Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Improve running-in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

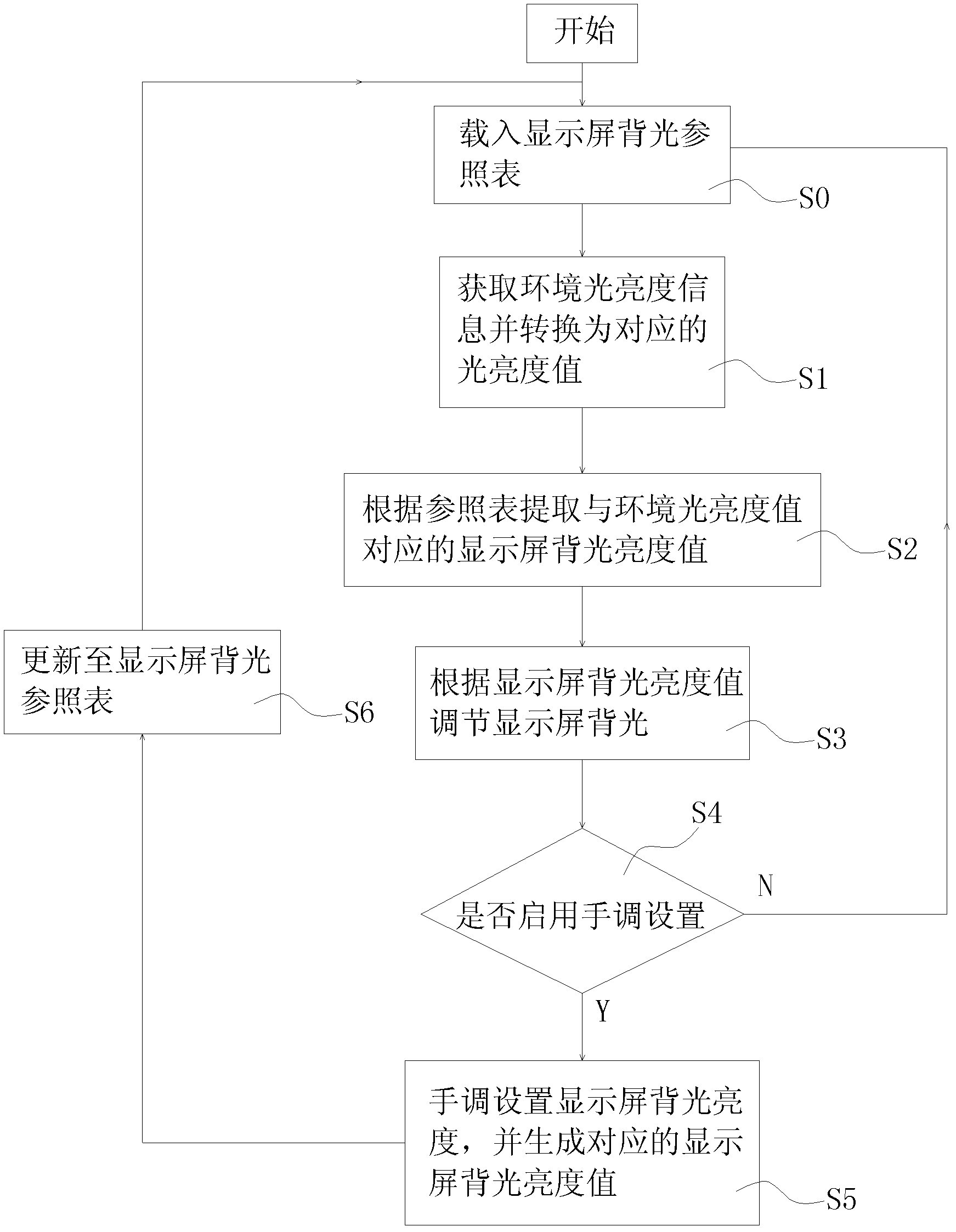

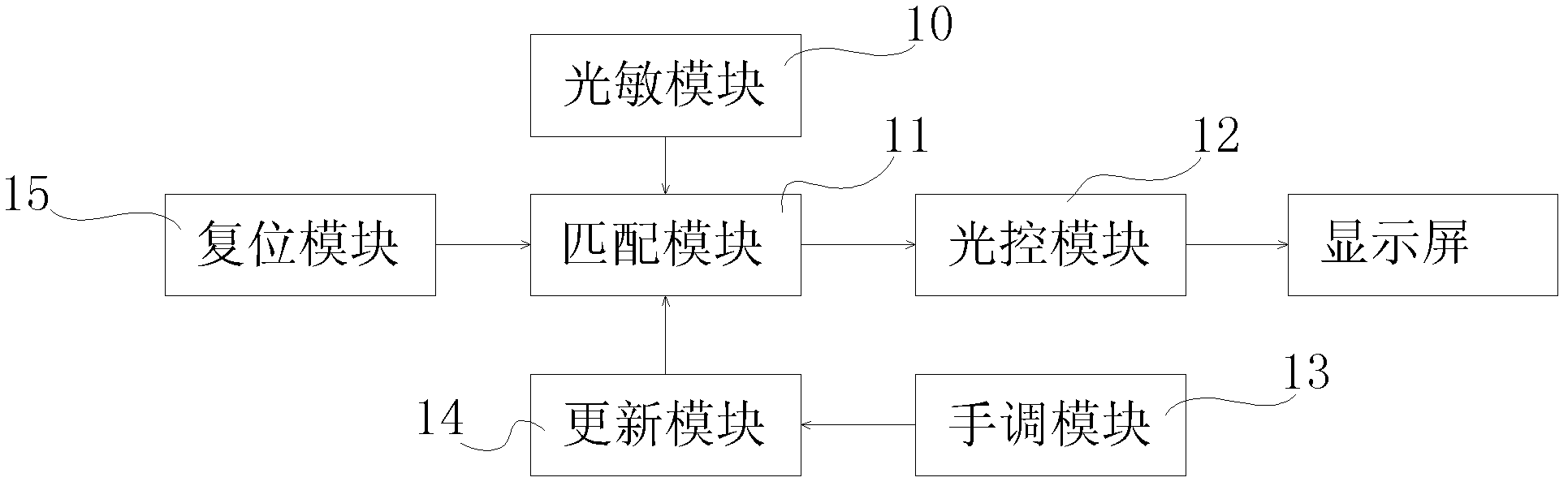

Intelligent regulation method for display screen backlight brightness and system for intelligent regulation method

InactiveCN102592547AMeet comfort requirementsImprove running-inStatic indicating devicesMan machineComputer science

The invention provides an intelligent regulation method for display screen backlight brightness, which is characterized by comprising the following steps of: presetting a reference table in which display screen backlight values and environment light brightness valves correspond; acquiring the current environment light brightness valve, and setting the display screen backlight value according to the reference table; when a user feels that the display screen backlight brightness is not proper, performing manual setting; and after confirmation is ended, updating the new display screen backlight value into the reference table and enabling the new display screen backlight value to correspond to the current environment light brightness valve. The invention also provides a system for implementing the method, which is characterized by comprising a photosensitive module, a matching module, a light control module, a manual regulation module and an updating module. According to the intelligent regulation method for the display screen backlight brightness, not only can the automatic regulation function of the display screen backlight brightness be utilized but also the personal requirements of different users can be met, and thereby, the man-machine running-in degree is increased, and the comfort requirements of the users on visual sensation can be met.

Owner:GUANGDONG BUBUGAO ELECTRONICS IND

Phosphating liquor of manganses series

InactiveCN101063199AGood stabilityLess sedimentMetallic material coating processesSoftened waterSodium nitrite

The invention discloses a manganese series liquid phosphide in surface chemical technical domain, which comprises the following steps: allocating with mass ratio as 2. 0-8. 0 phosphoric acid, 1-10 horse sun husband salt, 2-8 sodium nitrate, 0. 5-5 zinc nitrate, 3. 0-5. 0 nickel nitrate, 1-4 sodium nitrite, 0. 5-6 hydrogen dioxide solution and 45-60 softened water; getting the product. This invention can improve wear resistance and prolong durability of gear.

Owner:宋晨玮

Composite metal powder for sintered bearing, and sintered oil-retaining bearing

InactiveCN1241250AImprove running-inImprove corrosion resistanceTransportation and packagingShaftsSurface layerIron powder

Composite metal powder for sintered bearings, prepared by coating surface layers of particles of iron powder with 10 wt.% to less than 30 wt.% of copper based on the iron powder so that the particle size of the coated iron powder is at most 80 meshes, the content of the powder of at most 350 meshes is at most 30%, and the specific surface area of the powder is 450-750 cm<SP>2< / SP> / g according to the subsieve sizer method. This metal powder can provide an oil-retaining bearing for motors, which is capable of providing a low gas-permeability without decreasing the oil content and which has a low and constant coefficient of friction, a high corrosion resistance, a high adaptability and a high durability, readily at a low cost.

Owner:PORITE +1

Sliding component of compressor, sliding component base, scroll component, and compressor

ActiveCN101395377AHigh tensile strengthFull durabilityRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsHardnessEngineering

Owner:DAIKIN IND LTD

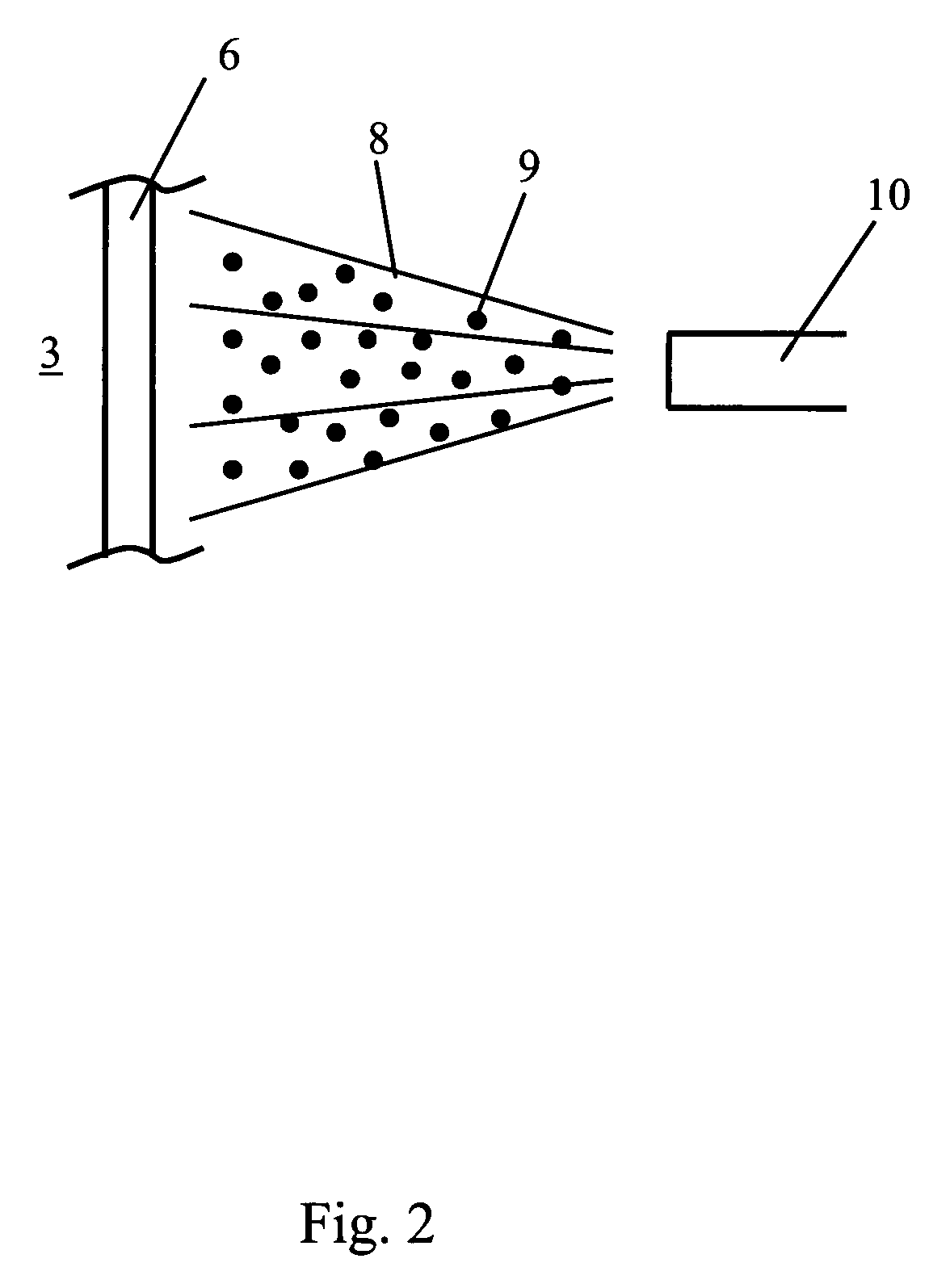

Blade tip coating that can be rubbed off

ActiveUS20120121431A1Increase flexibilityLow manufacturing expenditureMolten spray coatingPropellersPorous layerAlloy

The present invention relates to a method for producing a component, in particular a blade for a gas turbine, wherein a main body (2) is provided, to which a running-in layer (6) is applied, which can be worn away at least partially during operation to form an accurately fitting surface (11), wherein the running-in layer is applied by kinetic cold-gas compacting, and a component, in particular a blade for a gas turbine, comprising a main body, to which a running-in layer is applied, which can be worn away at least partially during operation to form an accurately fitting surface, wherein the running-in layer is a porous layer made of a Ti alloy.

