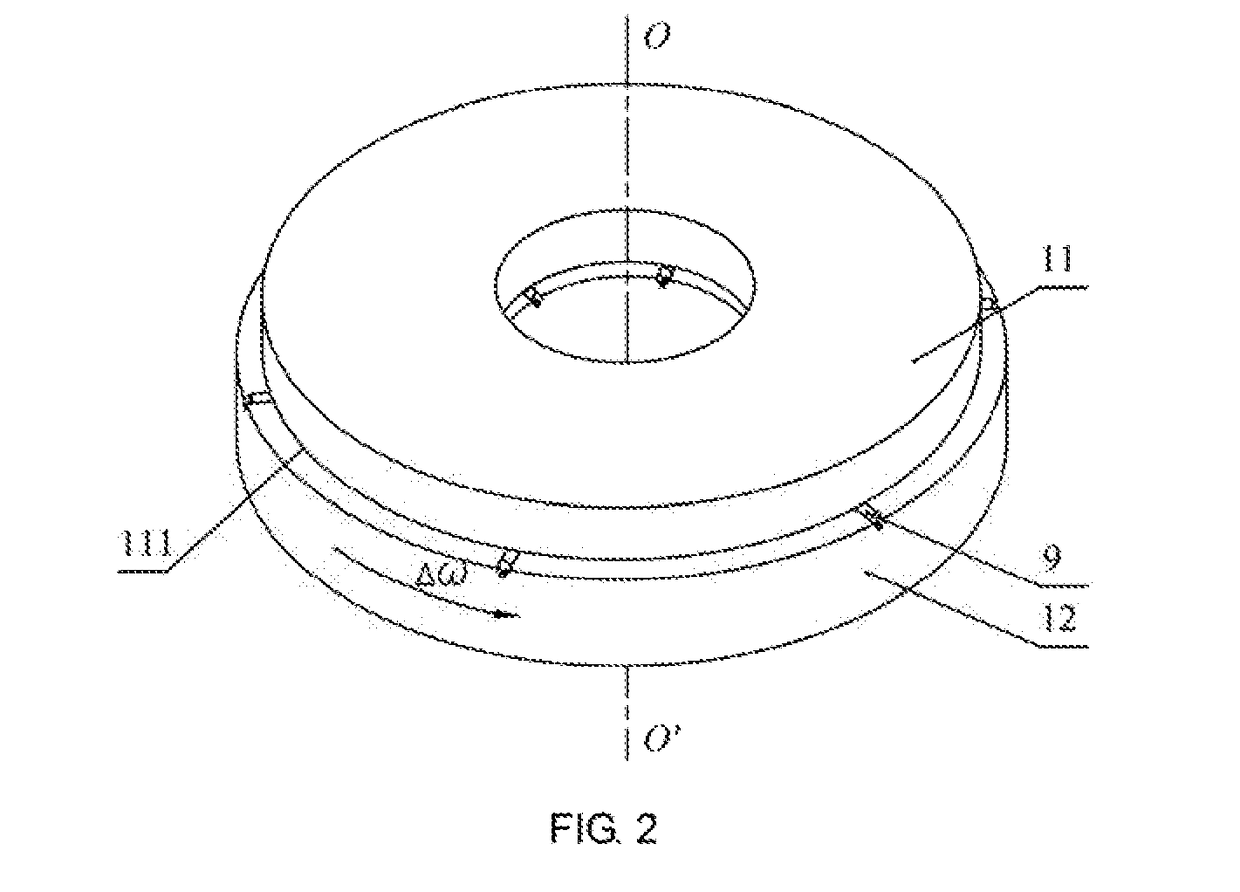

ActiveUS20170274494A1High shape accuracyHigh dimensional consistencyLapping machinesLapping toolsHigh volume manufacturingSurface grinding

A double-disc straight groove cylindrical-component surface grinding disc, includes a first grinding disc and a second grinding disc, rotating relative to each other; the the first grinding disc's working face is planar; the second grinding disc's surface, opposite the first grinding disc, includes a set of radial straight grooves, with groove faces of the straight grooves are the working face of the second grinding disc; the cross-sectional outline of the working face of the second grinding disc is arcuate or V-shaped or is a V-shape having an arc; during grinding, a workpiece spins inside the straight grooves, while under the effect of an advancing apparatus, the workpiece slides in translational motion along the straight grooves. The described grinding disc device has high-volume production capabilities, and the shape accuracy and size consistency of the cylindrical roller's cylindrical surface and the efficiency in machining are improved, and machining cost is reduced.

Owner:TIANJIN UNIV

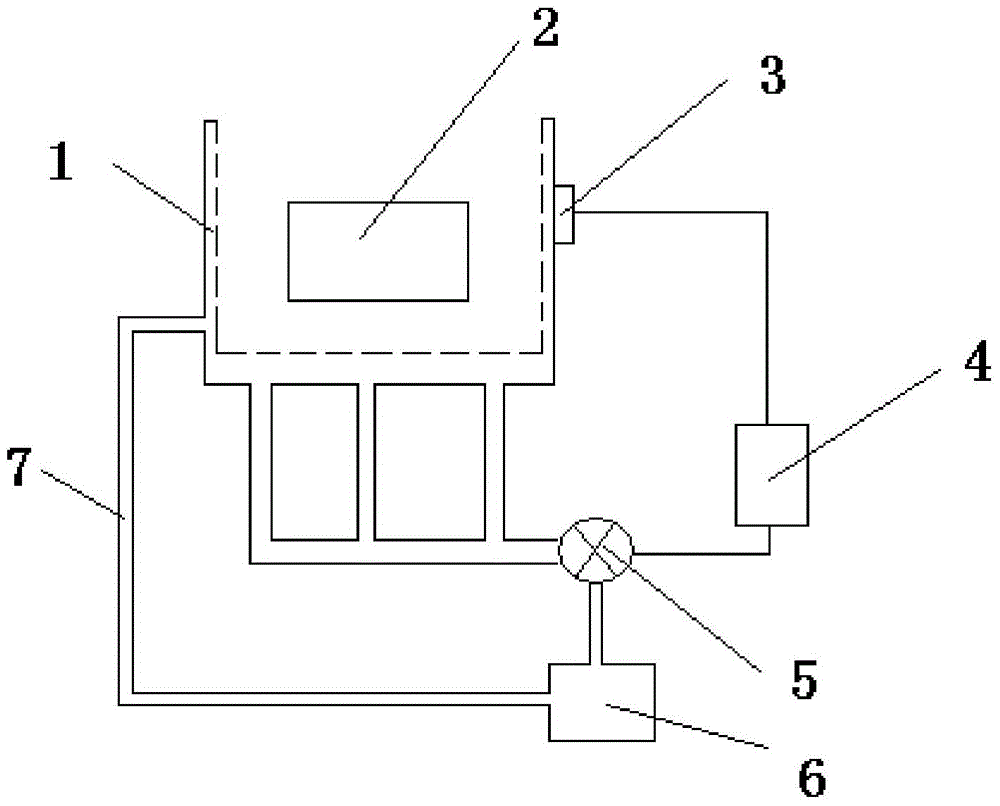

Magnesium-lithium alloy surface treatment device

ActiveCN104862685AEfficiency for uniform surface preparationImprove Surface Treatment EfficiencyMetallic material coating processesLithiumSalt spray test

The invention discloses a magnesium-lithium alloy surface treatment device, and aims to enable a magnesium-lithium alloy to be uniform in a conversion film layer in the chemical conversion process and to generate no corrosion spots in inspection by a salt spray test. The magnesium-lithium alloy surface treatment device is characterized by comprising a treatment tank for placing treatment liquid, wherein multiple liquid spray holes are formed in the bottom of the treatment tank; the liquid spray holes are connected with a variable frequency pump through a liquid channel formed in the bottom of the treatment tank; the variable frequency pump is connected to a treatment liquid source; a control end of the variable frequency pump is connected to a controller; a position sensor is arranged on the side wall of the treatment tank, and is connected to the controller; when a magnesium-lithium alloy workpiece is treated, the treatment liquid is sprayed through the liquid spray holes to suspend the magnesium-lithium alloy workpiece in the treatment liquid; the position sensor detects position change information of the magnesium-lithium alloy workpiece to return to the controller; and the controller adjusts the liquid outlet pressure of the variable frequency pump according to the position change information so as to stably suspend the magnesium-lithium alloy workpiece in the treatment liquid.

Owner:西安四方超轻材料有限公司

Method for improving wear resistance of parts of high-pressure hydraulic pump

ActiveCN110629170AImprove wear resistanceHigh hardnessVacuum evaporation coatingSputtering coatingCarbide coatingGas phase

The invention belongs to the technical field of hydraulic pump manufacturing, and particularly relates to a method for improving wear resistance of parts of a high-pressure hydraulic pump. The methodfor preparing the anti-wear high-pressure hydraulic pump through the physical vapor deposition technology for surface carburization and coating treatment, the advantages of carbide coatings, PVD methods, carburization techniques and multilayer composite structures are combined, a carburized diffusion layer is prepared by an ion sputtering method between the carbide coatings and workpiece substrates, namely, the surface carburizing treatment is performed on the surfaces of the parts by means of ion sputtering method, and then multilayer composite coatings of the HfMoZrTiC / Mo are deposited byusing an ion plating method and a magnetron sputtering composite method, the physical property difference between the coatings and substrate materials is relieved, the hardness of the substrate materials is improved, the adhesion performance of the coatings and the substrates is enhanced, the comprehensive performance such as wear resistance of the parts of the hydraulic pump is improved, and thesurface treatment efficiency and the service life of the workpieces are effectively prolonged.

