Slow release coated wax of efficient slow release composite fertilizer

A compound fertilizer and slow-release bag technology, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of difficult solvent recovery, poor slow-release performance, high energy consumption, etc., and achieve energy saving, strong adaptability, and good release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

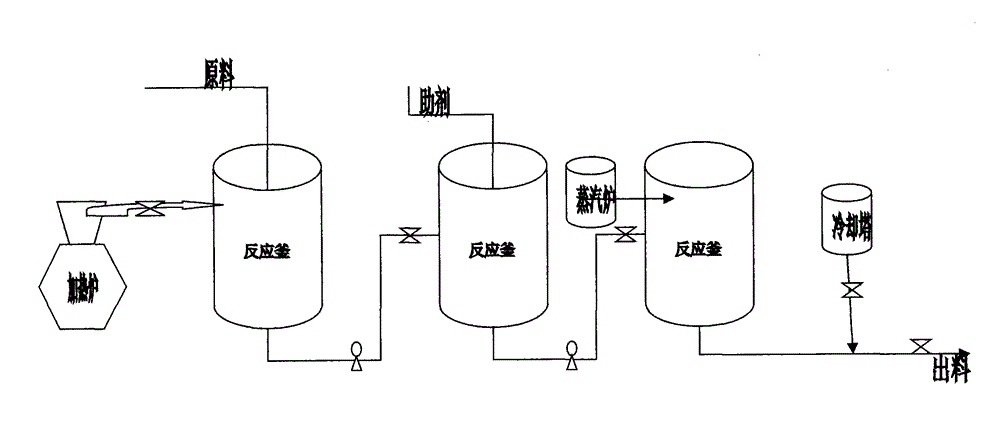

Method used

Image

Examples

Embodiment 1

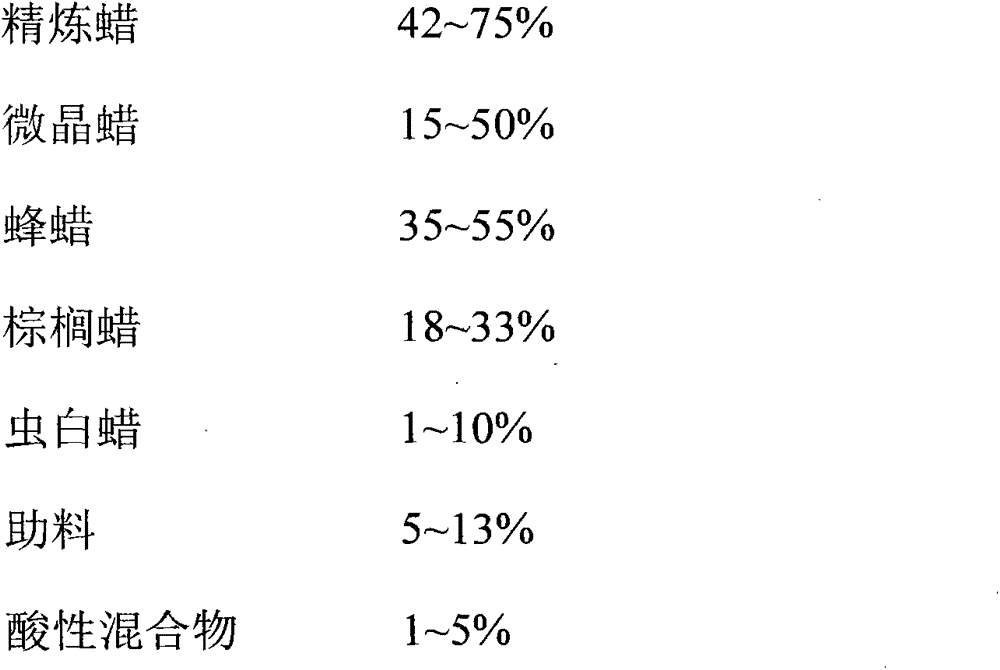

[0020] Take 1998kg-3567kg of refined wax, 714kg-2378kg of microcrystalline wax, 1665kg-2616kg of beeswax, 856kg-1569kg of palm wax, 48kg-476kg of paraffin wax, at a temperature of 85°C-95°C Melt at low temperature, then mix it and stir until it is fully stirred, add 281 kg to 579 kg of additives, and a small amount of additives, raise the temperature to 95 ° C to 105 ° C, and react for 20 to 40 minutes to obtain the present invention. Said slow-release coating wax.

[0021]

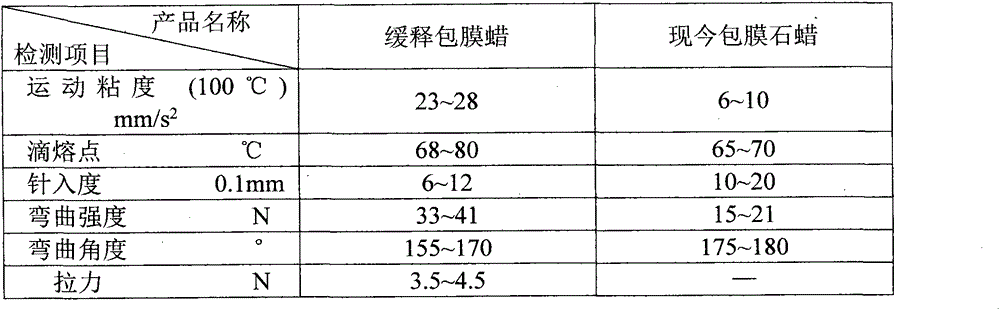

[0022] Every index of said slow-release coated wax of the present invention is all better than the coated paraffin used now, and its advantage is:

[0023] 1. High kinematic viscosity can improve the efficiency of spraying, simple production, and the coating surface is uniform and the thickness is consistent.

[0024] 2. The high and low drop melting point can be determined according to the local geographical environment and geological temperature.

[0025] 3. The penetration and bending strength are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com