Piston with steel top and aluminum skirt for 230SG type gas engine

A technology of piston and steel top, applied in the direction of piston, engine components, machine/engine, etc., can solve the problems of insufficient rigidity, low power, large linear expansion coefficient, etc., and achieve the effect of increasing power, increasing service life and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

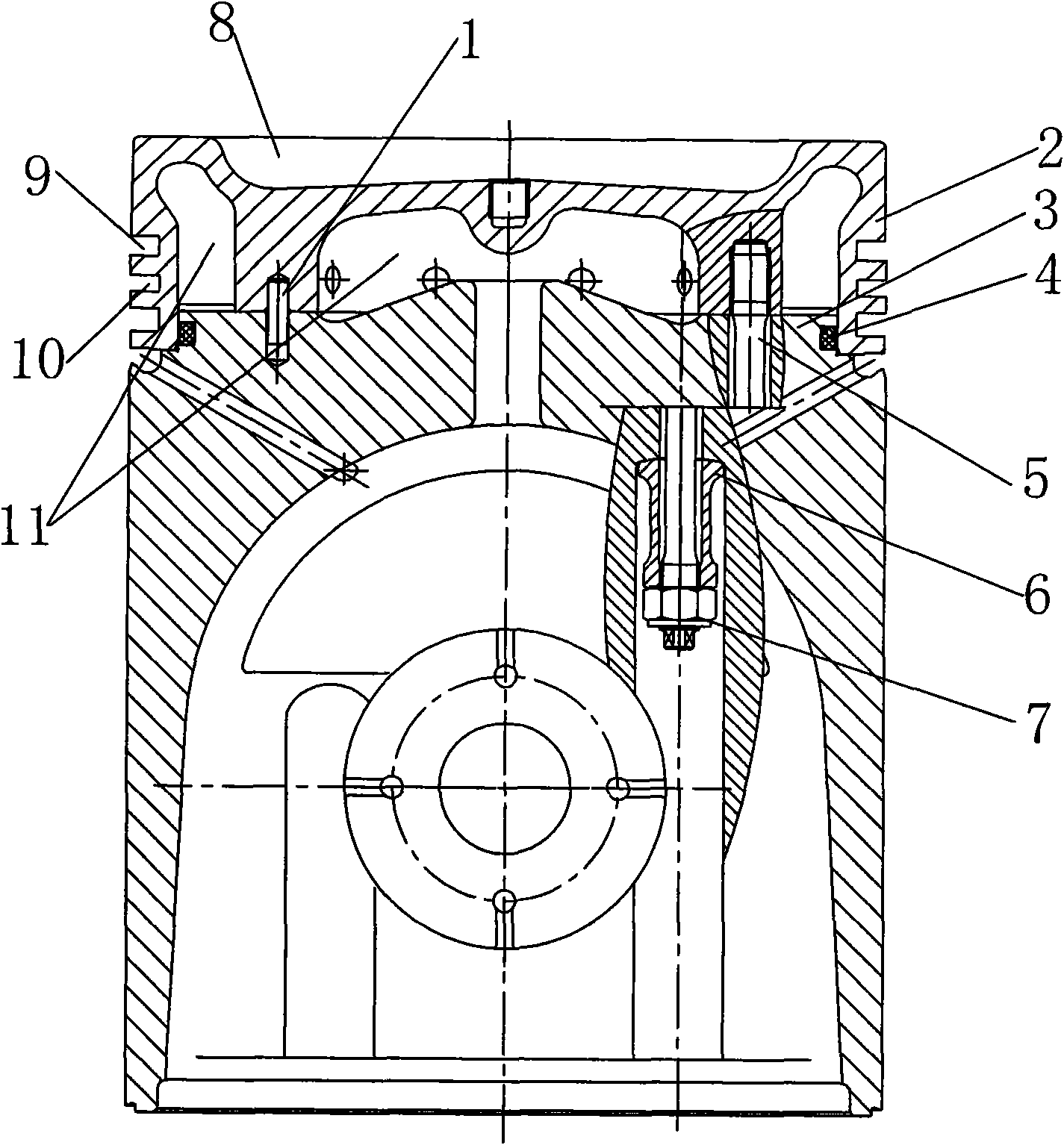

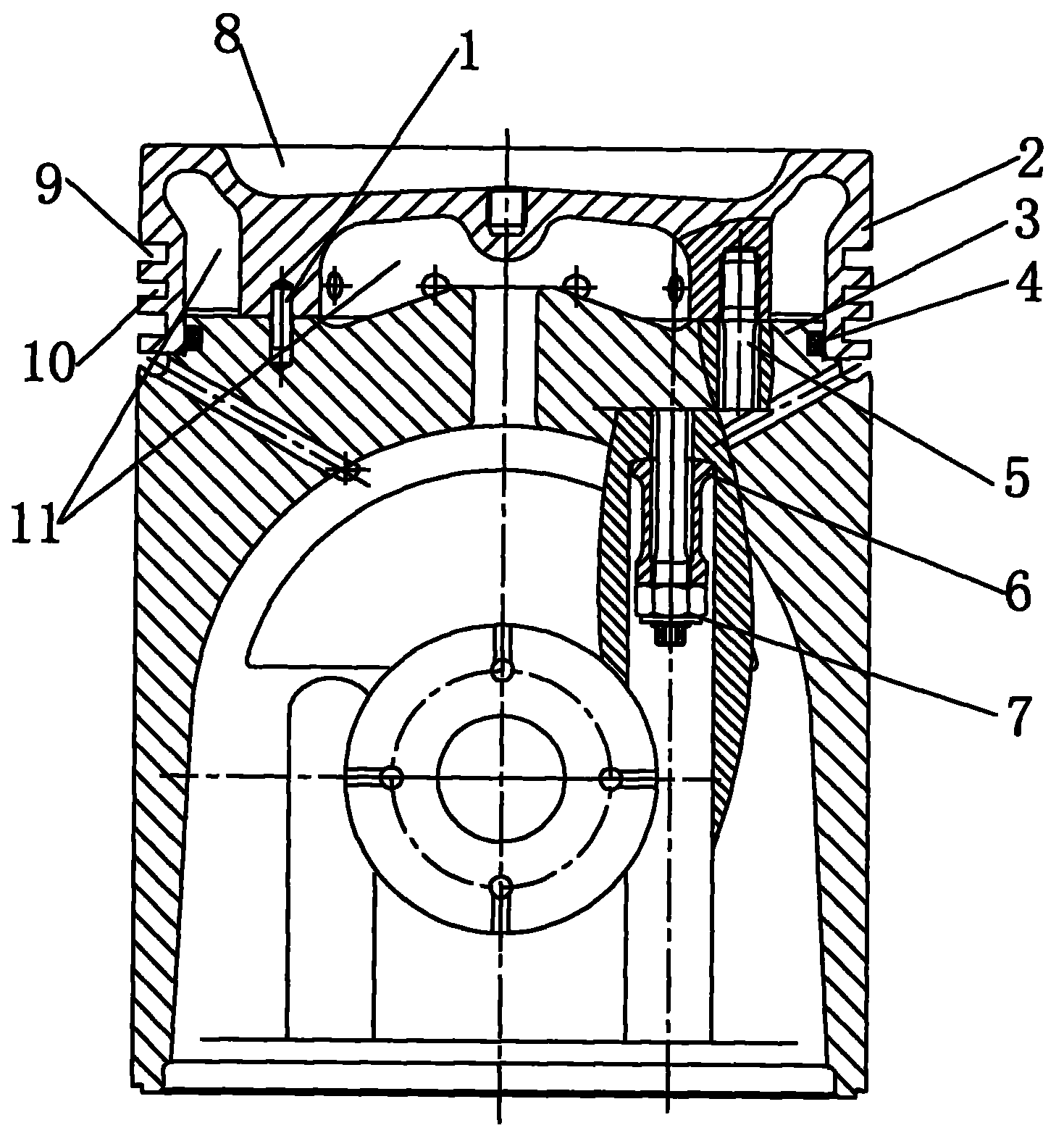

[0012] Steel top aluminum skirt piston of the present invention, as figure 1 As shown, it includes a steel piston top 2 and an aluminum skirt 3 coaxially connected with the piston top to form a piston. The piston top 2 is made of 42CrMoA alloy structure diamond, and the skirt body 3 is made of 4A11 aluminum. Cast aluminum, which limits the shaking range of the piston and reduces the impact on the cylinder. The upper end of the skirt body 3 is provided with a short column with a diameter smaller than that of the skirt body, and the connecting end of the piston top 2 and the skirt body 3 is provided with an inner hole matching the diameter of the short column, and the piston top realizes the sleeve connection through the cooperation of the inner hole and the short column , A sealing ring 4 is provided between the stub and the inner hole, and the piston top 2 and the skirt body 3 are connected as one by the cooperation of the bolt 5 and the nut 7. For the convenience of installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com