Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Improve wear reduction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for size restoring and reinforcing of outer wall and inner wall of water-cooling cylinder sleeve of engine

InactiveCN103710660AImprove wear resistanceImprove wear reduction performanceMolten spray coatingCylinder headsWear resistantWater cooling

The invention relates to a method for size restoring and reinforcing of an outer wall and an inner wall of a water-cooling cylinder sleeve of an engine. According to the method, a nickel-based anti-attrition and wear-resistant coating is prepared on the inner wall of the cylinder sleeve by utilizing an inner hole plasma spraying technique, and a nickel-aluminum composite coating is prepared on the outer wall of the cylinder sleeve by utilizing an supersonic speed plasma spraying technique. The cylinder sleeve scrapped due to the abrasion and the corrosion can be remanufactured, and the size of the cylinder sleeve is restored according to the actual requirement; meanwhile, the abrasion performance of the inner wall as well as the corrosion resistance of the outer wall of the cylinder sleeve are improved, the service life is prolonged, the remanufacture possibility is improved, the restoring cycle is reduced, and the energy, the fund and the labor force are saved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Nano composite anti-wear coating composition used for hot forging die and application thereof

InactiveCN101210325AImprove wear resistanceHigh wear reductionMetallic material coating processesNanometreCarbon nanotube

The invention discloses a nanometer composite abrasion-resistant coating combination used for a hot forging mold and application thereof. The raw material of the combination contains ceramic nanopowder and a carbon nanotube with a volume ratio of 1:(1-4), Co with a volume of 40 to 50% the mixed volume of the ceramic nanopowder and the carbon nanotube, and a binding agent with a volume of 3 to 4 times than the mixed volume of the ceramic nanopowder and the carbon nanotube. The application of the combination comprises the following steps of: mixing the ceramic nanopowder with the carbon nanotube and Co at the ratios, adding the binding agent at the ratio, mixing uniformly, applying on the surface of a hot forging mold to be processed to form a coating layer with a thickness of 0.2 to 0.5 mm, and scanning the coating layer with a high-energy laser beam to form the nanometer composite abrasion-resistant coating on the surface of the hot forging mold. The nanometer composite abrasion-resistant coating has the advantages of high hardness, high abrasion resistance, high abrasion reduction performance, high processing speed, high efficiency and strong adaptability, and the service life of the mold can be increased by above 35%.

Owner:ZHEJIANG UNIV OF TECH +1

Nickel-base composite coat containing nano diamond and ultrasound wave auxiliary preparation method thereof

InactiveCN101122044AGrain refinementHigh hardnessElectrolytic coatingsUltrasound - actionUltrasonic cavitation

The invention discloses a nickel-based composite plating layer containing nano diamonds and an ultrasonic auxiliary preparation method for the plating layer. The invention relates to the nickel-based composite plating layer and the preparation method of the plating layer. The nickel-based composite plating layer containing nano diamonds is with metal nickel or nickel alloy as the matrix, and nano diamond grains evenly diffused in. The preparation method includes the following procedures: preparation of the nano composite bath liquid: the nano composite plating layer is prepared in ultrasonic wave. In the plating layer, the nano diamond grains are evenly diffused in the nickel matrix in nano scale, so as to refine the metal grains and obviously improve the hardness and tribological performance of the original nickel plating layer. The invention uses ultrasonic cavitation to make sure of even scattering of the nano diamonds in the bath solution and plating layer, and promotes the codeposition of the nano grains and the metal. The nano composite plating layer can effectively improve the anti-abrasion and abrasion reduction performances of the surface of work pieces, extend the service life of them, and is widely applicable to easily wearable work pieces, such as moulds, all bearings, gears, engines, drive parts, etc.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Copper iron tin powder composition and preparation method thereof

The invention provides a copper iron tin powder composition and a preparation method thereof. The preparation method of the copper iron tine powder composition includes: firstly, mixing copper powder and iron powder, and dispersing mixture to obtain copper and iron pre-alloy powder; and secondly, adding spindle oil after smashing and screening the pre-alloy powder, and then adding tin powder and graphite powder to obtain the copper iron tin powder composition. As content of copper and tin is increased and the spindle oil is added, wear resistance of the powder composition is improved. Meanwhile, iron powder in the copper iron tin powder composition is exposed by smashing during preparation, and accordingly, strength of the powder composition is improved. Therefore, the copper iron tin powder composition is high in strength and wear resistance.

Owner:湖南汇融科技有限公司

Surface antiseptic treating agent for cable bridge frame

InactiveCN101085889ARaise the ratioOvercome the problem of poor scratch resistanceCellulose coatingsAnti-corrosive paintsWear resistantRare earth

The invention relates to a kind of corrosion-resistant and erosion resistant coating material, which in detail is a corrosion-resistant material for cable bridge surface. The invention adds flaky zinc powder concentration for traditional dacromet coating formulation, adds penetrating agent, surface active agent, hardening agent and rare earth material. The coating layer on the surface is characterized by high adhesion power, good wearing resistant performance, good antiweatherability and stable chemically-resistant property, and suitability for wild environment utilization for a long time, which as long as 30 years.

