High-temperature resisting and high-pressure resisting injecting and extracting integrated double-layer hollow sucker rod

A hollow sucker rod, high-pressure technology, which is used in the production of fluids, drill pipes, and earthwork drilling, etc., can solve the problem that the vacuum double-layer hollow sucker rod cannot meet the high temperature process requirements, and save the time and structure of the pipe string. Reasonable design and the effect of filling technical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

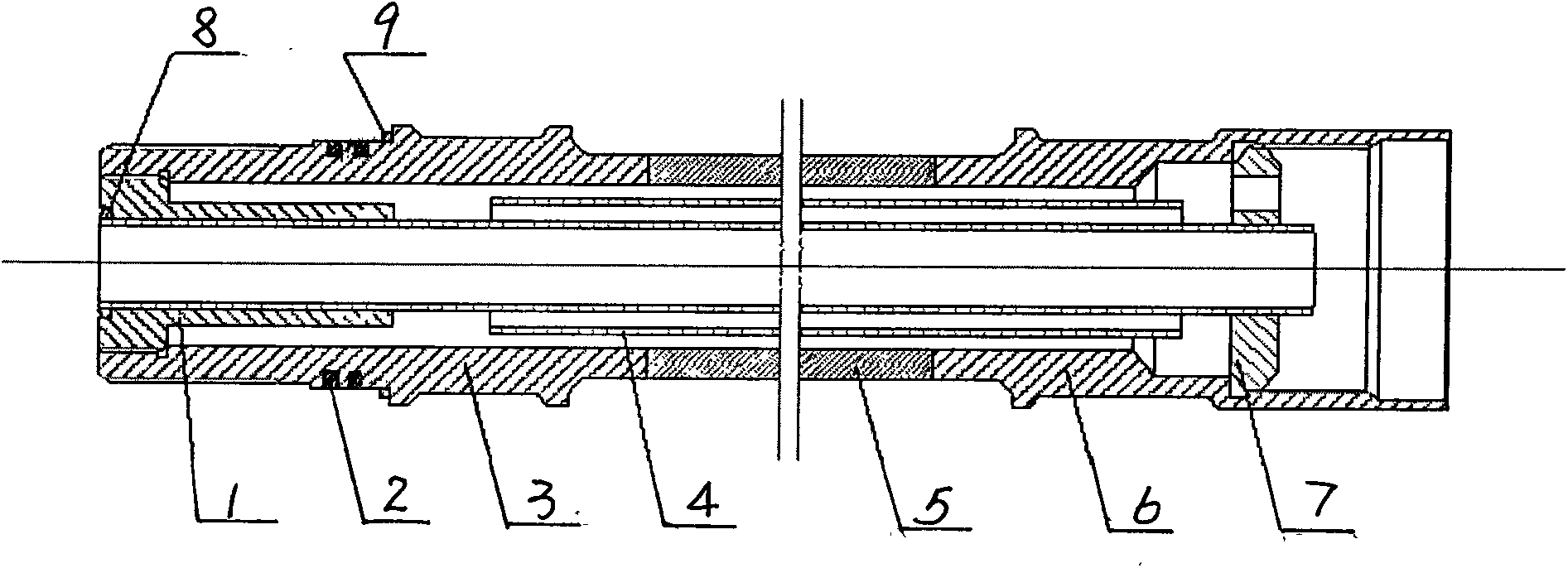

[0012] See attached figure 1 . The high-temperature and high-pressure resistant integrated double-layer hollow sucker rod for injection and production of the present invention includes a hollow rod and a center pipe 4 .

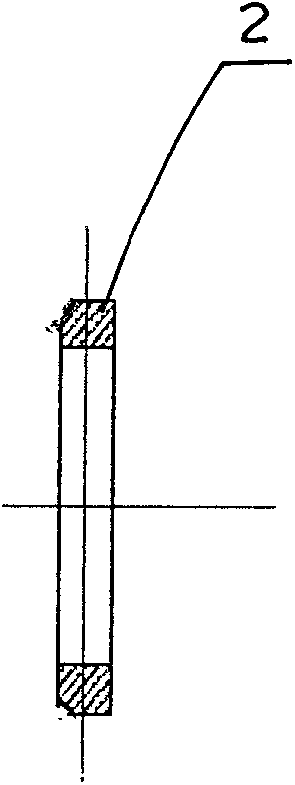

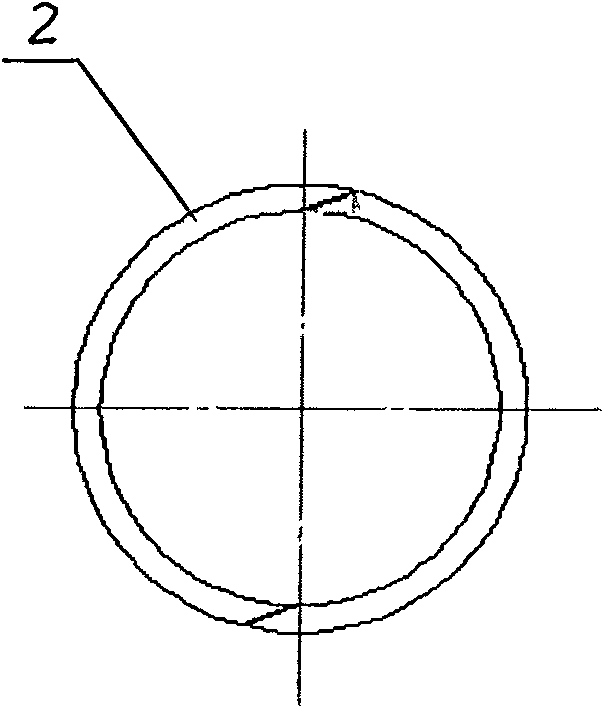

[0013] The upper joint 6, the rod body 5, and the lower joint 3 of the hollow rod are fixedly connected sequentially from top to bottom. A metal sealing ring I2 is installed in the annular groove at the upper end of the connection thread of the lower joint 3, and the metal sealing ring I2 is composed of two half rings, and the joint of the two half rings is a bevel joint (see attached figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com