Water-based paint remover applied to zipper production and preparation method thereof

A paint remover, water-based technology, applied in the field of paint cleaning, can solve the problems of high cost and complicated raw materials, and achieve the effect of low cost, strong paint removal ability, and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

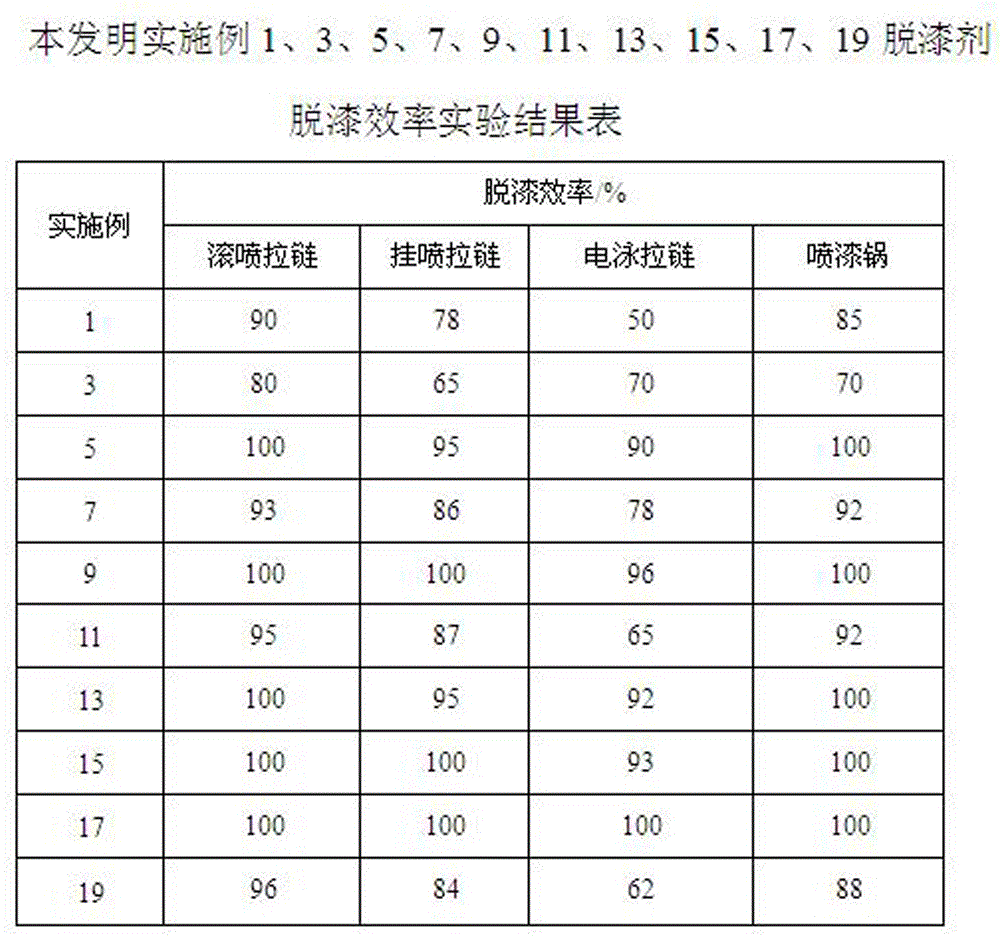

Examples

Embodiment 1

[0038] A water-based paint remover for zipper production, which consists of a main solvent in parts by mass: 24 parts of N-methylpyrrolidone; a cosolvent: 28 parts of 95% ethanol; an activator: 15 parts of formic acid; an emulsifier: 3 parts Composed of 1 part OP-10, 2 parts cetyltrimethylammonium bromide (CTMAB); penetrant: 8 parts triethanol; 20 parts deionized water.

Embodiment 2

[0040] A preparation method for water-based paint remover in slide fastener production, it is prepared according to the following steps:

[0041] Group A solution: configuration of main solvent, co-solvent and activator:

[0042]According to the number of parts by mass, the main solvent: 24 parts of N-methylpyrrolidone; the co-solvent: 28 parts of 95% ethanol; the activator: 15 parts of formic acid; group solution.

[0043] Group B solution: configuration of emulsifier, penetrant and aqueous solution:

[0044] In terms of parts by mass, add emulsifier: 3 parts of OP-10, 2 parts of cetyltrimethylammonium bromide (CTMAB), penetrant: 8 parts of triethanolamine into the mixing tank and stir evenly; then add 20 Parts of deionized water were stirred at normal temperature and pressure until completely homogeneous to obtain the group B solution.

[0045] Add the prepared Group B solution into the preparation kettle of Group A solution, and stir evenly at room temperature to obtain ...

Embodiment 3

[0047] A water-based paint remover used in the production of zippers, which consists of a main solvent in parts by mass: 20 parts of dimethyl sulfoxide; a cosolvent: 28 parts of isopropanol; an activator: 18 parts of salicylic acid; an emulsifier: 1 part of OP-7, 2 parts of cetyltrimethylammonium bromide (CTMAB); penetrant: 10 parts of thiourea, 21 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com