Owner:孔繁明

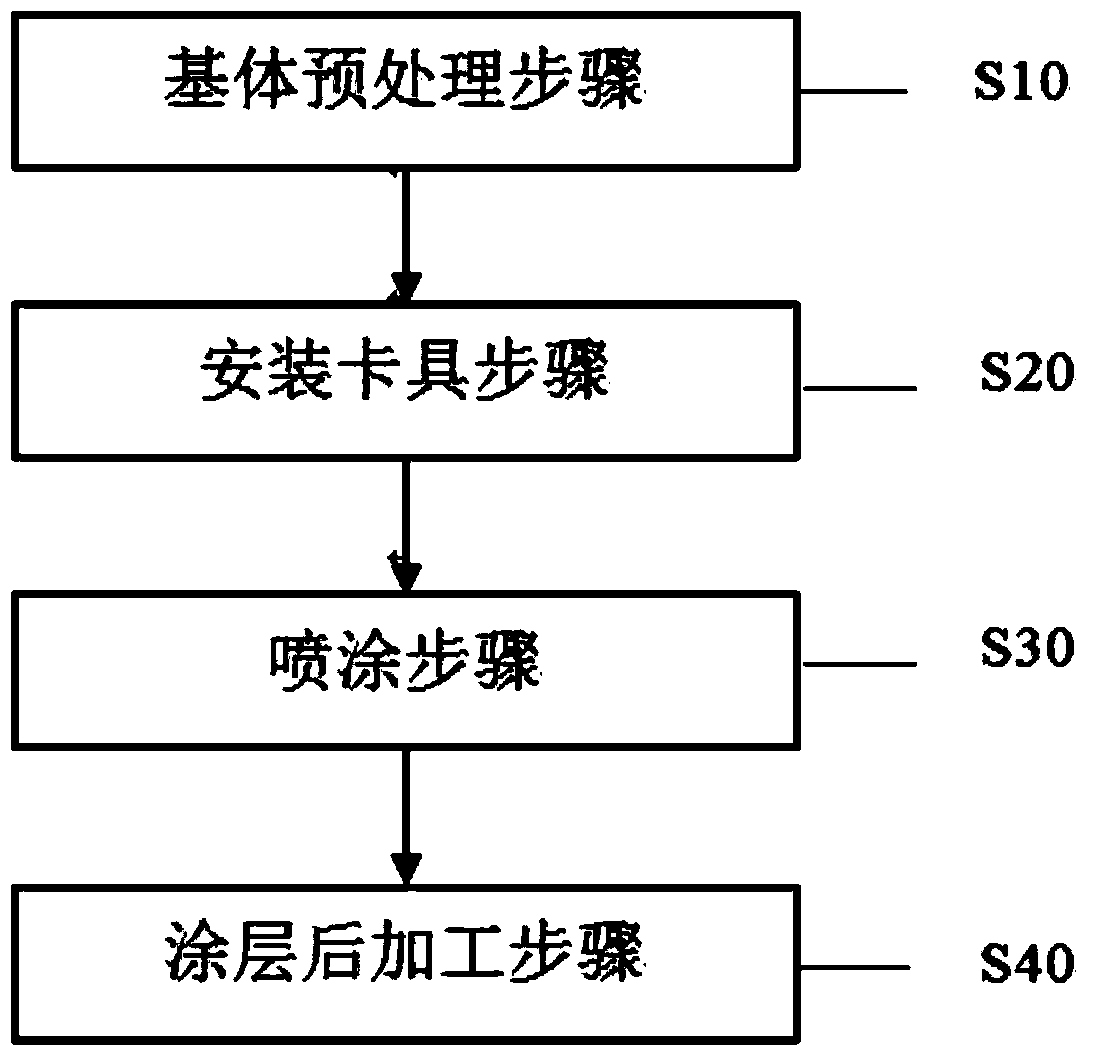

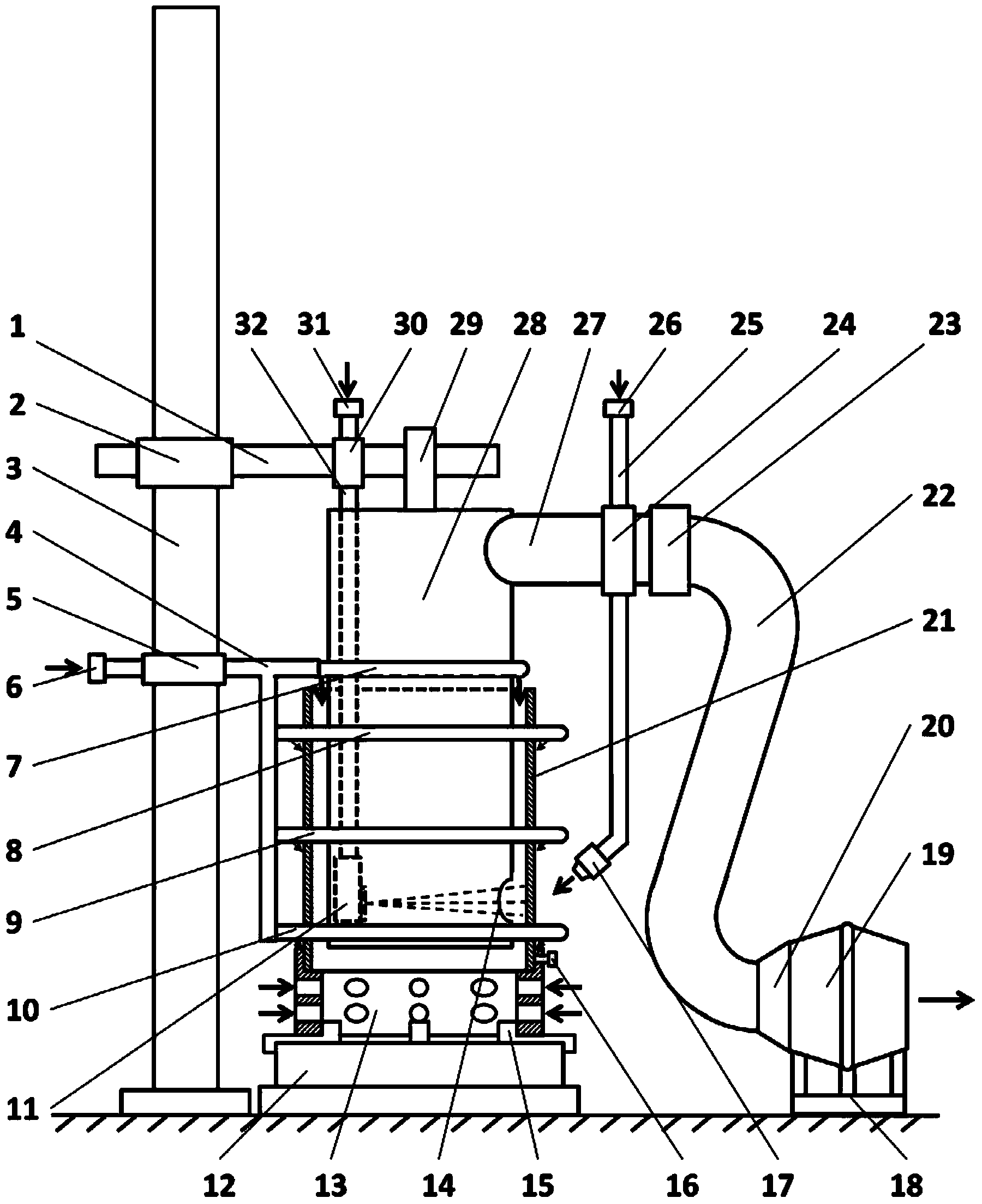

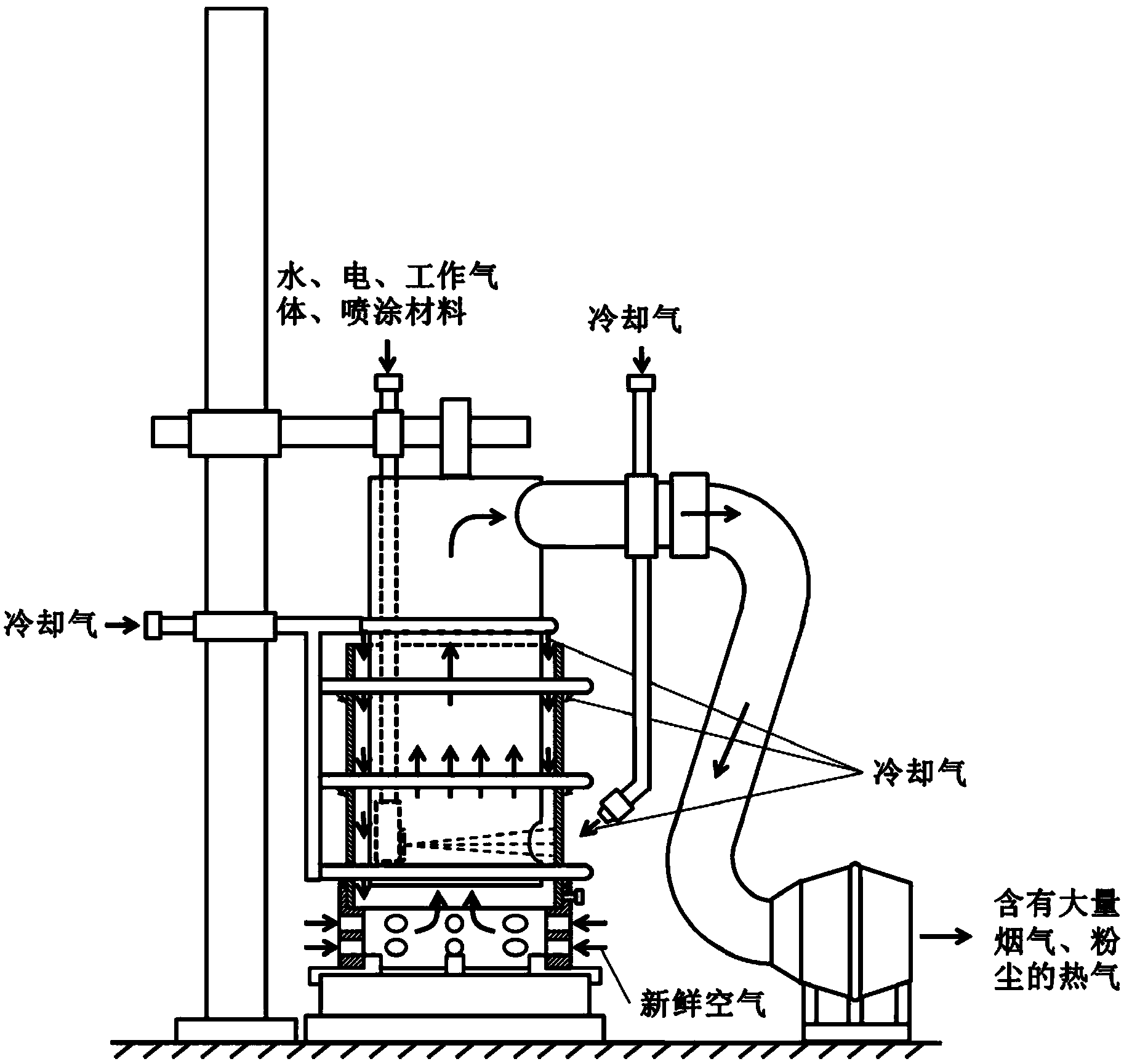

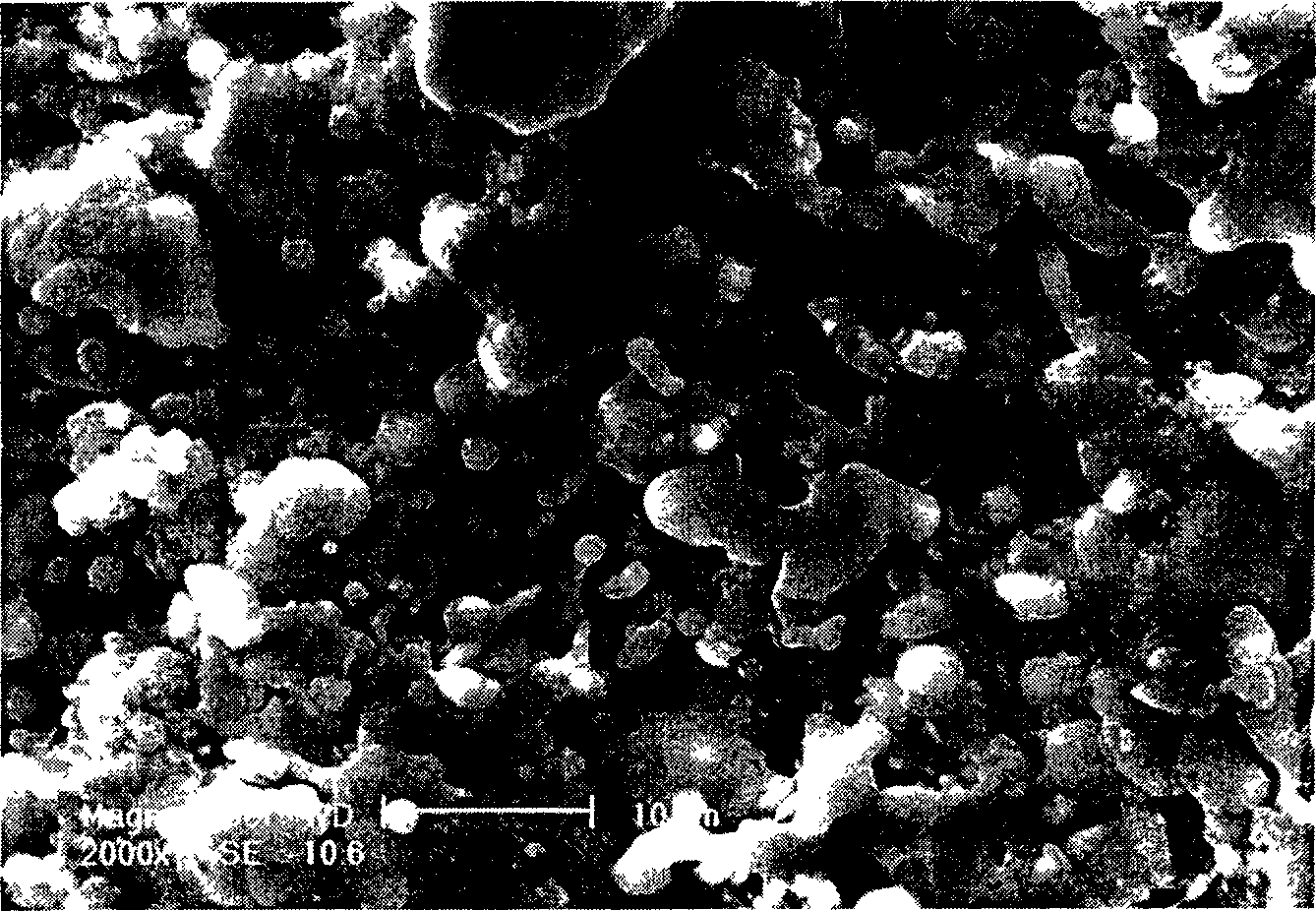

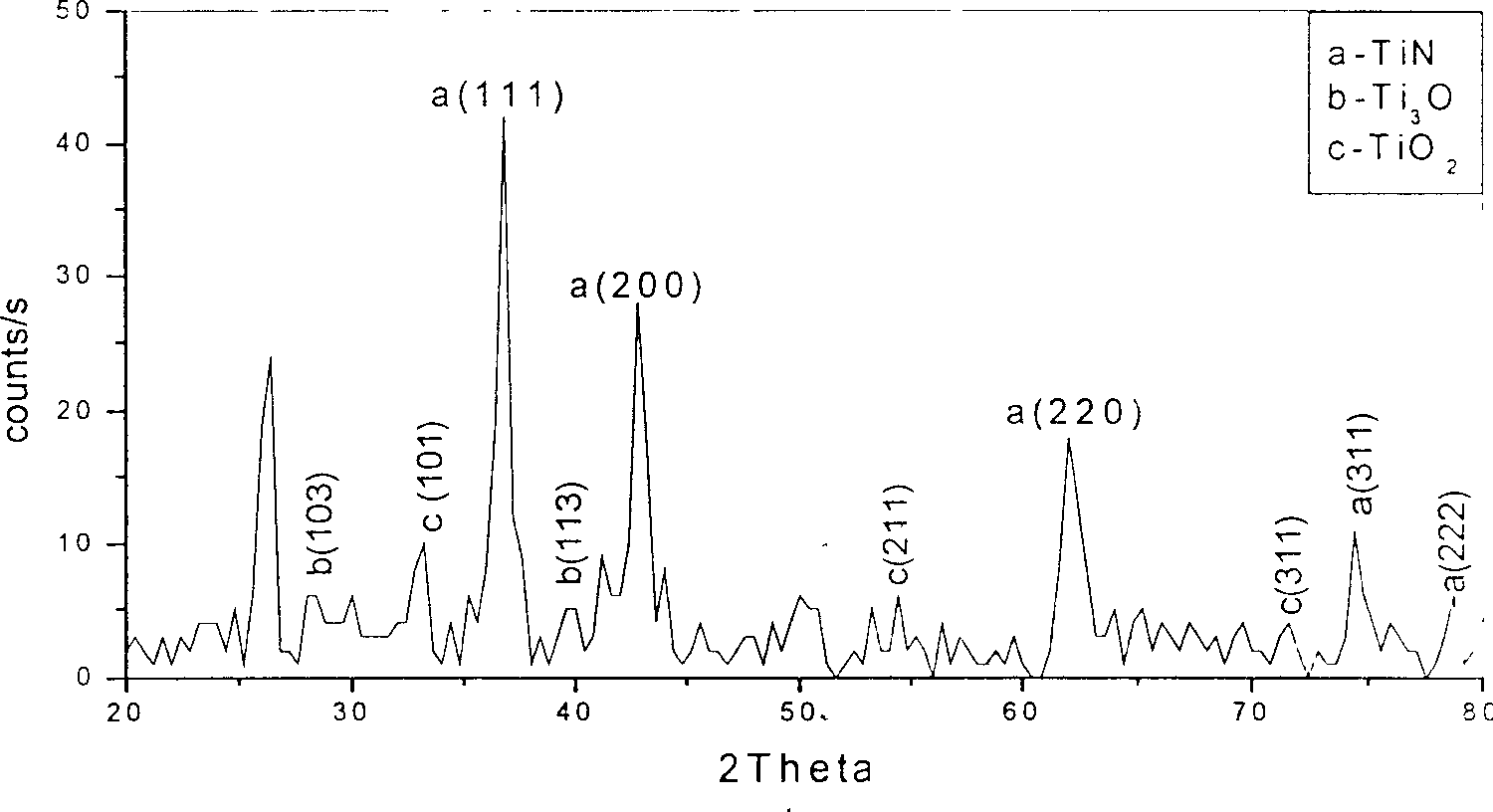

Method for reaction plasma spraying nano crystal titanium nitride coating

InactiveCN1616712AImprove production efficiencySimple methodMetallic material coating processesCeramic coatingTitanium nitride

The reaction and plasma spraying process of preparing nano crystal titanium nitride coating on alloy base layer in metal or ceramic substrate includes the main steps of: pre-treating substrate, feeding mixed ion gas to start arc, feeding self-melting alloy powder into plasma flow for spraying to form the alloy base layer; and feeding nitrogen-containing reacting gas into the reaction chamber and feeding metal powder into the flame flow for spraying to form nano crystal titanium nitride coating on the alloy base layer. The process can form coating with raised toughness, wear resistance, friction reducing property and heat shock resistance, as well as thickness up to 600 microns, high smelting point, high hardness and excellent chemical stability. The present invention is mainly used in preparing high smelting point nano nitride ceramic coating.

Owner:HEBEI UNIV OF TECH

Lubricating oil

ActiveCN107338100AThe effect of reducing low temperature viscosityImprove viscosity indexLubricant compositionReducerBase oil

The invention relates to a lubricating oil. The lubricating oil comprises, by weight, 4-4.5 parts of a dispersant, 2-3 parts of a viscosity modifier, 0.5-0.8 part of an anti-wear agent, 0.2-0.3 part of a wear reducer, 0.05-0.1 part of a detergent, and base oil, and the total weight part is 100. The effect of the compatibility of all modification components is far better than the superposed effect of individual modification components in affection of the performances of the base oil, so the wear resistance and the dispersion performance of the lubricating oil are remarkably improved.