Owner:JINING UNIV

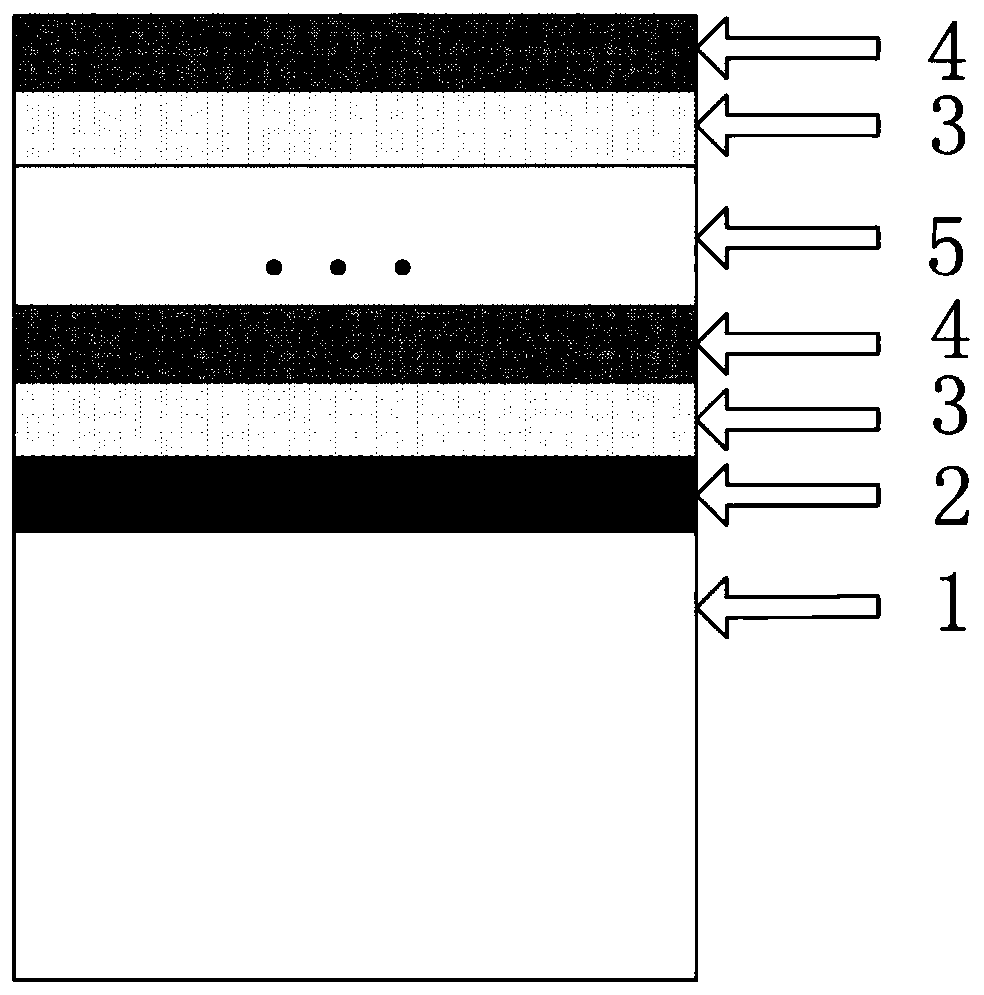

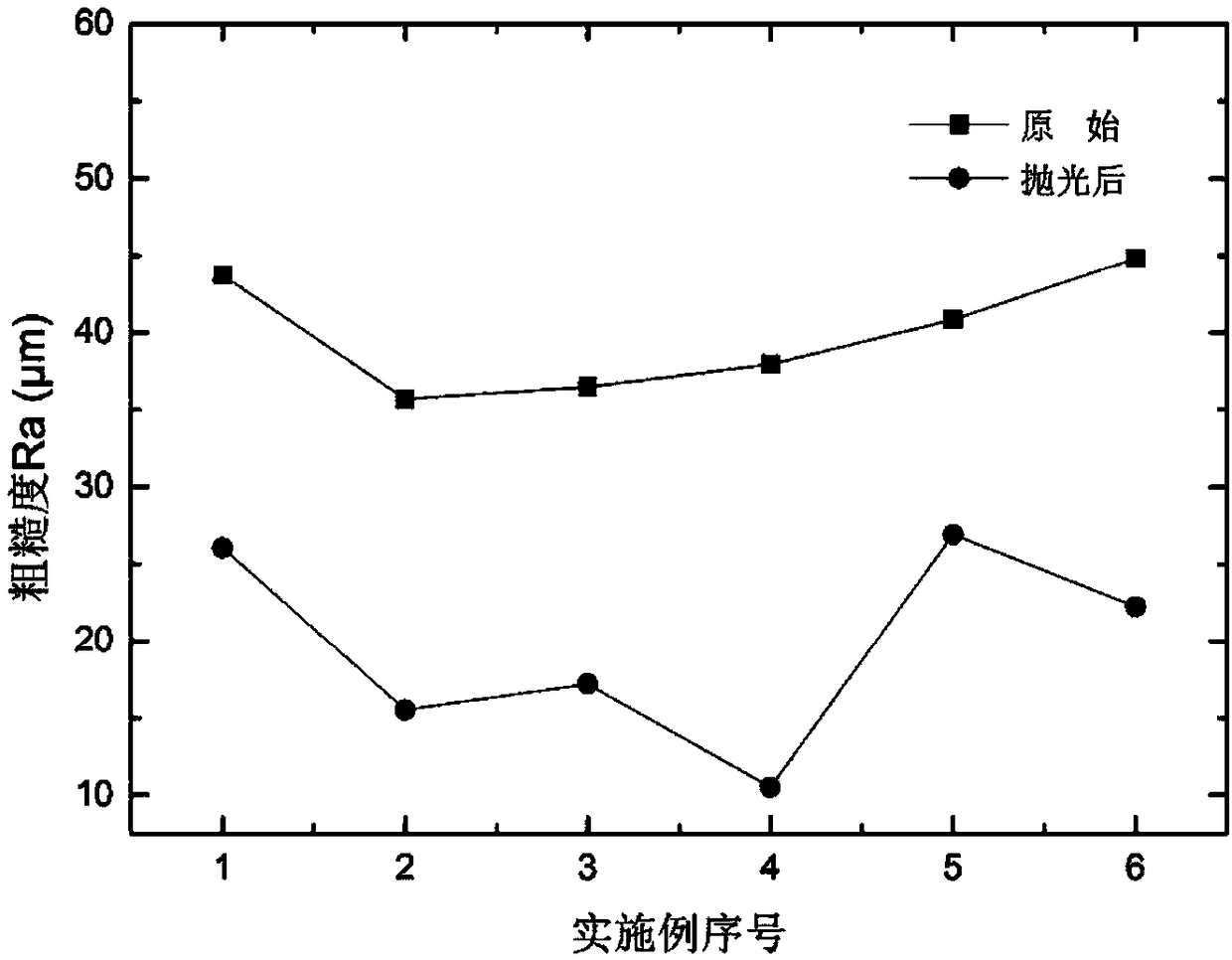

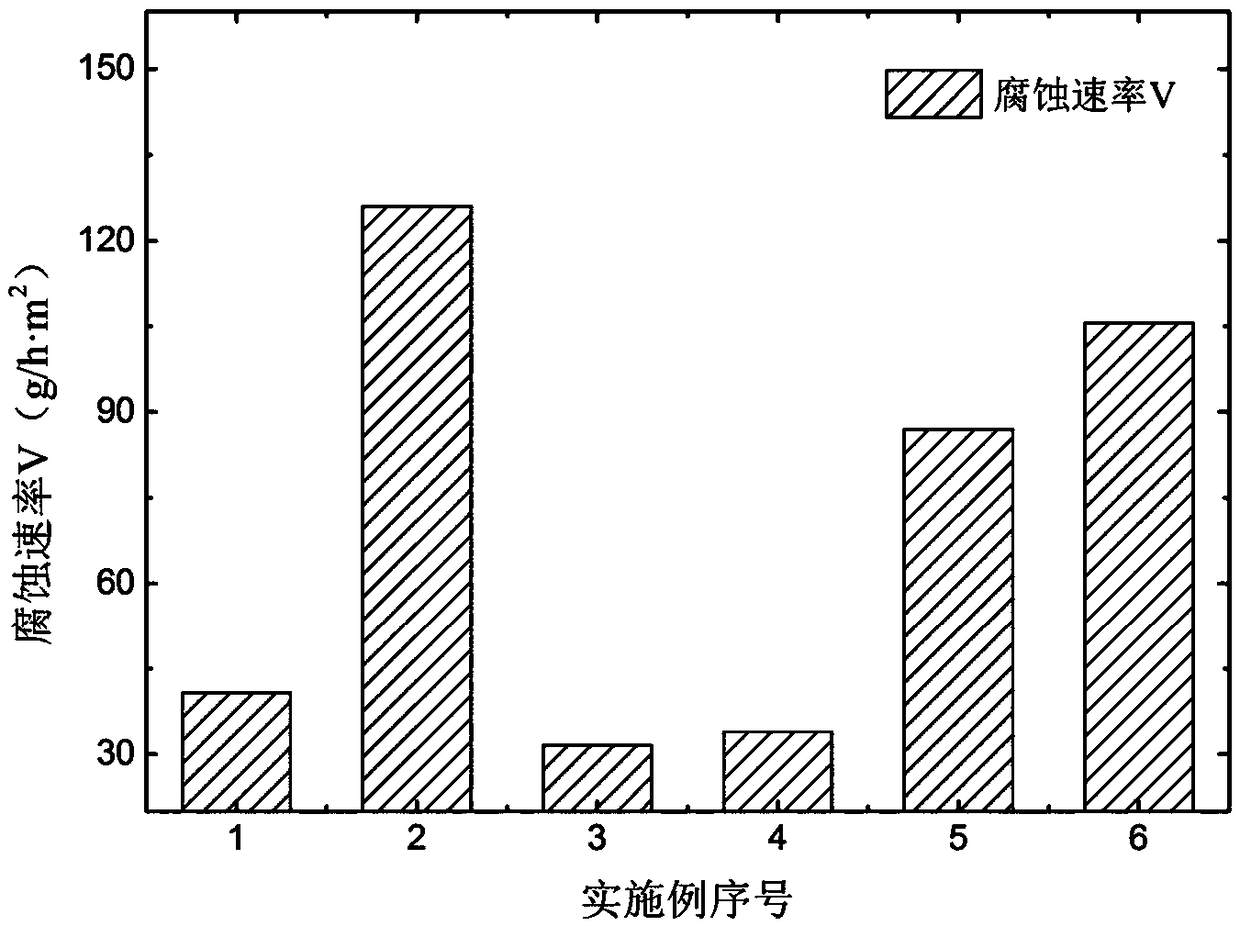

Surface treatment liquid for 3D printed stainless steel parts and surface treatment device

ActiveCN109097778AIncrease brightnessReduce roughnessEdge grinding machinesPolishing machinesPhosphoric acidSilicon dioxide

The invention discloses surface treatment liquid for 3D printed stainless steel parts and a surface treatment device. The surface treatment liquid comprises soda boiling liquid, a pickling solution and a chemical polishing solution. The soda boiling liquid is composed of sodium hydroxide, nitrates and salt containing chloride ions. The pickling solution is composed of hydrochloric acid, sodium chloride, ferric chloride and a corrosion inhibitor. The chemical polishing solution is composed of nano-scale silica abrasives, 36wt% of hydrochloric acid, 85wt% of phosphoric acid, 68wt% of nitric acid, a corrosion inhibitor, a viscosity modifier, a brightener, an OP-10 emulsifier, a complexing agent and deionized water. The surface treatment liquid for the 3D printed stainless steel parts and thesurface treatment device have the characteristics of effectively reducing the surface roughness of the 3D printed stainless steel parts, improving the surface flatness and being good in surface treatment quality and high in surface treatment efficiency.

