Piston type air cylinder

A piston type and cylinder technology, which is applied in variable capacity pump components, liquid variable capacity machines, machines/engines, etc. It can solve problems such as poor sealing performance, rising lubricating oil temperature in air compressors, thermal deformation of cylinder pistons, etc. problem, to achieve the effect of enhancing heat dissipation performance, improving oil scraping effect, and good running-in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

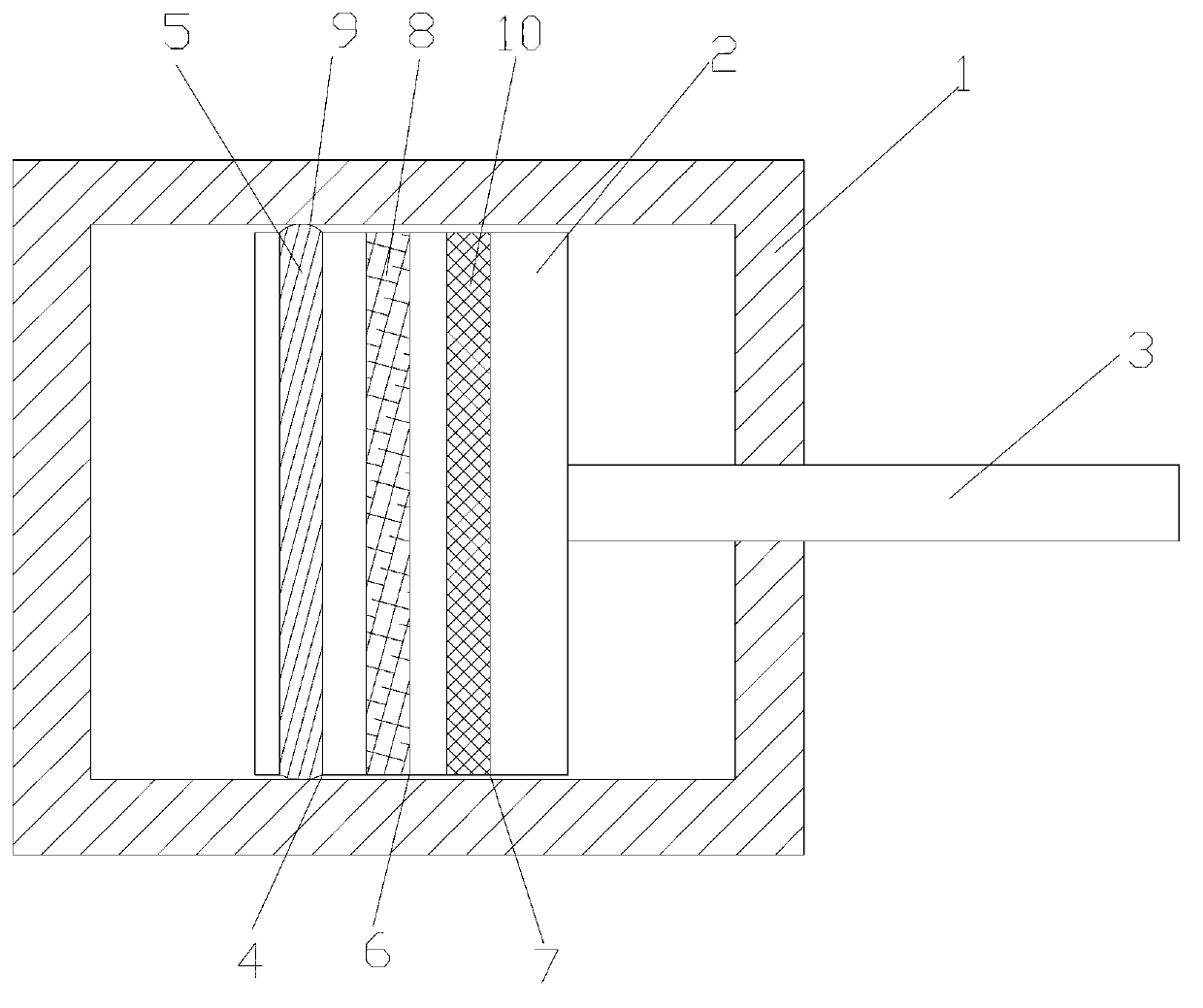

[0013] attached Figure 1-2 It is a piston-type cylinder according to the present invention, which includes a cylinder body 1, a piston 2, and a piston rod 3. The piston 2 is provided with three annular grooves; a piston ring 5 is installed in the first annular groove 4, and a piston ring 5 is installed in the first annular groove 4. 2. The oil scraper ring 8 is installed in the third annular groove 6 and 7; the outer edge surface of the piston ring 5 is provided with an arc-shaped protrusion 9 in contact with the inner wall of the cylinder; the scraper ring installed in the third annular groove 7 The oil ring 8 is a three-lobed oil scraper ring 10; the material of the piston ring 5 and the oil scraper ring 8 is alloy cast iron; the axial gap of the annular groove is 0.05-0.067mm.

[0014] According to the present invention, three annular grooves are arranged on the piston 2, and a pis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial clearance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com