Owner:沈阳德远科技有限公司

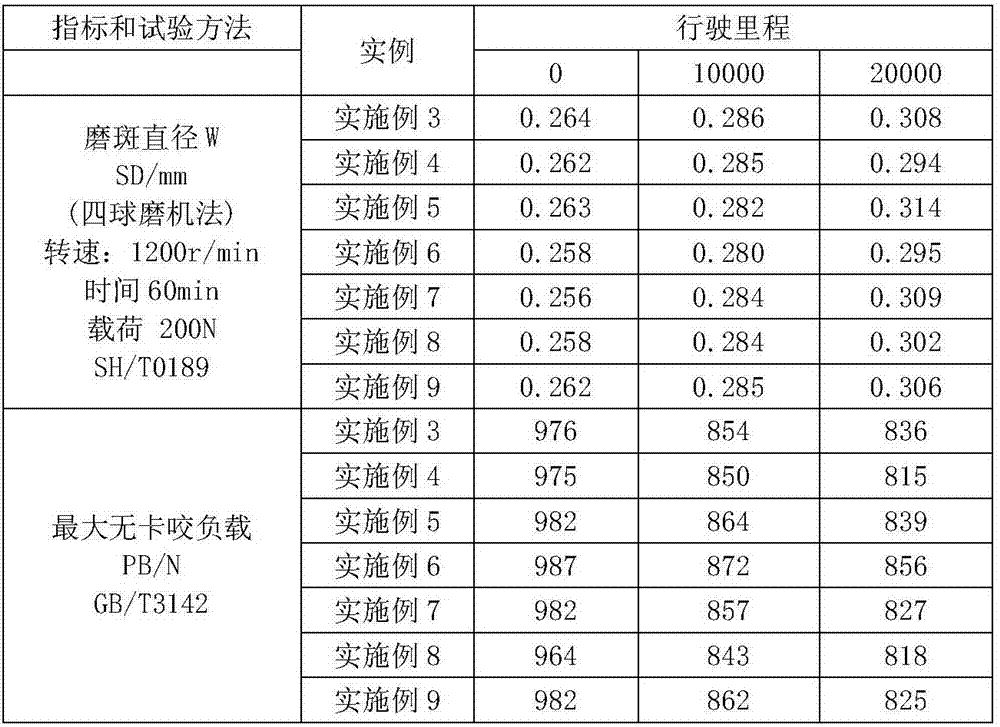

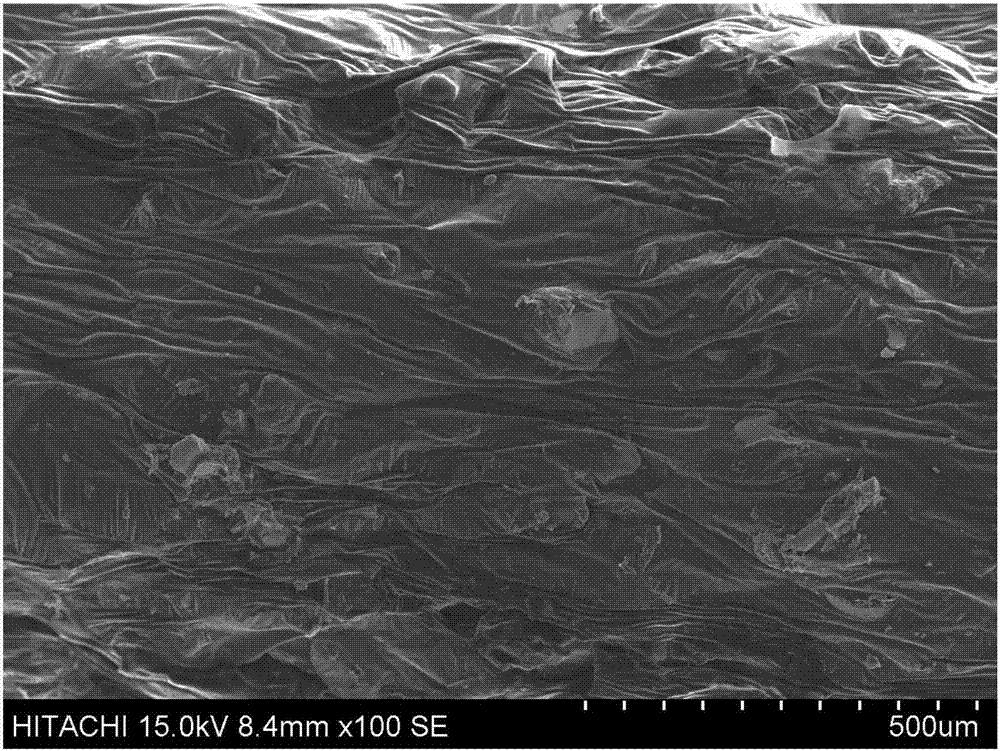

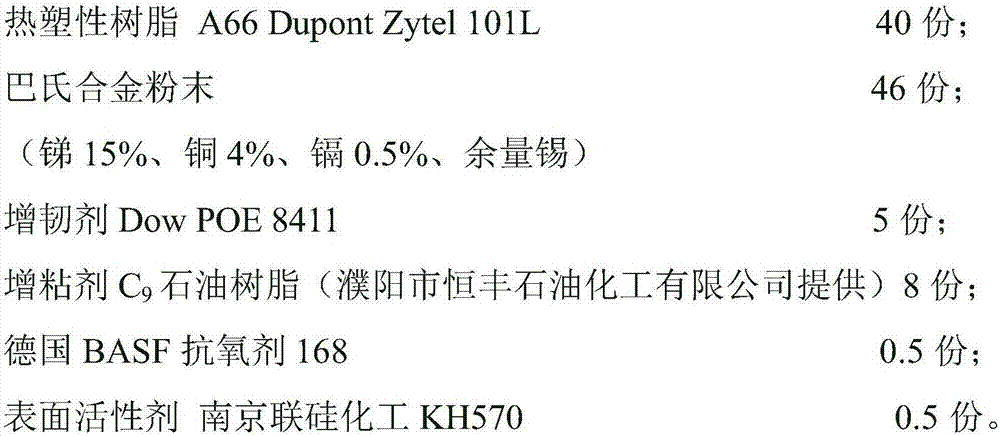

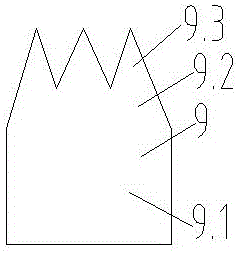

Anti-friction material based on FDM 3D printing, preparation method of anti-friction material and method for enhancing anti-friction property of product made of material

The invention relates to an anti-friction material based on FDM 3D printing, a preparation method of the anti-friction material and a method for enhancing an anti-friction property of the product made of the material. The anti-friction material based on FDM 3D printing is a material which is mainly made of babbitt metal powder and thermoplastic resin. The preparation method comprises the following steps: (1) mixing various components in a composition, and preferably fully mixing the components for 5-30 minutes by a high-speed mixer; and (2) carrying out melt plastification on a mixture obtained by mixing in the step (1) through a double-screw extruder, and carrying out granulation through a granulator. The method for enhancing the anti-friction property of the product made of the anti-friction material based on FDM 3D printing comprises the following steps: (1) preparing the anti-friction material based on FDM 3D printing into a 3D printing product; and (2) placing the 3D printing product obtained in the step (1) into an electromagnetic induction heating furnace, and melting babbitt metal so that a gap in the product is filled with the melted babbitt metal. The anti-friction material for FDM 3D printing has anti-friction characteristic.