Owner:ZHEJIANG UNIV OF TECH

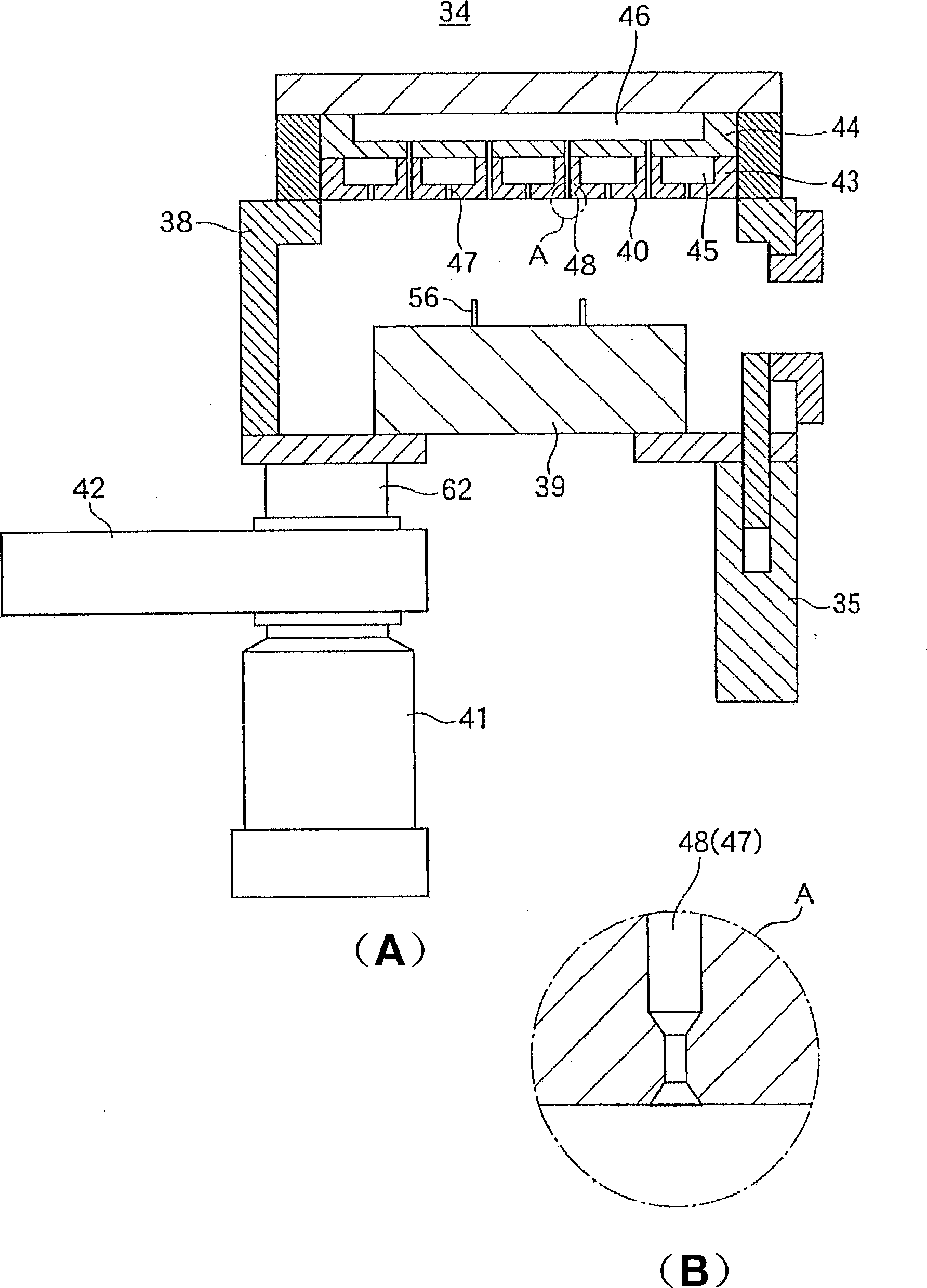

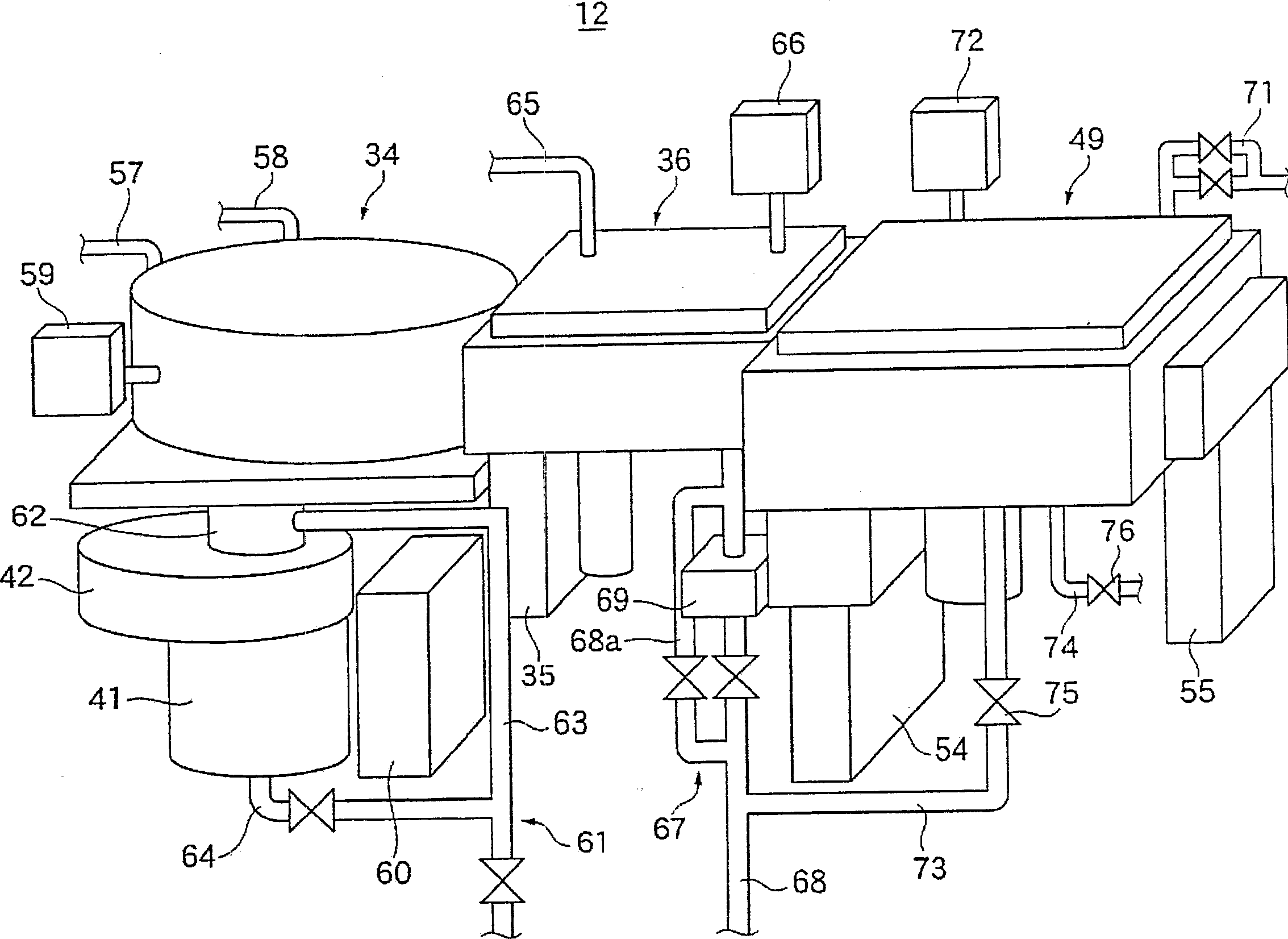

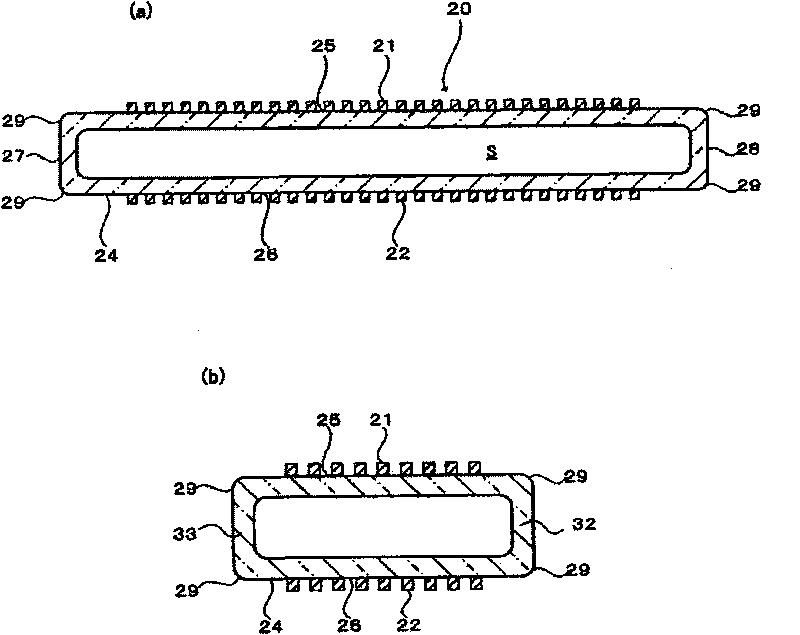

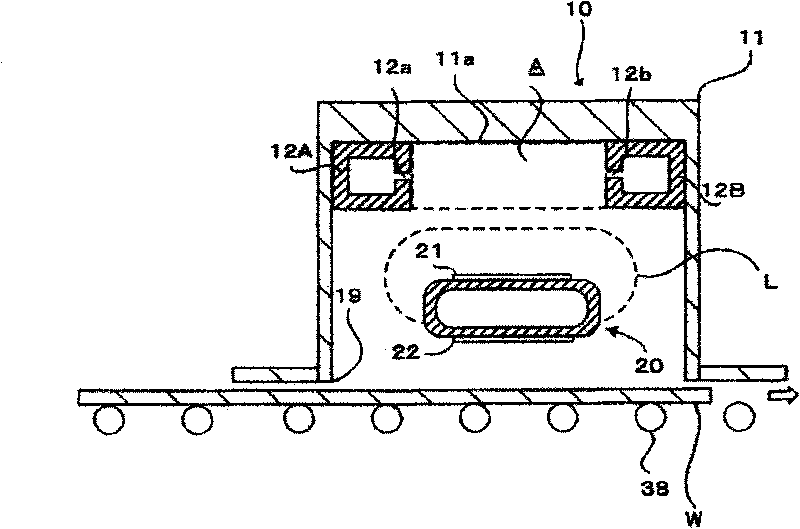

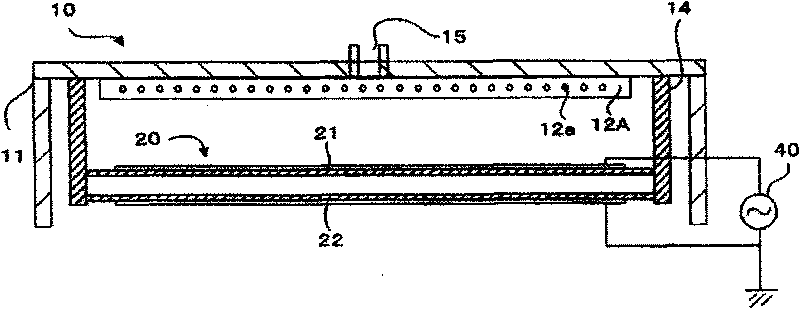

Quasi-molecule lamp apparatus

ActiveCN101740316AImprove cooling effectUniform replacementLighting heating/cooling arrangementsSemiconductor/solid-state device manufacturingFeeding tubeMechanical engineering

The present invention provides a quasi-molecule lamp apparatus having improved surface treatment efficiency and light-emitting efficiency of vacuum ultraviolet lights. The quasi-molecule lamp apparatus comprises a lamp casing (10), a quasi-molecule lamp (20), air feeding tubes (12A) having air spraying outlets (12a) and a carrying and delivering mechanism (38). A plurality of air feeding tubes are positioned discretely in the lamp casing (10) of the quasi-molecule lamp apparatus (10) which irradiates quasi-molecule lights to an object to be processed, two adjacent air feeding tubes have at least a couple of air spraying outlets, wherein, one air spraying outlet in positioned on one of the air feeding tubes and the other air spraying outlet is positioned on the other air feeding tube, and the two one air spraying outlets are a couple, the spraying directions of the couple of air spraying outlets are opposing or intersected in the room (A) between the two adjacent air feeding tubes, and the quasi-molecule lamp is positioned vertically below the room (A).

Owner:USHIO DENKI KK

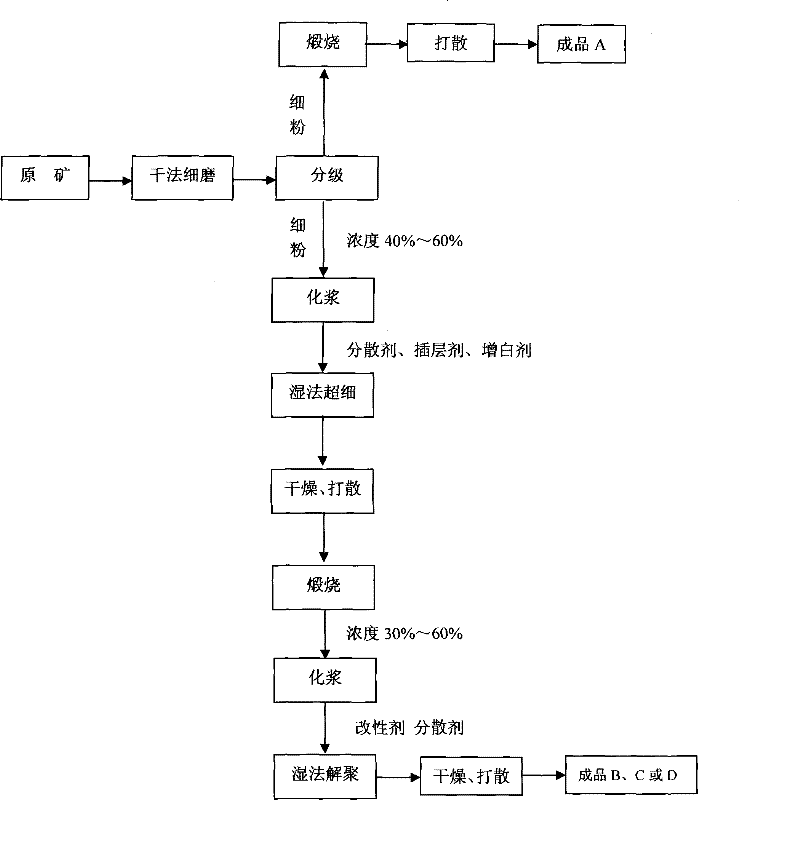

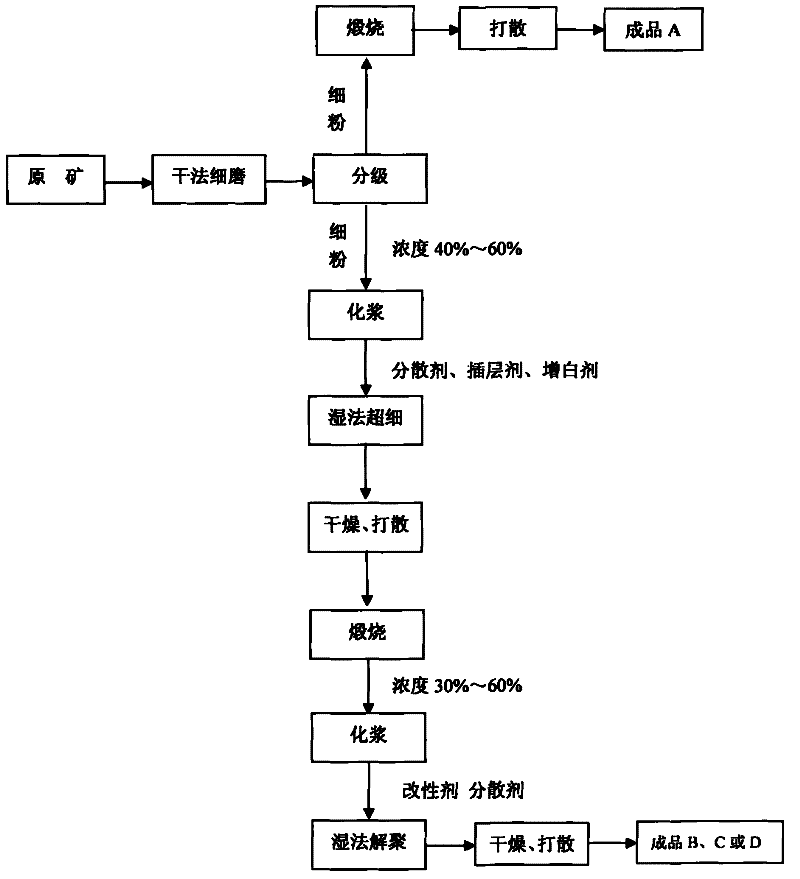

Method for producing ultra-fine calcination white bole with combination of dry and wet method

The invention discloses a dry-wet combination method to prepare superfine calcined kaolin. After grinding by dry method, the kaolin raw ore grains are classified according to the grain size. The superfine with the grain greater than 1250 meshes can be made into a finished product by direct calcination. While for the meal with the grain less than 1250 meshes, dispersing agent, intercalation agent,and whitening agent can be added simultaneously under wet grinding, so as to improve the grinding efficiency, shorten the grinding time, and reduce the energy consumption during grinding process, as well as improve the mixing effect of the whitening agent and the kaolin. The meal scattered and dried after grinding, is sent into rotary kiln for calcinations. The kaolin is grinded again after calcination by wet grinding method. The dispersing agent and modifying agent are added simultaneously, to combine the superfine grinding and the modifying of product simultaneously. The modified powder is grinded to obtain the other finished product after drying and scattering. The invention allows superfine calcined kaolin with different specification during the same production line by the control of the process condition, thus reducing the working procedure, improving the added value of product, broadening the application field and product performance, so as to meet the requirements of different customers.

