Screw compressor with multi-layer coated rotor screw

A technology for screw compressors and compressor housings, applied in the direction of rotary piston machinery, mechanical equipment, engine components, etc., to achieve the effects of reduced risk of coating swelling, high running stability, and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

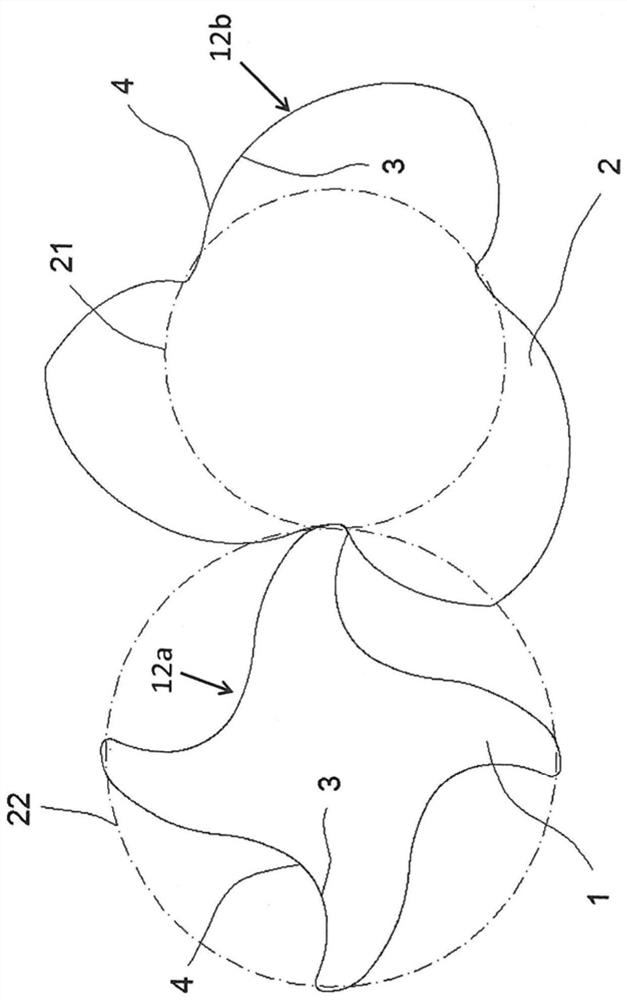

[0139] exist figure 1 An end surface cross section of a rotor screw pair according to the present invention is shown, and the rotor screw pair includes rotor screw 1, which is designed as a sub-rotor, and a rotor screw 2 designed as a main rotor. Only purely shown, the profile surfaces 12a, 12b of the rotor screws 1, 2 are respectively coated with the first inner layer 3 and the second outer layer 4, respectively. The rotor screws 1, 2 mesh each other, i.e., with its teeth to interleave with each other. For a feeding that has been mentioned, the fence for designing the rotor screw 1 designed as the sub-rotor is labeled with reference numeral 21, and the rotor screw 2 for designing as the main rotor is marked.

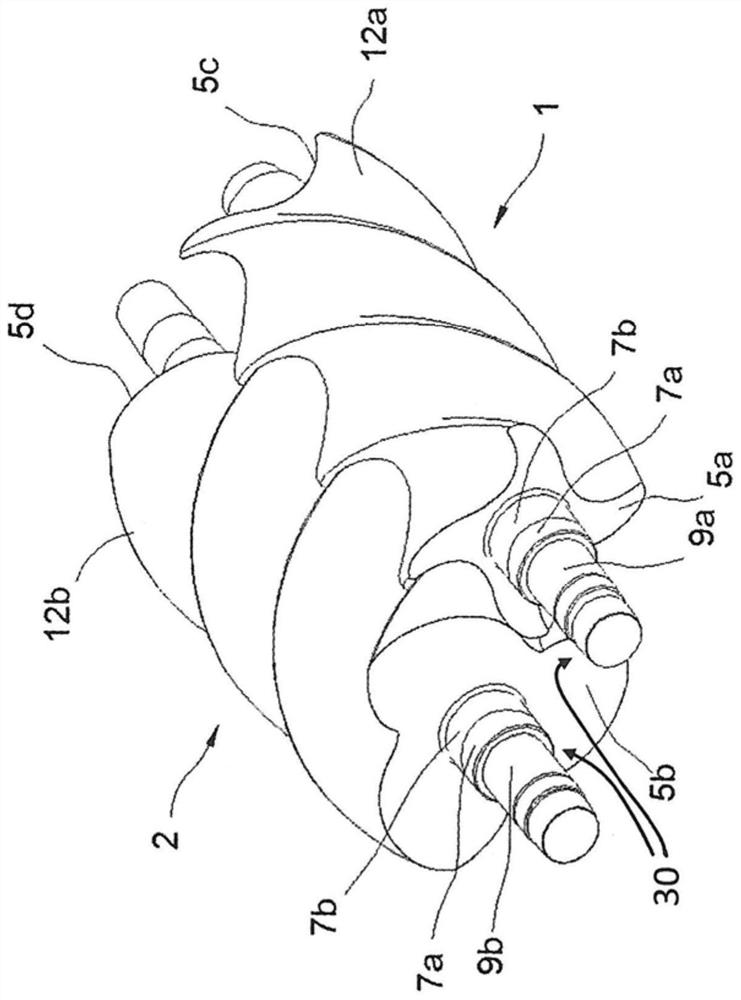

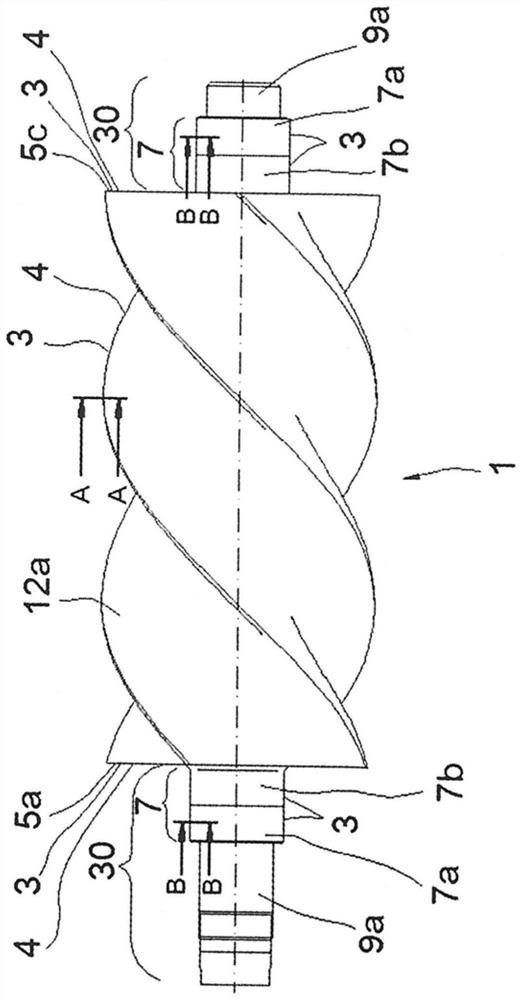

[0140] exist figure 2 In the perspective view, the rotor screws 1, 2 which are coupled to each other are shown. Here, the two rotor screws 1, 2 are interlaced from each other with the existing shaped curved surfaces 12a, 12b, or to each other, or to rotten into each other. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com