Owner:MTU AERO ENGINES GMBH

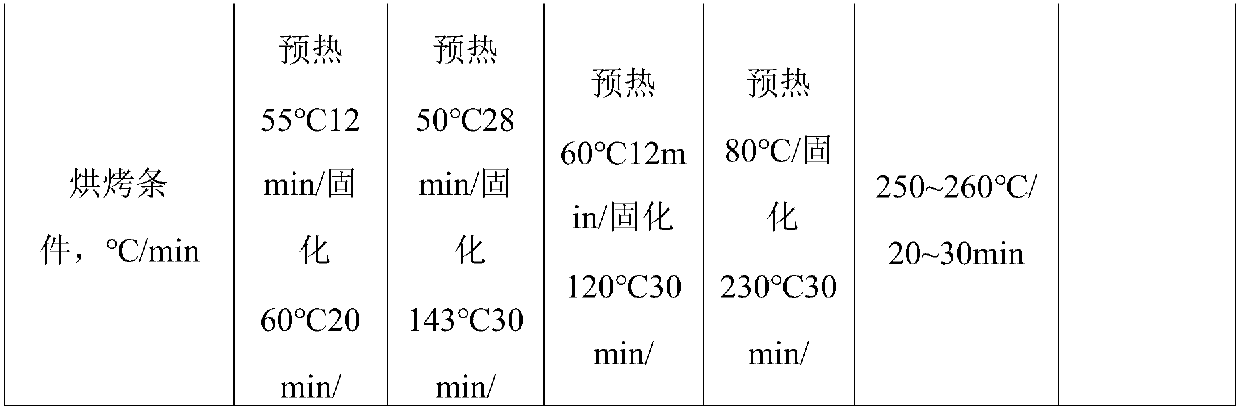

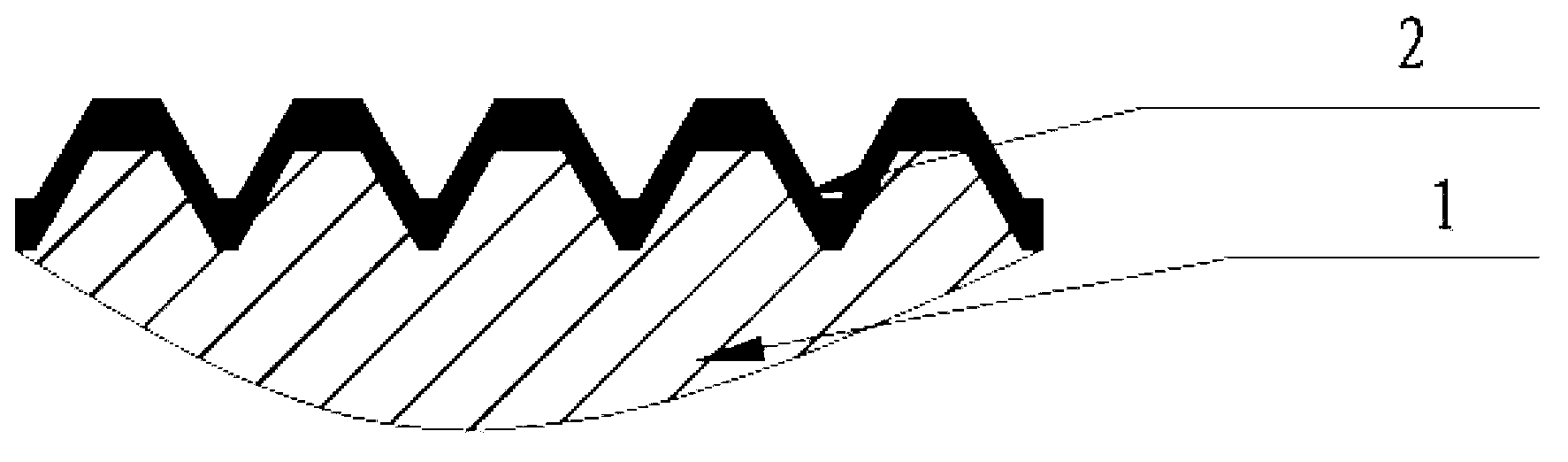

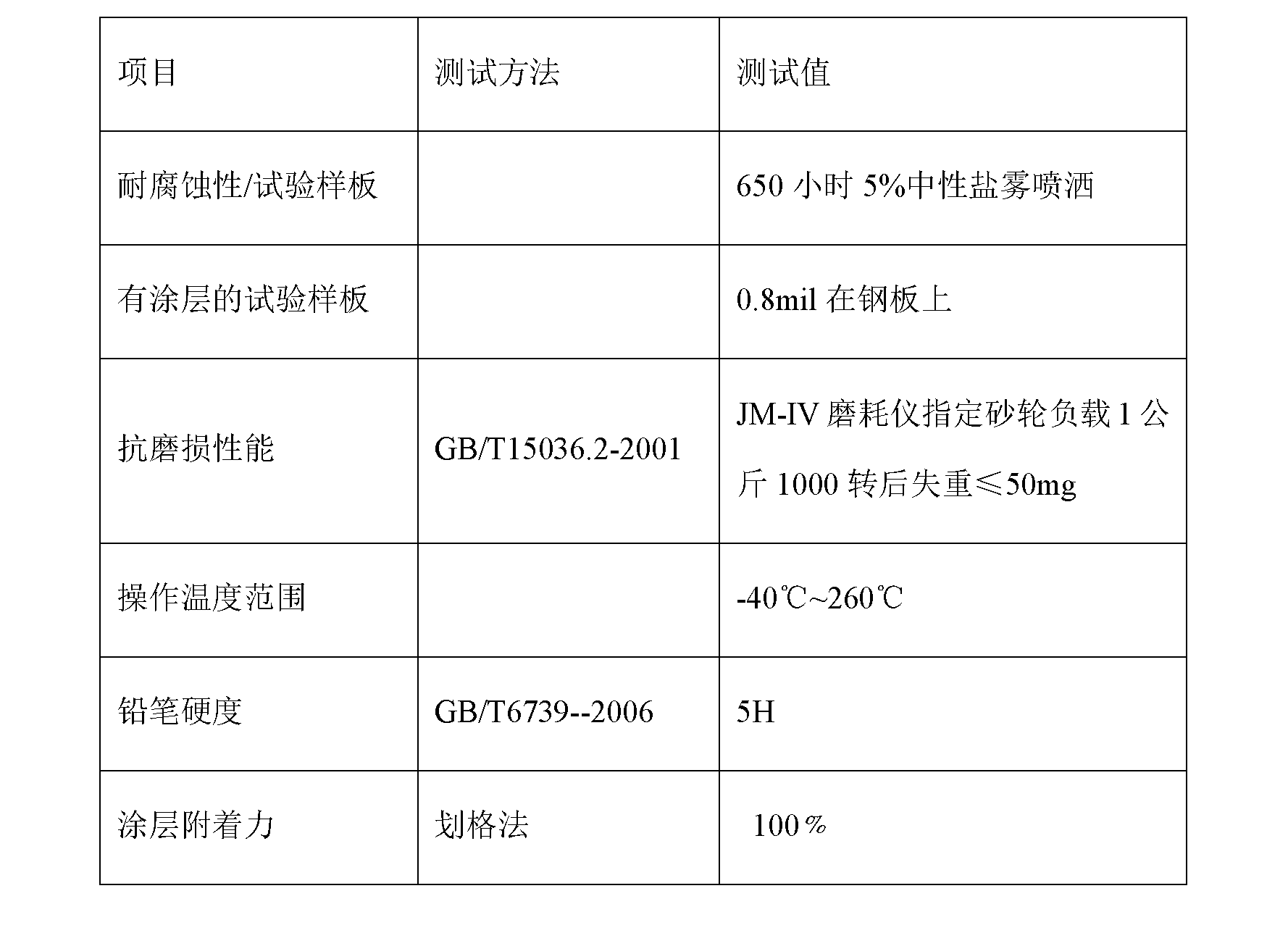

Processing technology for lubricating wear-resistant coating of bearing bush of engine

ActiveCN109248843ASolve environmental problemsImprove operational reliabilityPretreated surfacesEpoxy resin coatingsThermal sprayingWear resistant

The invention discloses a processing technology for a lubricating wear-resistant coating of a bearing bush of an engine. The processing technology comprises the steps of (1) pretreatment, wherein thesurface of the bearing bush is cleaned, after sand blasting treatment, the bearing bush is placed in a passivation pond for passivation treatment, and after passivation, the bearing bush is cleaned and dried; (2) pre-heating treatment, wherein after pretreatment, the bearing bush is placed in a drying oven and hated to 40-60 DEG C, and the temperature is preserved for 10-30 min; (3) spraying treatment, wherein the bearing bush is taken from the drying oven, and thermal spraying is conducted on the surface of the bearing bush by adopting the wear-resistant lubricating coating; (4) solidifying treatment, wherein the bearing bush is placed in the drying oven and heated to 120-160 DEG C for solidifying, and the solidifying time is 20-30 min; (5) packaging checking. According to the processingtechnology, a spraying mode is adopted for replacing a bearing bush electroplating mode, the environmentally friendly problem is solved, and the production cost is reduced; the processed lubricating wear-resistant coating of the bearing bush of the engine greatly improves the running reliability of the bearing bush of the engine, and the service life is long.

Owner:在邦润滑材料(上海)有限公司

Elementary powder sintered iron-copper-based oil-containing anti-friction material and preparation method thereof

The invention relates to an elementary powder sintered iron-copper-based oil-containing anti-friction material and a manufacturing method thereof. The anti-friction material is composed of the following raw materials in percentage by mass: 67%-71% of Fe, 28.4%-32.4% of Cu, 0.6% of Sn, and 0.7% of zinc stearate; the oil percentage in volume of the material is 17%-22%. The oil-containing anti-friction material adopts elementary iron and copper mixed powder, wherein iron powder is reduced iron powder, copper powder is mixed powder of electrolytic copper powder and atomized copper powder. The iron powder and the copper powder of the elementary iron and copper mixed powder are mixed uniformly, and thus the phenomenon of segregation due to different densities of iron powder and copper powder is avoided. The uniformly mixed powder is subjected to process operations of pressing, sintering, finishing, oil impregnation and the like to obtain the powder metallurgy iron-copper-based oil-containing anti-friction material with excellent properties. The oil-containing anti-friction material has the advantages that the raw materials adopt elementary mixed powder and are low in price; after sintering, the material is uniform in microstructure, free of segregation, and stable in property; the copper content is high, and the wear resistance is good; the material contains no lead, and meets environmental requirements; when the sintering temperature is 1040 DEG C, the wear resistance of the material even exceeds that of an iron-copper-based oil-containing anti-friction material prepared from pre-alloy powder.

Owner:SOUTHEAST UNIV

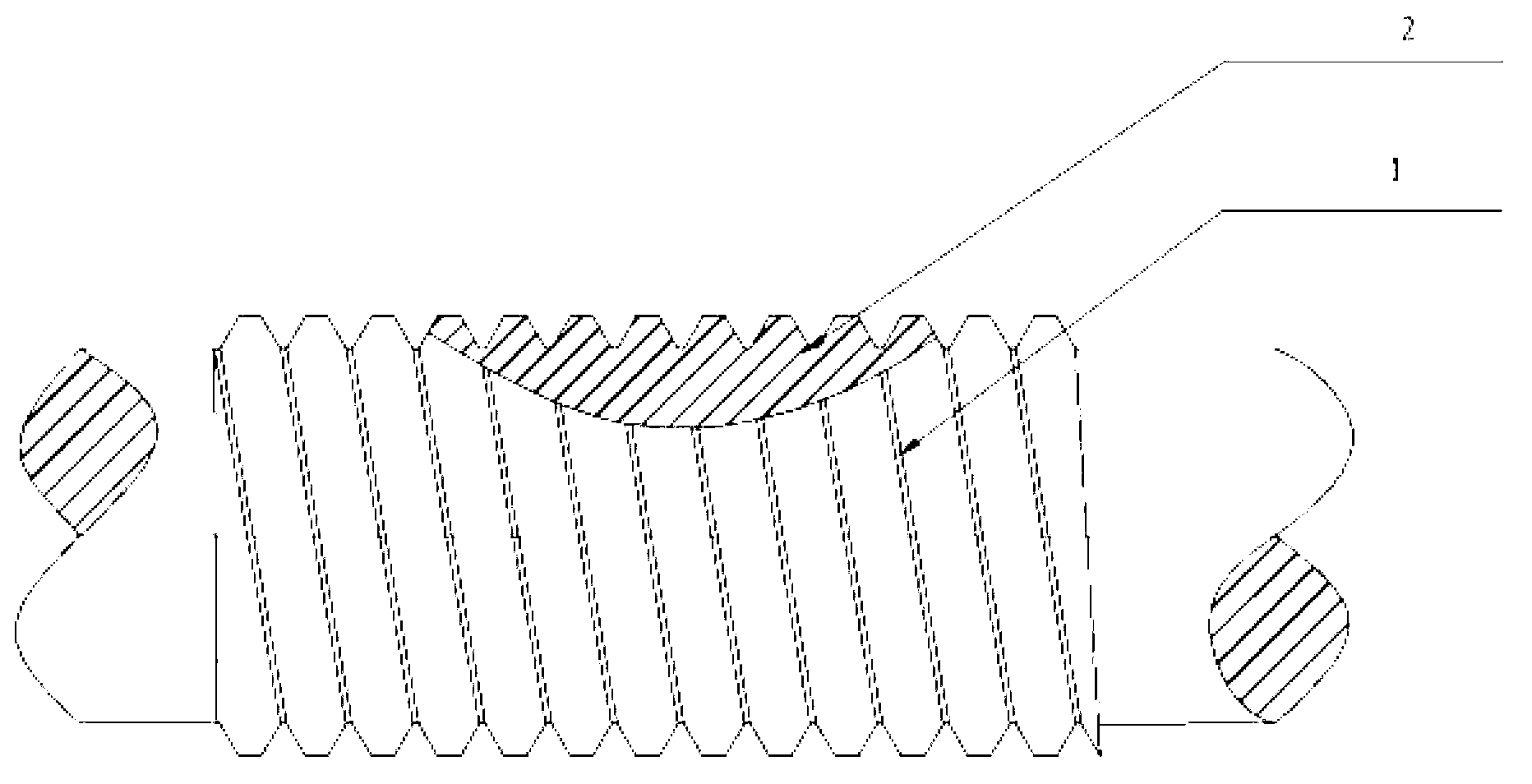

Automatic-door threaded rod and anti-friction coating thereof as well as spraying method of anti-friction coating

ActiveCN103214920AImprove the lubrication effectImprove wear resistanceSpecial surfacesEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an automatic-door threaded rod of a railway vehicle and an anti-friction coating thereof as well as a spraying method of the anti-friction coating. The dry film thickness of the anti-friction coating is 15-25 micrometers, the flashing point of the coating is 110 DEG C, and the specific gravity of the coating is 1200+ / -60g / L; and the coating comprises the following components in percentage by weight: 1-6% of molybdenum disulfide, 10-28% of graphite, 1-3% of graphite fluoride, 2-8% of tungsten disulfide, 0-3% of molybdenum diselenide, 1-3% of nanometer diamond, 1-5% of silicon nitride, 2-8% of aluminium oxide, 0-3% of silica, 0-2% of antimony trioxide, 3-15% of silicon carbide, 0-1.5% of carbon nanotube, 10-16% of polyester resin, 15-30% of epoxy resin, 6-20% of acrylic resin and 0-8% of powder surface treating agent. The automatic-door threaded rod of the railway vehicle, which adopts the anti-friction coating, has good self-lubrication and abrasion performance; the production process is simple; and the production cost is low.

Owner:SHANGHAI YILIN LUBRICATING MATERIAL

Alloy, in particular for a bearing coating

InactiveUS8147981B2Improve running-inImprove wear resistanceMolten spray coatingRolling contact bearingsAlloySolid solution

An alloy, in particular for an anti-friction coating, includes elements which form a matrix and at least a soft phase and / or a hard phase, which soft phase elements and / or hard phase elements form a solid solution or a bond with the matrix element. The soft phase and / or hard phase is dispersed in the matrix and the solid solution or bond is formed only in the region of the phase boundary of the matrix with the soft phase and / or with the hard phase.

Owner:MIBA SINTER AUSTRIA

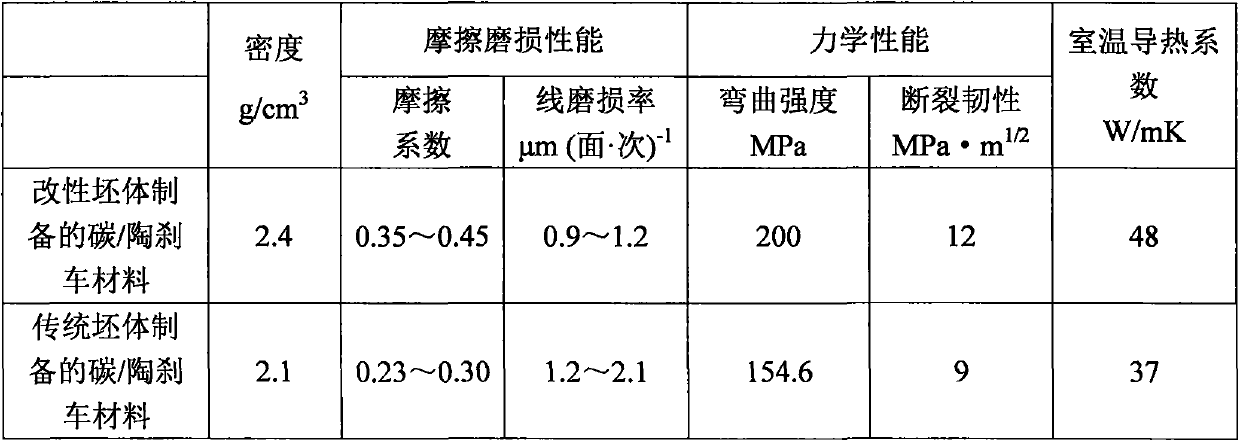

High-speed train carbon ceramic braking material manufacturing method

The invention relates to a high-speed train carbon ceramic braking material manufacturing method, which comprises: preparing a carbon fiber preform and a Ti3SiC2 slurry, carrying out vacuum pressure impregnation on the carbon fiber preform by using the Ti3SiC2 slurry, depositing pyrolytic carbon in the carbon fiber preform containing Ti3SiC2 ceramic powder by using propylene or natural gas as a reaction gas to obtain a low-density carbon / carbon composite material containing Ti3SiC2 ceramic powder, and carrying out liquid phase siliconizing on the prepared low-density carbon / carbon composite material to obtain the carbon ceramic braking material with characteristics of high Ti3SiC2 content and uniform distribution. According to the present invention, the prepared material has advantages ofhigh toughness, high thermal conductivity, high-temperature resistance, oxidation resistance and good friction and wear property; and the method has advantages of simple process and good reproducibility, and is suitable for mass production.