Owner:内蒙古蒙西高岭粉体股份有限公司

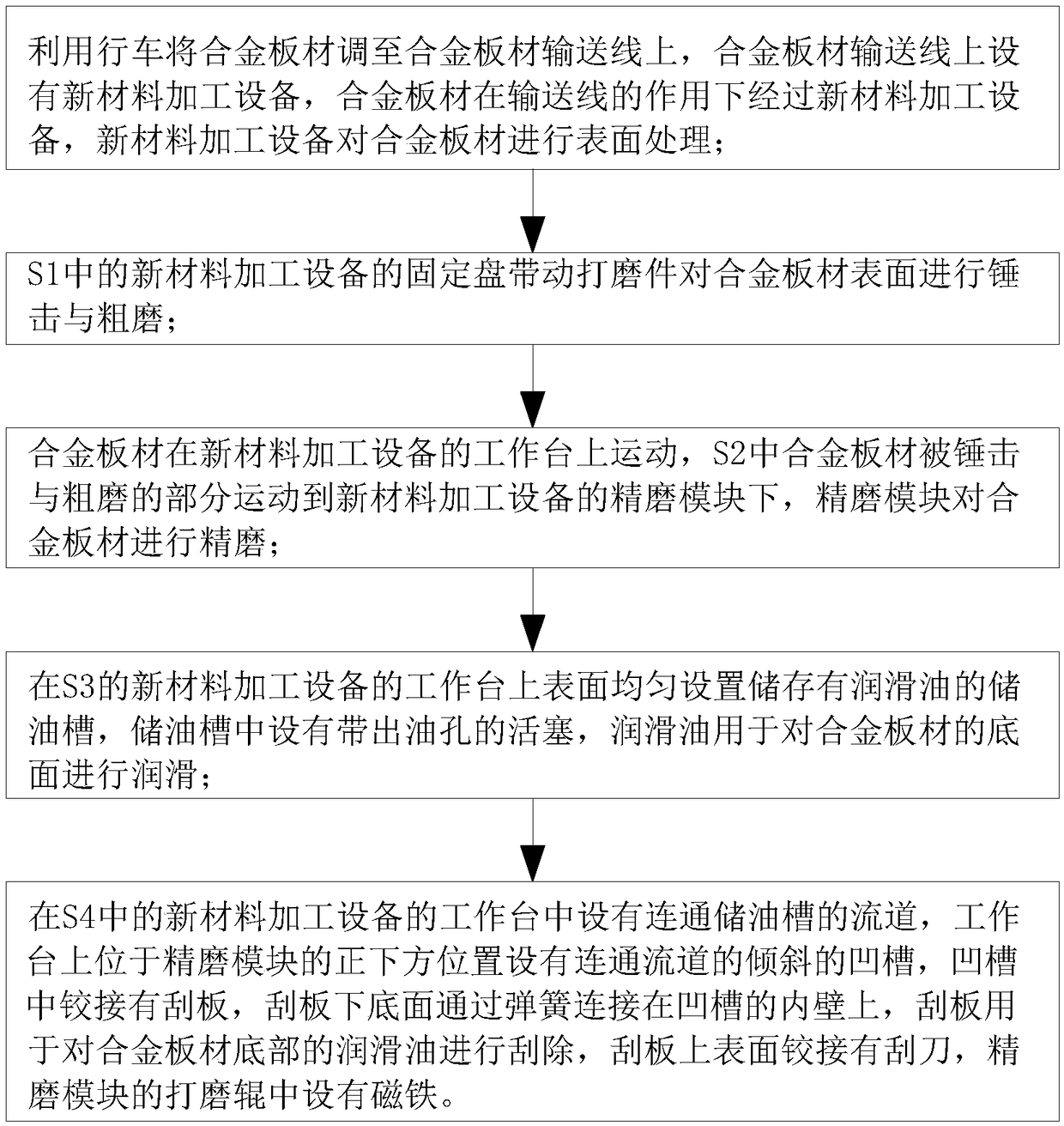

Alloy new material surface treatment process

ActiveCN109483370AImprove Surface Treatment EfficiencyQuality improvementGrinding machinesGrinding/polishing safety devicesAlloyNew materials

The invention belongs to the technical field of new material surface treatment, and particularly relates to an alloy new material surface treatment process. The process comprises the following steps that a crane is used for transferring an alloy board to an alloy board conveying line, and the alloy board passes through a new material machining device under the effect of the conveying line; a fixeddisc of the new material machining device drives a grinding part to carry out hammering and rough grinding on the alloy board surface, a hammered and roughly ground part of the alloy board moves to the position below a fine grinding module of the new material machining device, and the fine grinding module carries out fine grinding on the alloy board, oil storage tanks for storing the lubricatingoil are evenly arranged on the upper surface of a worktable of the new material machining device, and pistons with oil outlets are arranged in the oil storage tanks; a runner communicating with the oil storage tanks is arranged in the worktable of the new material machining device, the position, under the fine grinding module, of the worktable is provided with an inclined groove communicating withthe runner, a scraping plate is hinged into the groove, a scraping knife is hinged to the upper surface of the scraping plate, and a magnet is arranged in a grinding roller of the fine grinding module.

Owner:扬州新乐新材料有限公司

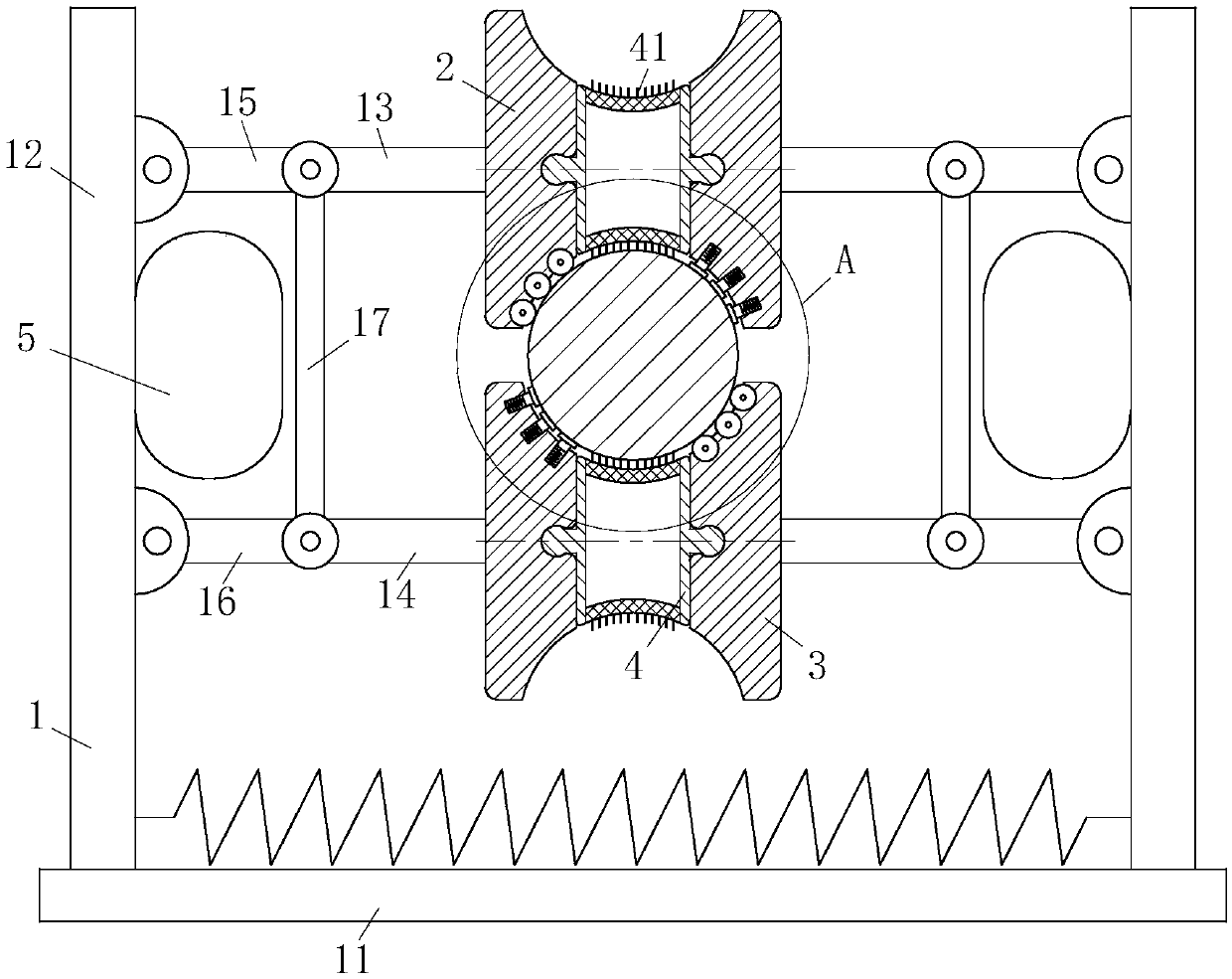

Metal wire surface treatment device

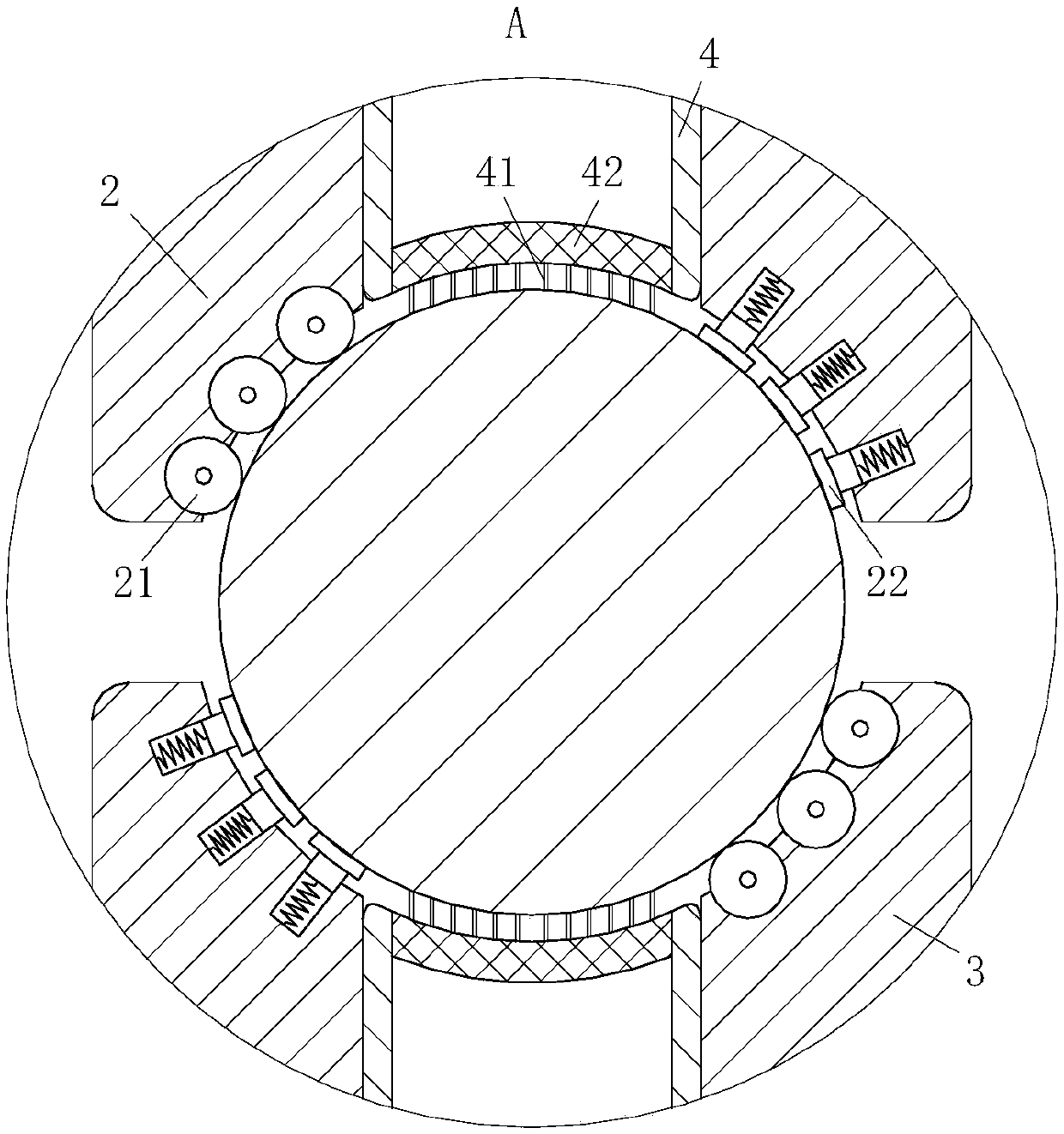

ActiveCN109454538AImprove Surface Treatment EfficiencyGood surface treatmentGrinding machine componentsRevolution surface grinding machinesBristleGrinding wheel