Owner:福州启智达三维科技有限公司

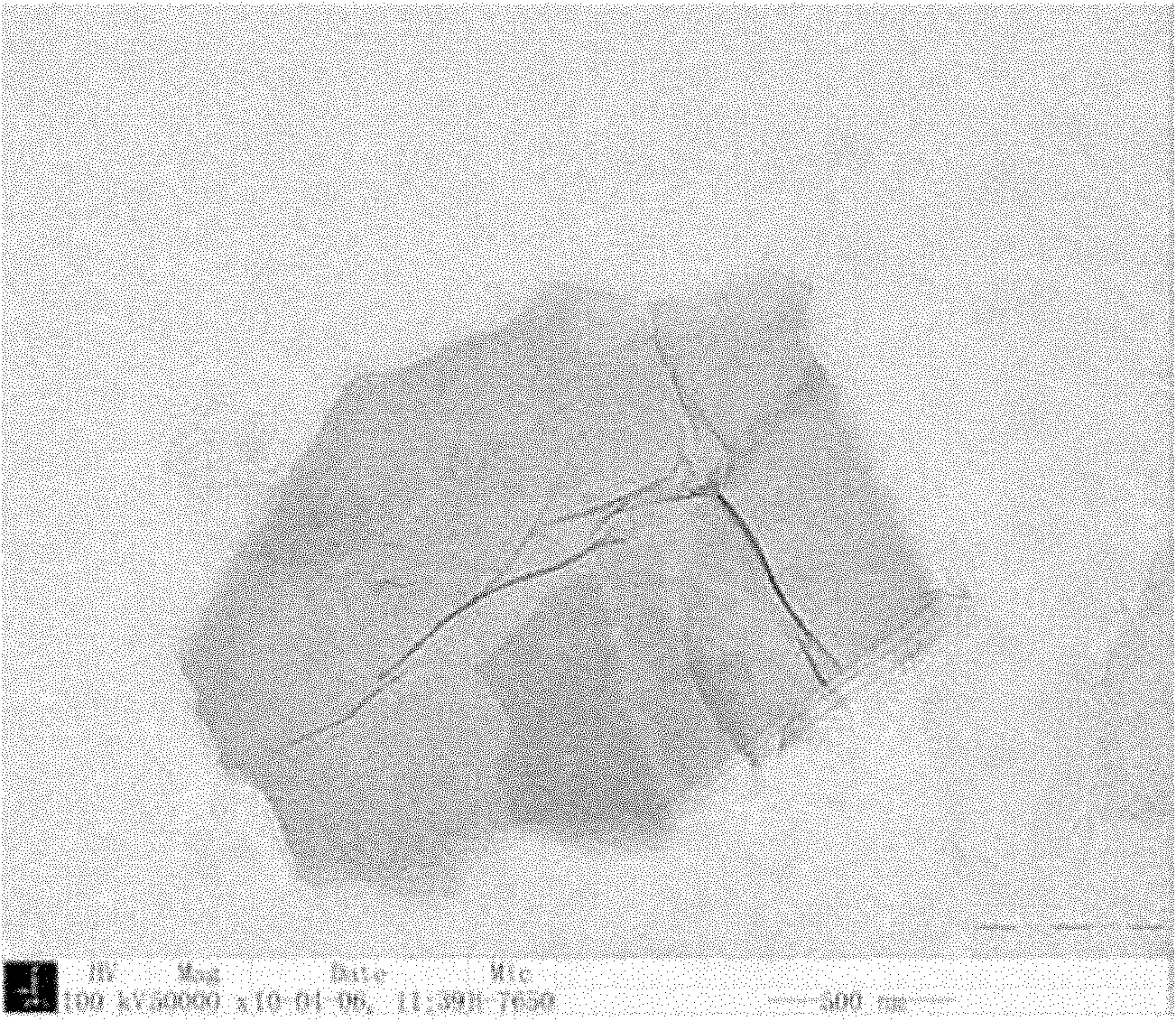

Method for preparing graphite oxide/macromolecular water-based cold rolling lubricating additive

InactiveCN102041139AStrong combinationImprove wear reduction performanceAdditivesDimethyl formamideEmulsion

The invention discloses a method for preparing a graphite oxide / macromolecular water-based cold rolling lubricating additive, and relates to a method for preparing a graphite oxide-based lubricating additive. The method solves the problems that the conventional cold rolling liquid has short service life, is easy to settle and break emulsion and has poor lubricating performance, poor anti-rust level, high viscosity and high residual carbon quantity and residual iron quantity. The method comprises the following steps of: adding graphite oxide into mixed solution of thionyl chloride and methylbenzene, performing reflux reaction to obtain graphite acetyl chloride, then adding the graphite acetyl chloride and water-soluble macromolecules into N,N-dimethyl formamide to react, drying the reaction system, dispersing the dried product into water, then adding ethanol to obtain sediment, and drying the sediment. The molecular structure of the water-based cold rolling lubricating additive has flexible polymer molecular chains, so the anti-friction performance of the lubricating additive is improved; the lubricating additive forms stable solution in water, and the solution has low viscosity, is not easy to settle and has long service life; and the lubricating additive has good anti-rust level and low residual carbon quantity and residual iron quantity. Through the water-based cold rolling lubricating additive, the friction spot diameter of the base liquid is reduced by 26.2 percent.

Owner:HARBIN INST OF TECH

Lubricating grease composition of automobile steering combination switch and preparation method

InactiveCN110157525AImprove adhesionImprove wear reduction performanceLubricant compositionAntioxidantEngineering

The invention relates to the technical field of lubricating greases, and discloses a lubricating grease composition of an automobile steering combination switch. The lubricating grease composition comprises the following components in percent by mass: 85-90% of a base oil and 10-15% of a thickener, and comprises in percent by the total mass of the above two components: 2-4% of a tackifier, 0.5-1.5% of an extreme pressure anti-wear agent, 0.4-1.6% of an antioxidant, and 4.0-6.0% of a solid lubricant. According to the lubricating grease composition of the automobile steering combination switch and a preparation method, the overall formula is simple, the lubricating grease for the automobile steering combination switch has the characteristics of excellent adhesion, plastic compatibility, shear resistance, wear reduction, noise reduction, electrical conductivity and long life, the practical performance of the lubricating grease is improved, the lubricating grease is suitable for using in the contact friction between a metal and a plastic, a plastic and a plastic in the temperature range of 40 DEG C-130 DEG C, the service life of a combination switch for automobiles can be effectively improved, problems of abnormal noise, short circuit, jam and the like of the combination switch for automobiles can be effectively avoided, and the use is convenient.

Owner:安徽和欣润滑科技有限公司

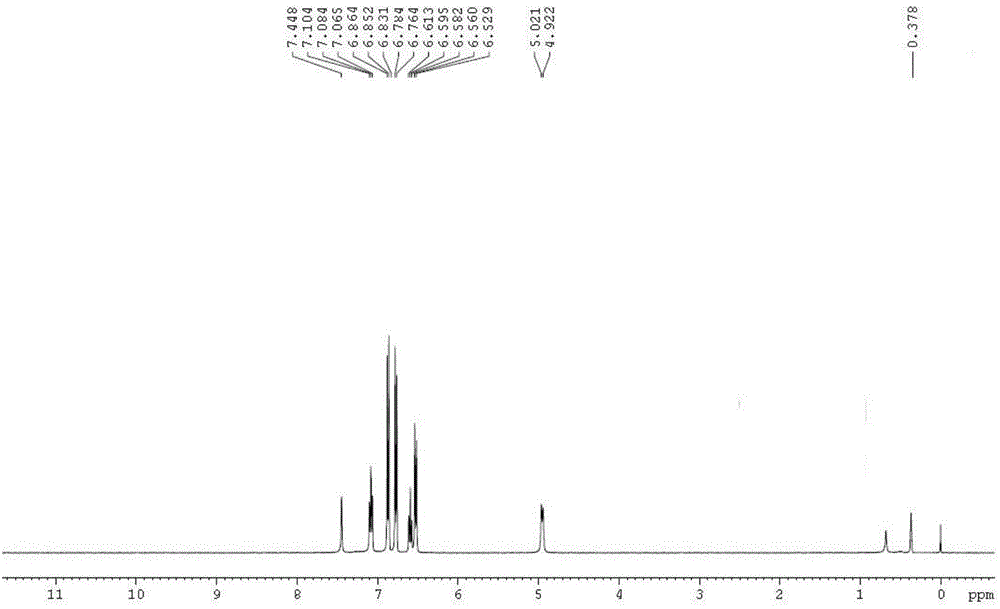

Calcium-based lubricating grease composition with excellent antifriction property and preparation method therefor

ActiveCN105586134AImprove wear reduction performanceImprove antioxidant capacityLubricant compositionBase oilHigh load

The invention discloses a calcium-based lubricating grease composition with excellent antifriction property. The lubricating grease composition contains the following ingredients in percentage by weight: 65-95wt% of lubricating base oil, 5-35wt% of calcium-based thickener and 0.1-15wt% of additive, wherein the additive contains a compound with a structure represented by a formula (I) shown in the description. The invention further provides a preparation method for the calcium-based lubricating grease composition with excellent antifriction property. The calcium-based lubricating grease composition disclosed by the invention contains the multipurpose additive, so that the antifriction capability and oxidation resistance of lubricating grease are greatly improved, and meanwhile, the influence on other properties of the calcium-based lubricating grease is low; and the high-temperature resistance, colloid stability and bearing capacity are still excellent, so that the lubricating grease composition can be adequate to harsh working conditions, such as high-temperature, high-speed, high-load and watery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Urea-based lubricating grease composition with excellent antifriction property and preparation method therefor

ActiveCN105586135AImprove wear reduction performanceImprove antioxidant capacityLubricant compositionMechanical stabilityBase oil

The invention discloses a urea-based lubricating grease composition with excellent antifriction property. The lubricating grease composition contains the following ingredients in percentage by weight: 65-95wt% of lubricating base oil, 5-35wt% of urea-based thickener and 0.1-15wt% of additive, wherein the additive contains a compound with a structure represented by a formula (I) shown in the description. The invention further provides a preparation method for the urea-based lubricating grease composition with excellent antifriction property. The urea-based lubricating grease composition disclosed by the invention contains the multipurpose additive, so that the antifriction capability and oxidation resistance of lubricating grease are greatly improved. The lubricating grease disclosed by the invention has excellent high-temperature properties, mechanical stability, oxidation resistance, colloid stability, waterproofing performance, bearing capacity, antifriction property and the like and can be adequate to harsh working conditions, such as high-temperature, high-speed, high-load and watery.

