Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve mechanical bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

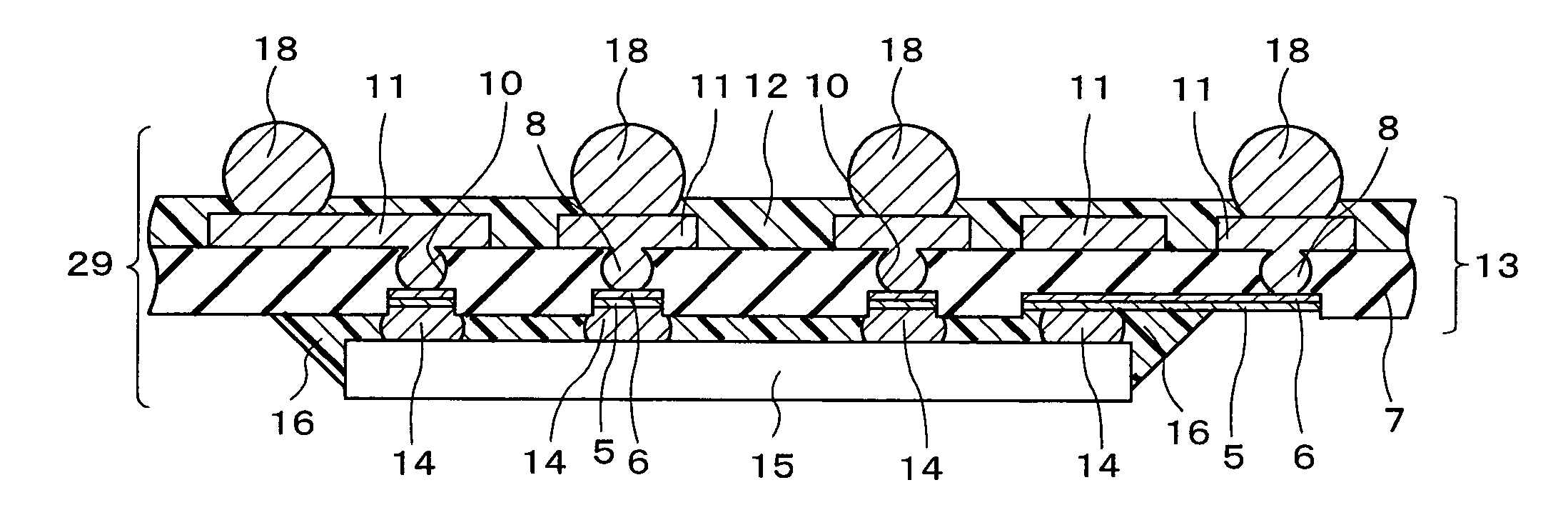

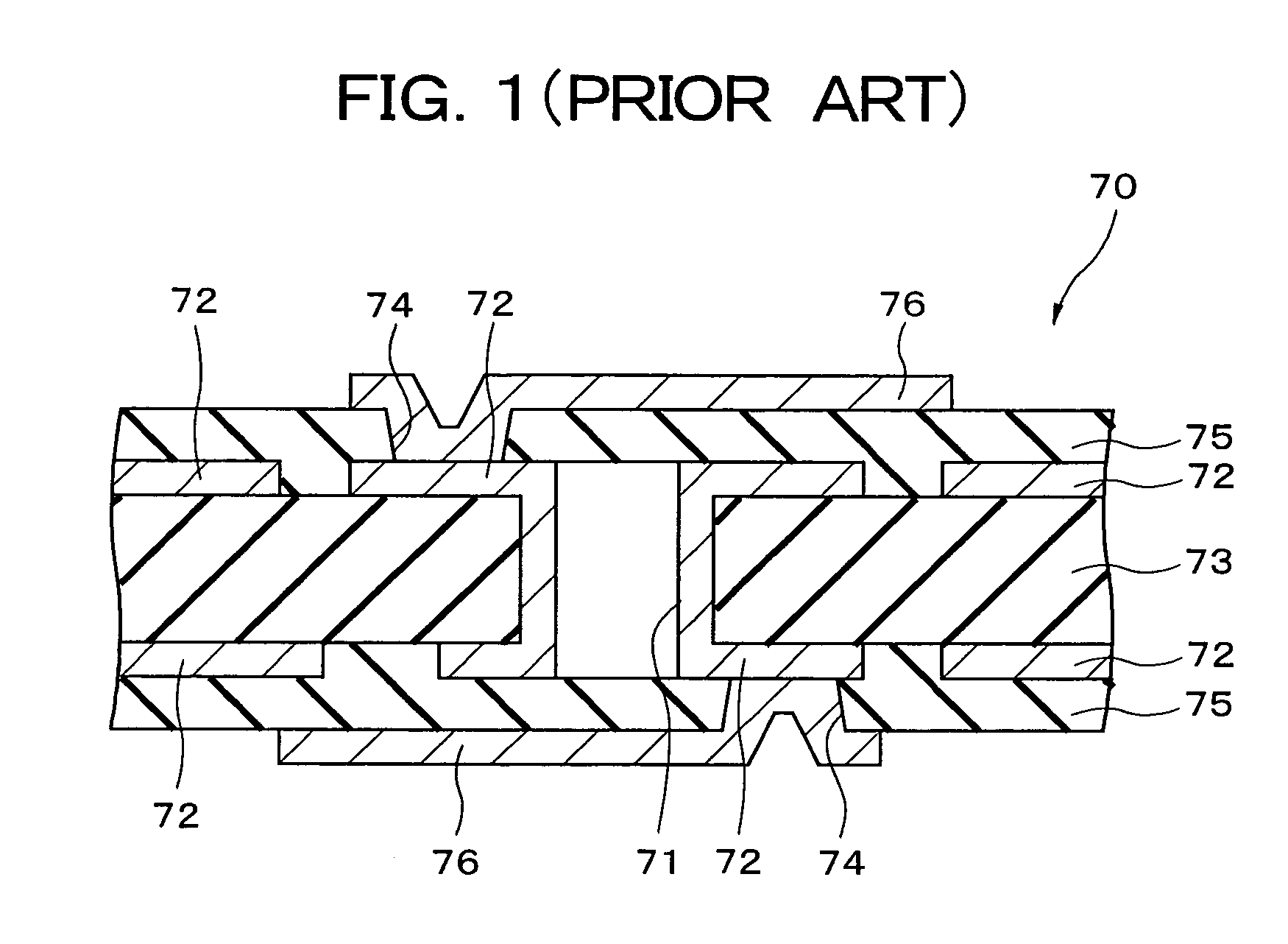

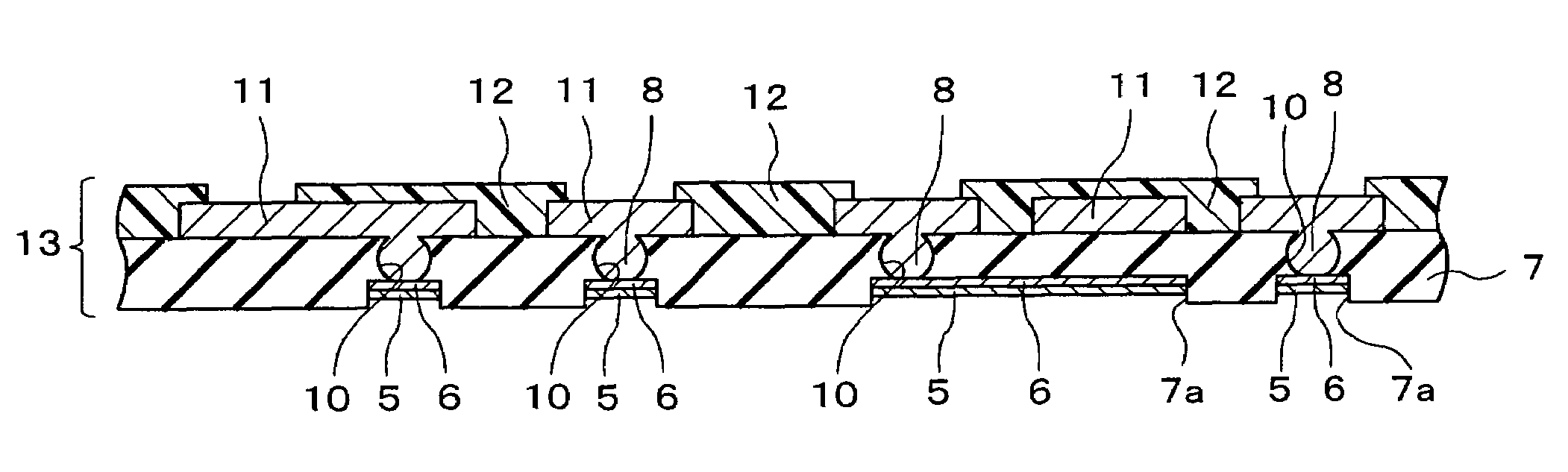

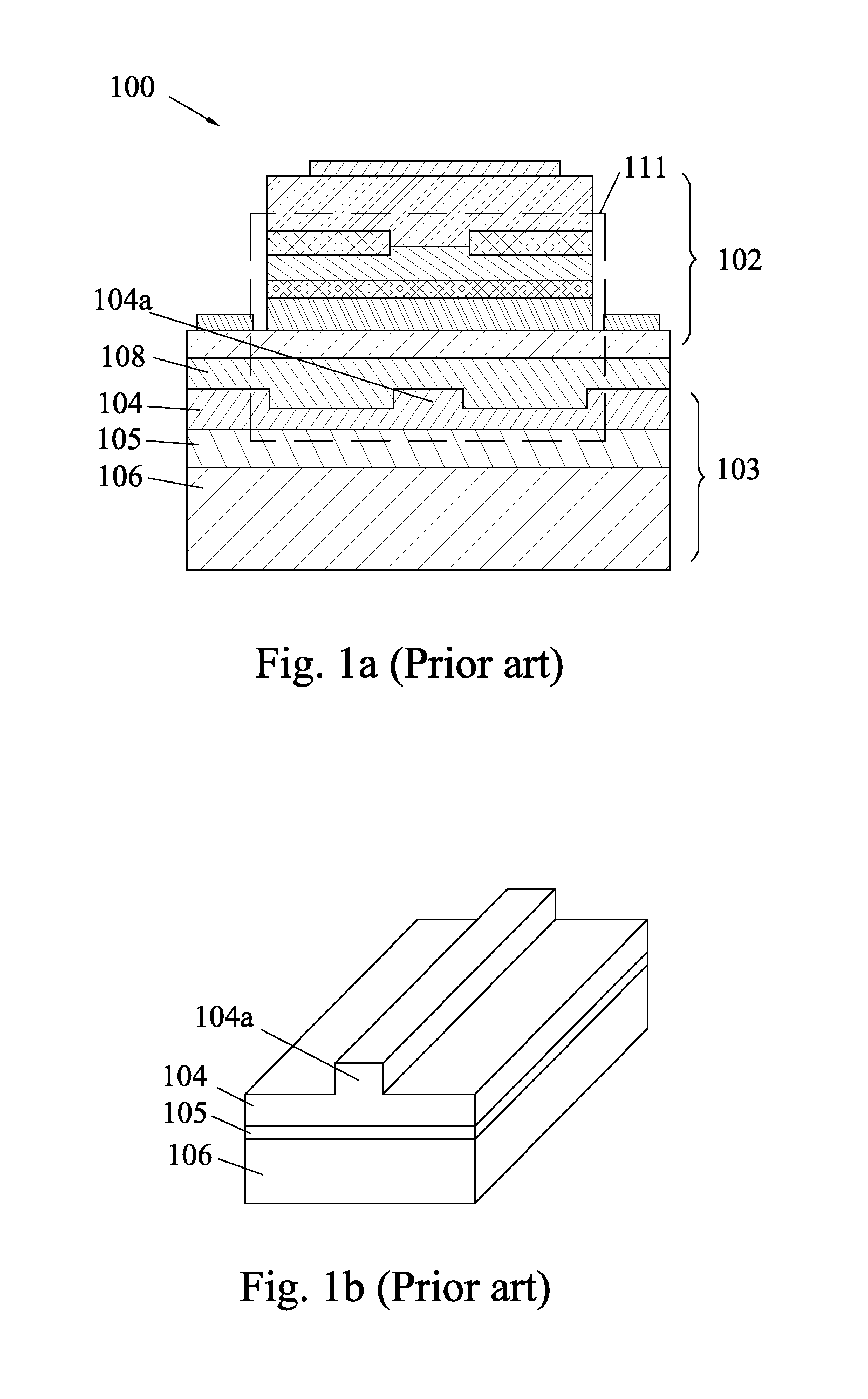

Wiring board, method for manufacturing same, and semiconductor package

ActiveUS20060283625A1Improve reliabilityImprove rendering capabilitiesPrinted electric component incorporationSemiconductor/solid-state device detailsSemiconductor packageBarrel Shaped

A wiring board in which lower-layer wiring composed of a wiring body and an etching barrier layer is formed in a concave portion formed on one face of a board-insulating film, upper-layer wiring is formed on the other face of the board-insulating film, and the upper-layer wiring and the wiring body of the lower-layer wiring are connected to each other through a via hole formed in the board-insulating film. The via hole is barrel-shaped, bell-shaped, or bellows-shaped.

Owner:RENESAS ELECTRONICS CORP

Wiring board, method for manufacturing same, and semiconductor package

ActiveUS7838779B2Increase the number ofReduce spacingPrinted electric component incorporationSemiconductor/solid-state device detailsBarrel ShapedSemiconductor package

A wiring board in which lower-layer wiring composed of a wiring body and an etching barrier layer is formed in a concave portion formed on one face of a board-insulating film, upper-layer wiring is formed on the other face of the board-insulating film, and the upper-layer wiring and the wiring body of the lower-layer wiring are connected to each other through a via hole formed in the board-insulating film. The via hole is barrel-shaped, bell-shaped, or bellows-shaped.