The invention belongs to the technical field of metal wire treatment devices, and particularly relates to a metal wire surface treatment device. The metal wire surface treatment device comprises a grinding module and a cleaning module. The grinding module comprises an annular grinding frame. An upper set of connecting rods and a lower set of connecting rods are arranged in the grinding frame in asliding manner. Grinding wheels are hinged to the ends, located in the grinding frame, of the connecting rods, and the parts, located outside the grinding frame, of the connecting rods are provided with teeth. Fixing blocks are arranged on the outer wall of the grinding frame and provided with first gears and second gears in an up-down symmetry manner. The cleaning module comprises a cleaning frame, a sliding groove is formed in the inner wall of the cleaning frame, and the cleaning frame is provided with a through groove. Four sliding blocks are arranged in the sliding groove through springsand internally rotationally provided with connecting shafts, and bristles are arranged on one sides of the connecting shafts. A first soft shaft is arranged at the upper end of each first gear, wherein the other end of the first soft shaft is connected with the first connecting shaft from top to bottom. The upper end of each second gear is provided with a second soft shaft, wherein the other end of the second soft shaft is connected with the third connecting shaft from top to bottom.

Owner:金寨智行知识产权运营有限公司

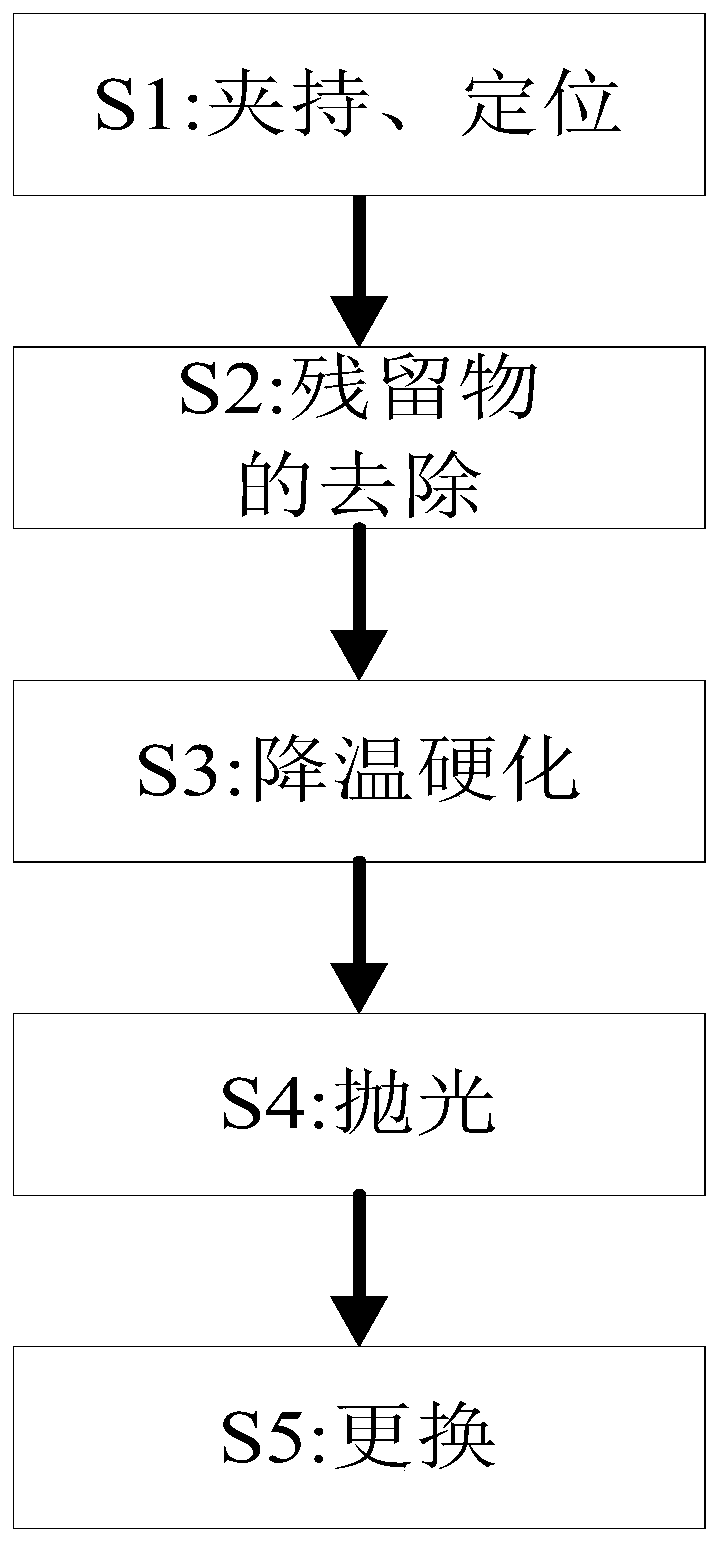

Surface treatment process for silica sol wax pattern of valve casting

ActiveCN111251159AGuaranteed thermalization temperature determinationAvoid accidental burnsPolishing machinesCleaning using toolsPolishingVALVE PORT

The invention provides a surface treatment process for a silica sol wax pattern of a valve casting. Working is completed by a base, a movable frame, a location bolt, a wrapping device, a circular ringgroup, a dual-purpose device, a cleaning device and an erection ring in a matching manner. The surface treatment process for the silica sol wax pattern of the valve casting is capable of solving theproblems that during manual wiping, residues need to be rapidly removed due to a high heat dissipation speed, however, rapid removal is difficultly realized by the manual wiping due to a high thermalization temperature, the case of scald possibly occurs in a wiping process, a distance between an electric drier and the wax pattern is difficultly determined when the wax pattern is heated by holdingthe electric drier with a hand, so that the case of a too low temperature or a too high temperature easily occurs, and when the wax pattern needs to be polished, the surface of the wax pattern is in athermalized state and difficultly moved, and polishing can only be carried out when the wax pattern is naturally cooled and hardened.

Owner:瑞安市三星防腐铸造有限公司

Surface treatment device used for machining Nixie tube

ActiveCN110340043AImprove surface cleanlinessQuality improvementCleaning using toolsCleaning using gasesEngineeringMachining

The invention discloses a surface treatment device used for machining a Nixie tube. The device comprises a rack, a worktable arranged on the upper end of the rack and used for bearing machining of a workpiece, feeding mechanisms which are located on the upper end of the worktable, symmetrically arranged and used for conveying the workpiece, and cleaning mechanisms located on the upper ends of thefeeding mechanisms and used for removingworkpiece surface pollutants. The bottom end of a second air cylinder is movably connected with a telescopic rod, the bottom end of the telescopic rod is fixedly connected with a push plate through a bolt, the bottom end of the push plate is fixedly provided with a brush through a bolt, the brush can treat the pollutants on the workpiece surface, when the second air cylinder is started, the second air cylinder pushes the telescopic rod to move downwards, the push plate moves the brush downwards to the workpiece surface to carry out surface treatment on the workpiece, the pollutants on the surface of the workpiece can be removedthrough the brush, the surface cleanliness of the workpiece in the next machining procedure can be improved, and the machining quality is improved.

Owner:ANHUI MINGYANG ELECTRONICS

A surface treatment device for processing digital tubes

ActiveCN110340043BImprove surface cleanlinessQuality improvementCleaning using toolsCleaning using gasesSurface cleaningEngineering

The invention discloses a surface treatment device for processing digital tubes, which includes a frame, a workbench located at the upper end of the frame for carrying workpiece processing, a feeding mechanism located at the upper end of the workbench and symmetrically arranged for transporting workpieces, and a feeding mechanism located at the upper end of the workbench. The upper end of the mechanism is used to clean the contaminants on the surface of the workpiece. The bottom end of the second cylinder is movably connected with a telescopic rod. The bottom end of the telescopic rod is fixedly connected to the push plate through bolts. The bottom end of the push plate is fixed with a brush through bolts. The brush can treat contaminants on the surface of the workpiece. When the second cylinder is turned on, the second cylinder pushes the telescopic rod to move downward, and then moves the brush down to the surface of the workpiece through the push plate to perform surface treatment on the workpiece, so that the brush cleans the workpiece. contaminants on the surface, thereby improving the surface cleanliness of the workpiece in the next processing step and improving the processing quality.