Owner:CHINA PETROLEUM & CHEM CORP +1

A lithium-based lubricating grease composition with excellent wear resistance and a preparing method thereof

ActiveCN105586115AImprove wear reduction performanceImprove antioxidant capacityAdditivesLithiumCarrying capacity

A lithium-based lubricating grease composition with excellent wear resistance is disclosed. Based on the weight of the composition, the composition comprises 65-95% by weight of lubricating base oil, 5-35% by weight of a lithium-based thickening agent and 0.1-15% by weight of an additive. The additive comprises a compound having a structure shown as a formula (I). A preparing method of the composition is also disclosed. The composition comprises the multiple-effect additive, and therefore oxidation resistance and wear resistance of the lubricating grease composition are largely improved, other properties of the lithium-based lubricating grease composition are not influenced, and the composition still has extremely good high-temperature resistance, colloid stability, carrying capacity and waterproofness, so that the composition can be qualified for severe work conditions, such as high temperature, high speeds, high loads and high water contents.

Owner:CHINA PETROLEUM & CHEM CORP +1

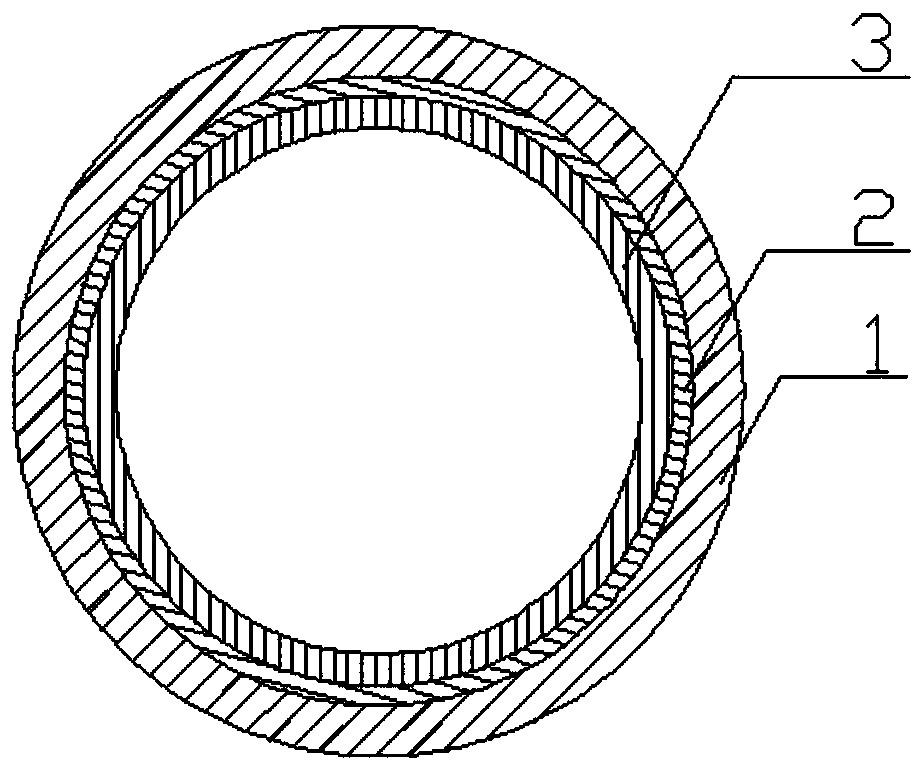

High-bearing-capacity self-lubricating shaft sleeve and preparation method thereof

ActiveCN109268393AShorten the production cycleSimple production processShaftsBearing componentsEpoxyWorking temperature

The invention discloses a high-bearing-capacity self-lubricating shaft sleeve and a preparation method thereof. The high-bearing-capacity self-lubricating shaft sleeve consists of a metal base, a middle abrasion-resistant layer and a surface spraying layer, wherein the surface spraying layer is prepared from, by weight, 1-5 parts of graphite, 2-5 parts of molybdenum disulfide, 1-4 parts of aramidfiber powder, 2-5 parts of polytetrafluoroethylene micro powder, 0.5-3 parts of curing agent, 0.5-2 parts of flexibilizer, 5-10 parts of dimethyl sulfoxide, 10-15 parts of n-butyl alcohol, 1-33 partsof acetone and 45-50 parts of epoxy resin, and the middle abrasion-resistant layer is a nitriding treatment layer. The high-bearing-capacity self-lubricating shaft sleeve has excellent abrasion resistance, self-lubricating property, fatigue durability, impact resistance and creep resistance, is especially suitable for self lubrication of engineering mechanical parts under the special working conditions of high working temperature, large dust amount, high load and the like. In addition, the shaft sleeve production period is short, the cost is low, and the shaft sleeve can replace domestic imported products.

Owner:合肥波林新材料股份有限公司

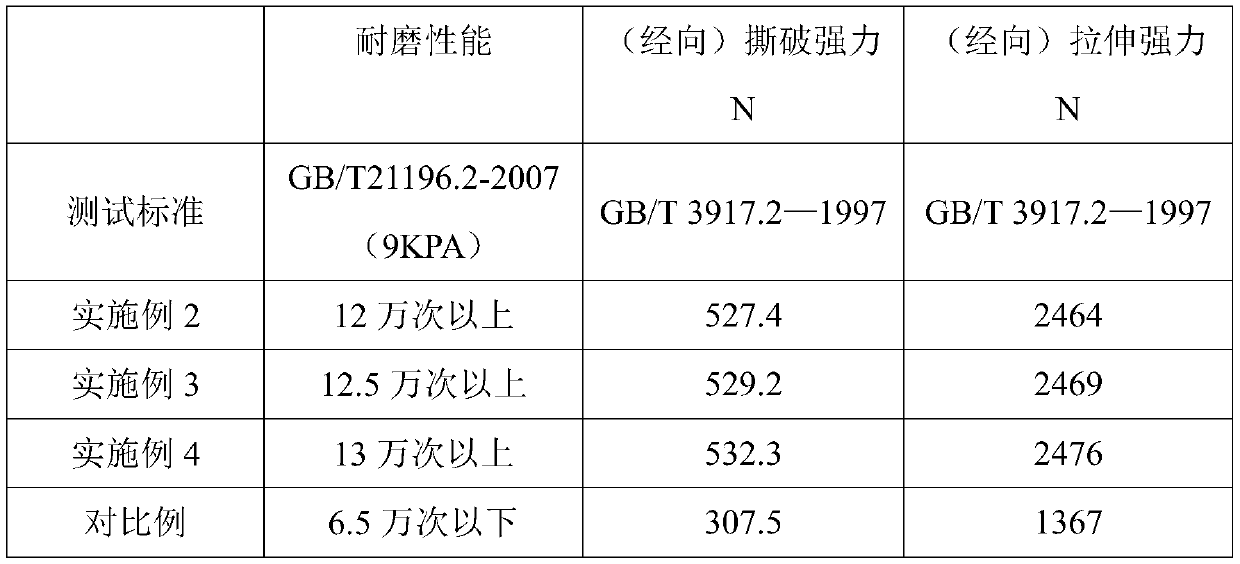

High-wear-resistance screen cloth and preparation method thereof

ActiveCN111088595AImprove wear resistanceHigh tear strengthWarp knittingConjugated synthetic polymer artificial filamentsPolymer scienceHexamethylenediamine

The invention discloses high-wear-resistance screen cloth and a preparation method thereof. The high-wear-resistance screen cloth is prepared from high-wear-resistance composite monofilaments througha weaving process. Each high-wear-resistance composite monofilament comprises an inner layer and an outer layer, wherein the periphery of the inner layer is coated with the outer layer; the ratio of the sectional area of the inner layer to the sectional area of the outer layer is 10: (7.5-9); the inner layer comprises the following raw materials in parts by weight: 90-95 parts of polyhexamethyleneadipamide, 5-8 parts of polydecamethylene sebacamide and 4-6 parts of carboxylated carbon nanotubes, and the outer layer comprises the following raw materials in parts by weight: 13-16 parts of polyhexamethylene adipamide, 80-85 parts of polydecamethylene sebacamide, 6-8 parts of poly(tetramethylene adipamide), 2-3 parts of graphene, 3-4.5 parts of nano silicon dioxide, 3-5 parts of a lubricant and 4-6 parts of a dispersant. The high-wear-resistance screen cloth disclosed by the invention is excellent in wear resistance; and the high-wear-resistance screen cloth has the advantages of high (meridional) tearing strength, high (meridional) tensile strength, high strength, favorable mechanical properties and long service life.

Owner:FUJIAN FENGYUANSHENG TEXTILE TECH CO LTD

Nano composite anti-wear coating composition used for hot forging die and application thereof

InactiveCN101210325BExtended failure cycleExtended service lifeMetallic material coating processesCarbon nanotubeHigh energy laser beam

The invention discloses a nanometer composite abrasion-resistant coating combination used for a hot forging mold and application thereof. The raw material of the combination contains ceramic nanopowder and a carbon nanotube with a volume ratio of 1:(1-4), Co with a volume of 40 to 50% the mixed volume of the ceramic nanopowder and the carbon nanotube, and a binding agent with a volume of 3 to 4 times than the mixed volume of the ceramic nanopowder and the carbon nanotube. The application of the combination comprises the following steps of: mixing the ceramic nanopowder with the carbon nanotubeand Co at the ratios, adding the binding agent at the ratio, mixing uniformly, applying on the surface of a hot forging mold to be processed to form a coating layer with a thickness of 0.2 to 0.5 mm,and scanning the coating layer with a high-energy laser beam to form the nanometer composite abrasion-resistant coating on the surface of the hot forging mold. The nanometer composite abrasion-resistant coating has the advantages of high hardness, high abrasion resistance, high abrasion reduction performance, high processing speed, high efficiency and strong adaptability, and the service life ofthe mold can be increased by above 35%.

