Al-Pb alloy wear resistant layer preparation method based on friction stir processing

An alloy wear-resistant layer and friction stir technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of limited improvement in homogenization, high cooling speed, uneven Al-Pb alloy, etc., and achieve improved segregation Problems, the effect of reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

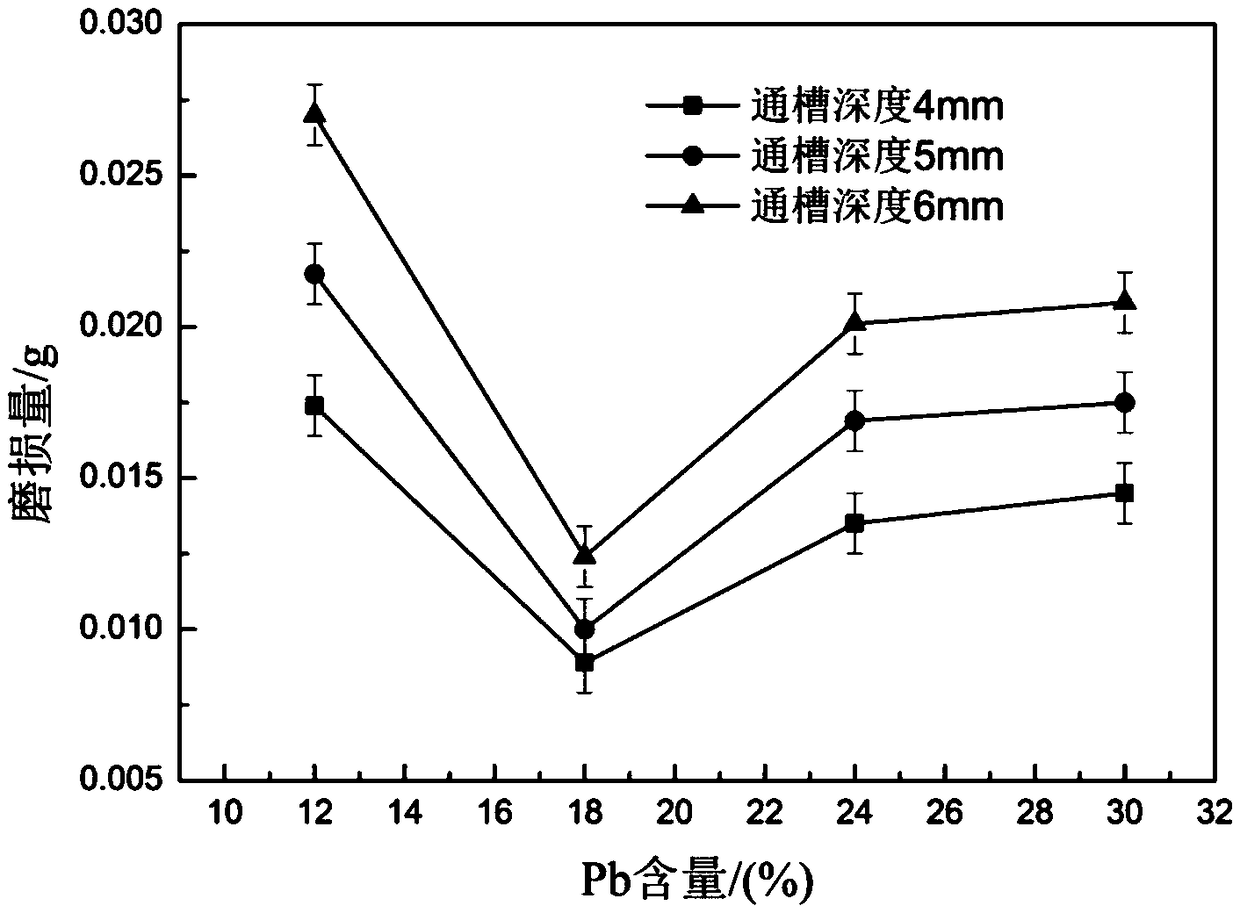

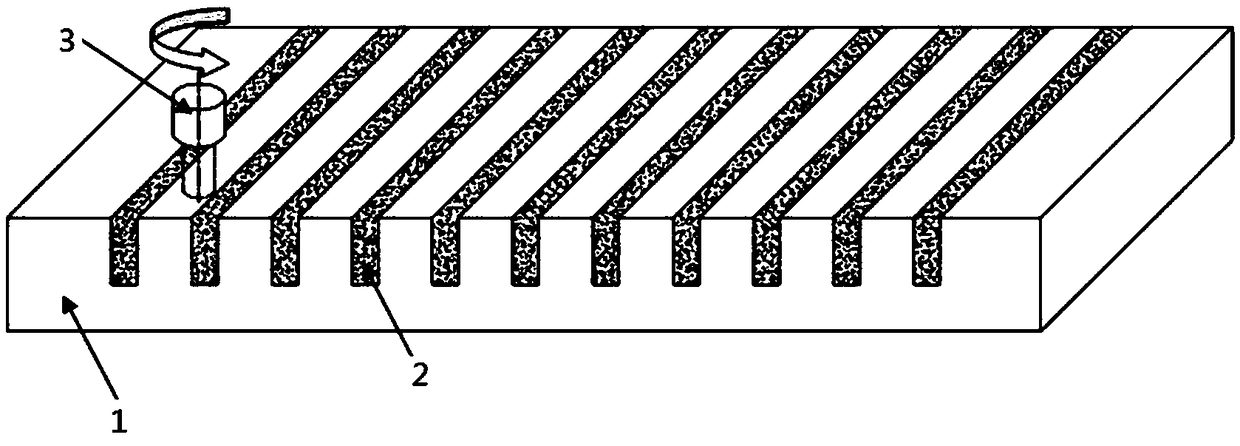

[0026] Substrate 1 is made of 1060 pure aluminum plate, the size is 160×100×6mm, the chemical composition is Si: 0.25%, Fe: 0.35%, Mn: 0.03%, Mg: 0.03%, Al: 99.6%, and it is ground by CNC grinding machine Keep the upper and lower ends of the aluminum plate parallel, and cut out 0.37mm (width)×4mm (depth), 0.58mm (width)×4mm (depth), 0.79mm (width)×4mm (depth), 1.03mm (width) × 4mm (depth) through the groove 2, the groove spacing is 6mm, use acetone to remove the oil in the groove, and finally use ultrasonic cleaning to clean the aluminum plate, the particle size of the lead powder is 5, 8, 10μm, and the density is 5.65g / cm 3 According to the aforementioned formula, the slot widths of 0.37mm, 0.58mm, 0.79mm, and 1.03mm correspond to lead contents of 12%, 18%, 24%, and 30%, respectively.

[0027] Use a key to evenly fill the groove with lead powder. The needleless stirring head is made of 45 steel, and the set rotation speed is 800-1000r / min, and the travel speed is 50-80mm / mi...

Embodiment 5-8

[0034] Substrate 1 is made of 1060 pure aluminum plate, the size is 160×100×8mm, the chemical composition is Si: 0.25%, Fe: 0.35%, Mn: 0.03%, Mg: 0.03%, Al: 99.6%, and it is ground by CNC grinding machine Keep the upper and lower ends of the aluminum plate parallel, and cut 0.37mm (width) × 5mm (depth), 0.58mm (width) × 5mm (depth), 0.79mm (width) × 5mm (depth) on the surface of 4 aluminum plates, respectively. 