Owner:ANHUI MINGYANG ELECTRONICS

Aluminum alloy profile machining system and method

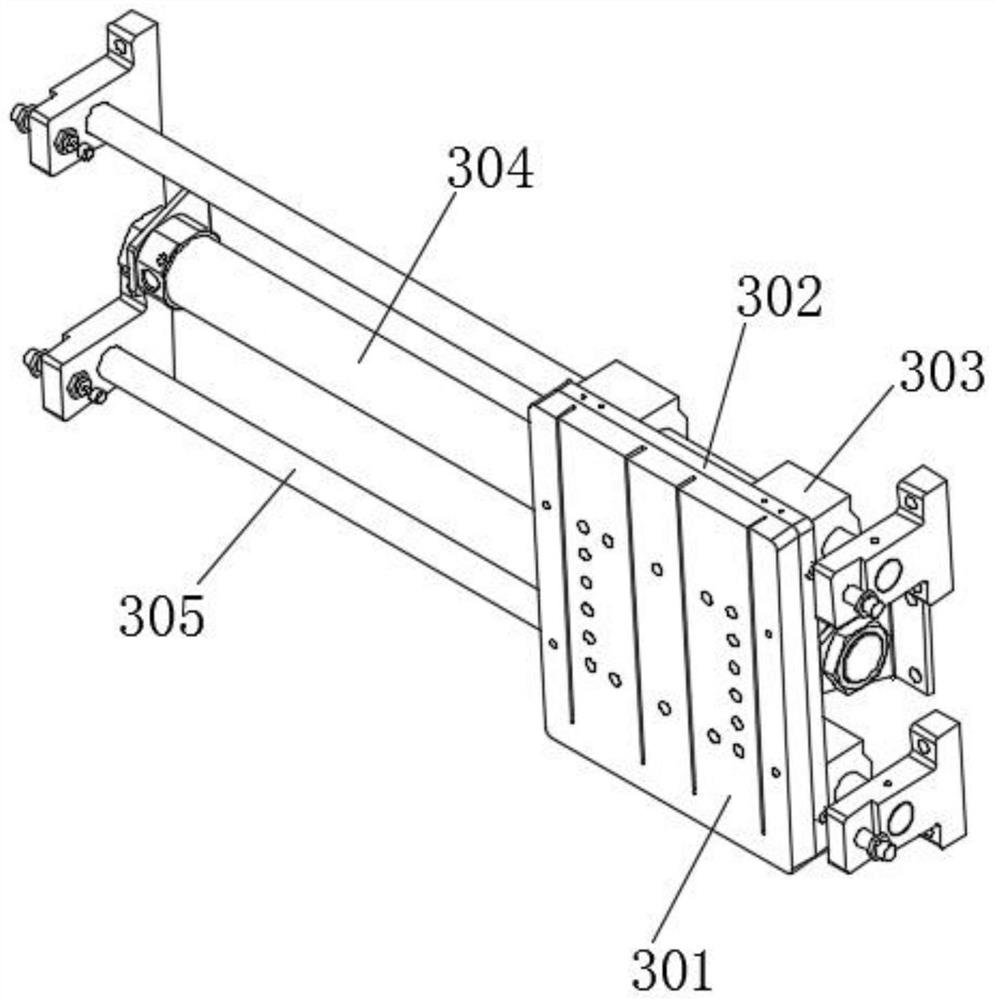

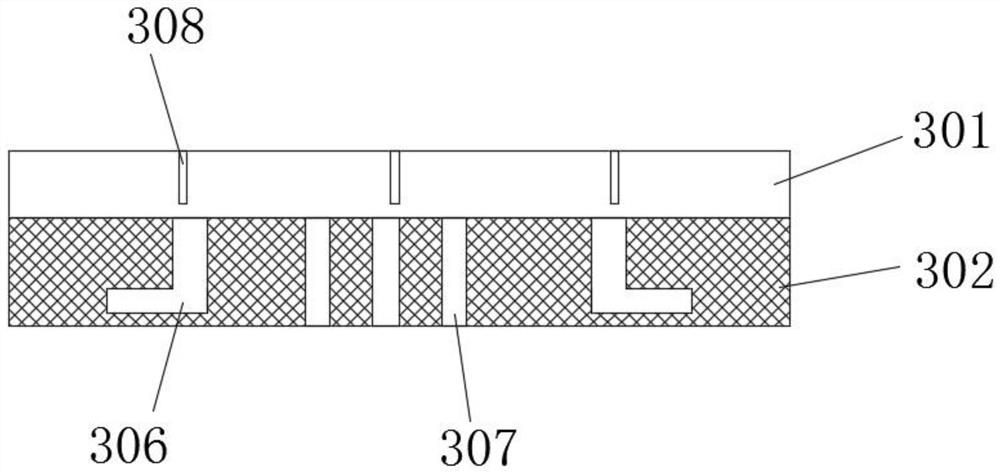

PendingCN114714204AImprove processing efficiencyCooperate wellGrinding carriagesGrinding drivesGear wheelTransmission belt

The aluminum alloy profile machining system comprises a toothed belt, a circulating turnover device, a machining device, a toothed belt wheel, a servo motor, a supporting guide shaft, a connecting bottom plate, a connecting cam, a fixing side plate, a connecting top plate, a transmission belt, a protective clamping cover, a connecting fluted disc, a fixing belt wheel, a supporting belt wheel, a positioning gear and a guide belt wheel. Fixing side plates used for supporting are symmetrically and fixedly installed on the upper end face of the connecting bottom plate. According to the aluminum profile machining device, by arranging the circulating turnover device, when an aluminum profile is machined, a supporting guide shaft can synchronously supply power to a connecting cam and a guide belt wheel, so that the circulating turnover device and the machining device can be matched in a non-intermittent mode, and then circulating turnover operation is conducted on the aluminum profile through circulating mechanical grinding and matched grinding; and non-intermittent cooperation between equipment is improved to the maximum degree, and meanwhile the machining efficiency of the aluminum profile is improved.

Owner:曹楚明

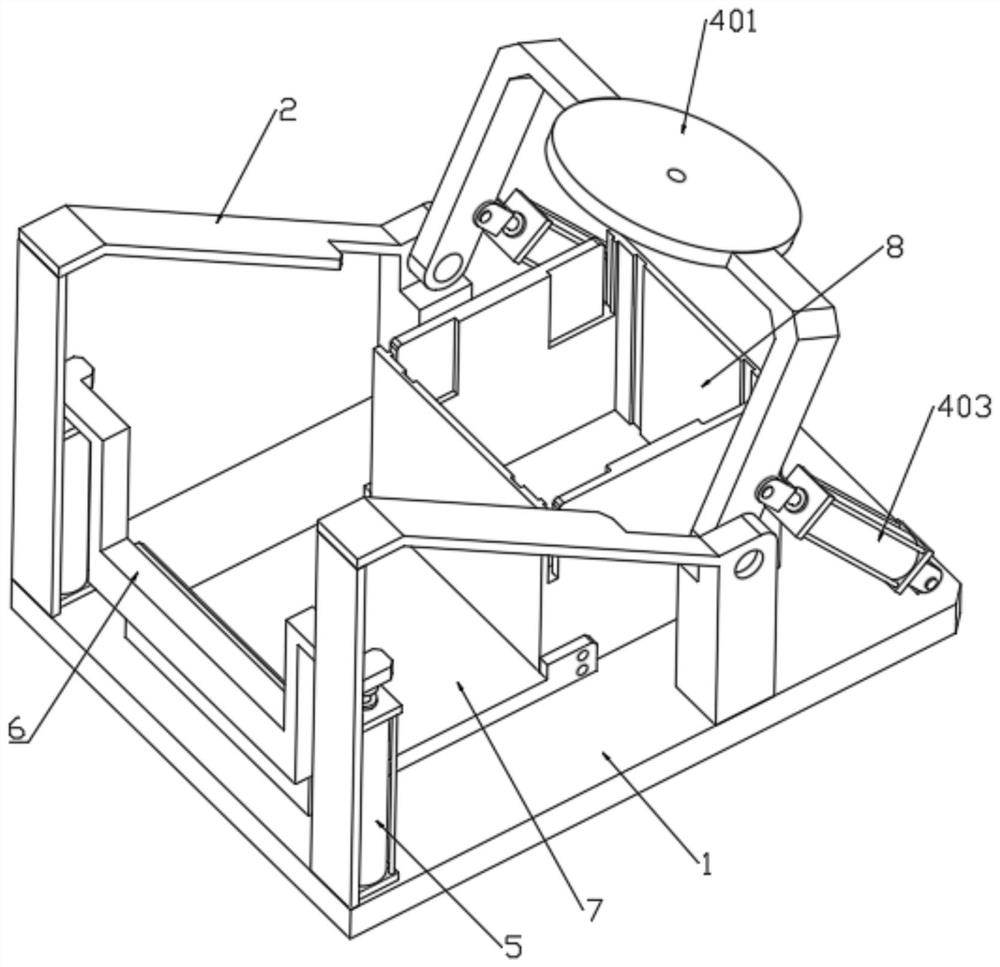

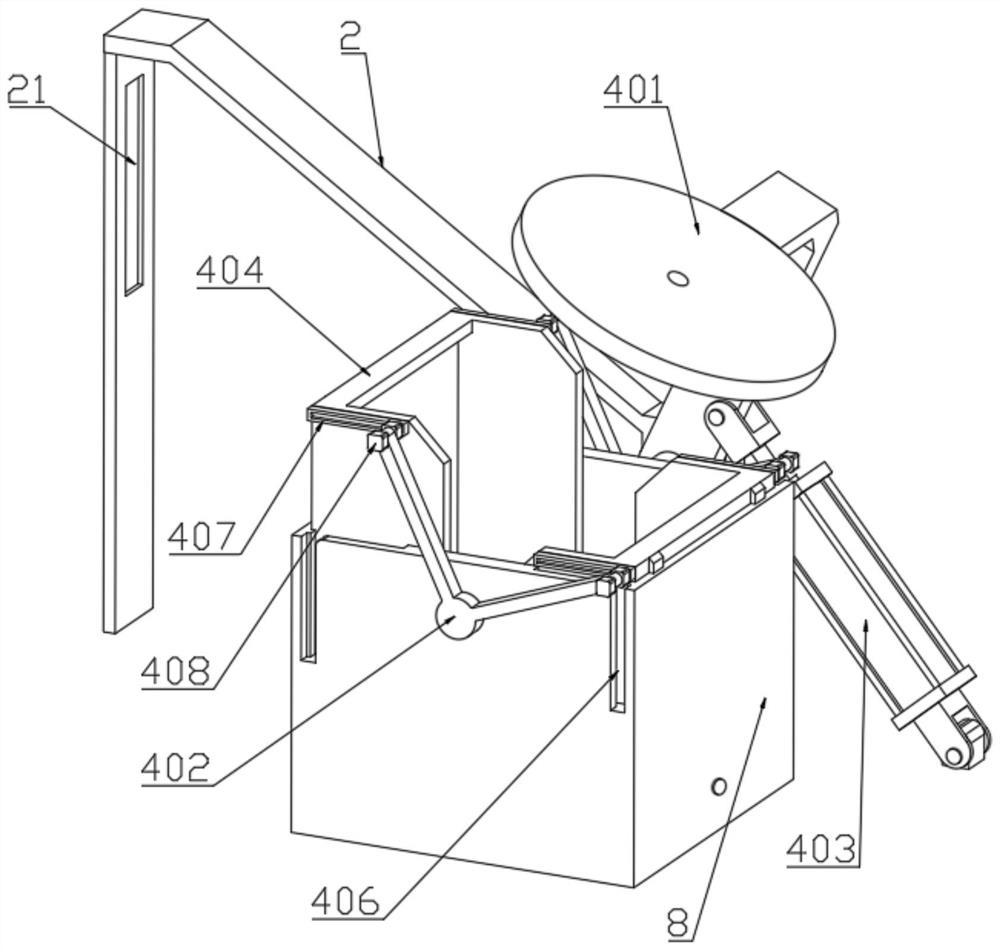

Dacromet surface treatment device for complex automobile structural part

ActiveCN112427228AImprove processing efficiencyAvoid Dip Coating Different EffectsPretreated surfacesCoatingsHydraulic cylinderExhaust pipe

The invention discloses a Dacromet surface treatment device for a complex automobile structural part, and relates to the technical field of workpiece coating. The Dacromet surface treatment device comprises a base, a supporting frame, a dip-coating mechanism and a splash-proof swing mechanism, wherein the supporting frame is arranged on the base, and two symmetrically-arranged guide grooves are formed in the supporting frame. According to the Dacromet surface treatment device, the dip-coating mechanism and the splash-proof swing mechanism are arranged, so that workpieces such as an engine exhaust pipe are coated in a dipping-spin-drying mode, the workpiece surface treatment efficiency is improved, phenomena of gel and layering of coating liquid are prevented, and the different dip-coatingeffects of the workpiece surfaces are avoided; air attached to corresponding portions such as deep holes and narrow cavities can be effectively broken, so that the whole workpieces can be effectivelydip-coated; and a second hydraulic cylinder and a baffle are arranged in the splash-proof swing mechanism, so that the workpieces can be timely blocked during spin-drying, the centrifugal speed does not need to be reduced to prevent the coating liquid from splashing, and the surface treatment efficiency is further improved while thorough spin-drying is guaranteed.