Owner:山西西沟龙鼎新材料集团有限公司

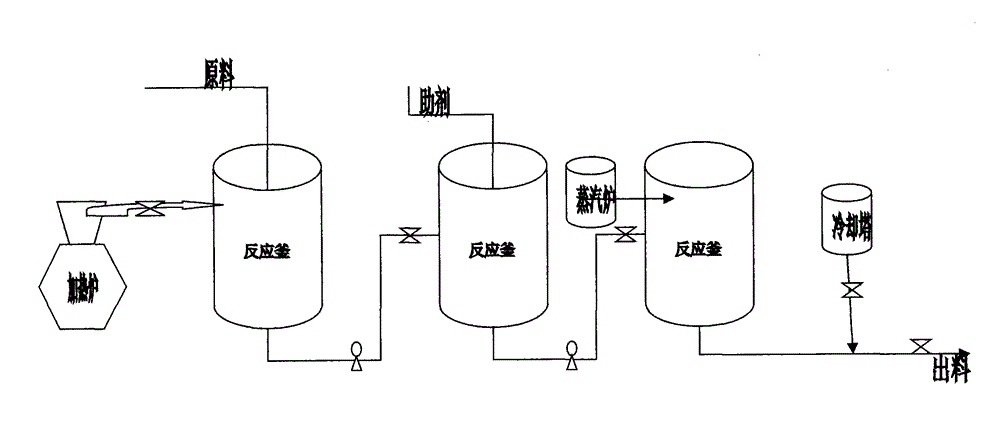

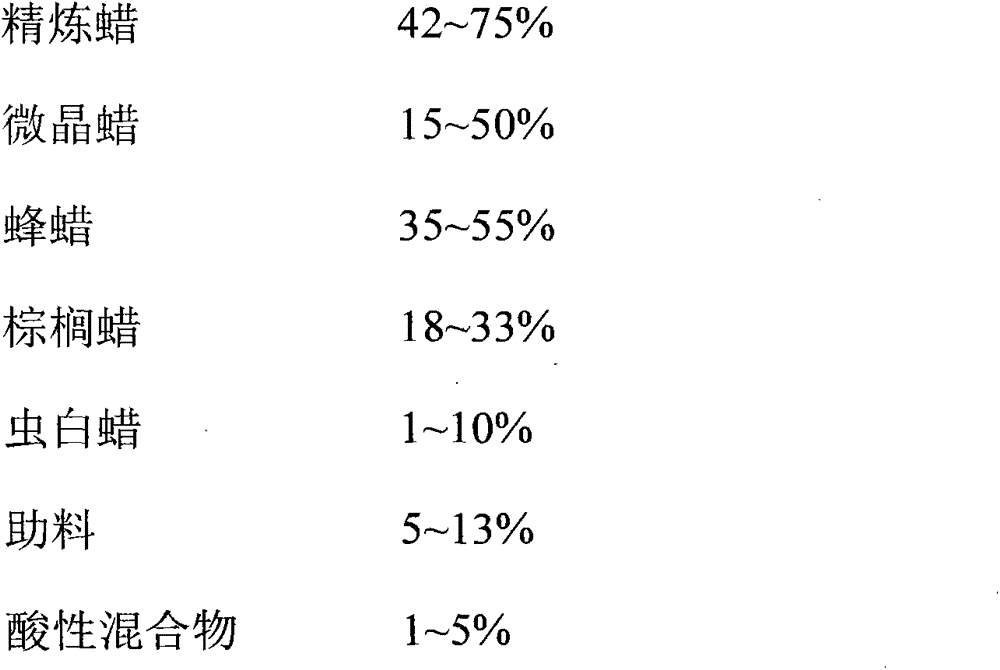

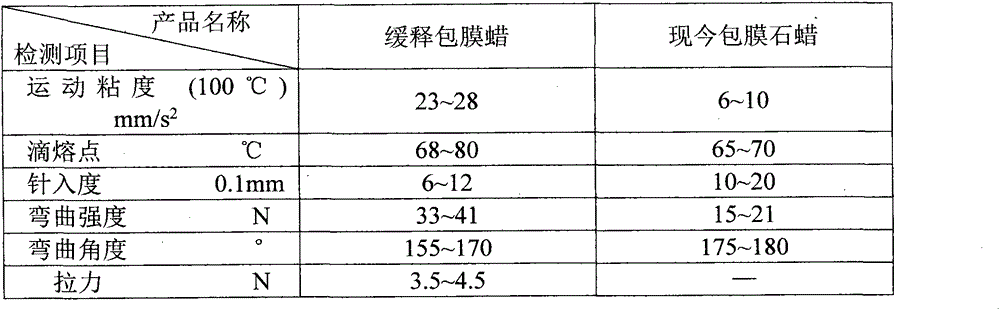

Slow release coated wax of efficient slow release composite fertilizer

InactiveCN104003784AAdjustable and controllable drop melting pointNo damage to technical indicatorsFertilizer mixturesMicrocrystalline waxUltimate tensile strength

The invention relates to a slow release coated wax of an efficient slow release composite fertilizer. The slow release coated wax of an efficient slow release composite fertilizer is glistened particles, and is prepared through a reaction of main raw materials comprising 42-75wt% of refined wax, 15-50wt% of microcrystalline wax, 35-55wt% of beeswax, 18-33wt% of palm wax and 1-10wt% of Chinese insect wax, and substances comprising an additive, an assistant, a biodegradation promotion substance, an acidic mixture and an organic material at 95-105DEG C for 20-40min. The slow release coated wax of an efficient slow release composite fertilizer has the advantages of simple preparation, wide raw material sources, good toughness and strength, good slow release effect in soil, neutralization of alkaline soil, and no pollution to the environment.

Owner:DALIAN NINGHUA MICROCRYSTALLINE WAX CHEM

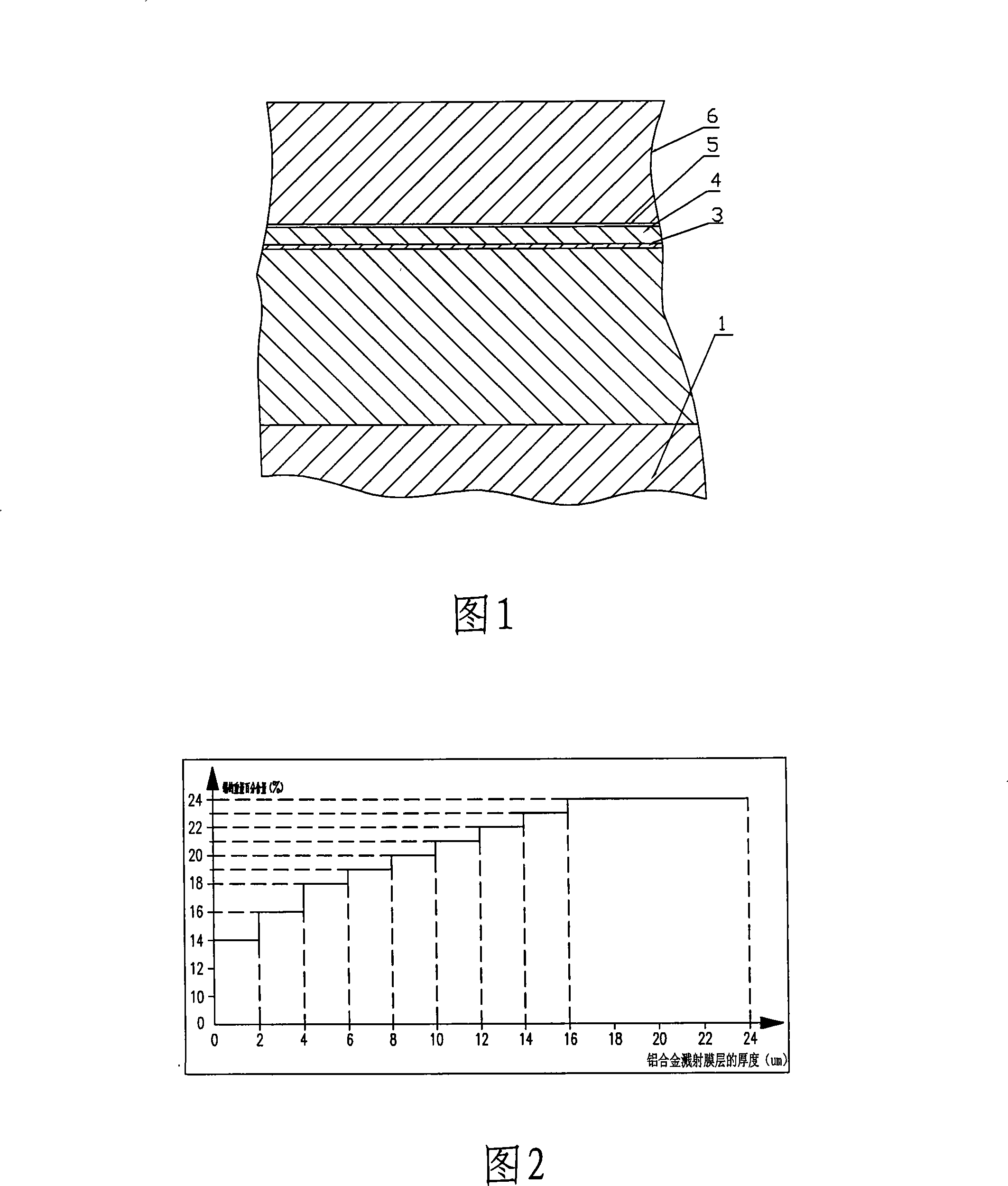

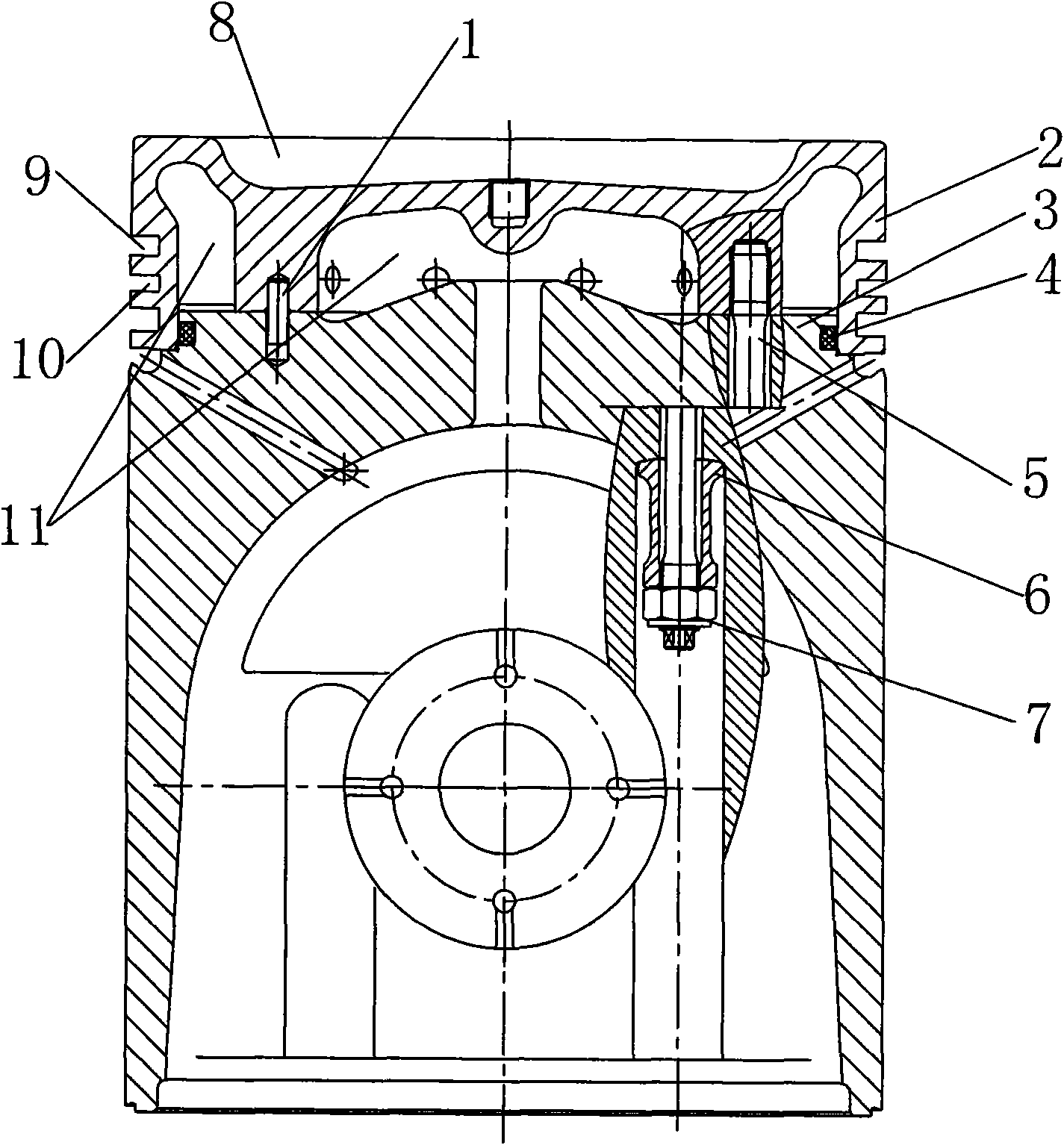

Method for preparing tin content step-up PVD bushing in antifriction layer

InactiveCN101215685AImprove carrying capacityImprove running-inVacuum evaporation coatingSputtering coatingSputteringSurface layer

The invention relates to a method for preparing a PVD bearing whose tin content is increased in a friction reducing layer. After a Ni gate layer is sputtered on the bearings, first the bearings are smelted into massive alloy in a vacuum melting furnace then is pressed to form, after cooling, and the bearings are assembled into a target. Aluminum alloy target and a bearing base are arranged in a sputtering chamber, the vacuum degree of the back bottom of the sputtering chamber is Pa, the working gas is argon, sputtering pressure, sputtering power, base temperature of the sputtering chamber are adjusted, then the absolute value of the contingent negative bias is decreased from 460-520V to 100-160V in four hours, the tin content in a sliding layer is ascended from a bottom layer to a surface layer in a cascade. The PVD bearing with the distribution has the carrying capacity which is reached to 70-100N / mm2, and has excellent ant-plastering performance or running-in characteristic. The conformability and adaptability are very important particularly in a beginning period of running a diesel engine, and the PVD bearing which is provided by the scheme is rightly capable of meeting the demands.

