Method for reaction plasma spraying nano crystal titanium nitride coating

A titanium nitride and nanocrystalline technology, which is applied in the coating, metal material coating process and other directions to achieve the effect of improving preparation efficiency, good chemical stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

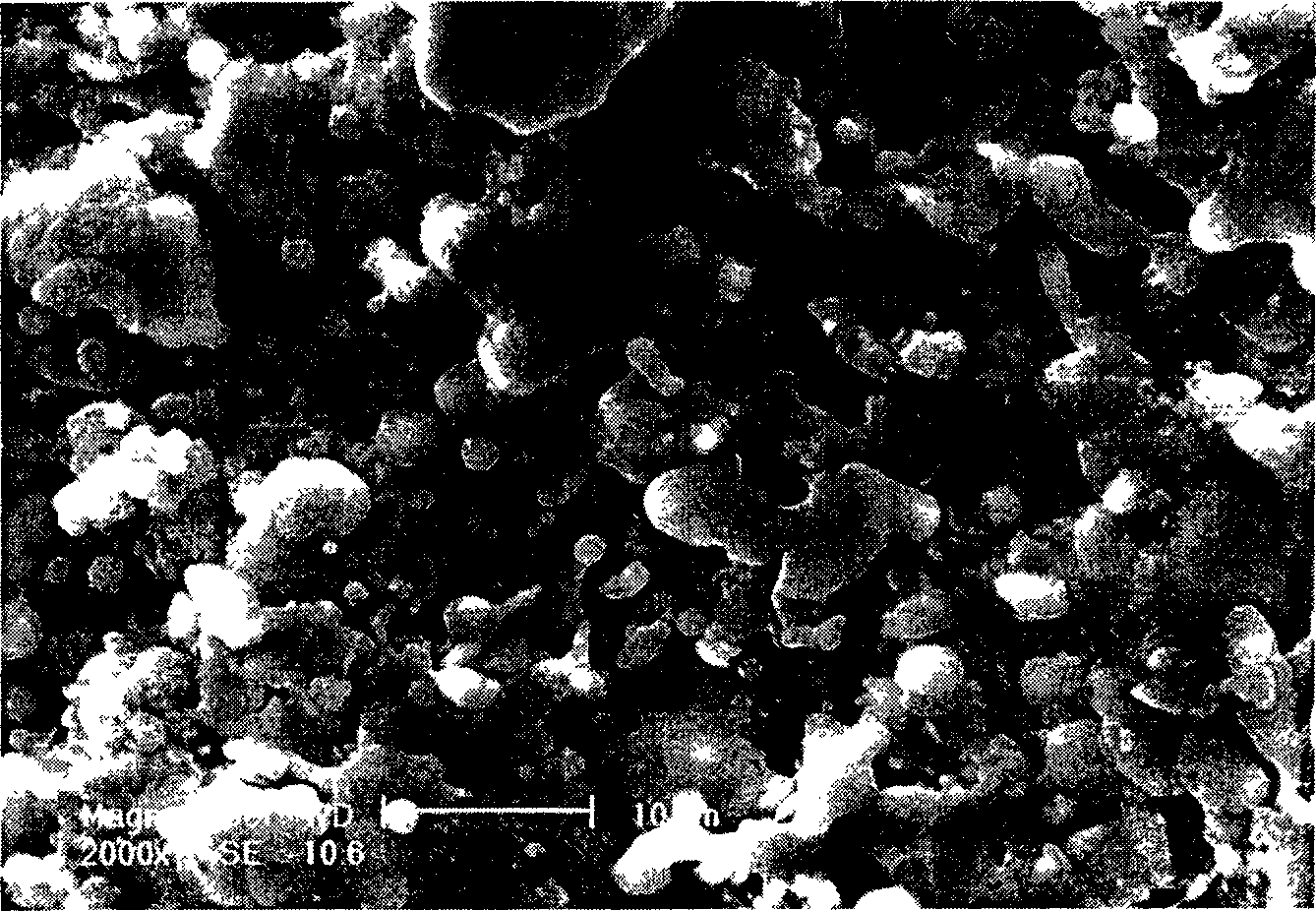

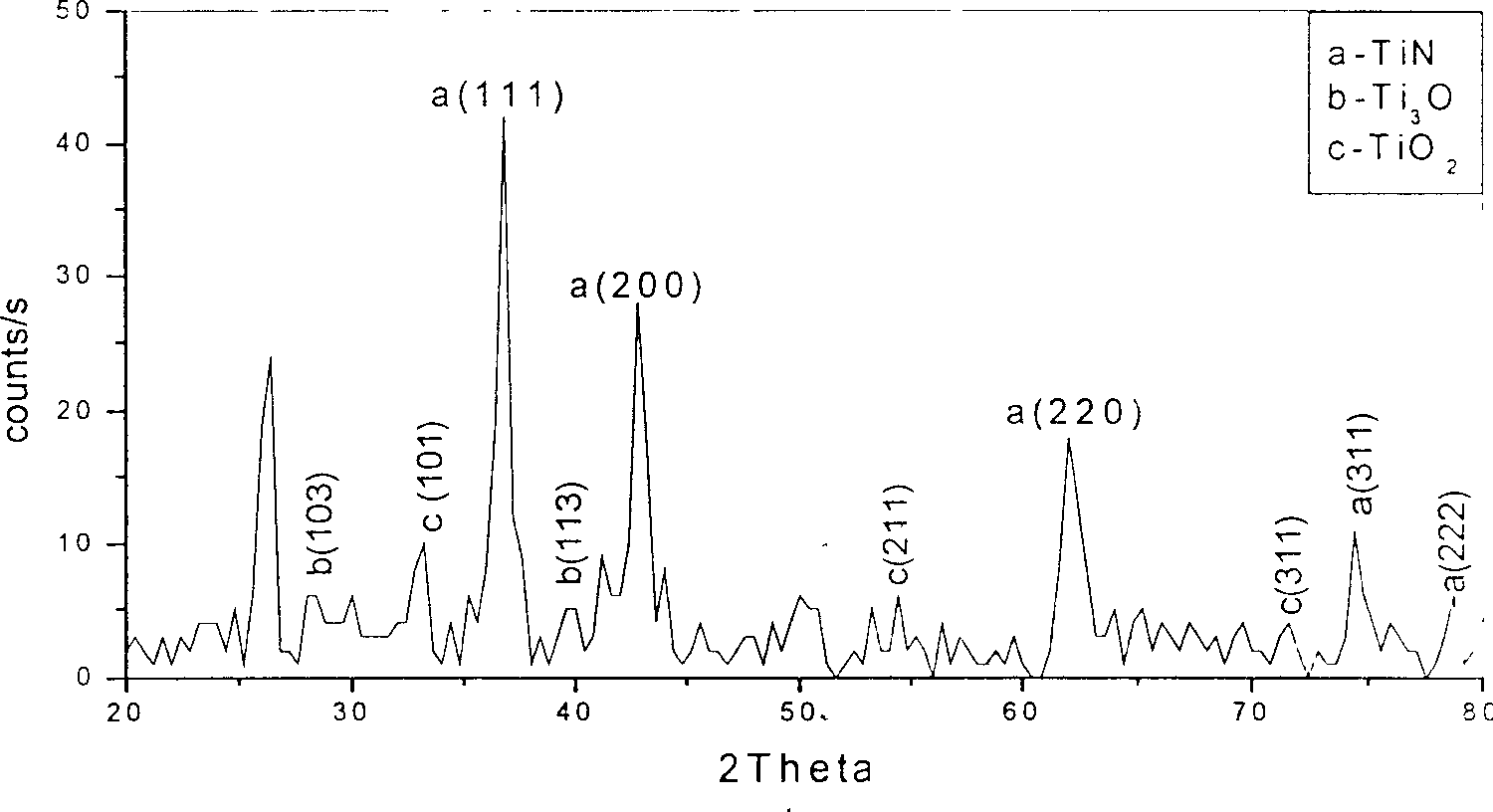

Image

Examples

Embodiment 1

[0051] Such as Figure 20 As shown, spray coatings on Q235 steel in the following order:

[0052] (1) Spray corundum (Al 2 o 3 ), roughen the surface and expose a fresh metal surface;

[0053] (2) 500g, 140-320 mesh nickel-aluminum alloy powder (Ni90) is packed into a powder feeder; the powder feeder is produced by Beijing Entropy Cole Company; the nickel-aluminum alloy powder is produced by Beijing Institute of Chemical Metallurgy.

[0054] (3) Connect the power supply of the spraying equipment control cabinet; the spraying equipment is produced by Jiujiang Spraying Equipment Factory;

[0055] (4) Delivery flow is 0.02m 3 / h of industrial nitrogen and 0.01m 3 / h of industrial argon;

[0056] (5) Turn on the power supply of the spray gun, adjust the air flow, control the arc power to 24.5KW, the spraying distance to 120mm, and the powder feeding air flow to 0.03m 3 / h, spray nickel-aluminum alloy (Ni90) bottom layer on the surface of the metal substrate; the spray gun is ...

Embodiment 2

[0075] The preparation process is the same as in Example 1, the process parameters for spraying the alloy bottom layer are the same as in Example 1, and the process parameters for spraying the TiN coating are different from Example 1.

[0076] Spray coating on Q235 steel in the following order:

[0077] (1) Spray corundum (Al 2 o 3 ), roughen the surface and expose a fresh metal surface;

[0078] (2) Put 500g, -140~+320 mesh nickel-aluminum alloy powder (Ni90) into the powder feeder; the powder feeder is produced by Beijing Entropy Cole Company;

[0079] (3) Connect the power supply of the spraying equipment control cabinet; the spraying equipment is produced by Jiujiang Spraying Equipment Factory;

[0080] (4) Delivery flow is 0.02m 3 / h of industrial nitrogen and 0.01m 3 / h of industrial argon;

[0081] (5) Turn on the power supply of the spray gun, adjust the air flow, control the arc power to 24.5KW, the spraying distance to 120mm, and the powder feeding air flow to ...

Embodiment 3

[0099] The preparation process is the same as in Example 1, the process parameters of the sprayed alloy bottom layer are the same as in Example 1, and the process parameters of the sprayed TiN coating are different from Examples 1 and 2

[0100] Spray coating on Q235 steel in the following order

[0101] (1) Spray corundum (Al 2 o 3 ), roughen the surface and expose a fresh metal surface;

[0102] (2) Put 500g, -140~+320 mesh nickel-aluminum alloy powder (Ni90) into the powder feeder; the powder feeder is produced by Beijing Entropy Cole Company;

[0103] (3) Connect the power supply of the spraying equipment control cabinet; the spraying equipment is produced by Jiujiang Spraying Equipment Factory;

[0104] (4) The delivery flow rate is 1.5L / h of industrial nitrogen and 1.5L / h of industrial argon;

[0105] (5) Turn on the power supply of the spray gun, adjust the air flow, control the arc power to 26KW, spray distance 110mm, powder feeding air flow 0.03m / h, spray nickel-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com