Owner:安徽省振华科技工业有限公司

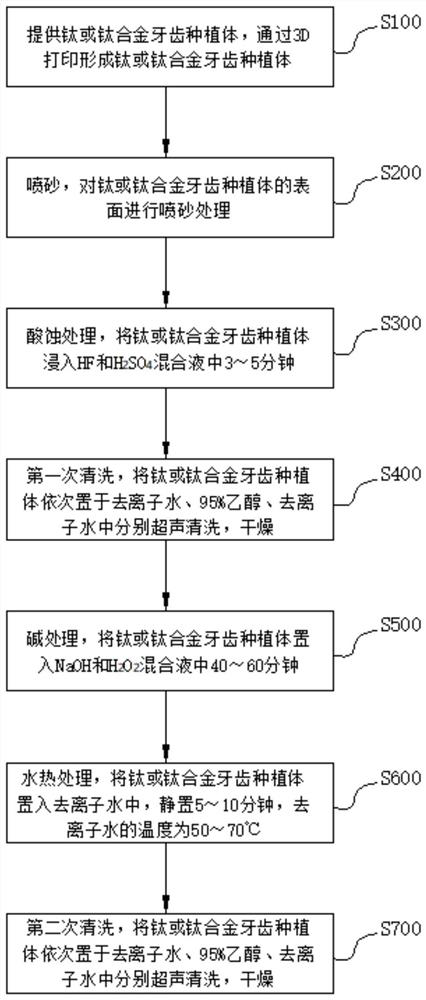

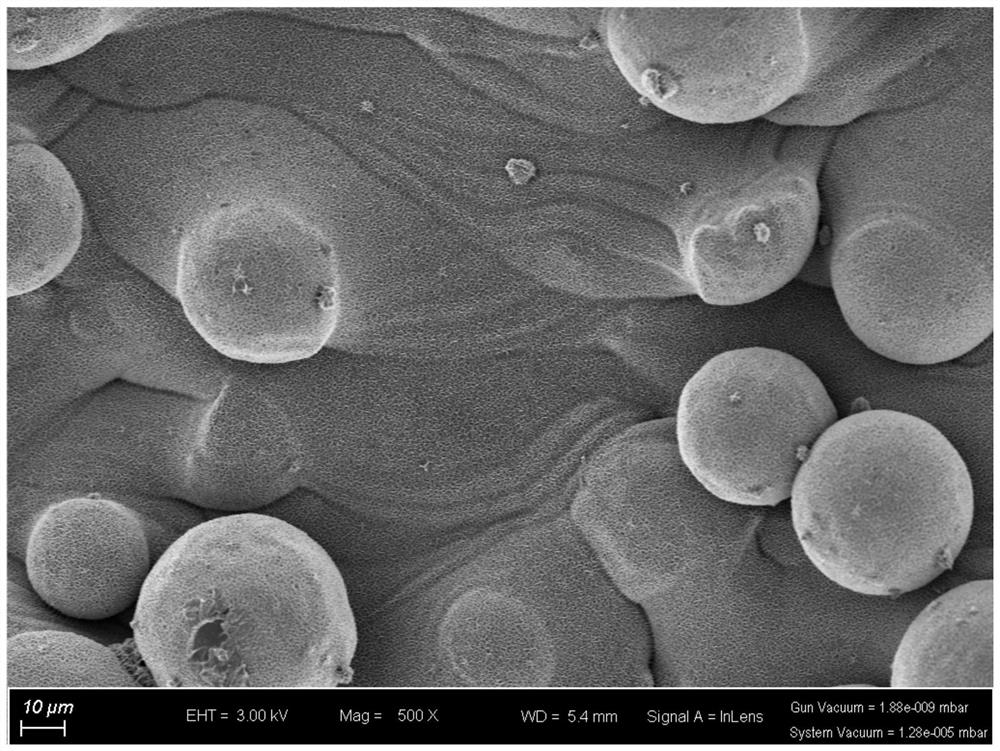

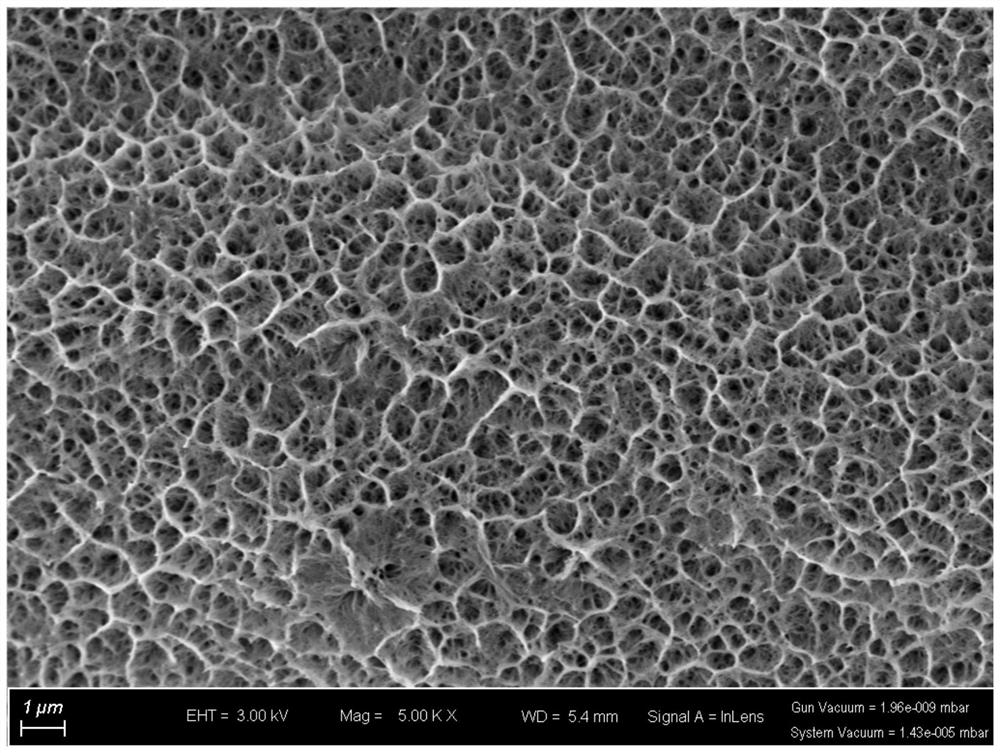

Surface treatment process of titanium or titanium alloy dental implant

ActiveCN113814418AFast preparationQuick customizationDental implantsAdditive manufacturing apparatusAcid etchingSand blasting

The invention relates to the technical field of dental implant, in particular to a surface treatment process of a titanium or titanium alloy dental implant. The surface treatment process comprises the following steps that firstly, a roughened surface is formed on a titanium or titanium alloy dental implant through 3D printing treatment, particles which are not tightly attached or are in a semi-molten state in 3D printing are removed through sand blasting treatment, the surface of the titanium or titanium alloy dental implant is further coarsened, an oxide layer and attached impurities on the surface of the titanium or titanium alloy dental implant can be removed by adopting a mixed solution of HF and H2SO4 for acid etching, alkali treatment is carried out by adopting a mixed solution of NaOH and H2O2, a nano-scale multi-layer stacked spongy or mesh-shaped interpenetrating structure is formed on the surface of the titanium or titanium alloy dental implant, so that the micro-morphology of the surface of the titanium or titanium alloy dental implant is effectively improved, the hydrophilicity, the bone bonding rate and the bonding strength of the surface of the titanium or titanium alloy dental implant are improved, and the healing time is effectively shortened.

Owner:珠海乔丹科技股份有限公司

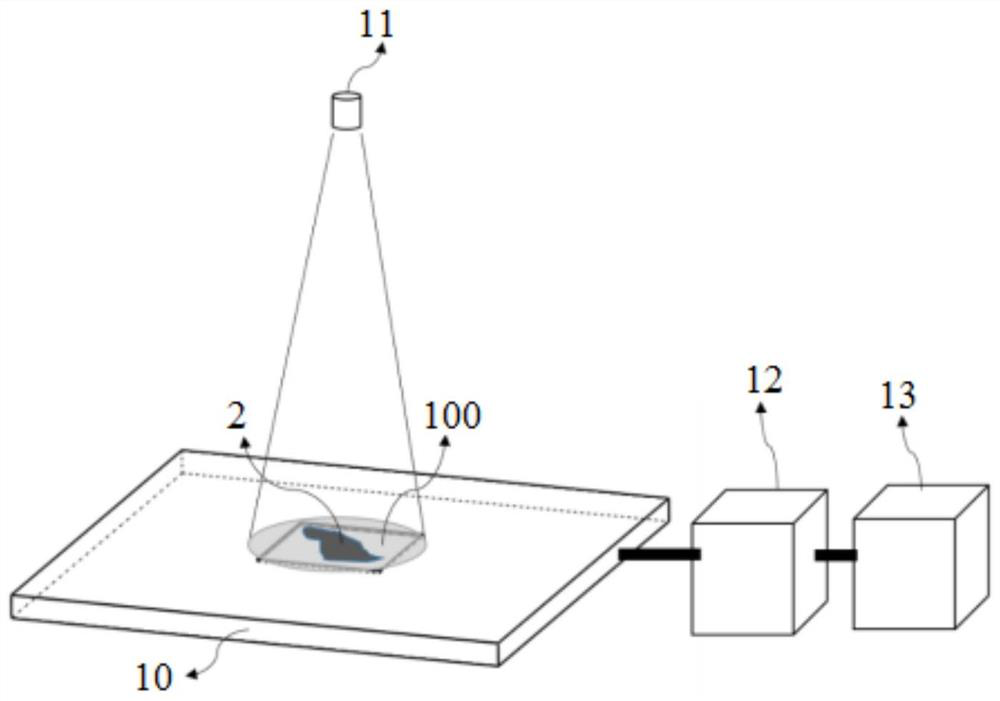

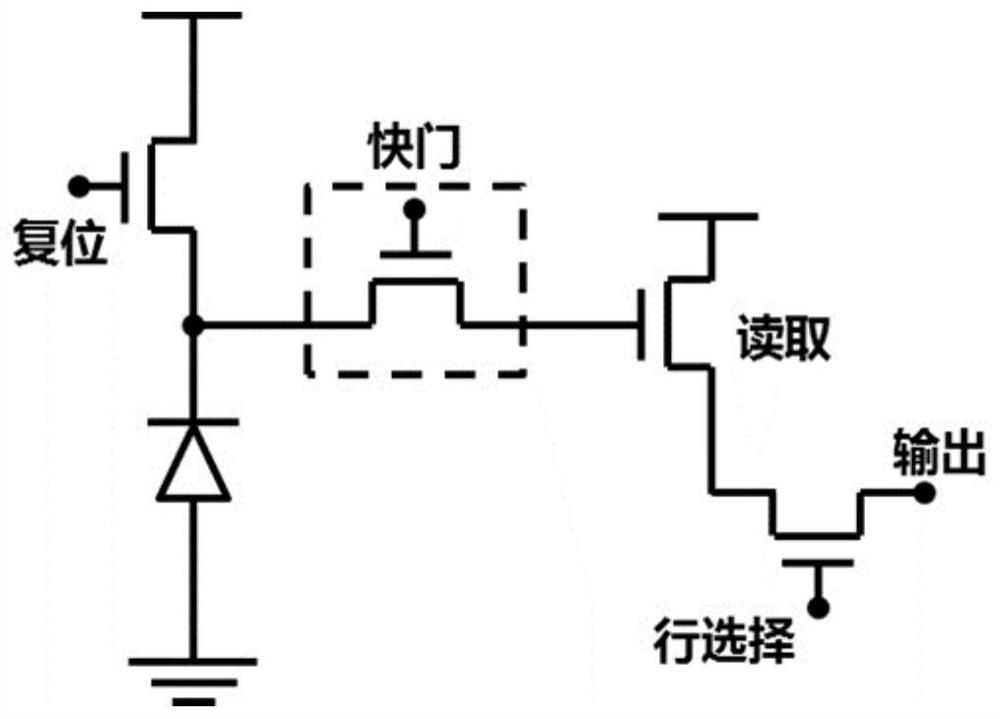

Full-view imaging device for pathological tissue slide

PendingCN111610187AHelp detection efficiencyEasy to detectMaterial analysis by optical meansMicroscopesImage sensorImage resolution

The invention discloses a full-view imaging device for a pathological tissue slide, and the device comprises an image sensor chip, wherein a photosensitive area is arranged in the middle of the imagesensor chip, and the pathological tissue slice is directly fixed on the surface of the photosensitive area so as to record projection microscopic image data of the pathological tissue slide; the light-emitting surface of a light source device covers the photosensitive area and is used for providing illumination during pathological tissue slide imaging; a driving device is used for respectively providing driving force for the image sensor chip and the light source device; and computer equipment is used for receiving and processing the projection microscopic image data of the pathological tissueslide. Beneficial effects are as follows: the full-view imaging device is low in structural complexity; the imaging process is simple and convenient, imaging in the full-view range can be achieved while the resolution is guaranteed, the detection efficiency of pathological tissue slide is improved, the view field range only depends on the size of a photosensitive area of the image sensor chip, and one-time full-view imaging can be conducted on the pathological tissue slide under the centimeter-level and sub-centimeter-level sizes.