Owner:CHONGQING YUEJIN MACHINERY

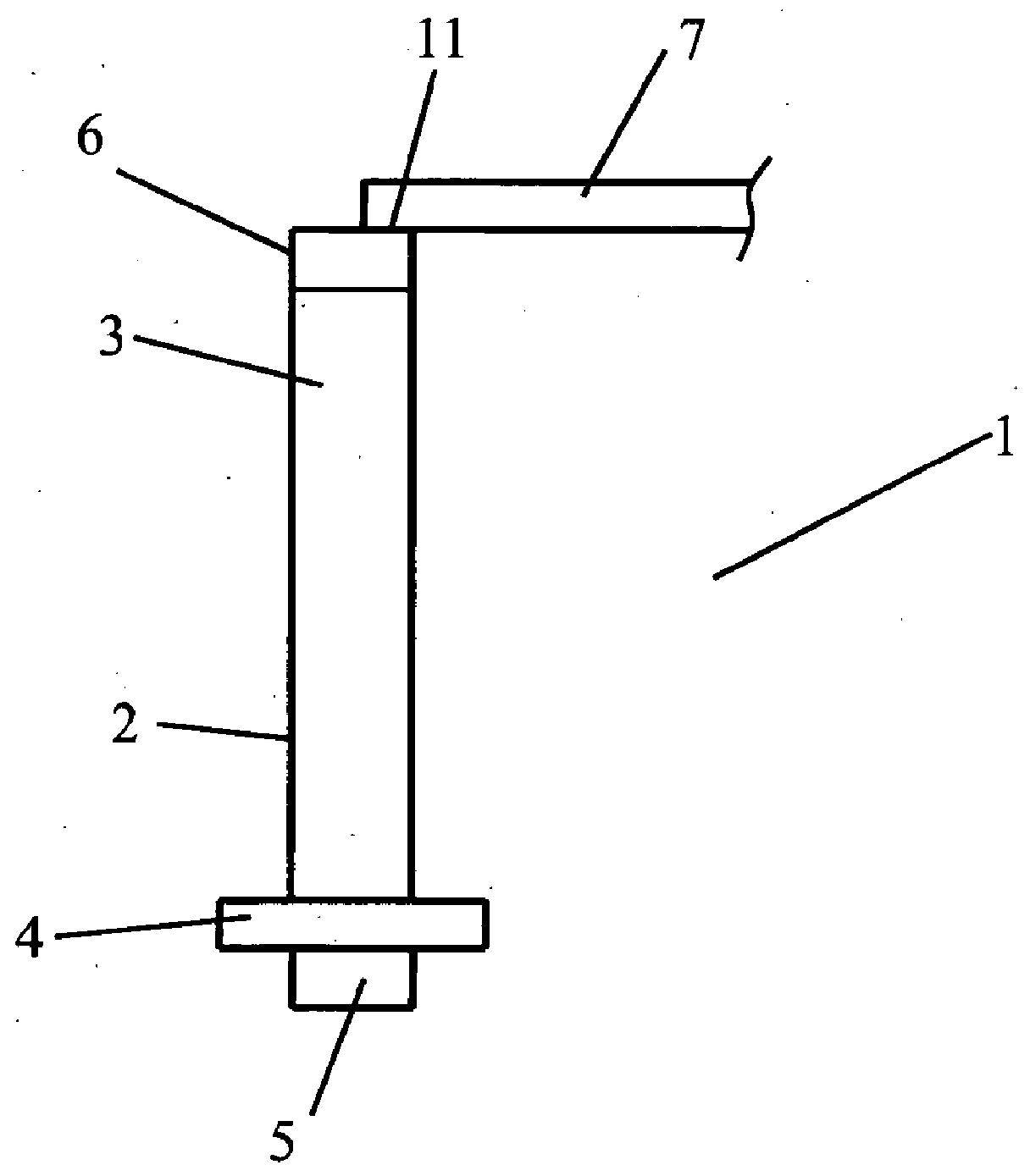

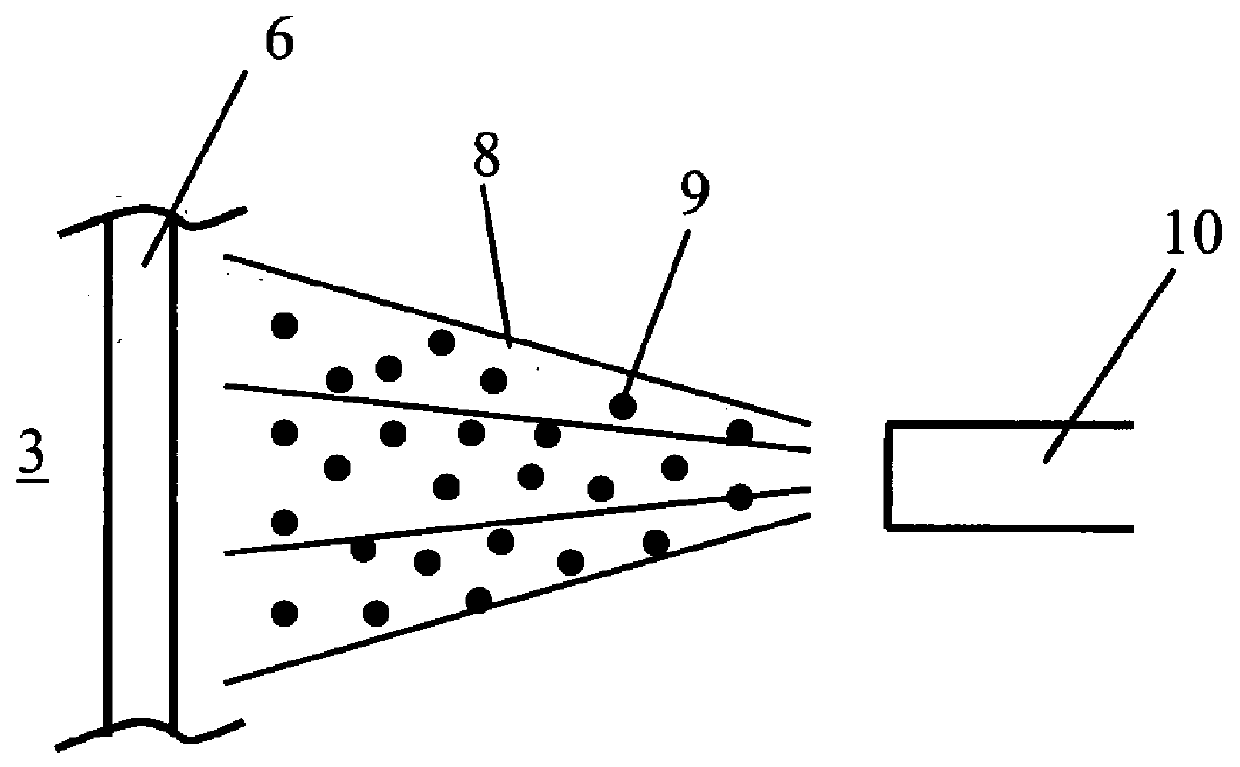

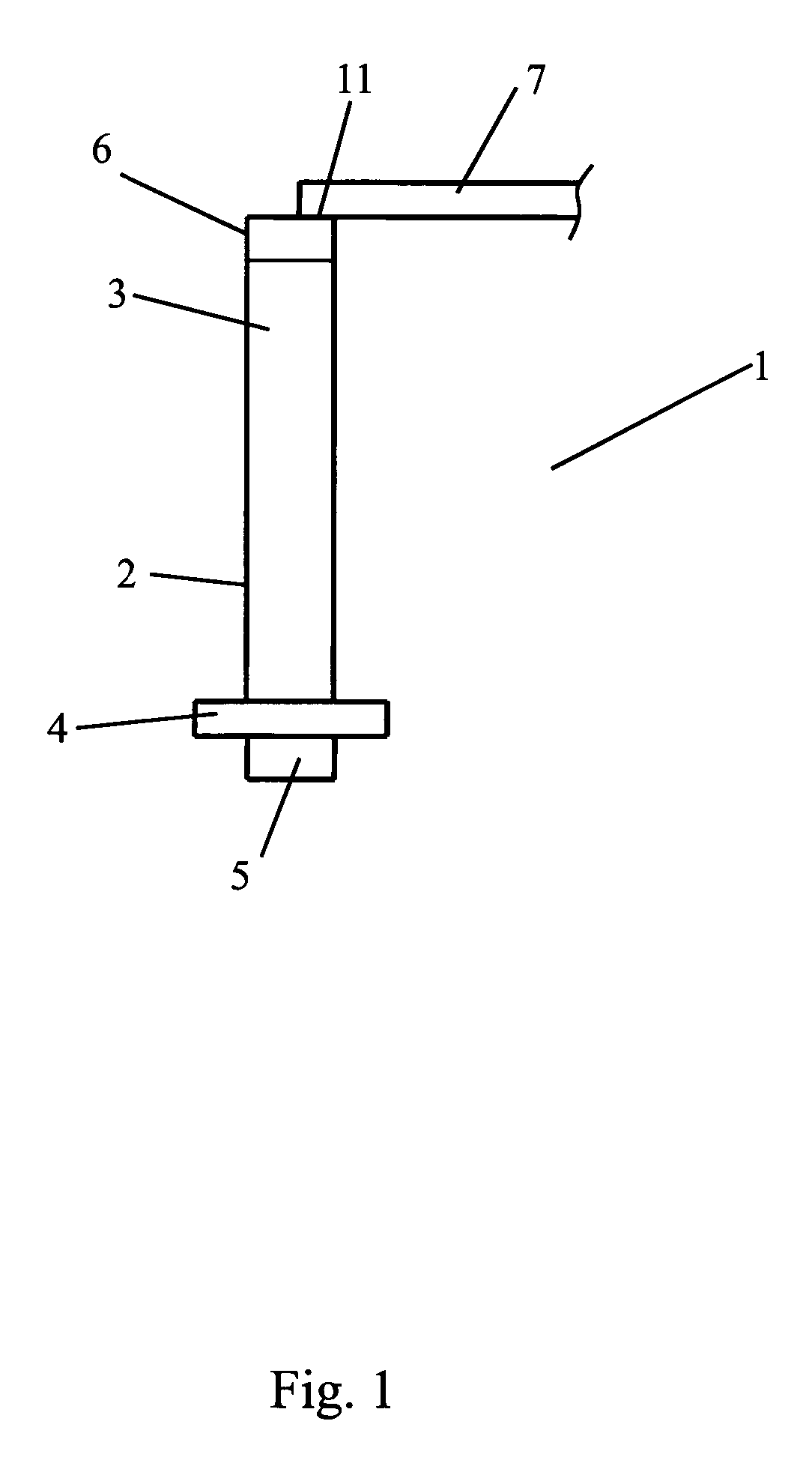

Piston with steel top and aluminum skirt for 230SG type gas engine

InactiveCN101929404AHigh strengthExtended service lifeMachines/enginesPistonsEngineeringCircular face

The invention discloses a piston with a steel top and an aluminum skirt for a 230SG type gas engine. The piston comprises a steel piston top [2] and an aluminum skirt body [3] which is coaxially connected with the piston top [2] to form the piston, the upper end of the skirt body [3] is provided with a short column with the diameter smaller than the diameter of the skirt body [3], a connection end of the piston top [2] and the skirt body [3] is provided with an inner bore matched with the short column in diameter, the sleeved connection of the piton top [2] is realized through the matching of the inner bore and the short column, a sealing ring [4] is arranged between the short column and the inner bore, the piston top [2] is integrated with the skirt body [3] into a whole through the matching of a bolt [5] and a nut [7], the upper part of the piston top [2] is provided with a groove [8] sinking inwards, and the external circular face of the piston top [2] is provided with two gas ring grooves [9] and an oil ring groove [10]. The invention has long service life without power reduction.

Owner:TONGLING JINGHENG MACHINERY

Preparation method of friction material with good running-in performance

ActiveCN102796268AImprove running-inPlay the role of fixed lubrication componentsOther chemical processesAcrylonitrileSilicon dioxide

The invention discloses a preparation method of a friction material with good running-in performance. The friction material comprises the following components: 16-18 parts by weight of a butadiene-acrylonitrile modified phenol-formaldehyde resin, 2-3 parts by weight of an aramid fiber, 3-5 parts by weight of a copper fiber, 7-9 parts by weight of a vermiculite fiber, 5-7 parts by weight of a calcium carbonate crystal whisker, 3-5 parts by weight of a 60-150 mesh silicon dioxide, 3-5 parts by weight of a 200-320 mesh aluminium oxide, 2-4 parts by weight of a colloid supramoly, 6-8 parts by weight of a 120 mesh scale graphite, 3-5 parts by weight of a 200 mesh antimony sulfide powder, and 10-12 parts by weight of a 200 mesh light calcium carbonate. The preparation method comprises the following steps: preparing the raw materials, feeding the raw materials except the scale graphite and the colloid supramoly into a mixer to be mixed for about 4-6 hours, feeding the two kinds of the scale graphite and the colloid supramoly into the mixer to be mixed with the above mixture for 3-5 hours; hot compacting the mixture under a compacting pressure of about 26-28MPa at a temperature of about 170-180 DEG C and at a compacting speed of about 0.1-0.2 mm / second, and performing exhaust in the middle; and finally controlling the mixture at a constant temperature of 160-180 DEG C for about 8-10 hours.

Owner:临泉县联正电子商务有限公司

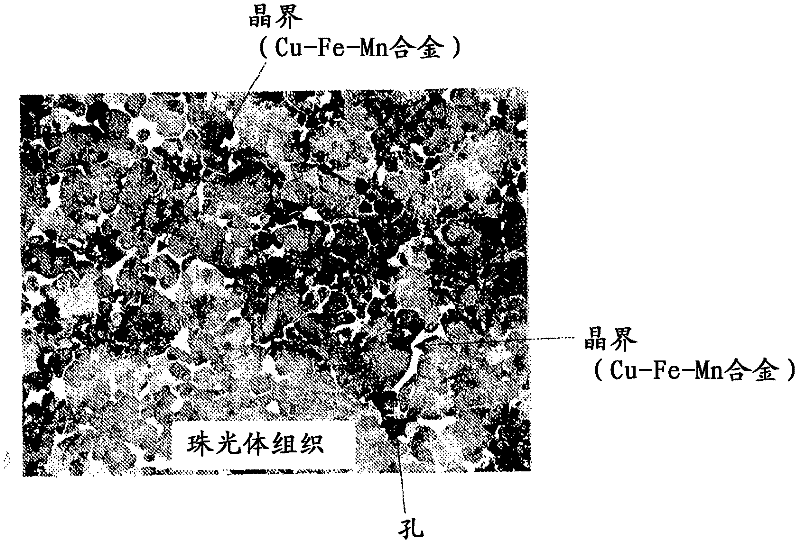

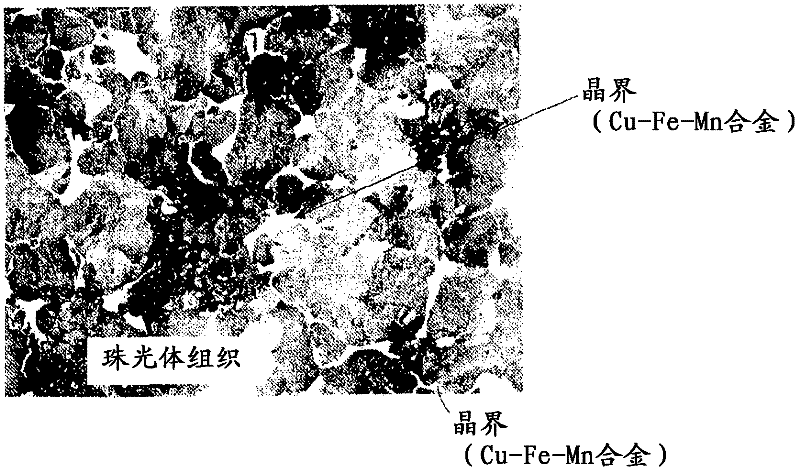

Iron-based sintered sliding member, and process for production thereof

Disclosed are: an iron-based sintered sliding member, in which the precipitation of free cementite in the structure does not occur, and which has excellent sliding properties including friction and abrasion; and a process for producing the sliding member. An alloy powder in an amount of 3 to 20 mass% and a carbon powder in an amount of 1 to 5 mass% are added to and mixed with an iron powder which is the main component to produce a mixed powder, wherein the alloy powder contains 4 to 6 mass% of manganese and 3 to 5 mass% of iron, with the remainder being copper. The mixed powder is filled in a mold to form a compressed powder having a desired shape. The compressed powder is sintered at a temperature of 1000 to 1100 DEG C for 60 minutes in a heating furnace which has been adjusted to a neutral or reductive atmosphere.

Owner:OILES CORP

Blade tip coating that can be rubbed off

ActiveUS9260784B2Increase flexibilityLow manufacturing expenditureLiquid surface applicatorsMolten spray coatingPorous layerAlloy

The present invention relates to a method for producing a component, in particular a blade for a gas turbine, wherein a main body (2) is provided, to which a running-in layer (6) is applied, which can be worn away at least partially during operation to form an accurately fitting surface (11), wherein the running-in layer is applied by kinetic cold-gas compacting, and a component, in particular a blade for a gas turbine, comprising a main body, to which a running-in layer is applied, which can be worn away at least partially during operation to form an accurately fitting surface, wherein the running-in layer is a porous layer made of a Ti alloy.

Owner:MTU AERO ENGINES GMBH

Method for Gas Carbonitriding

ActiveCN104711509AImprove running-inReduce stress peaksSolid state diffusion coatingMachineProtection layer

A method of forming a wear protection layer for a machine component that forms a slide pairing with a further machine component includes gas-carbonitriding at least one of the machine components in order to minimize wear. The gas-carbonitriding includes forming a thin uniform bonding layer and a comparatively thick diffusion layer thereunder. The gas-carbonitriding is performed at a low temperature and for a long duration.