Owner:ZHEJIANG UNIV OF TECH +1

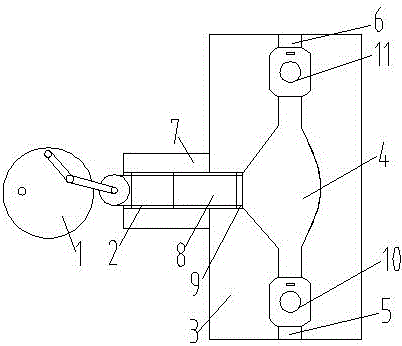

Medical infusion machine

InactiveCN106215277ALow costImprove reliabilityMedical devicesPressure infusionEngineeringMechanical engineering

The invention discloses a medical infusion machine which comprises an intelligent control system, an alarming device, a driving device and a piston reciprocating pump. The alarming device, the driving device and the piston reciprocating pump are connected with the intelligent control system respectively, the piston reciprocating pump comprises a pump body and a piston body mounted on the side face of the pump body, a pump cavity is arranged in the pump body and communicated with a piston cavity of the piston body, a piston rod is arranged in the piston body, and a sealing ring is arranged between the piston body and the piston rod. The medical infusion machine is more accurate in infusion flow control, capable of realizing infusion with different flows for different patients and different medicine liquids, more durable and higher in reliability.

Owner:鲁绍荣

Grease composition for assembling standard sections of tower crane and preparation method of grease composition

ActiveCN104164289AImprove wear reduction performanceGood adhesion resistanceLubricant compositionLithiumSulfonate

The invention relates to a grease composition for assembling standard sections of a tower crane and a preparation method of the grease composition. The grease composition comprises the following components in percentage by weight: 78.8%-94.8% of common lithium-based grease, 0.2%-0.8% of antioxidant, 0.8%-3.2% of graphite powder, 1.0%-4.5% of light calcium carbonate, 0.5%-3.0% of sorbitan monooleate, 0.4%-2.2% of phenolic resin, 2.0%-6.0% of sulfonate and 0.3%-1.5% of polyisobutene. The special grease composition for assembling the standard sections of the tower crane is obtained by adding additives such as the antioxidant, an antifriction agent, an anti-locking and anti-occluding agent, an anti-rust agent, a tackifying agent and the like into the common lithium-based grease taken as a carrier. According to the grease composition, the corrosion speed of shaft pins of the tower crane can be slowed, the shaft pins are prevented from being corroded and bonded with a shaft sleeve during building construction, and the pin shafts of the standard sections of the tower crane can be smoothly assembled and disassembled. The service cycle of the grease composition is within 1-2 years.

Owner:CHINA PETROLEUM & CHEM CORP

Pectin-modified micro-emulsion cutting fluid

InactiveCN106635355AImprove high temperature resistanceImprove toughnessLubricant compositionGlycerolCocamidopropyl betaine

The invention discloses pectin-modified micro-emulsion cutting fluid. The pectin-modified micro-emulsion cutting fluid is prepared from the following raw materials: refined mineral oil, TEA-lauryl sulfate, polyoxyethylene lauryl ether, cocamidopropyl betaine, fatty alcohol-polyoxyethylene ether, triethanolamine, antifoaming agent, amide borate, palmitic acid, sodium chloride, glycerol, tetraethoxysilane, oleic acid, acrylamide, azodiisobutyronitrile 3-4, aluminum borate whisker, pectin, dihydroxyl pentasulfide, a proper amount of ethyl acetate, a proper amount of ammonia water, a proper amount of absolute ethyl alcohol and a proper amount of deionized water. The prepared micro-emulsion cutting fluid has very high anti-friction extreme pressure performance, can be used for preventing adhesive wear of tools, increasing surface machining accuracy and prolonging the service lives of the tools, can meet the cooling performance in a machining process, and has a good cleaning effect; through a unique formula design, the pectin-modified micro-emulsion cutting fluid has very high biological stability and a long life cycle, and is free from irritation and pollution.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

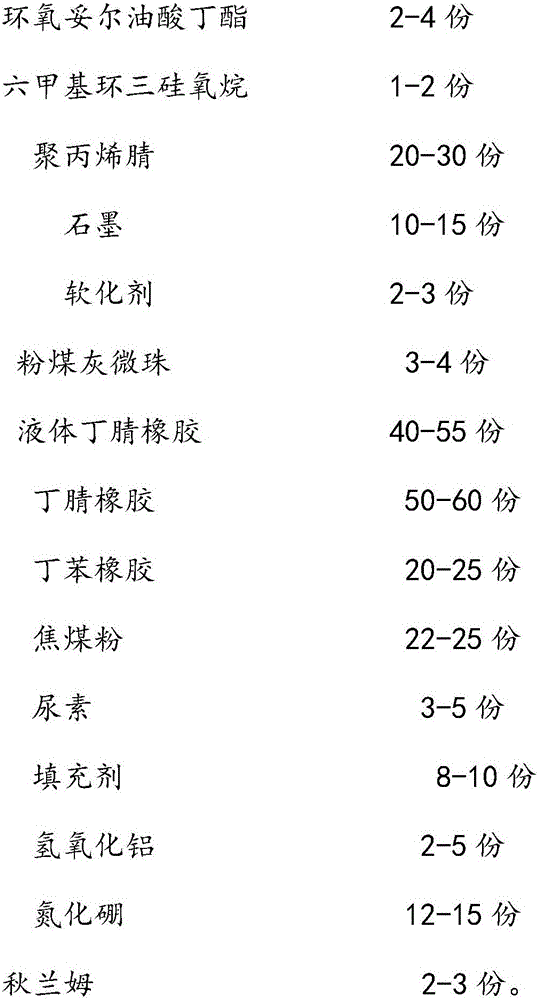

Elastic rubber material applicable to work at high temperature

InactiveCN105400006AHigh strengthImprove thermal conductivityArtifical filament manufactureRubber materialSodium sulfate

The invention discloses an elastic rubber material applicable to work at a high temperature. The elastic rubber material is prepared from, by weight, 1.6-2 parts of Arabic gum, 1-2 parts of zinc dialkyl dithiophosphate, 1-1.4 parts of accelerant DM, 2-3 parts of epoxy tall butyl oleate, 1-1.4 parts of hexamethyl cyclotrisiloxane, 24-27 parts of polyacrylonitrile, 12-13 parts of graphite, 3-4 parts of coal ash microbeads, 0.7-1 part of lauryl sodium sulfate, 42-55 parts of liquid nitrile rubber, 0.6-1 part of methacrylic acid, 52-60 parts of chemigum, 20-25 parts of butadiene styrene rubber, 23-25 parts of coking coal powder, 4-5 parts of urea, 8-11 parts of carbon black, 14-17 parts of aluminium nitride and 2-3 parts of thiuram. The prepared rubber material is good in stability, high in thermal conductivity, capable of bearing the high temperature, free of deformation and damage, meanwhile good in strength, good in chemical corrosion resistance, good in impact elasticity, high in wear resistance and long in service life.

Owner:安徽创奇乐智能游乐设备有限公司

Corrosion-resistant scaffolding composite electroplate liquid

The invention discloses corrosion-resistant scaffolding composite electroplate liquid. The corrosion-resistant scaffolding composite electroplate liquid comprises, by weight, 6.8-9 parts of aniline, 0.1-0.2 part of ammonium persulfate, 50-60 parts of boric acid, 220-250 parts of nickel sulfate, 40-50 parts of nickel chloride, 0.2-0.3 part of lauryl sodium sulfate, 0.6-0.8 part of sodium citrate, 50-60 parts of teflon emulsion, 3-4 parts of a cationic surface active agent FC134, 1.5-3 parts of lanthanum oxide, 20-30 parts of crylic acid, 0.1-0.3 part of cetyl trimethyl ammonium bromide, 0.1-0.2 part of a silane coupling agent kh550, a proper amount of ethyl alcohol and a proper amount of deionized water. The electroplate liquid prepared through the method is simple in technology and short in consumed time, a good coating can be formed on the surface of a plated piece, and binding force is good. Moreover, the abrasive resistance and corrosion resistance are greatly improved, and the corrosion-resistant scaffolding composite electroplate liquid is worthy of popularization.