Owner:南京九川科学技术有限公司 +1

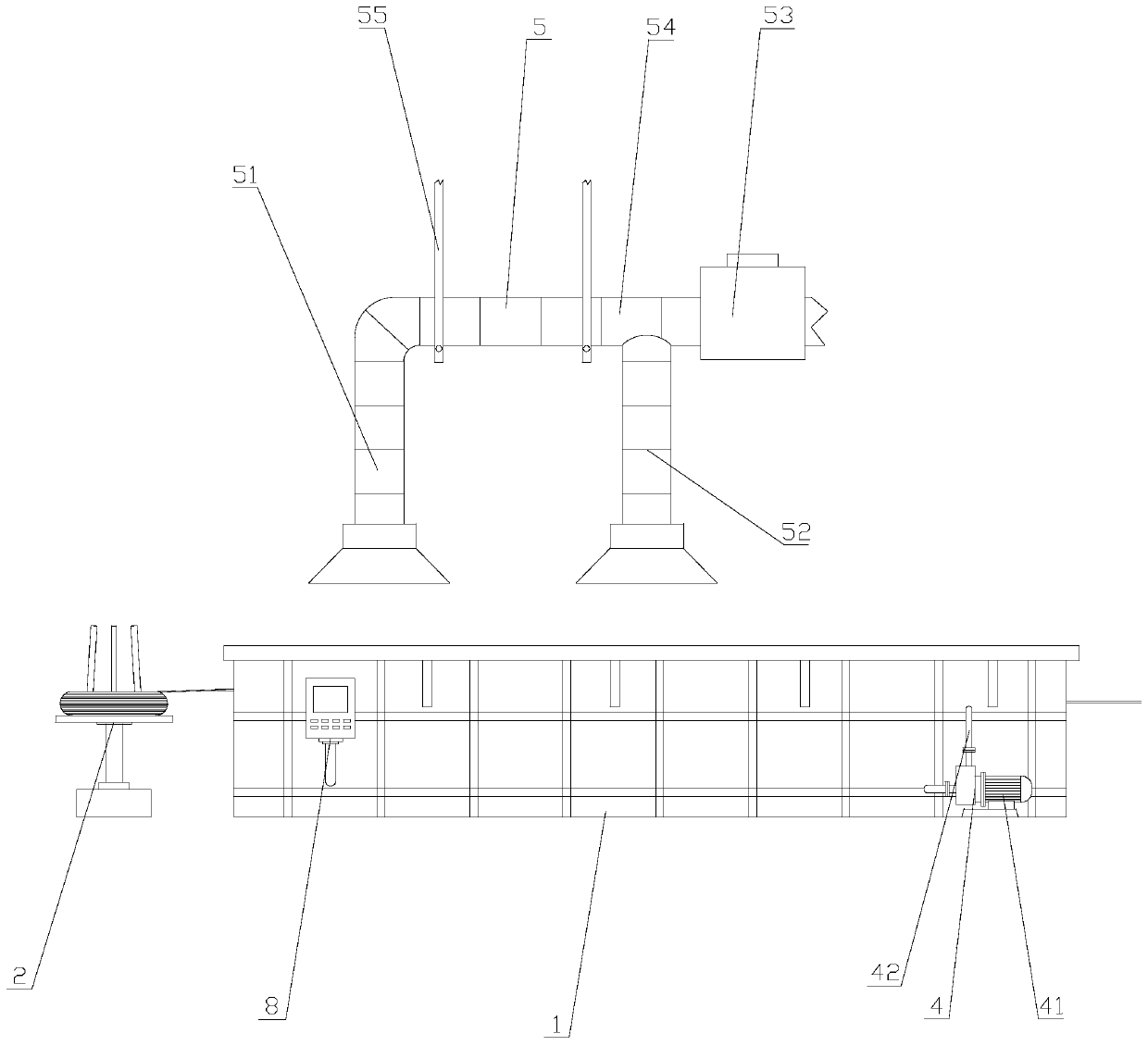

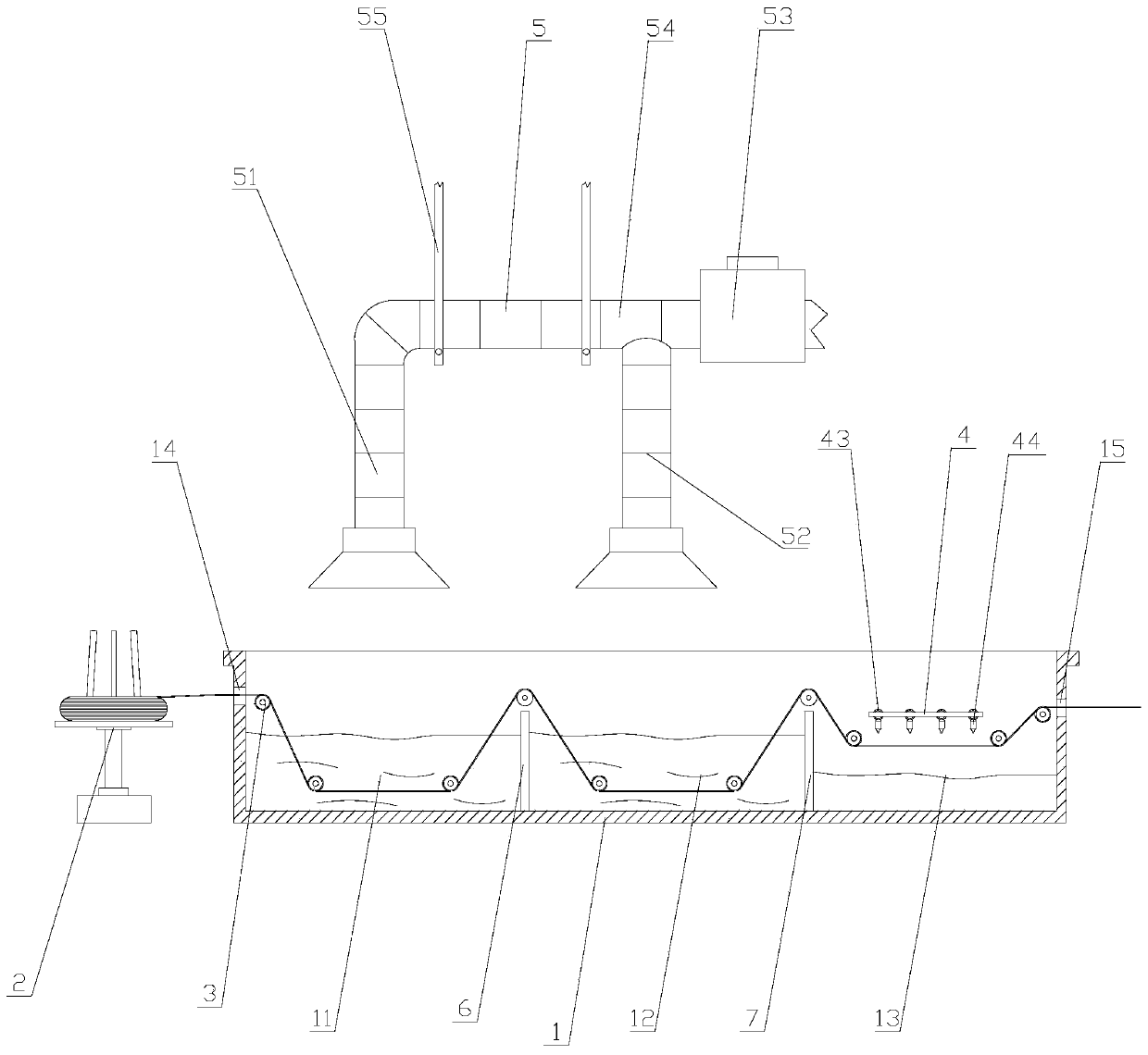

High-performance surface treatment device for steel bar base material used for bolt

PendingCN110438516AImprove Surface Treatment EfficiencyImprove processing efficiencyRebarTreatment quality

The invention discloses a high-performance surface treatment device for a steel bar base material used for a bolt. The high-performance surface treatment device comprises an acid pickling tank, a wireunreeling rotary disc, multiple conveying wire guide wheels, a sprinkling device, an exhaust device, an acid pickling tank first partition plate, an acid pickling tank second partition plate and a control panel. The acid pickling tank is a rectangular tank body, and the acid pickling tank first partition plate and the acid pickling tank second partition plate are vertically arranged in the acid pickling tank and divide the acid pickling tank into three independent cavities. By means of the high-performance surface treatment device for the steel bar base material used for the bolt, the surfacetreatment efficiency of the steel bar base material used for the bolt can be improved, the surface treatment quality is improved, surface treatment equipment can be used for being directly connectedwith wire drawing equipment in bolt production, the steel bar base material is directly guided into bolt production equipment after surface treatment, steps are saved, waste gas generated in the acidpickling process can be collected due to the arrangement of the exhaust device, subsequent treatment of the waste gas is facilitated, and damage of the acid pickling waste gas to the environment and the human body is reduced.

Owner:浙江明铖金属科技股份有限公司

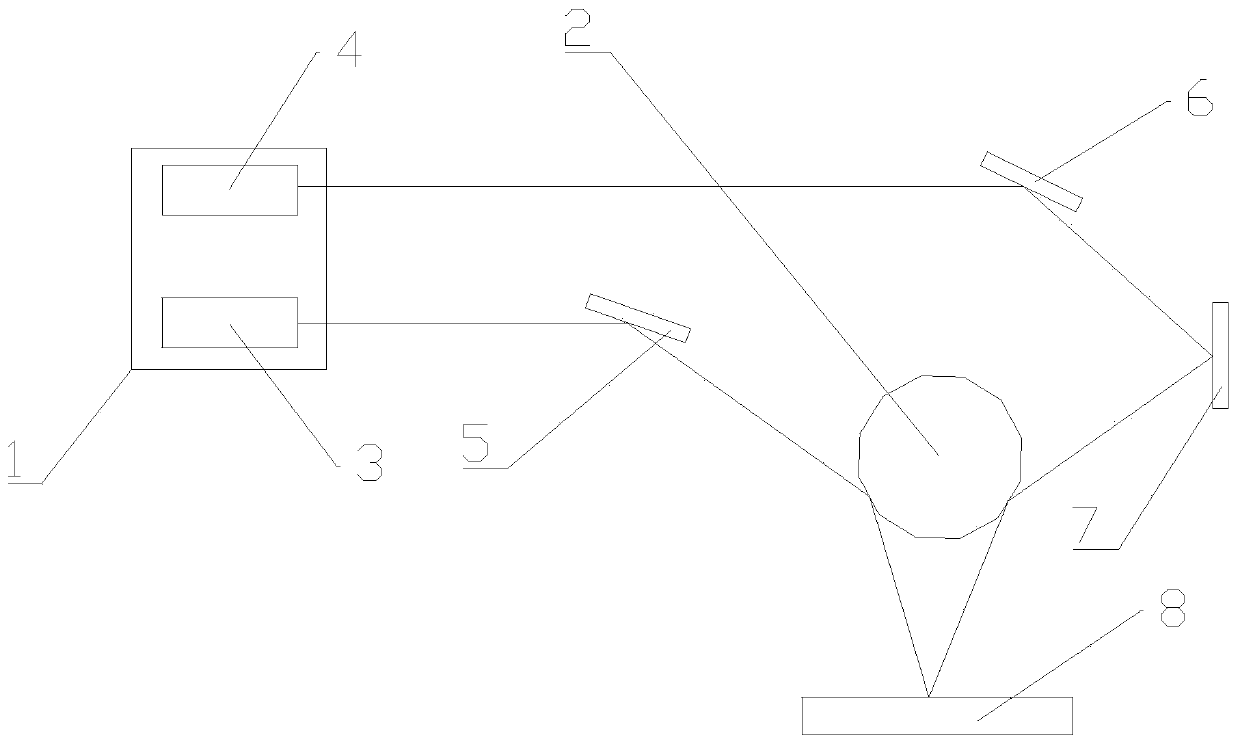

Laser surface treatment equipment

ActiveCN110340531AImprove Surface Treatment EfficiencyLow costLaser beam welding apparatusOptoelectronicsPre treatment

The invention provides laser surface treatment equipment. A laser assembly, a reflection assembly and a polygonal rotating mirror are arranged, the laser assembly comprises a first laser emission source and a second laser emission source which are sequentially arranged from bottom to top, and the power of lasers emitted by the first laser emission source is different from that of lasers emitted bythe second laser emission source. The reflection assembly reflects the lasers emitted by the first laser emission source and the lasers emitted by the second laser emission source to different side faces of the polygonal rotating mirror. The polygonal rotating mirror reflects the received lasers to a to-be-treated part for surface treatment while rotating. The first laser emission source and thesecond laser emission source different in power are arranged at the same time, pretreatment can be carried out while metal surface oxide and pollutants are removed, prepares are made for the later derusting procedure, and therefore the surface treatment efficiency is improved, and cost is reduced; and the two laser emission sources are arranged up and down so that the occupied area can be reducedeasily.

Owner:福建拓烯新材料科技有限公司

A preparation process of anti-friction and wear-resistant gear parts

ActiveCN111485070BExtended service lifeMitigation of physical performance differencesVacuum evaporation coatingSputtering coatingFriction reductionCarbide coating

The invention belongs to the technical field of gear manufacturing, and in particular relates to a preparation process of anti-friction and wear-resistant gear parts, a method for preparing a high-pressure anti-friction and wear-resistant hydraulic pump by performing surface carburization and coating treatment through physical vapor deposition technology, and the carbide Combining the coating, PVD method and carburizing technology, a carburizing diffusion layer is prepared between the carbide coating and the workpiece substrate by ion sputtering, that is, the surface of the workpiece is first carburized by ion sputtering. , and then use ion plating and magnetron sputtering composite method to deposit VCrWSiC / Cr carbide coating with gradient composition to slow down the difference in physical properties between the coating and the substrate material, improve the hardness of the substrate material, and enhance the coating and substrate. Adhesion performance, thereby improving the comprehensive performance of gear parts such as anti-friction and wear resistance, effectively improving the surface treatment efficiency and the service life of the workpiece.

Owner:JINING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com