Owner:ROBERT BOSCH GMBH

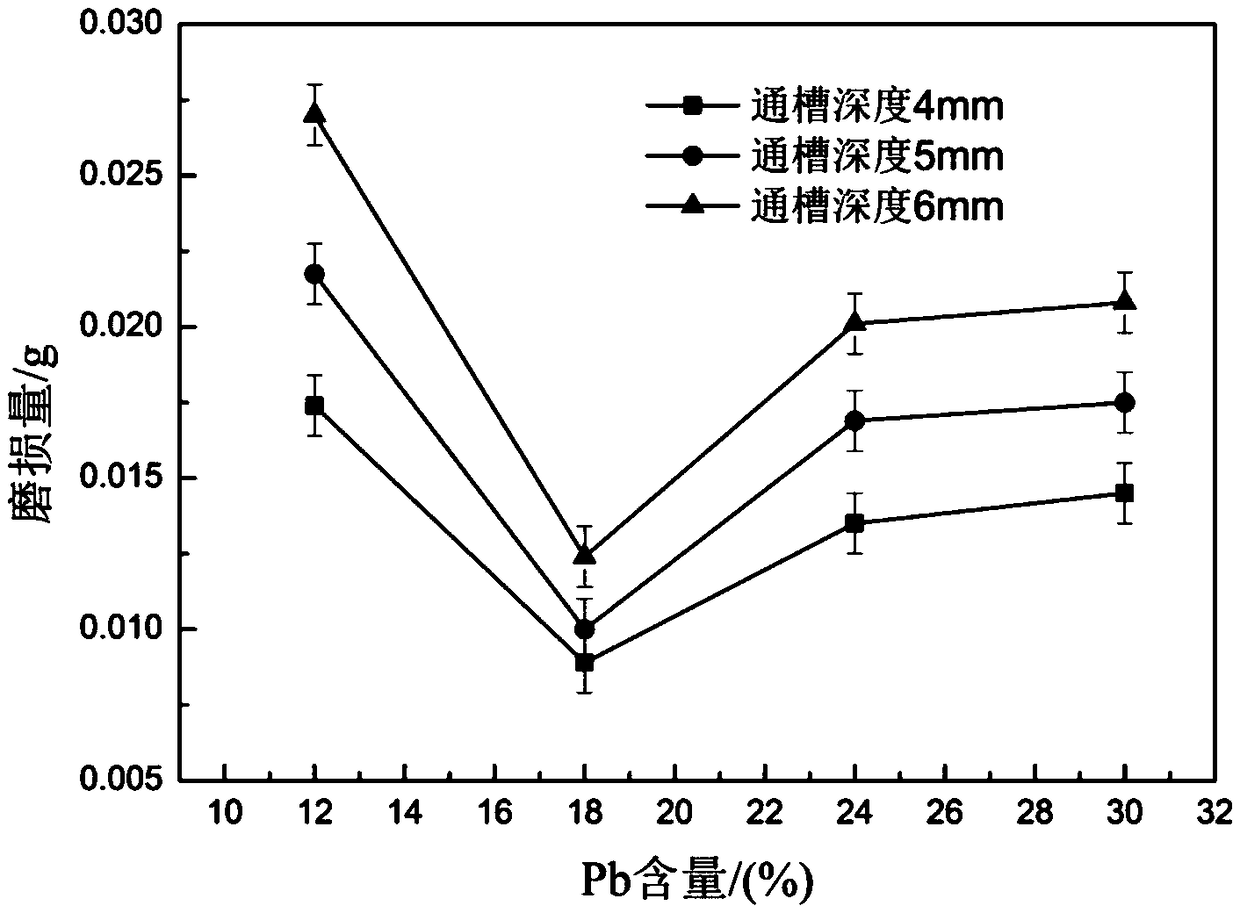

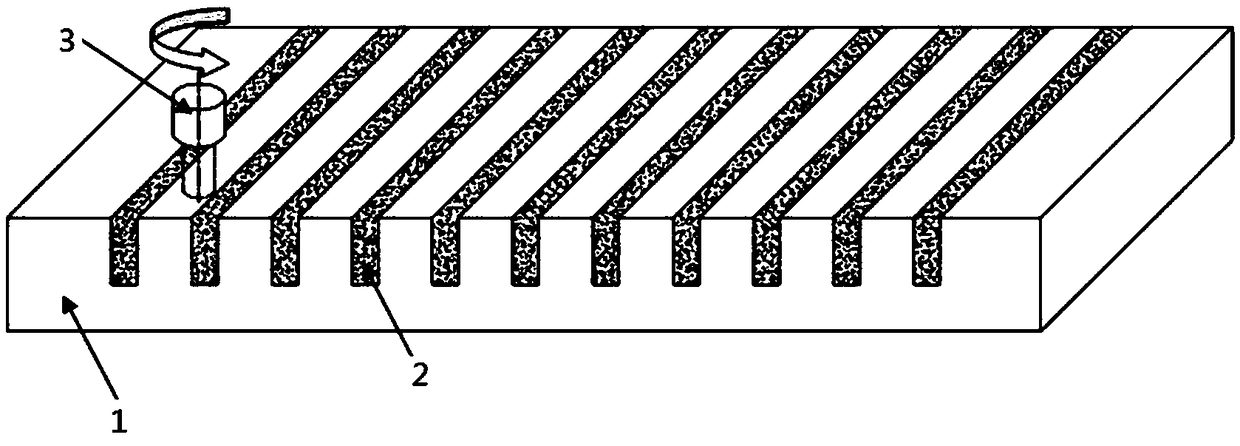

Al-Pb alloy wear resistant layer preparation method based on friction stir processing

ActiveCN109048037AImprove running-inImprove segregationNon-electric welding apparatusNeedle freeWear resistant

The invention discloses an Al-Pb alloy wear resistant layer preparation method based on friction stir processing, comprising the steps of: forming a straight slot in the surface of an aluminum plate,filling lead powder in the straight slot; pressing the end face of the stirring head into the surface of the aluminum plate base body with a little of depth by using a needle-free stirring head, , sealing the opening of the straight slot filled with lead powder with a rotating action of the stirring head, so as to prevent phenomenon of lead liquefying and the overflow when the needle stirring headis directly used for stirring; forming an Al-Pb alloy wear resistant layer on the surface of the aluminum plate by adopting the needle stirring head for stirring and friction stir processing. According to the Al-Pb alloy wear resistant layer preparation method based on friction stir processing, with the friction stir processing, pure aluminum becomes to have thermoplasticity by rapid rotation ofthe stirring head a stirring head , and lead particles are liquefied and sufficiently stirred into a pure aluminum matrix; the cooled lead is embedded within the aluminum matrix with larger sized particles, a minor amount of "Pb wrapping Si" microstructures that improves the abrasive resistance of aluminum lead alloy are formed, so that the segregation problem caused by large specific gravity difference of the aluminum lead is improved to a certain extent, the material can be used for bearing bush of automobile.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

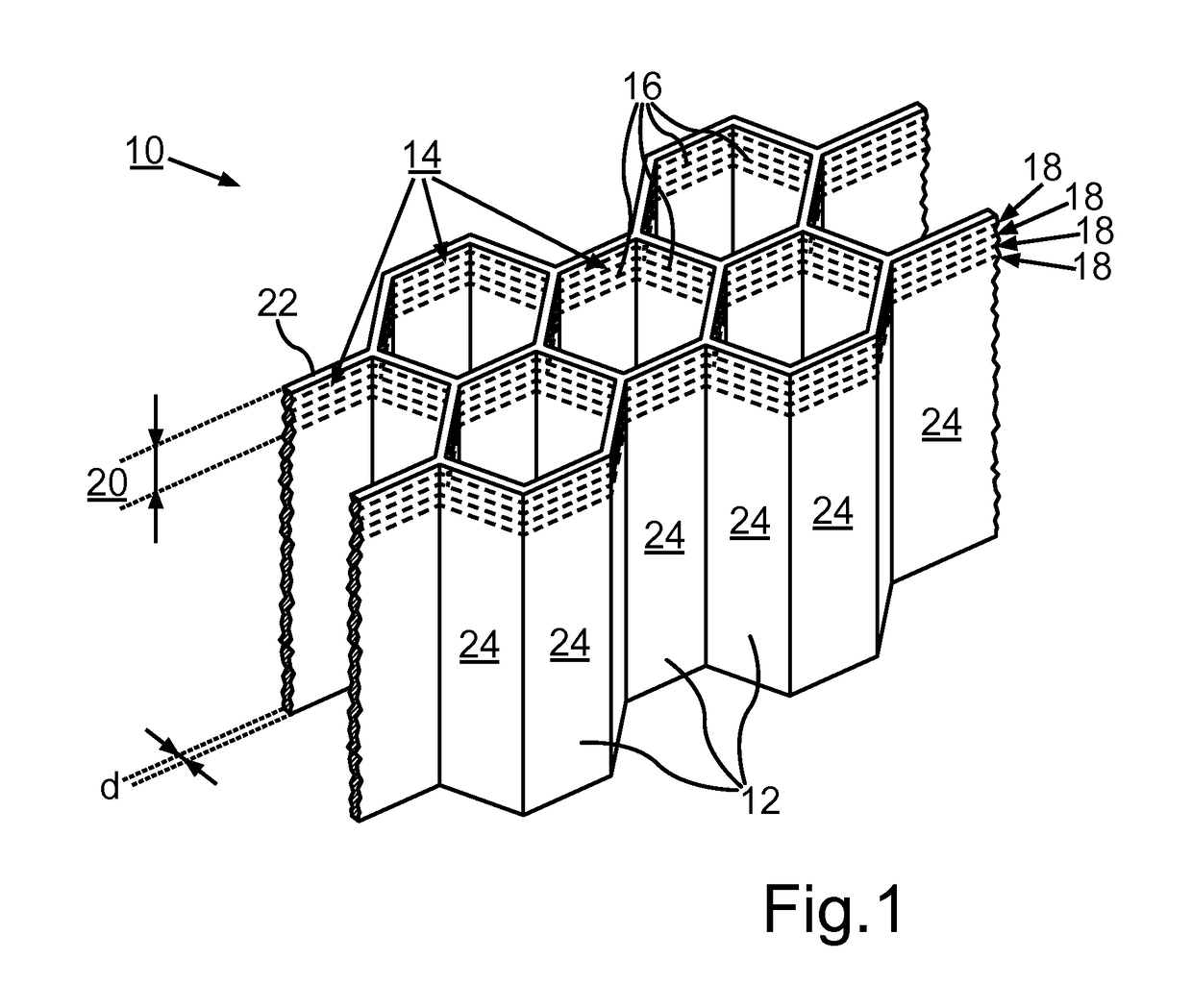

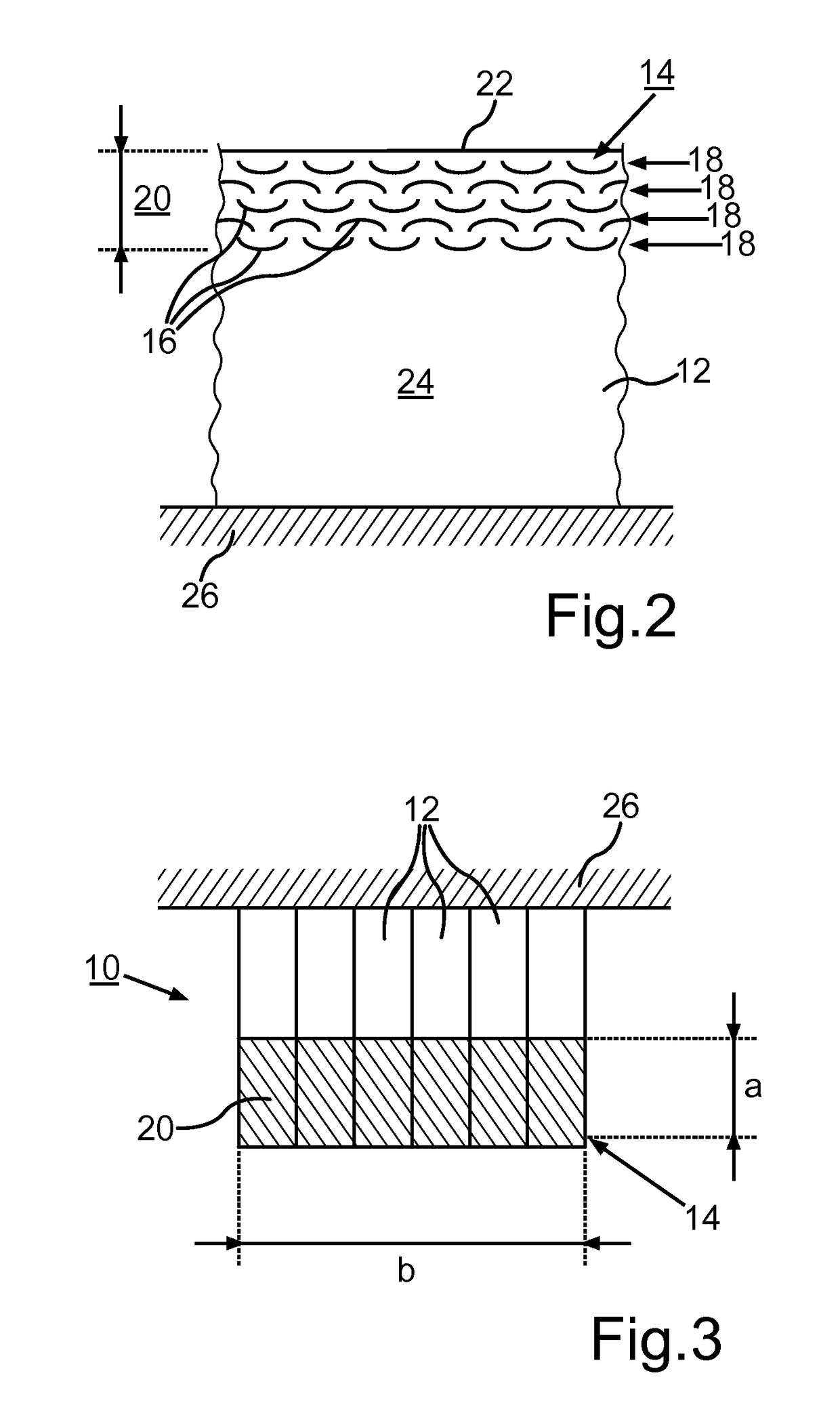

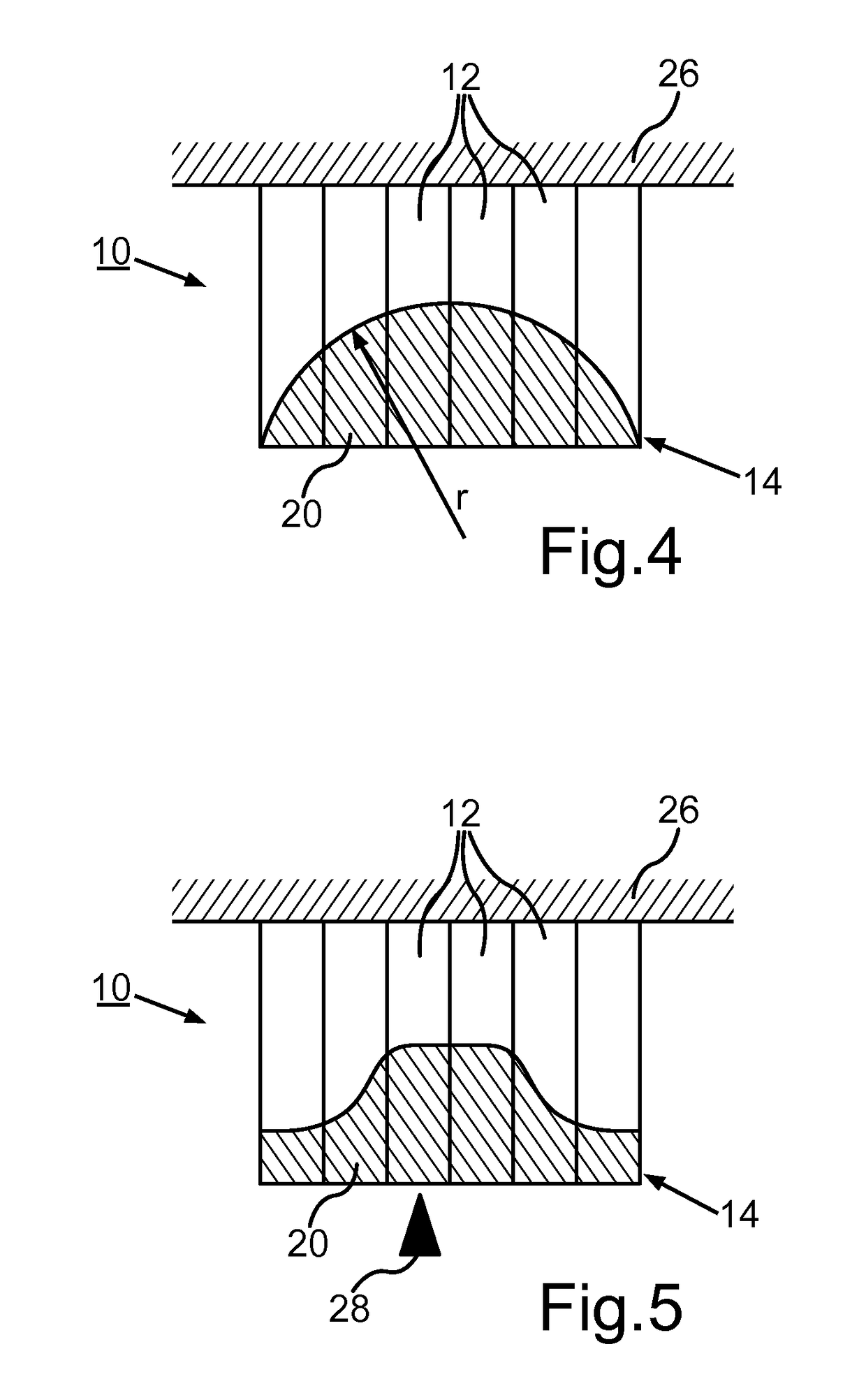

Seal, method for producing a seal and turbomachine

ActiveUS10184346B2Simple sealing structureImprove running-inTurbinesAdditive manufacturing apparatusEngineeringMechanical engineering

The invention relates to a seal (10) for sealing a gap between a stationary component and a moving component, in particular for sealing a radial gap between a rotor and a stator of a turbomachine, comprising at least one sealing segment (12) with an edge zone (14) facing the gap, whereby the seal (10) is produced layer-by-layer by a free-forming method, in particular a generative or additive method. A plurality of pre-defined weak regions (16) is formed in the edge zone (14) of the sealing segment (12). In addition, the invention relates to a method for producing a seal (10) as well as a turbomachine.