1.03mm (width) × 5mm (depth) through the groove 2, the groove spacing is 6mm, use acetone to remove the oil in the groove, and finally use ultrasonic cleaning to clean the aluminum plate, the particle size of lead powder is 5, 8, 10 μm, and the density is 5.65g / cm 3 According to the aforementioned formula, the slot widths of 0.37mm, 0.58mm, 0.79mm, and 1.03mm correspond to lead contents of 12%, 18%, 24%, and 30%, respectively.

[0035] Use a key to evenly fill the groove with lead powder. The needleless stirring head is made of 45 steel, and the set rotation speed is ...

Embodiment 9-12

[0042] Substrate 1 is made of 1060 pure aluminum plate, the size is 160×100×10mm, the chemical composition is Si: 0.25%, Fe: 0.35%, Mn: 0.03%, Mg: 0.03%, Al: 99.6%, and it is ground by CNC grinding machine Keep the upper and lower ends of the aluminum plate parallel, and cut 0.37mm (width) × 6mm (depth), 0.58mm (width) × 6mm (depth), 0.79mm (width) × 6mm (depth) on the surface of the four aluminum plates, respectively. 1.03mm (width) × 6mm (depth) through the groove 2, the groove spacing is 6mm, use acetone to remove the oil in the groove, and finally use ultrasonic cleaning to clean the aluminum plate, the particle size of lead powder is 5, 8, 10μm, and the density is 5.65g / cm 3 According to the aforementioned formula, the slot widths of 0.37mm, 0.58mm, 0.79mm, and 1.03mm correspond to lead contents of 12%, 18%, 24%, and 30%, respectively.

[0043] Use a key to evenly fill the groove with lead powder. The needleless stirring head is made of 45 steel, and the set rotation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com