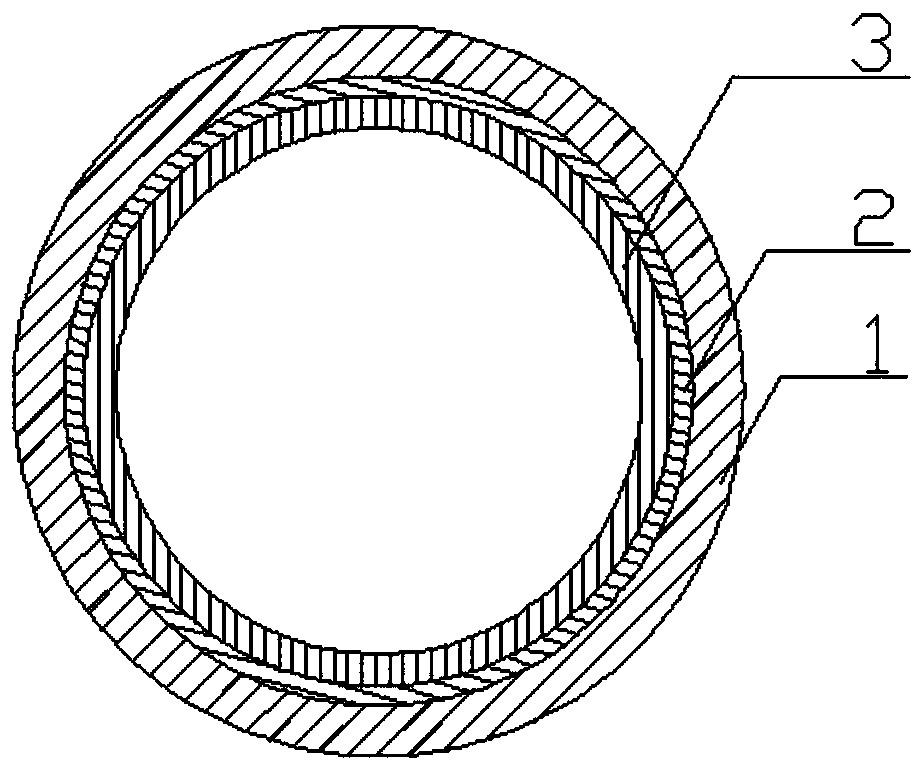

High-bearing-capacity self-lubricating shaft sleeve and preparation method thereof

A self-lubricating bushing and high-load bearing technology, applied in shafts, bearings, mechanical equipment, etc., can solve the problems of insufficient surface bearing capacity and anti-wear performance, erosion of the metal matrix on the friction surface, and serious equipment running noise. The effect of improving hardness, short production cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation steps of the high-load self-lubricating bushing of this embodiment are as follows:

[0038] (1) Preparation of shaft sleeve base material:

[0039] a. Heat treatment: 20CrMo seamless steel pipe is used for blanking, and the pressure in the vacuum furnace is quenched at 0.04MPa. The temperature is 850°C. After 3 hours of heat preservation, oil cooling is carried out, and then high temperature tempering is carried out at 580°C, and heat preservation is carried out for 4 hours. After cooling with the furnace, the quenched and tempered shaft sleeve blank is obtained, and the matrix hardness is HRC24-28;

[0040] b. Turning: turning the blank obtained after quenching and tempering;

[0041] c. Drill the inner hole: process the inner hole of the workpiece obtained by turning;

[0042] (2) Nitriding treatment:

[0043] Put the shaft sleeve obtained above in the well-type furnace at 350°C for 2 hours, then transfer it to the well-type salt bath furnace for ni...

Embodiment 2

[0053] The preparation steps of the high-load self-lubricating bushing of this embodiment are as follows:

[0054] (1) Preparation of shaft sleeve base material:

[0055] a. Heat treatment: 35CrMo seamless steel pipe is used for blanking, quenching treatment is carried out in a vacuum furnace at a pressure of 0.08MPa, the temperature is 880°C, oil cooling is carried out after 2 hours of heat preservation, and then high temperature tempering is carried out at 590°C, and heat preservation is carried out for 3 hours After cooling with the furnace, the quenched and tempered shaft sleeve blank is obtained, and the matrix hardness is HRC24-28;

[0056] b. Turning: turning the blank obtained after quenching and tempering;

[0057] c. Drill the inner hole: process the inner hole of the workpiece obtained by turning;

[0058] (2) Nitriding treatment:

[0059] Put the shaft sleeves obtained above in the well-type furnace at 300°C for 2 hours, then transfer to the well-type salt bath ...

Embodiment 3

[0069] The preparation steps of the high-load self-lubricating bushing of this embodiment are as follows:

[0070] (1) Preparation of shaft sleeve base material:

[0071] a. Heat treatment: 20CrMnTi seamless steel pipe is used for blanking, and the pressure in the vacuum furnace is quenched at 0.06MPa. The temperature is 880°C. After 2 hours of heat preservation, oil cooling is carried out, and then high temperature tempering is carried out at 610°C, and heat preservation is carried out for 3 hours. After cooling with the furnace, the quenched and tempered shaft sleeve blank is obtained, and the matrix hardness is HRC24-28;

[0072] b. Turning: turning the blank obtained after quenching and tempering;

[0073] c. Drill the inner hole: process the inner hole of the workpiece obtained by turning;

[0074] (2) Nitriding treatment:

[0075] Put the shaft sleeves obtained above in the well-type furnace at 400°C for 1 hour, then transfer to the well-type salt bath furnace for nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com