Owner:MTU AERO ENGINES GMBH

Technology of utilizing liquid-solid rolling cladding method to prepare bimetallic bearing

InactiveCN104690555AGood compressive and tensile mechanical propertiesGood fatigue strengthOther manufacturing equipments/toolsSliding contact bearingsComposite strengthZinc

The invention discloses a technology of utilizing a liquid-solid rolling cladding method to prepare a bimetallic bearing. According to the technical scheme, the technology comprises the following steps: adopting the liquid-solid rolling cladding method combining a casting method with a composite method; directly pouring zinc-based aluminum alloy molten metal to a base metal; cooling, solidifying and rolling by water cooled rolls to produce a composite board without larger plastic deformation. The technology disclosed by the invention has the characteristics as follows: the bimetallic bearing alloy prepared by the technology is excellent in compression resistance, tension resistance, mechanical property, friction performance, high-temperature stability performance and casting property; meanwhile, the liquid-solid rolling cladding method is a near net-shape processing method organically combining the hot dip aluminum plating with aluminum alloy cast rolling, so that the method is high in combined strength, low in production cost, less in equipment investment, high in production efficiency, low in energy consumption and high in composite board binding strength, and further has a good market prospect.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

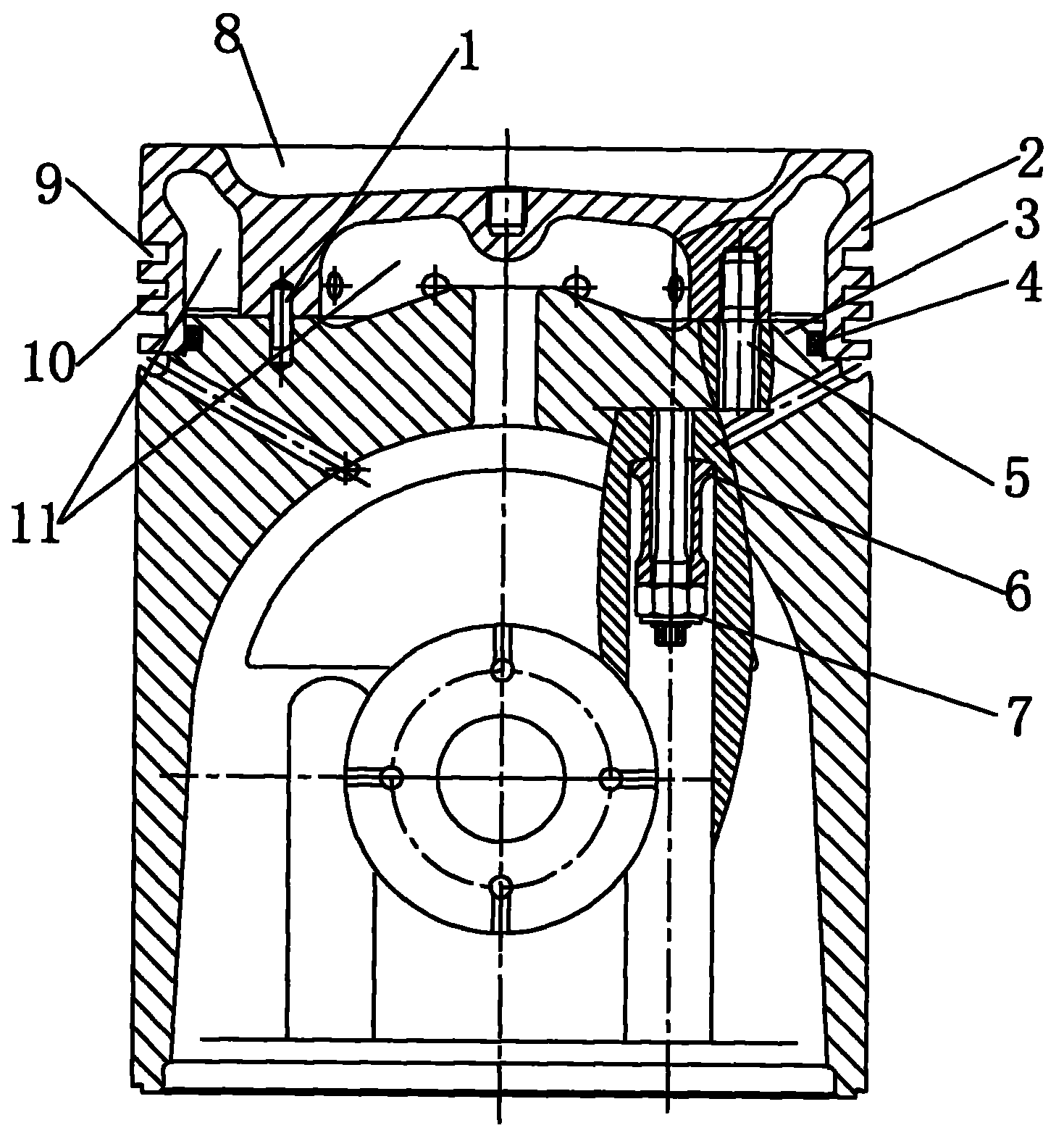

Piston type air cylinder

InactiveCN102996414AGood sealing performanceGood running-in performancePositive displacement pump componentsPositive-displacement liquid enginesRadiation propertiesCylinder block

The invention discloses a piston type air cylinder, comprising a cylinder body, a piston and a piston rod, wherein three annular grooves are arranged in the piston; a piston ring is mounted inside the first annular groove; oil scraping rings are mounted inside the second annular groove and the third annular groove; arc bumps in contact with the inner wall of the air cylinder are arranged on the outer edge face of the piston ring; and the oil scraping ring mounted inside the third annular groove is a three-petal type oil scraping ring. According to the scheme provided by the invention, the three annular grooves are arranged in the piston, and the piston ring provided with the arc bumps is mounted inside the first annular groove, so that one line in contact with the air cylinder can be kept when the piston is tilted. Therefore, the sealing property is good; the air cylinder is difficult to scrap; the grinding-in property is good; and the oil scraping rings are mounted inside the second annular groove and the third annular groove, and the three-pedal type oil scraping ring is mounted inside the third annular groove, so that an oil scraping effect is improved, and the heat radiation property is enhanced.

Owner:王伏南

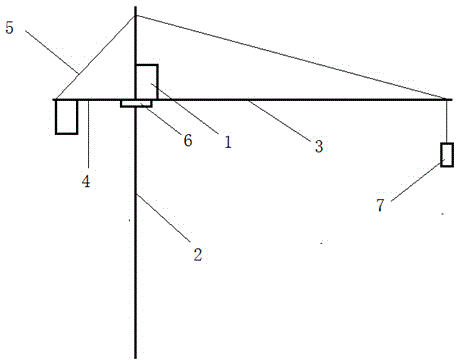

Multifunctional fixed crane

ActiveCN104555753AIncrease negative impactImprove running-inLoad-engaging elementsCranesEngineeringTower

The invention discloses a multifunctional fixed crane. The multifunctional fixed crane comprises a lifter operating room, a tower body, an arm frame, a balancing arm, a lifting mechanism, a swing mechanism and a multifunctional self-adaptive lifting hook assembly, wherein the lifter operating room is arranged at the top end of the tower body; the arm frame and the balancing arm are perpendicular to and connected with the tower body which vertically stands on the ground; the lifting mechanism is connected with the arm frame and the lifter operating room; the swing mechanism is arranged at the top end of the tower body and the bottom of the lifter operating room; the multifunctional self-adaptive lifting hook assembly is connected with the lifting mechanism. Through the manner, the multifunctional fixed crane provided by the invention has the advantages that the multifunctional self-adaptive lifting hook assembly comprises special lifting hooks which are connected with steel wire ropes in a hanging manner to complete loading and unloading operation, the negative effects of the lifting hooks on cargoes to be loaded or unloaded are better increased, the accidental sliding and the accidental vibration of the cargoes to be loaded or unloaded can be avoided, the running-in degree of the lifting hooks and the steel wire ropes is greatly enhanced, and the stability and the operation efficiency of the loading and unloading operation are improved.

Owner:JIANGSU ZHENGDONG PORT MACHINERY MANUFACYURING

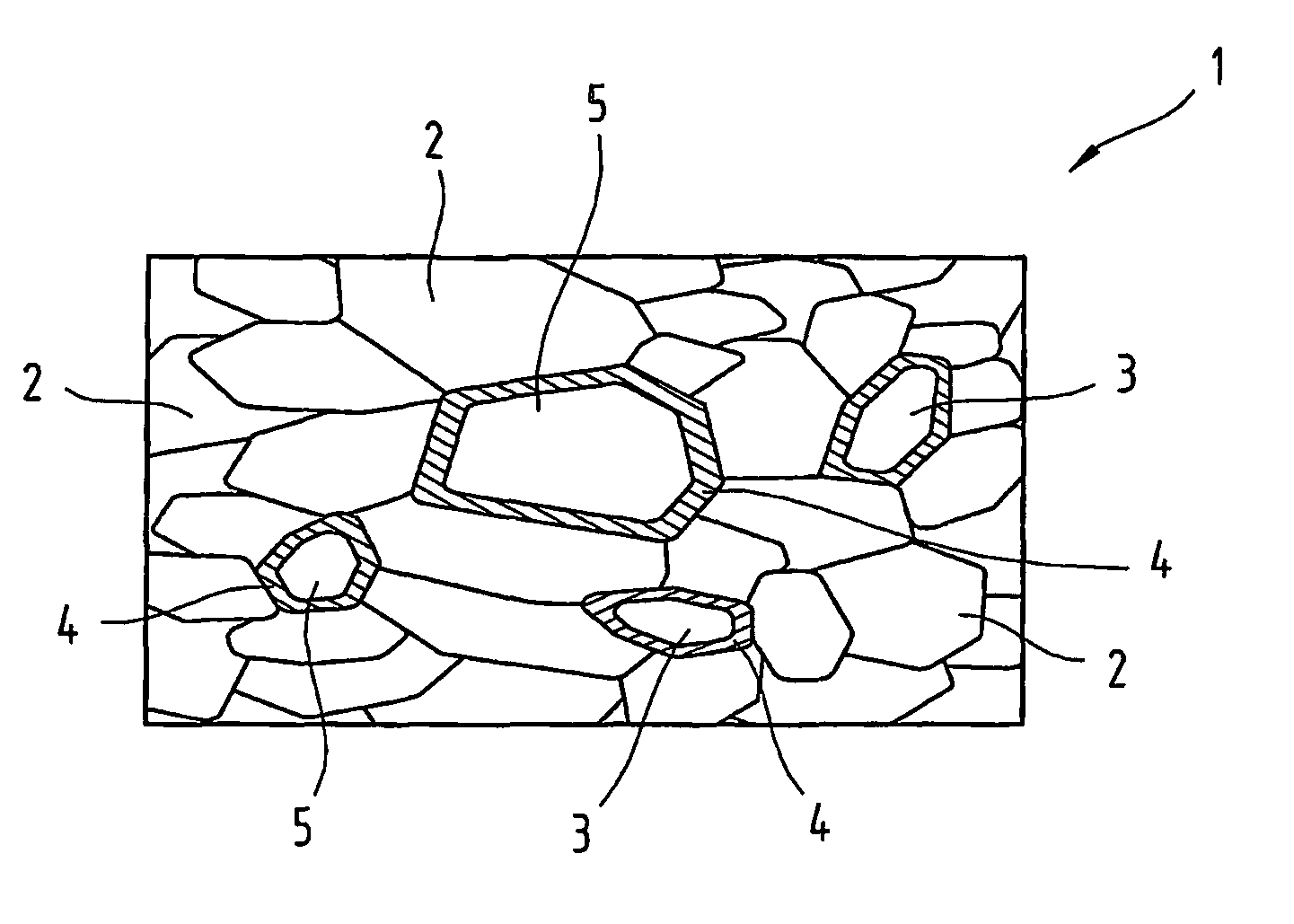

Alloy, in particular for a bearing coating

InactiveUS20110071061A1Improve running-inImprove wear resistanceMolten spray coatingRolling contact bearingsAlloySolid solution

An alloy, in particular for an anti-friction coating, includes elements which form a matrix and at least a soft phase and / or a hard phase, which soft phase elements and / or hard phase elements form a solid solution or a bond with the matrix element. The soft phase and / or hard phase is dispersed in the matrix and the solid solution or bond is formed only in the region of the phase boundary of the matrix with the soft phase and / or with the hard phase.

