Quasi-molecule lamp apparatus

An excimer lamp and excimer technology, applied in the field of excimer lamp devices, can solve the problems of inert gas retention, rise and decrease of luminescent gas temperature, etc., and achieve the effect of easy shrinkage and ease of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

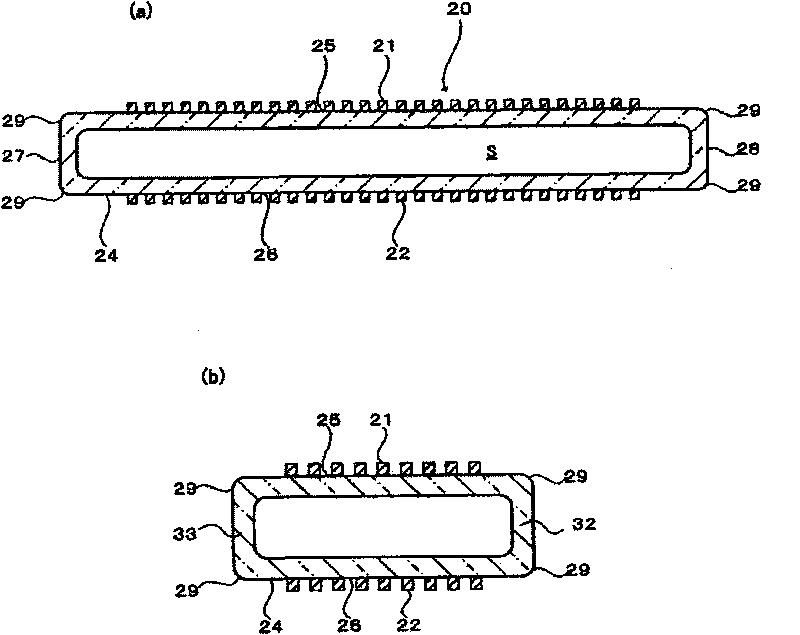

[0036] figure 1 (a) and figure 1 (b) is a schematic configuration diagram of an example of the excimer lamp 20 provided in the excimer lamp device of the present invention, figure 1 (a) is a cross-sectional view along the length direction, figure 1 (b) is a cross-sectional view along the width direction.

[0037] Such as figure 2 As shown, the excimer lamp 20 is made of silica glass as a dielectric material, and has a flat square tube-shaped discharge vessel 24 with rounded four corners. The discharge space S formed inside the discharge vessel 24 is filled with, for example, a rare gas such as xenon gas or a gas mixed with a halogen gas such as chlorine gas as the discharge gas. Excimer light of different wavelengths is generated depending on the type of discharge gas. The discharge gas is usually filled with a pressure of about 10 to 100 KPa.

[0038]In the discharge vessel 24, a flat wall 25 on the upper side and a flat wall 26 on the lower side are separated from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com