Owner:ANHUI CHANGQING ELECTRONICS MACHINERY GRP

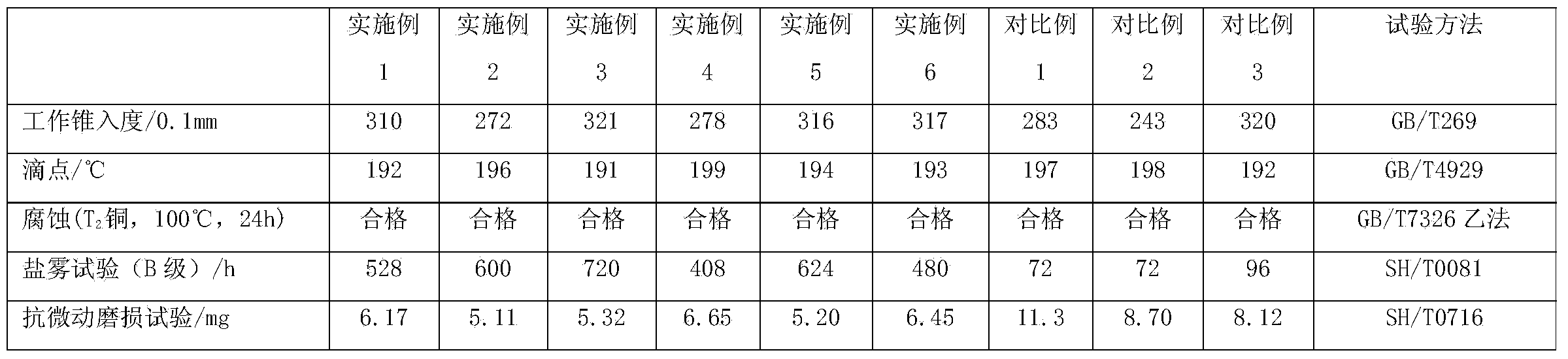

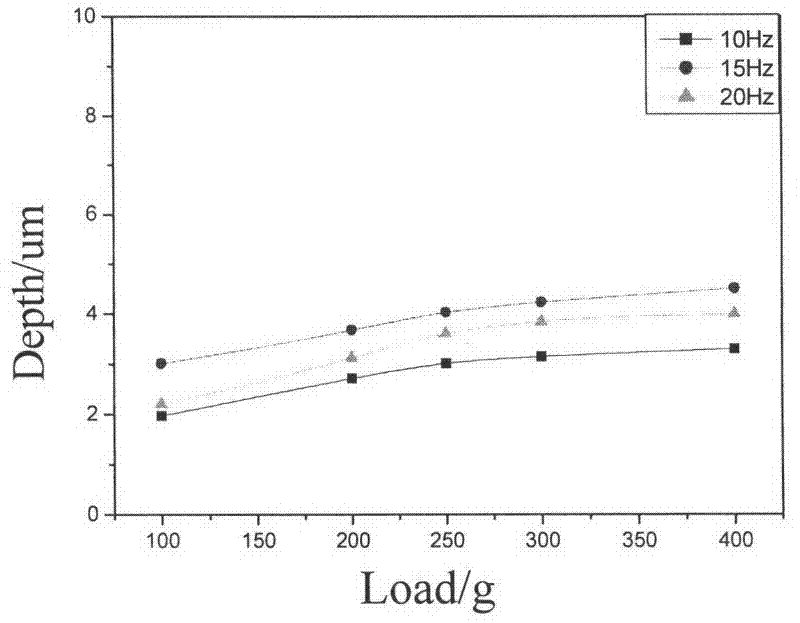

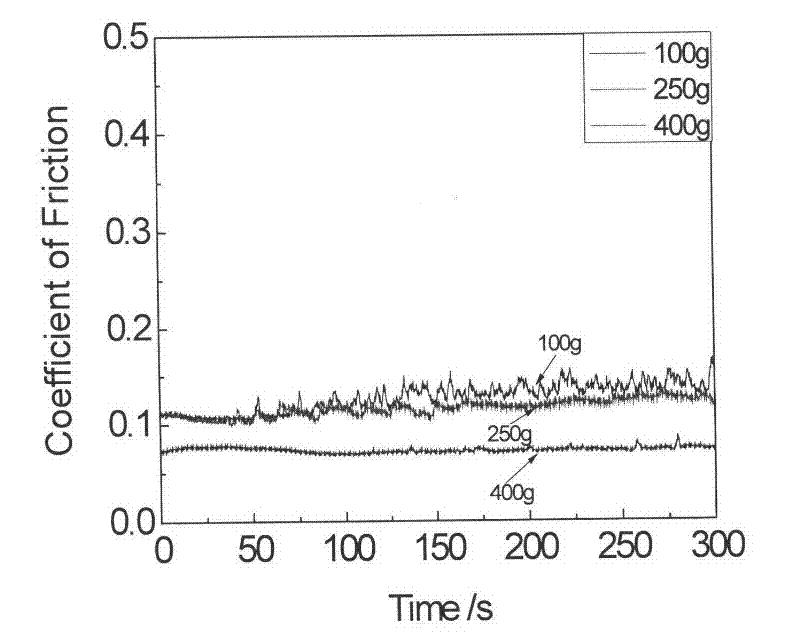

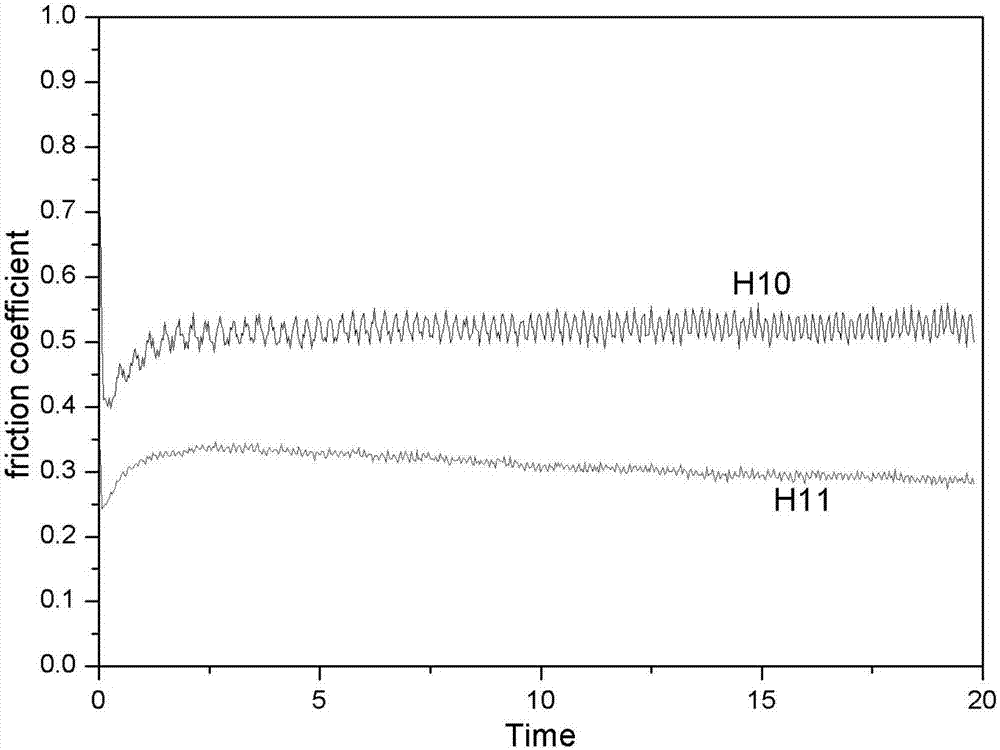

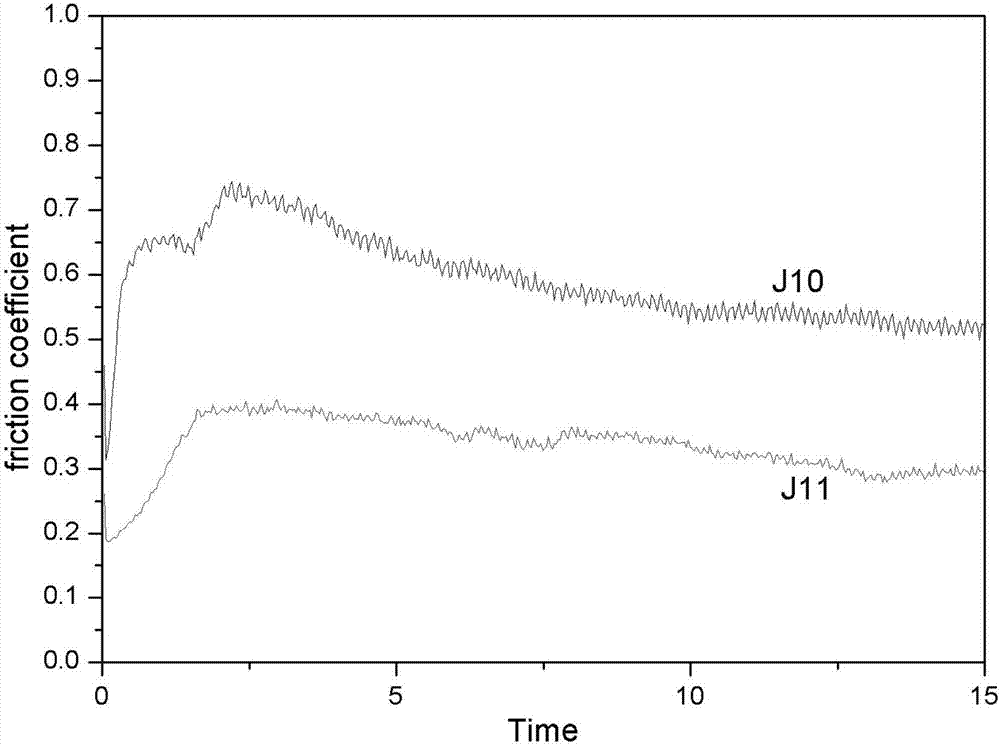

Method for raising surface friction and wear properties by changing loads

InactiveCN102435519AImprove wear resistanceImprove wear reduction performanceInvestigating abrasion/wear resistanceWear resistantHardness

A method for raising surface friction and wear properties by changing loads belongs to the field of the surface friction and wear properties. The method provided by the invention comprises the following steps of: planning the surface of carbon steel No.45 to obtain a surface with its roughness being Ra 3.2; carrying out quenching and tempering treatment, heating a workpiece of 100mm*85mm*20mm (length*width*height) to 840 DEG C, keeping warm for two hours, rapidly placing into 10% of a salt solution for cold quenching to make the workpiece to be completely quenched, carrying out high-temperature tempering processing on the workpiece, keeping warm at the temperature of 560 DEG C for 1.5 hours to obtain carbon steel No.45 with its hardness being about 35 HRC; and finally processing the processed carbon steel No.45 into a test piece of 22mm*20mm*4 (length*width*height). The test piece undergoes a friction test, the load is set at 100g-400g and the time is 300s. When the load is 400g, the friction coefficient of the test piece is the lowest, and the wear resistant and antifriction performance of the test piece are obviously raised.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

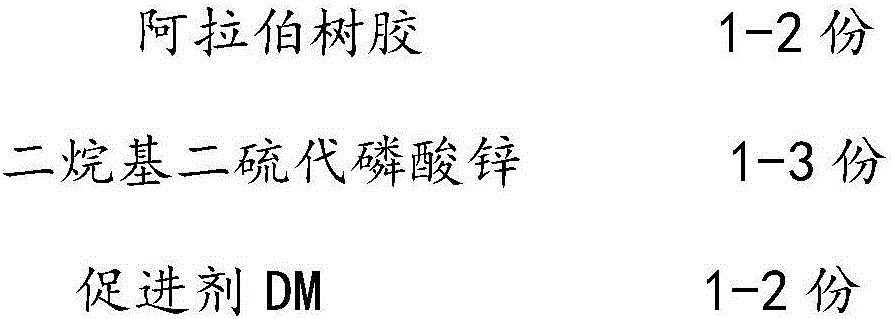

Rubber material applied in high-temperature working environment and preparation method thereof

The invention discloses a rubber material applied in a high-temperature working environment and a preparation method thereof. The rubber material is prepared from, by weight, 1-2 parts of arabic gum, 1-3 parts of zinc dialkyl dithiophosphate, 1-2 parts of an accelerant DM, 2-4 parts of epoxy tall oil acid butyl ester, 1-2 parts of hexamethyl cyclotrisiloxane, 20-30 parts of polyacrylonitrile, 10-15 parts of graphite, 2-3 parts of a softening agent, 3-4 parts of fly ash microspheres, 40-55 parts of liquid nitrile rubber, 50-60 parts of nitrile rubber, 20-25 parts of butadiene styrene rubber, 22-25 parts of coking coal powder, 3-5 parts of urea, 8-10 parts of a filling agent, 2-5 parts of aluminum hydroxide, 12-15 parts of boron nitride and 2-3 parts of thiuram. The rubber material has the good high temperature resistance, acid resistance, oil resistance and flame retardance and can be well applied to a high-temperature area.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

Low-friction-coefficient high-lubricity silicon core tube

The invention discloses a low-friction-coefficient high-lubricity silicon core tube. The silicon core tube is prepared from, by weight, 190-200 parts of n-decyl hydrocarbon, 65-75 parts of linear-chain undecylenic hydrocarbon, 190-200 parts of hydrogen containing silicon oil, 15-20 parts of hydroxystearic acid, 4-6 parts of lithium hydroxide, 45-55 parts of PE carrier resin, 5-7 parts of color master batch, 60-70 parts of high-density polyethylene, 6-8 parts of silicone, 3-5 parts of oleamide, 15-20 parts of nano zinc oxide, 6-8 parts of hydrogenated castor oil and 0.2-0.3 part of an antioxidant. The silicon core tube is excellent in friction performance, an optical fiber cable can be repeatedly drawn in the tube without shedding or stripping, excellent heat resistance is achieved, and the low-friction-coefficient high-lubricity silicon core tube is worthy of popularization.