Owner:RENESAS ELECTRONICS CORP

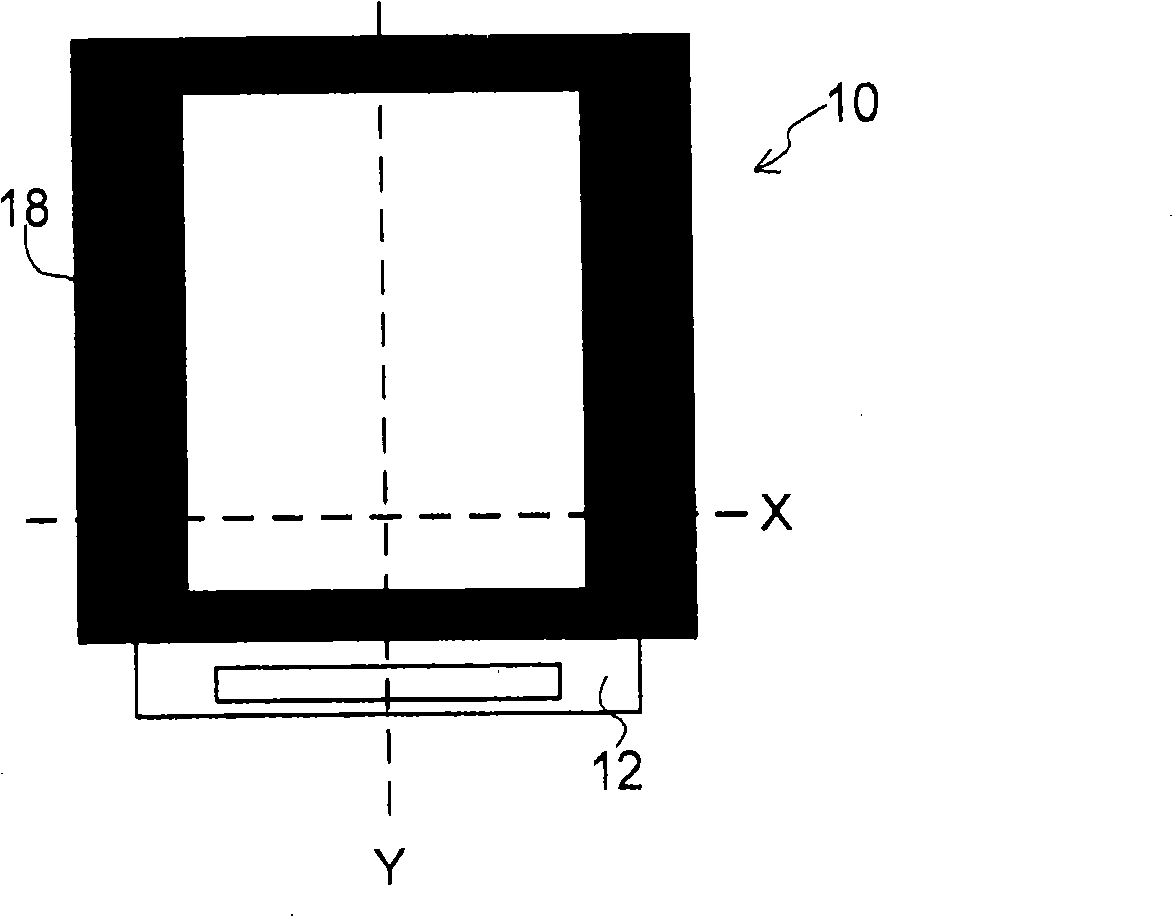

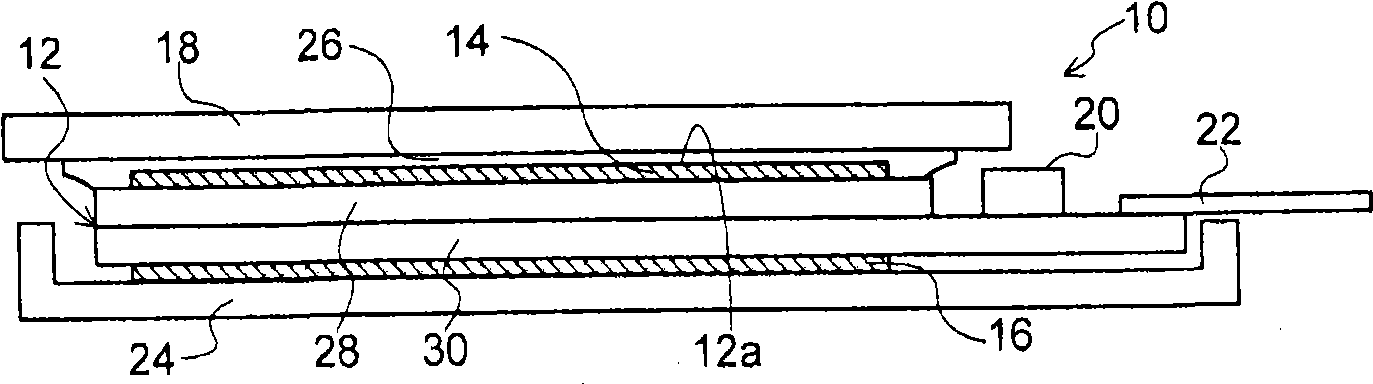

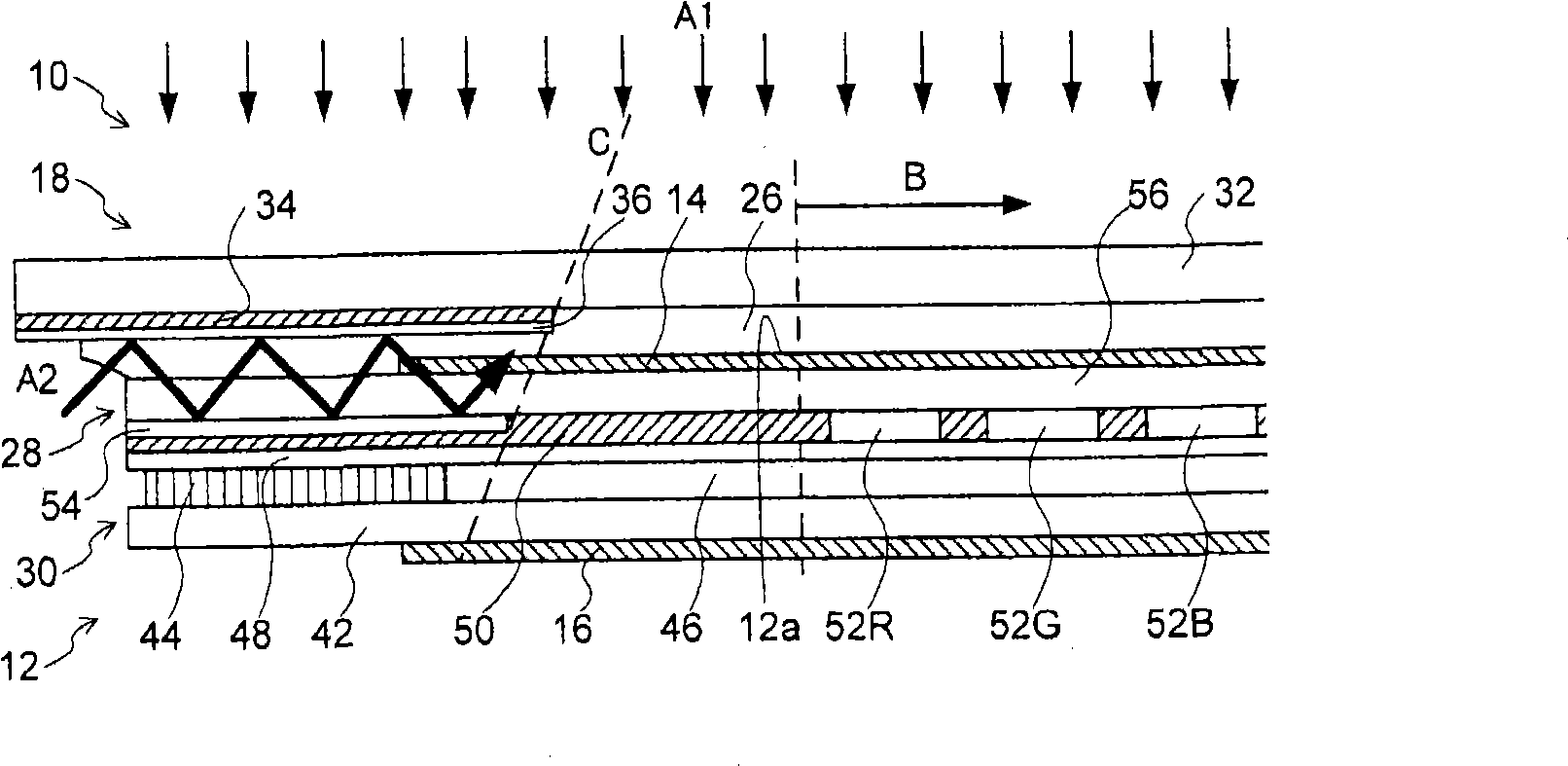

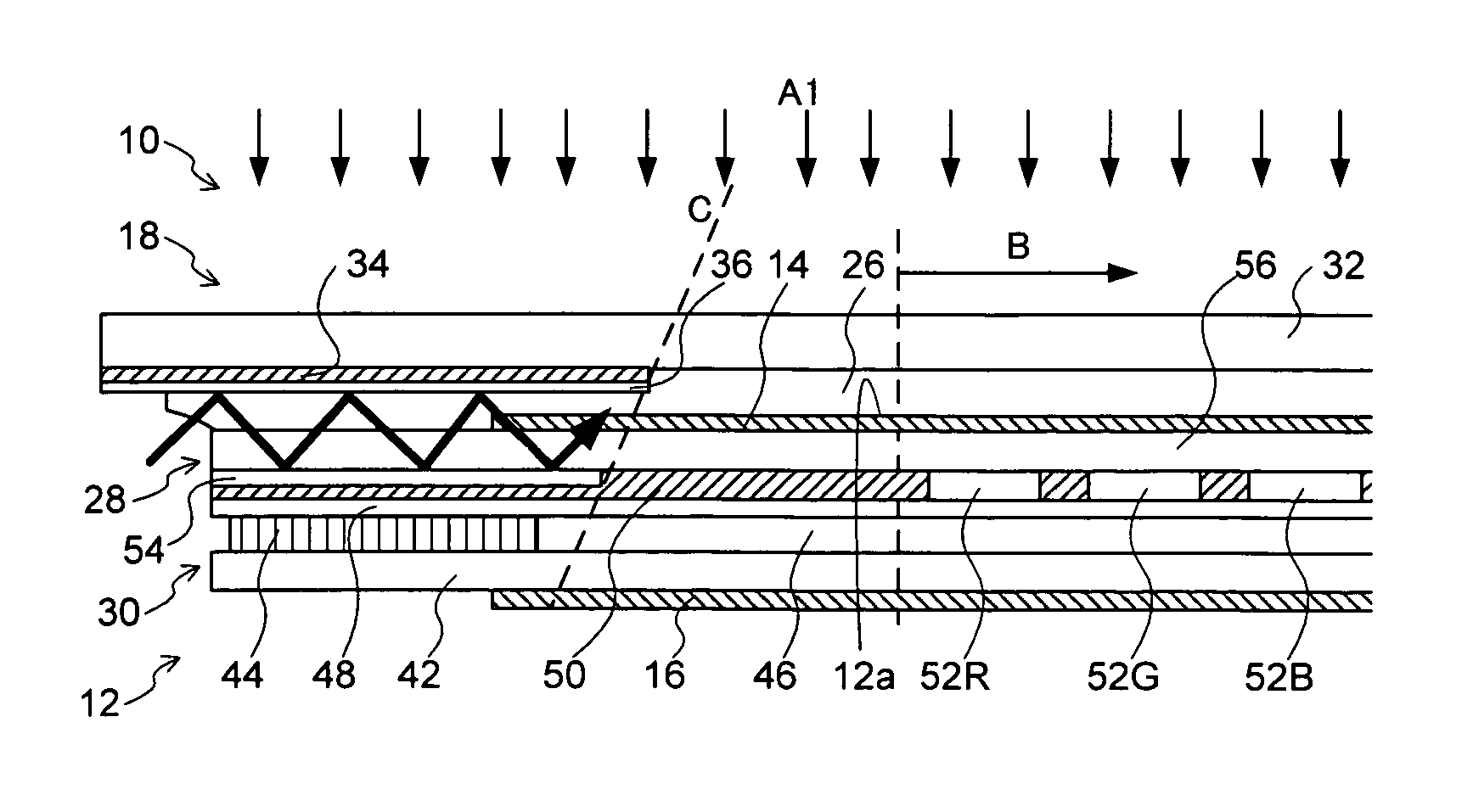

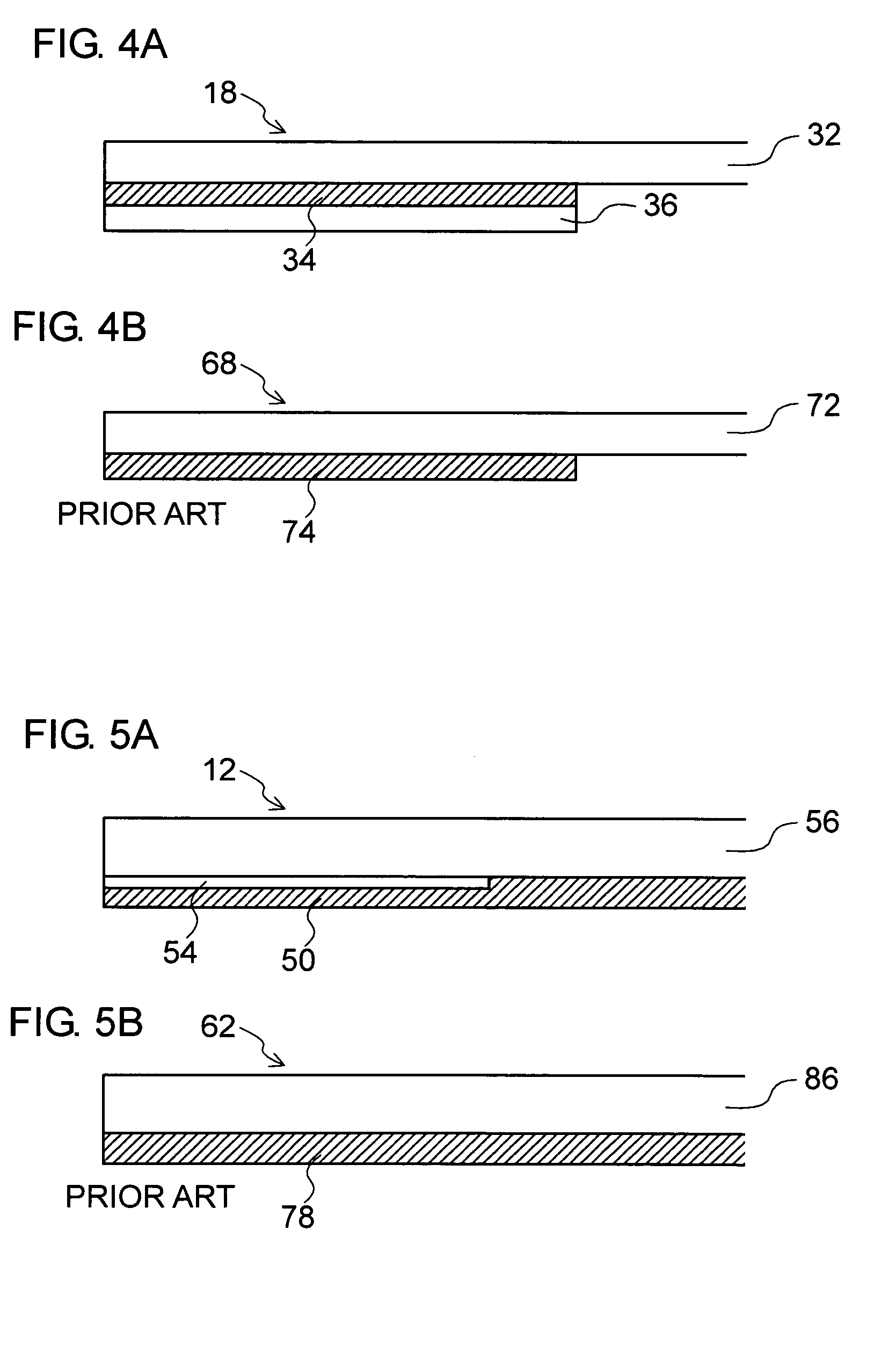

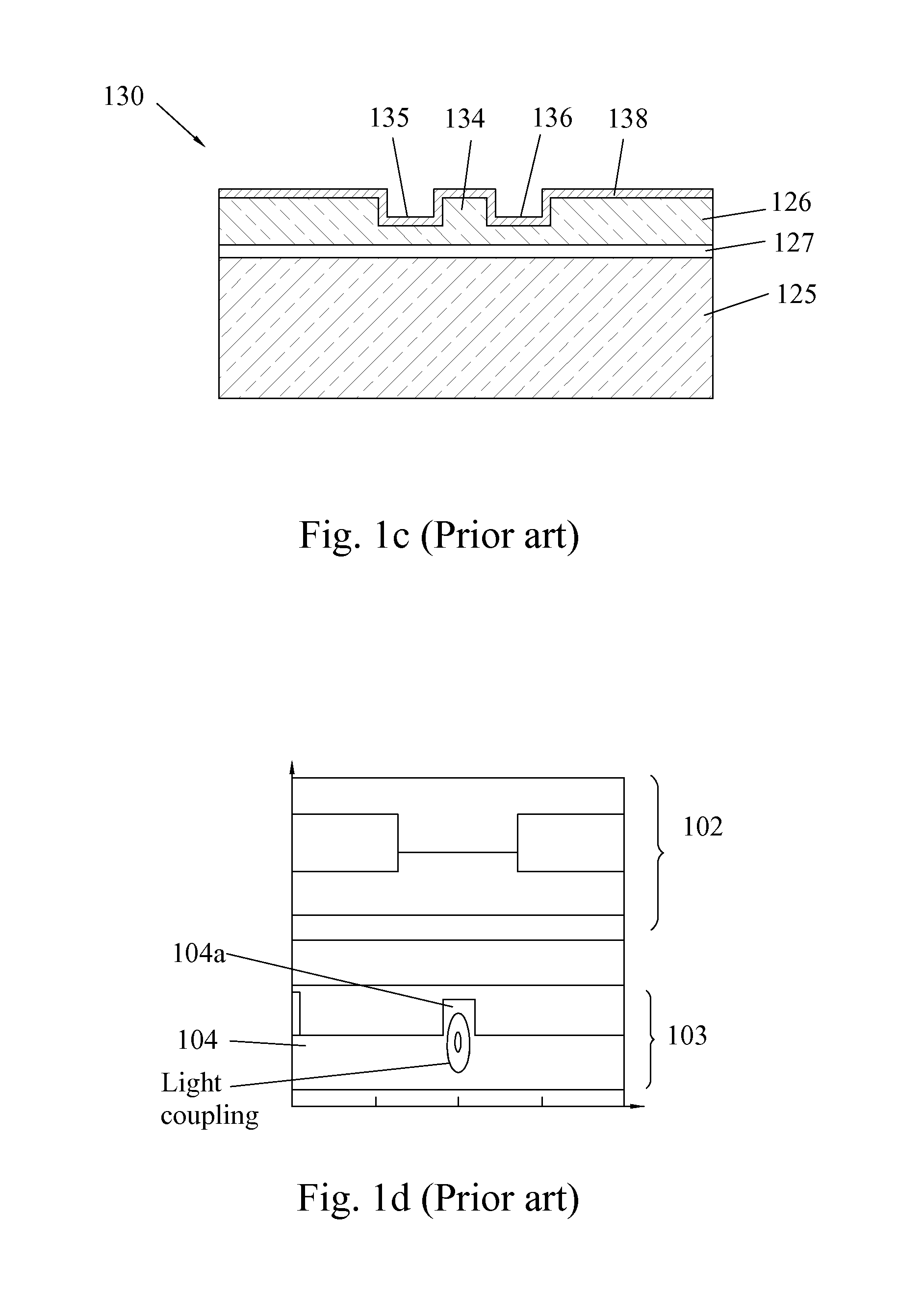