Owner:MIBA SINTER AUSTRIA

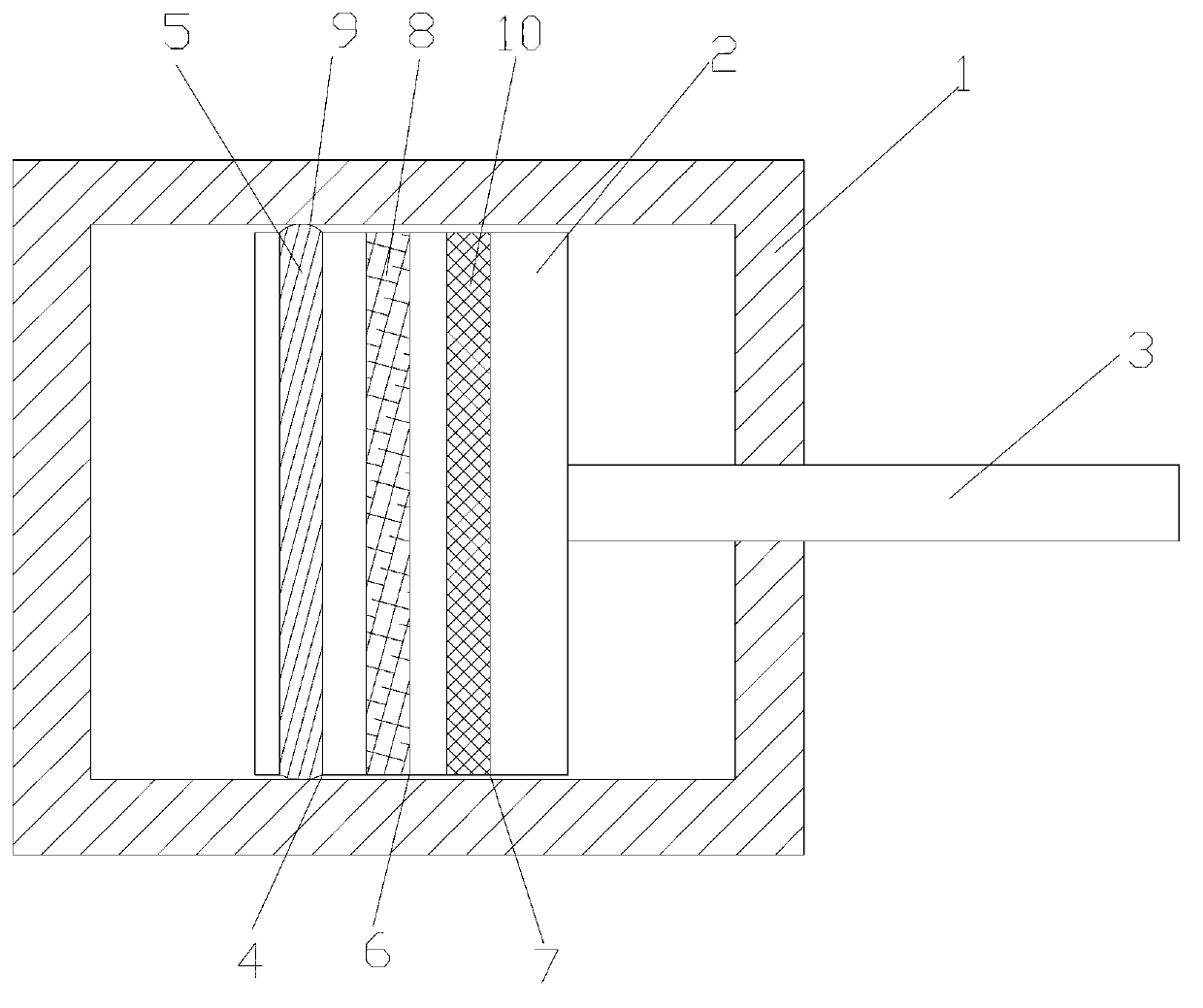

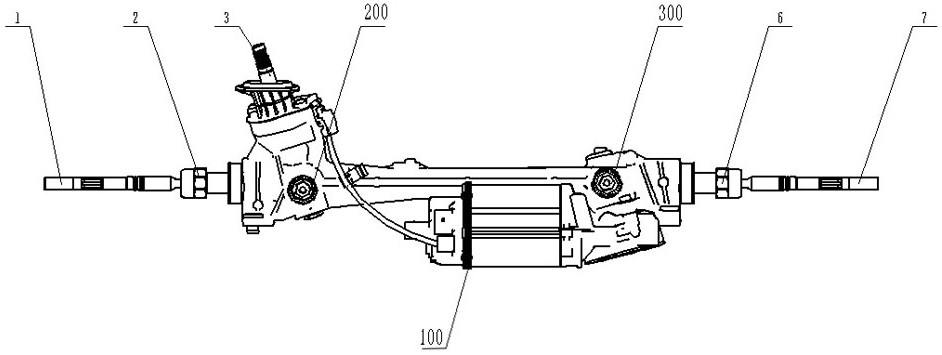

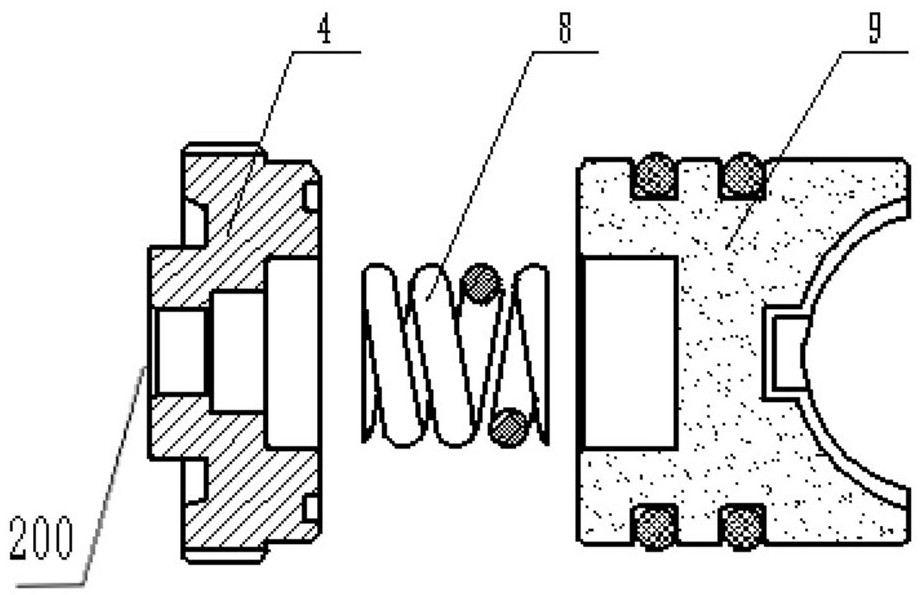

Double-gear type electric power steering gear and steering gear gap adjusting method

ActiveCN114162211AGuaranteed boost performanceGuaranteed boosting effectPortable liftingMechanical steering gearsElectric power steeringGear wheel

The invention discloses a double-gear type electric power-assisted steering gear and a steering gear gap adjusting method, the steering gear comprises a steering gear, a hand-operated end pull rod and a power-assisted end pull rod are arranged at the two ends of the steering gear respectively, and a first output end and a second output end are installed at the ends, away from each other, of the hand-operated end pull rod and the power-assisted end pull rod respectively; an input end is arranged at the upper end of the steering gear, and a hand-operated end gear rack gap adjusting mechanism and a power-assisted end gear rack gap adjusting mechanism are arranged on the two sides of the front end of the steering gear respectively. According to the gap adjustment method, the power-assisted end gap is adjusted preferentially, then the hand-assisted end gap is adjusted, the no-load rotation torque test is performed based on the state, the gap adjustment is performed according to the judgment principle in combination with the test condition, and the method can ensure that the gear rack gap and the no-load rotation torque are both in the optimal state at the same time. Therefore, the power-assisted performance and the power-assisted effect of the steering gear are ensured while no abnormal sound and the service life of the steering gear are ensured.

Owner:天津德科智控股份有限公司

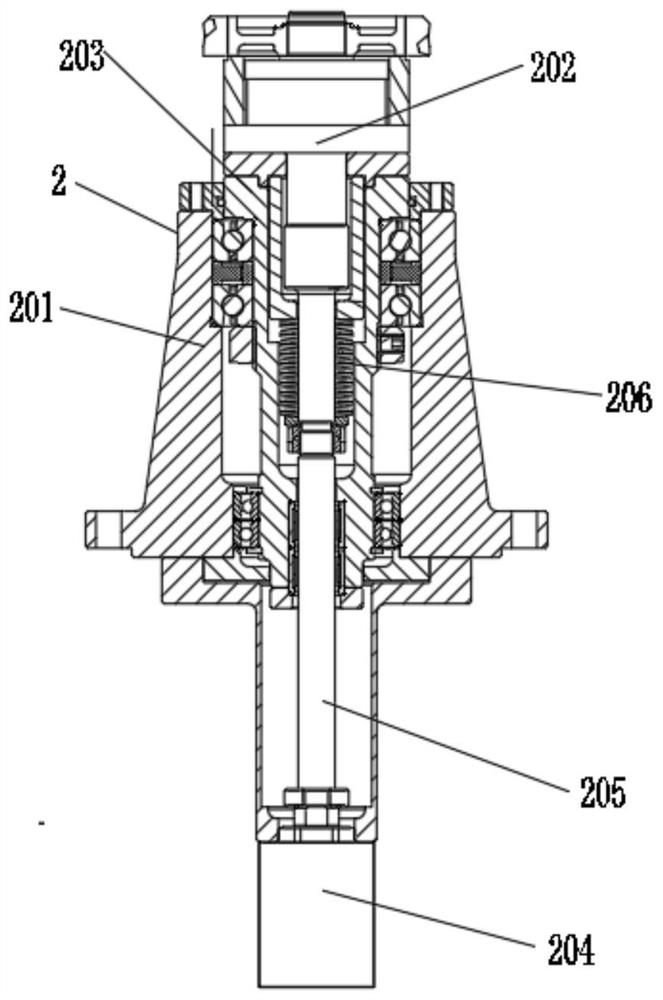

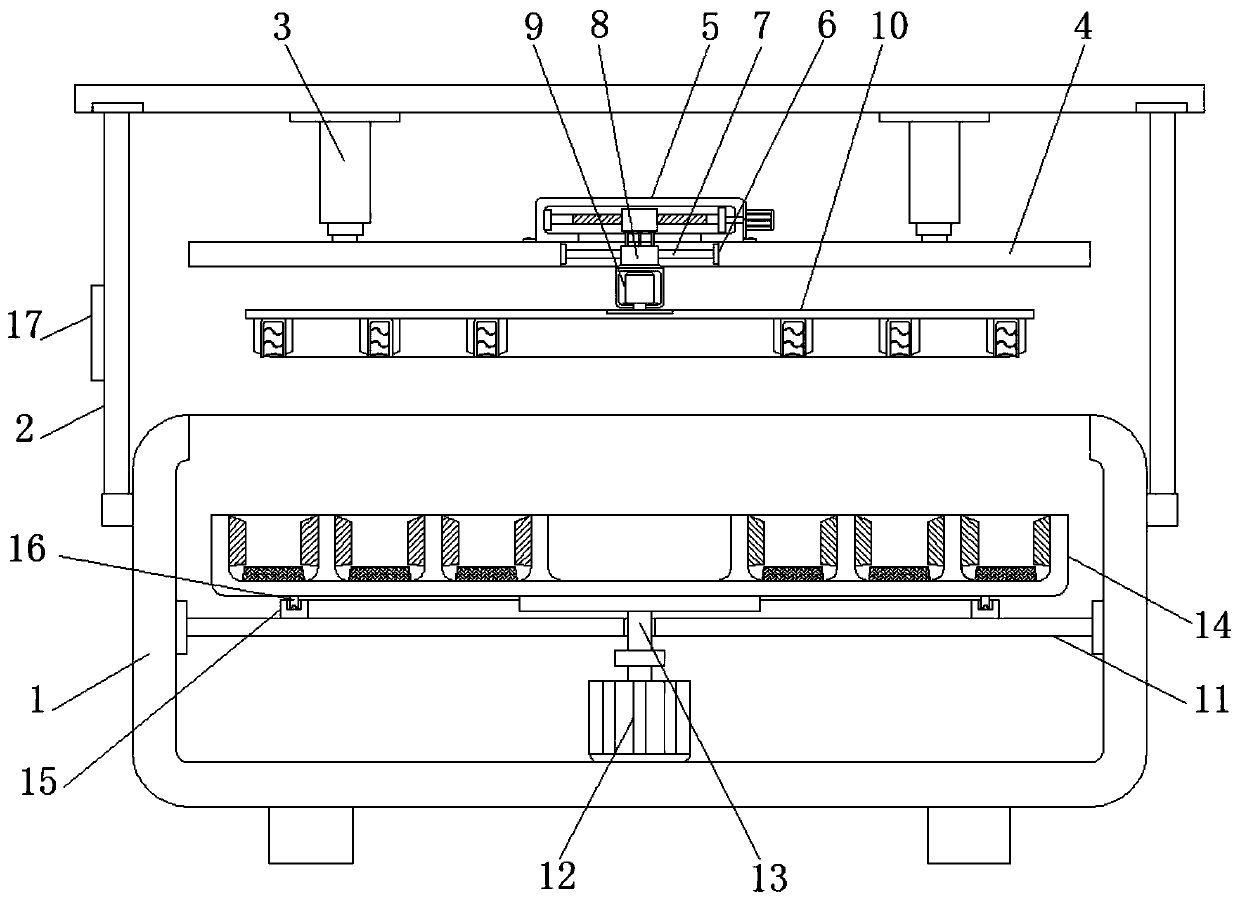

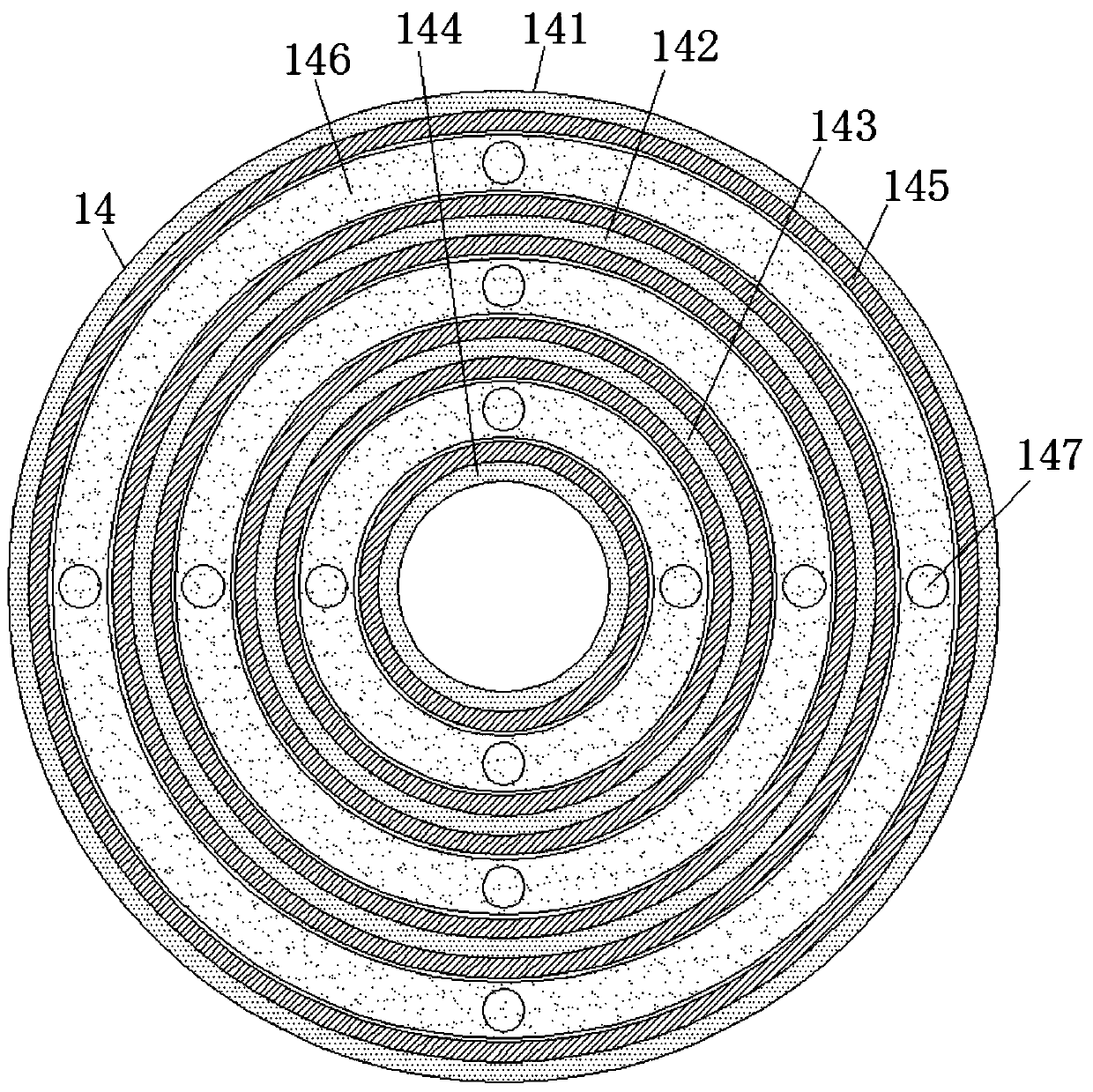

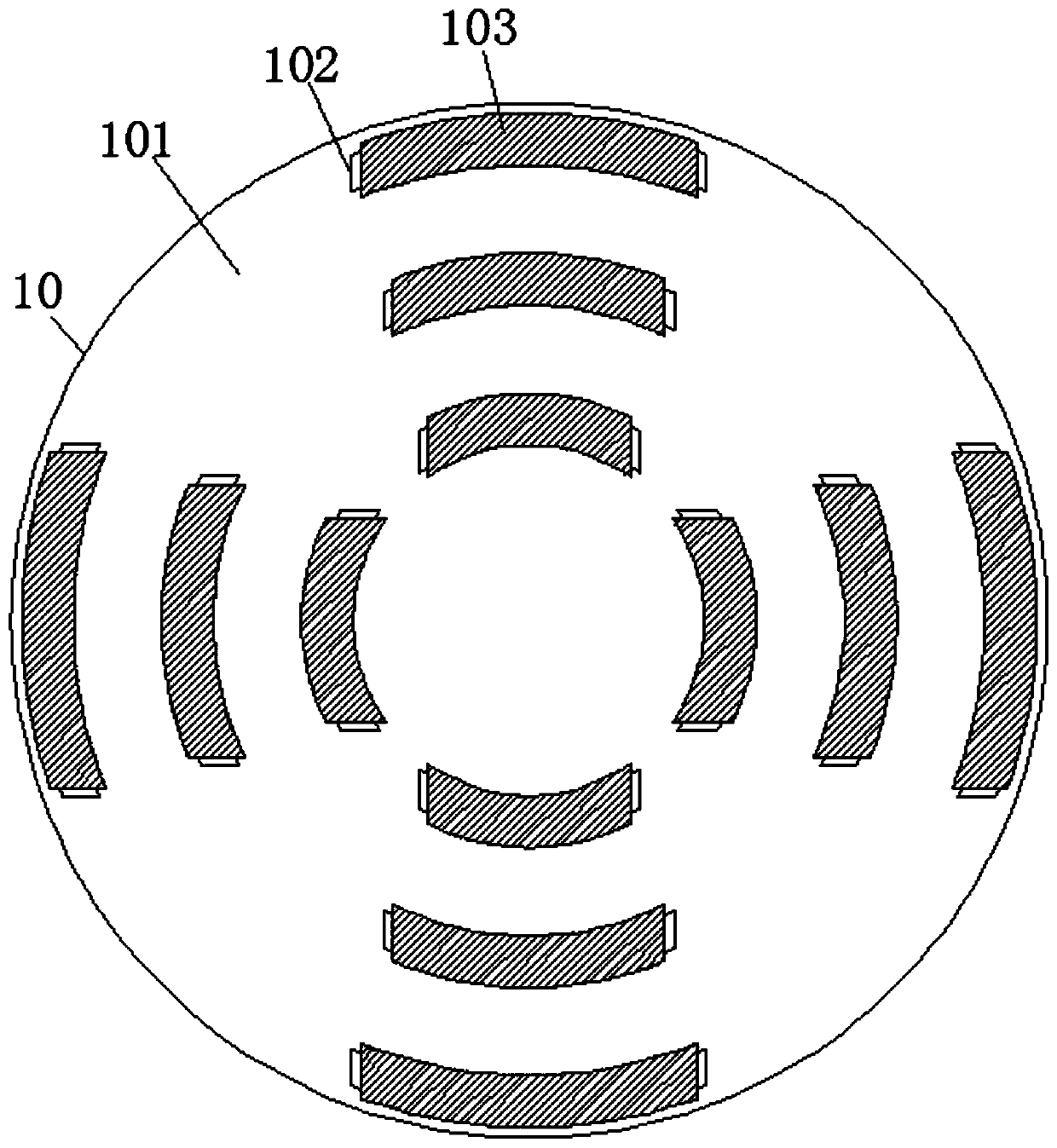

Worm gear running-in equipment of automobile steering system

PendingCN112775769AImprove running-inQuality improvementMachine part testingSeat surface grinding machinesMechanical engineeringHydraulic pressure

The invention discloses worm gear running-in equipment of an automobile steering system, and relates to the technical field of worm gear running-in equipment. The worm gear running-in equipment comprises an equipment body, the equipment body comprises a left sliding table feeding mechanism, a positioning mechanism, a worm measurement stress application small sliding table, a right sliding table feeding mechanism, a detection mechanism and a hydraulic system. The positioning mechanism comprises a shell, a hydraulic clamping mandrel, a rotating main shaft and a clamping oil cylinder, the hydraulic clamping mandrel is fixed to the rotating main shaft, an inner circle clamping structure is arranged on the hydraulic clamping mandrel, a worm wheel is installed on the hydraulic clamping mandrel in a clamping manner through the inner circle clamping structure. An ejector rod is connected between the output end of the clamping oil cylinder and the rotating main shaft. The surface of the worm gear is improved through the equipment body, certain lines are added on the surface of the worm gear after running-in, a certain grease storage function is achieved, and abnormal sound can be greatly reduced or does not exist; and the quality of an automobile steering device is improved.