Owner:ANHUI EFARAD ELECTRIC POWER TECH

Scaffold composite electroplating liquid with good decoration effect

InactiveCN106087012AImprove performanceHigh hardnessElectrolytic coatingsFriction reductionSurface-active agents

The invention discloses scaffold composite electroplating liquid with a good decoration effect. The scaffold composite electroplating liquid is prepared by the following raw materials in parts by weight: 6.8-9 of aniline, 0.1-0.2 of ammonium persulfate, 50-60 of boric acid, 220-250 of nickel sulfate, 40-50 of nickel chloride, 0.2-0.3 of lauryl sodium sulfate, 1-2 of phenyl sodium sulfate, 50-60 of polytetrafluoroethylene emulsion, 3-4 of cation surface active agent FC134, 1.8-2.5 of cerium oxide, 3.2-3.6 of antimony-doped tin oxide, 0.1-0.2 of silane coupling agent A171, a proper quantity of ethanol, and a proper quantity of de-ionized water. The prepared electroplating liquid is easy to operate an electroplating process, is not easy to fall, is excellent in durability, is excellent in hardness, wear resistance, friction reduction and oxidation resistance, is high in quality, and deserves popularization.

Owner:王世群

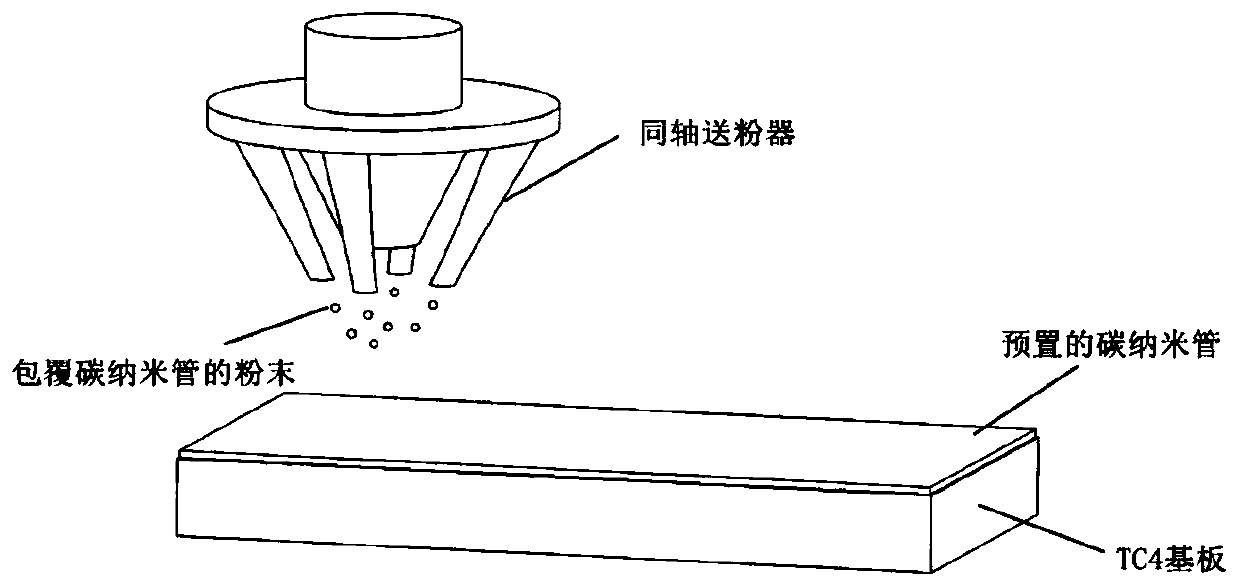

Method for preparing carbon nanotube reinforcing composite clad layers on surfaces of titanium alloys

InactiveCN110684976AImprove toleranceReduce burning lossMetallic material coating processesTitaniumTitanium alloy

The invention provides a method for preparing carbon nanotube reinforcing composite clad layers on the surfaces of titanium alloys. Carbon nanotube dispersion liquid is prepared; one part of the carbon nanotube dispersion liquid is uniformly mixed with nickel base self-fluxing alloy powder for drying to prepare mixed powder; the other part of the carbon nanotube dispersion liquid is coated on thesurfaces of titanium alloy basal bodies to obtain titanium alloy basal bodies prearranged with carbon nanotubes on the surfaces; and clad layers are formed on the surfaces of the titanium basal bodiesprearranged with the carbon nanotubes on the surfaces by the mixed powder through laser cladding by adopting a coaxial powder feeding mode. The wear resistance, the anti-attrition performance, the hardness and the high-temperature resistance of the clad layers on the surfaces of the titanium alloys can be improved. The method is simple in operation, excellent in process repeatability and lower incost, and can be widely used for surface treatment of the titanium alloys.

Owner:SHANDONG UNIV

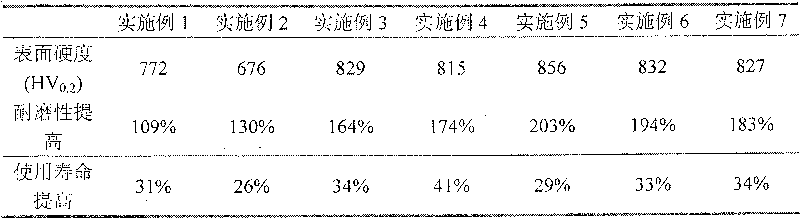

Aluminum alloy surface micro-arc oxidation coating and preparing method thereof

ActiveCN107034511AImprove wear resistanceImprove wear reduction performanceSurface reaction electrolytic coatingMicro arc oxidationElectrolysis

The invention discloses an aluminum alloy surface micro-arc oxidation coating and a preparing method thereof. Micron-order or nanoscale hexagonal boron nitride is added into a natrium aceticum electrolysis system, a suited electrolyte formula is explored, and then the ceramic coating with the high antifriction erosion and abrasive resistance is prepared in the optimized electrolyte system. Hexagonal boron nitride particles exist in the coating, and the high antifriction erosion and abrasive resistance are achieved. A film is prepared on the aluminum alloy surface to increase the abrasive resistance of the surface and accelerating further industrialized application of an aluminum alloy.

Owner:SHANDONG UNIV

High-hardness silicone-cored pipe with effect of protecting optical fibers

The invention discloses a high-hardness silicone-cored pipe with an effect of protecting optical fibers. The silicone-cored pipe is prepared from the following raw materials in parts by weight: 190-200 parts of n-decyl hydrocarbon, 65-75 parts of linear C11 olefin, 190-200 parts of hydrogen-containing silicone oil, 15-20 parts of hydroxystearic acid, 4-6 parts of lithium hydroxide, 45-55 parts of a PE carrier resin, 5-7 parts of color master batch, 60-70 parts of high density polyethylene, 3.4-5 parts of sepiolite fiber, 5-7 parts of silica sol, 0.3-0.4 part of an antioxidant, 0.3-0.4 part of benzotriazole, 0.3-0.5 part of a silane coupling agent a171 and a proper amount of deionized water. The silicone-cored pipe prepared by the invention is low in preparation cost, excellent in wear resistance, high in environmental load resistance, wide in application prospect and worthy of popularization, and the service life is prolonged.

Owner:黄振东

High-mechanical-strength silicon core pipe

The invention discloses a high-mechanical-strength silicon core pipe. The silicon core pipe is prepared from, by weight, 190-200 parts of deca-hydrocarbon, 65-75 parts of straight-chain undecylene, 190-200 parts of hydrogen containing silicone oil, 15-20 parts of hydroxystearic acid, 4-6 parts of lithium hydroxide, 45-55 parts of PE carrier resin, 5-7 parts of color master batch, 60-70 parts of high-density polyethylene, 3.4-4 parts of copper ore slag, 2.3-3 parts of liquid paraffin, 1.2-1.4 parts of lauric acid, 0.4-0.6 part of calcium sulfonate, 0.3-0.4 part of oleamide and an appropriate amount of water. A preparing method is easy to operate, high in stability and capable of being popularized on a large scale, and the prepared silicon core pipe is high in tensile strength, good in elongation at break and mechanical property, capable of meeting the use requirement of the market and worthy of popularization.

Owner:ANHUI EFARAD ELECTRIC POWER TECH

Scaffolding antistatic composite electroplate liquid

InactiveCN106400090AImprove wear reduction performanceImprove the lubrication effectElectrolytic coatingsSurface-active agentsAniline

The invention discloses scaffolding antistatic composite electroplate liquid. The scaffolding antistatic composite electroplate liquid comprises, by weight, 8-14 parts of attapulgite, 3-4 parts of dextrin, 6.8-9 parts of aniline, 0.1-0.2 part of ammonium persulfate, 50-60 parts of boric acid, 220-250 parts of nickel sulfate, 40-50 parts of nickel chloride, 0.2-0.3 part of lauryl sodium sulfate, 50-60 parts of teflon emulsion, 3-4 parts of a cationic surface active agent FC134, 1.5-3 parts of cerium oxide, a proper amount of ethyl alcohol and a proper amount of deionized water. The scaffolding antistatic composite electroplate liquid is simple in technology, the quality of obtained products is qualified, and the phenomenon of peeling is avoided; and the color and luster are uniform, the phenomenon of partial white spots is avoided, the surface is smooth and free of the sense of roughness, and therefore the scaffolding antistatic composite electroplate liquid is worthy of popularization.

Owner:ANHUI CHANGQING ELECTRONICS MACHINERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com