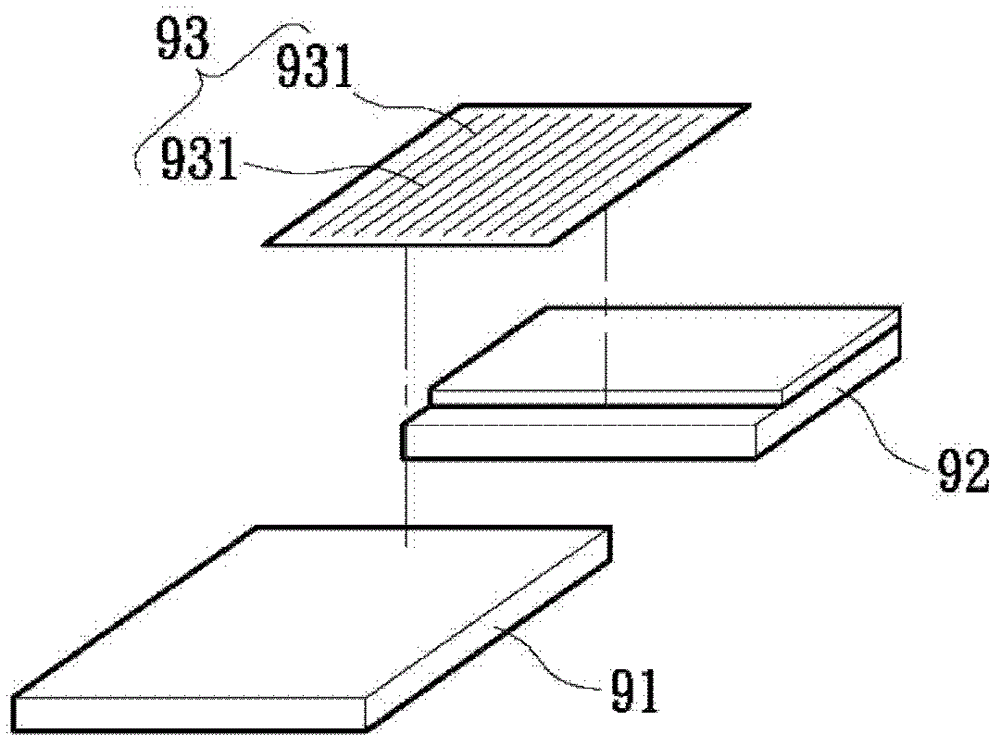

Display device

InactiveCN101510382AImprove mechanical bond strengthPreventing Image Quality DeteriorationNon-linear opticsIdentification meansLiquid-crystal displayImaging quality