Owner:SHANGHAI BAOZHUAN AUTOMATION TECH CO LTD

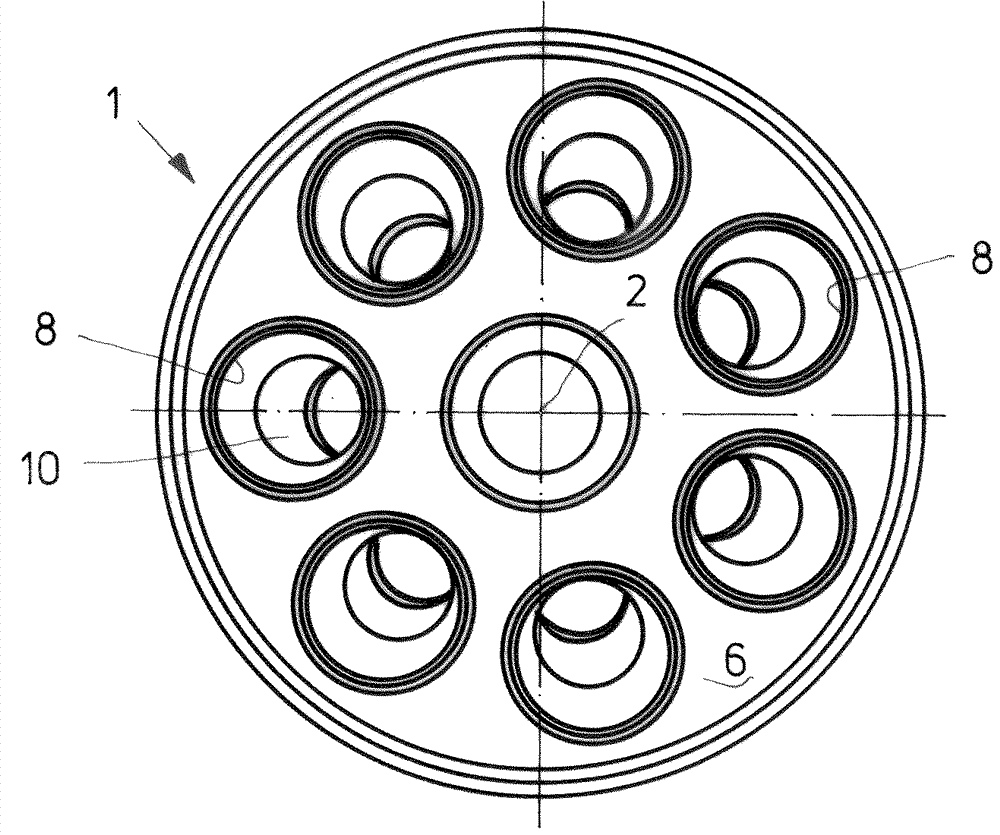

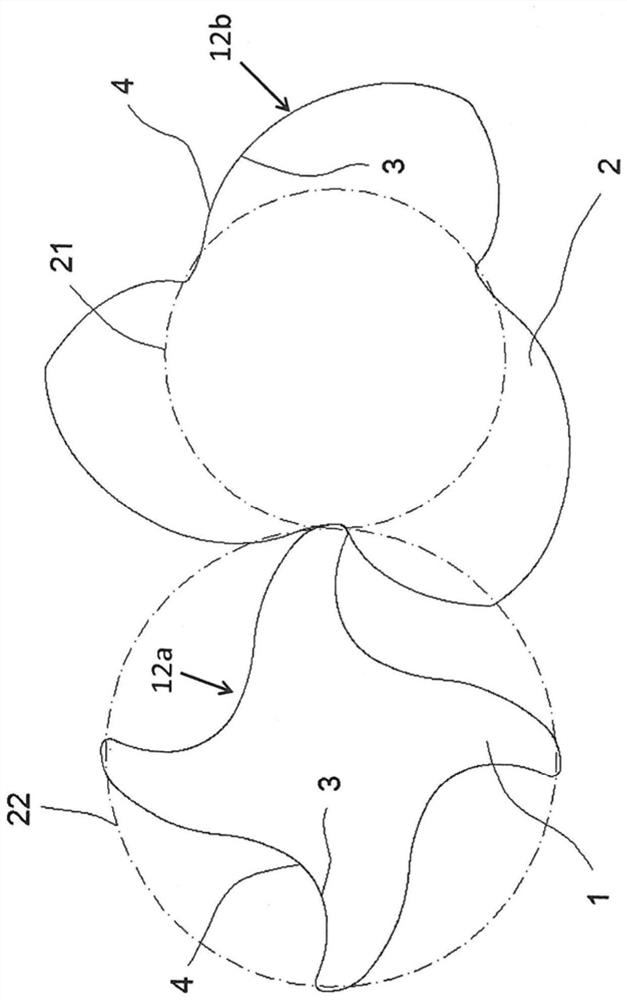

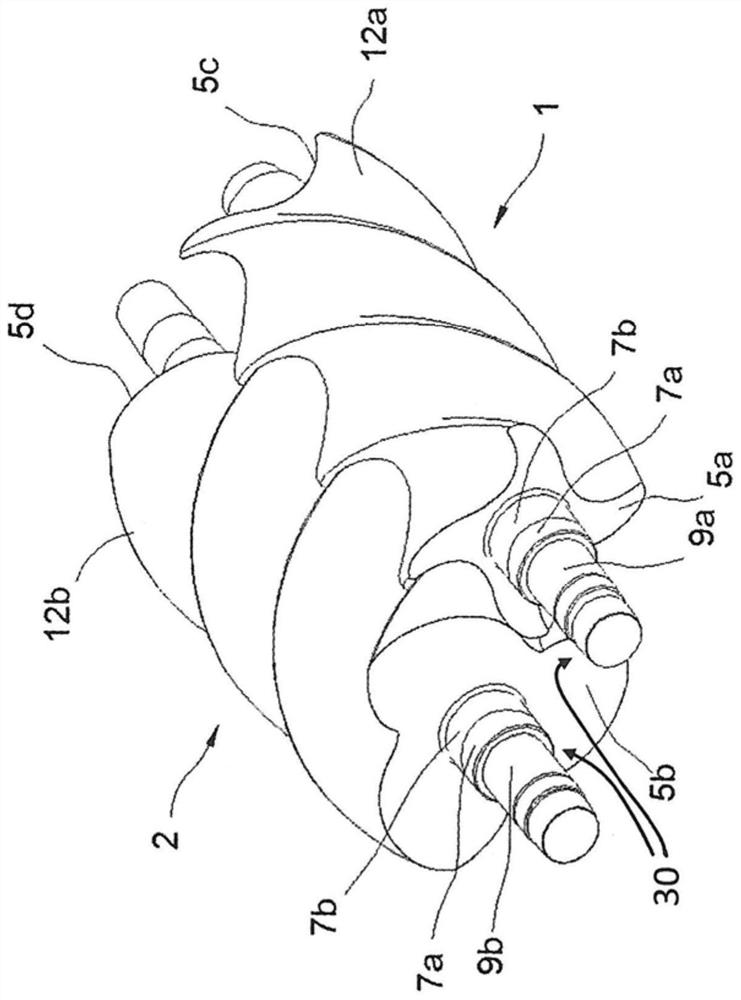

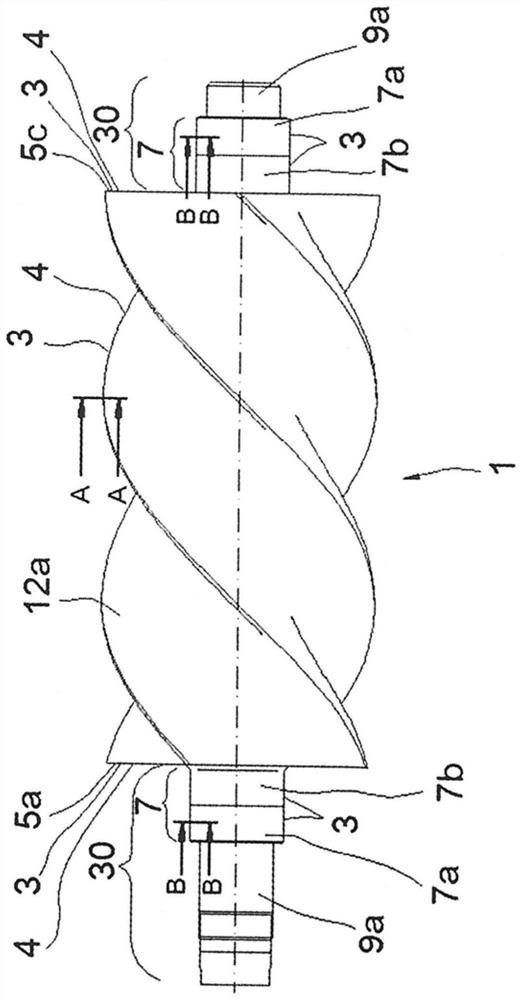

Screw compressor with multi-layer coated rotor screw

ActiveCN110621880BGood chemical resistanceCharacteristics unchangedSealing arrangement for pumpsRotary piston pumpsSynthetic materialsEngineering

A screw compressor comprising a compressor housing (11) having two rotor screws (1, 2) supported axially parallel therein, while the rotor screws are in a compression chamber (18) Mesh with each other, can be driven by a drive and synchronized with each other in their rotational movement, wherein the rotor screws (1, 2) each have a one-piece or multi-piece base body (24) and protrude from the end face (5a, 5b, 5c, 5d) shaft end (30), wherein the base body has two end surfaces (5a, 5b, 5c, 5d) and a profiled curved surface (12a, 12b) elongated therebetween, wherein at least the profiled curved surface (12a, 12b) is designed as multilayer, comprising a first inner layer (3) and a second outer layer (4), wherein both the first inner layer (3) and the second outer layer (4) comprise or are formed of a thermoplastic synthetic material, Particles ( 25 ) or pores ( 32 ) supporting the running-in process are embedded in the second outer layer ( 4 ), and the thermoplastic synthetic material defines a matrix for receiving the particles ( 25 ) or forming pores ( 32 ).

Owner:凯撒空压机有限公司

Preparation method of gearbox nano-diamond machine olein

PendingCN114621812AHigh purityReduce wearUltra-high pressure processesDiamondFriction torqueExplosive Agents

The invention relates to a preparation method of a gearbox nano-diamond oil extract, which can effectively solve the problems of reducing friction torque and surface wear, prolonging the service life of a transmission device, saving fuel oil and engine oil and reducing environment, and comprises the following steps of: preparing nano-diamond by adopting an explosive detonation method, chemically treating the nano-diamond, and removing organic matters and impurities in the nano-diamond. The purity of the nano-diamond is improved; carrying out surface modification, so that the nano-diamond is not agglomerated, is in a dispersed state and is mixed with lubricating oil base oil; and homogenizing to obtain the finished product olein. The lubricating oil has an anti-wear effect, reduces friction, saves fuel, reduces vibration and noise, realizes a dynamic automatic repair function of a friction pair, automatically repairs mechanical wear and processing defects, enhances the safety of a motor vehicle, shortens the running-in period of the vehicle, enables the running-in effect to be optimal, is a great innovation on lubricating oil, and has huge economic and social benefits.

Owner:河南海力特能源科技有限公司

Composite metal powder for sintered bearing, and sintered oil retaining bearing

InactiveCN1085794CEasy and cheap to makeReduce wearTransportation and packagingShaftsSurface layerIron powder

Composite metal powder for sintered bearings, prepared by coating surface layers of particles of iron powder with 10 wt.% to less than 30 wt.% of copper based on the iron powder so that the particle size of the coated iron powder is at most 80 meshes, the content of the powder of at most 350 meshes is at most 30%, and the specific surface area of the powder is 450-750 cm<SP>2< / SP> / g according to the subsieve sizer method. This metal powder can provide an oil-retaining bearing for motors, which is capable of providing a low gas-permeability without decreasing the oil content and which has a low and constant coefficient of friction, a high corrosion resistance, a high adaptability and a high durability, readily at a low cost.

Owner:PORITE +1

A disordered preliminary processing equipment applied to Wenwan walnuts

InactiveCN109129122BChange the way of clamping and positioning processingAvoid collision damageGrinding machinesGrinding work supportsWalnut NutRough surface

The invention relates to the technical field of Wenwan walnut processing, and discloses a disordered preliminary processing equipment applied to Wenwan walnuts. Both sides are fixedly connected with electric lifting rods by bolts, and a sealing cover matching the inner diameter of the top opening of the cylinder is fixedly connected between the ends of the two electric lifting rods. The upper surface of the sealing cover is provided with a horizontal movable groove. A load-bearing slide bar is fixedly connected between the inner walls of the left and right sides of the movable groove, and a load-bearing slide block is movably interspersed on the load-bearing slide bar. The disordered preliminary processing equipment applied to Wenwan walnuts enables all-round running-in of walnuts, greatly improves the running-in degree and uniformity of the rough surface of walnuts, changes the traditional way of clamping and positioning walnuts, and prevents walnuts The collision damage between them ensures the integrity of the walnut surface texture.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

A method for manufacturing gears from powder metallurgy anti-friction materials

ActiveCN111570805BImprove wear reduction performanceGuaranteed StrengthTransportation and packagingMetal-working apparatusGear wheelAlloy

The invention provides a method for manufacturing a gear from a powder metallurgy antifriction material, and relates to the field of powder metallurgy. The method for manufacturing gears based on powder metallurgy anti-friction materials includes a manufacturing method, an anti-friction alloy material formula and a cermet formula. The anti-friction alloy material used in the present invention utilizes a copper-iron-based composite base material, and the higher copper content ensures that the anti-friction material has superior corrosion resistance and running-in performance, and the texture of copper is relatively soft, which can reduce the coefficient of friction. Reduce noise, and cooperate with cermet materials to make gears with inner rings made of cermets and outer rings made of wear-reducing alloy materials. While improving the wear-reducing performance of the gears, the strength of the gears is guaranteed, and the formula of this method is added with stearate Zinc acid can lubricate the mold, reduce the resistance encountered in the demoulding process, and reduce the damage to the mold, and the tiny pores formed by the volatilization of zinc stearate during the sintering process can make the gear have a certain The oil content can form a self-lubricating effect.

Owner:南通旺鑫新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com