In a case of curing and bonding a liquid crystal display panel (LCD) and a translucent substrate by using an optical adhesive, in order to reduce bonding fluctuations occurring in the vicinity of a light shielding portion provided on a periphery of the translucent substrate, enhance mechanical bonding strength, and prevent deterioration of image quality, which arises from curing variations of the optical adhesive, there is provided a display device including: a display panel including a display surface; a translucent substrate opposed to the display surface; a light shielding portion provided on a periphery of a display surface side of the translucent substrate, for shielding light; and a light reflecting portion provided on a display surface side of the light shielding portion.

Owner:SEIKO INSTR INC

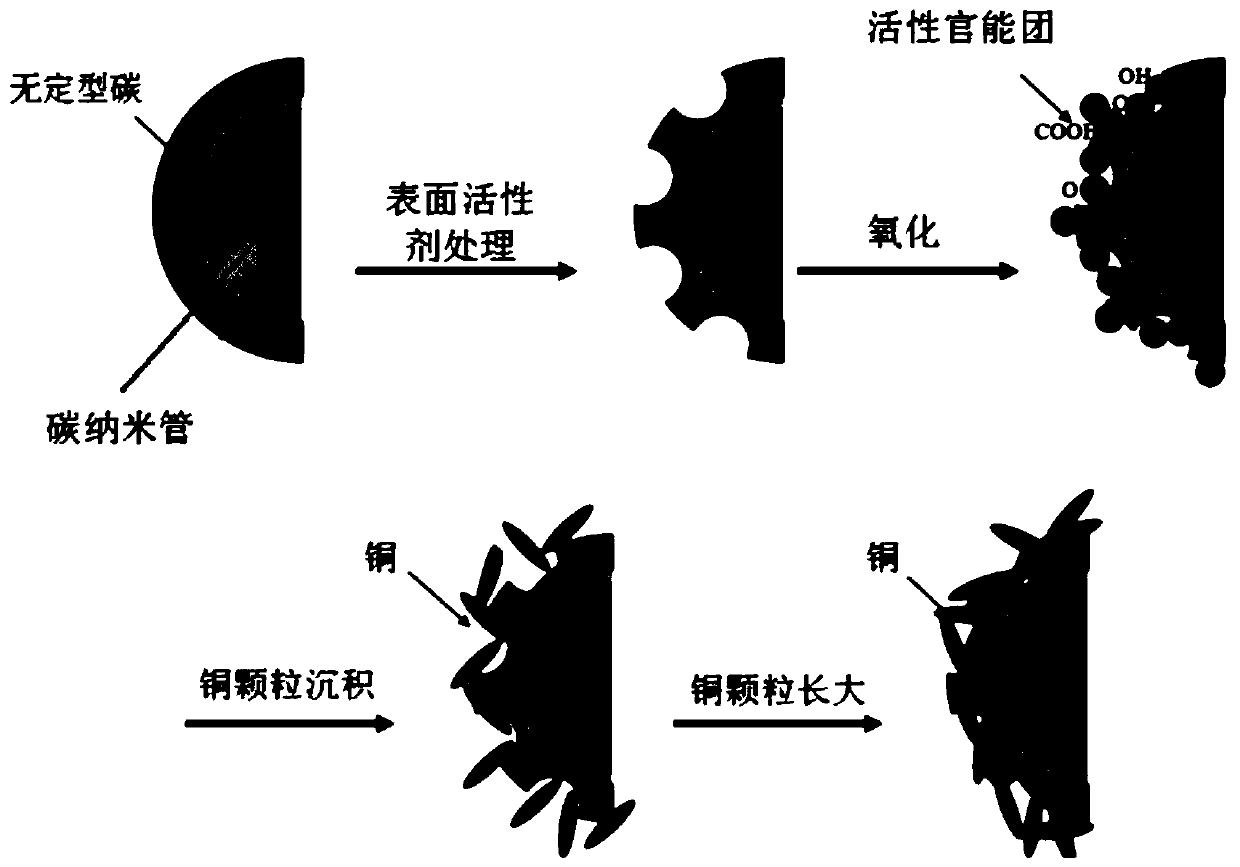

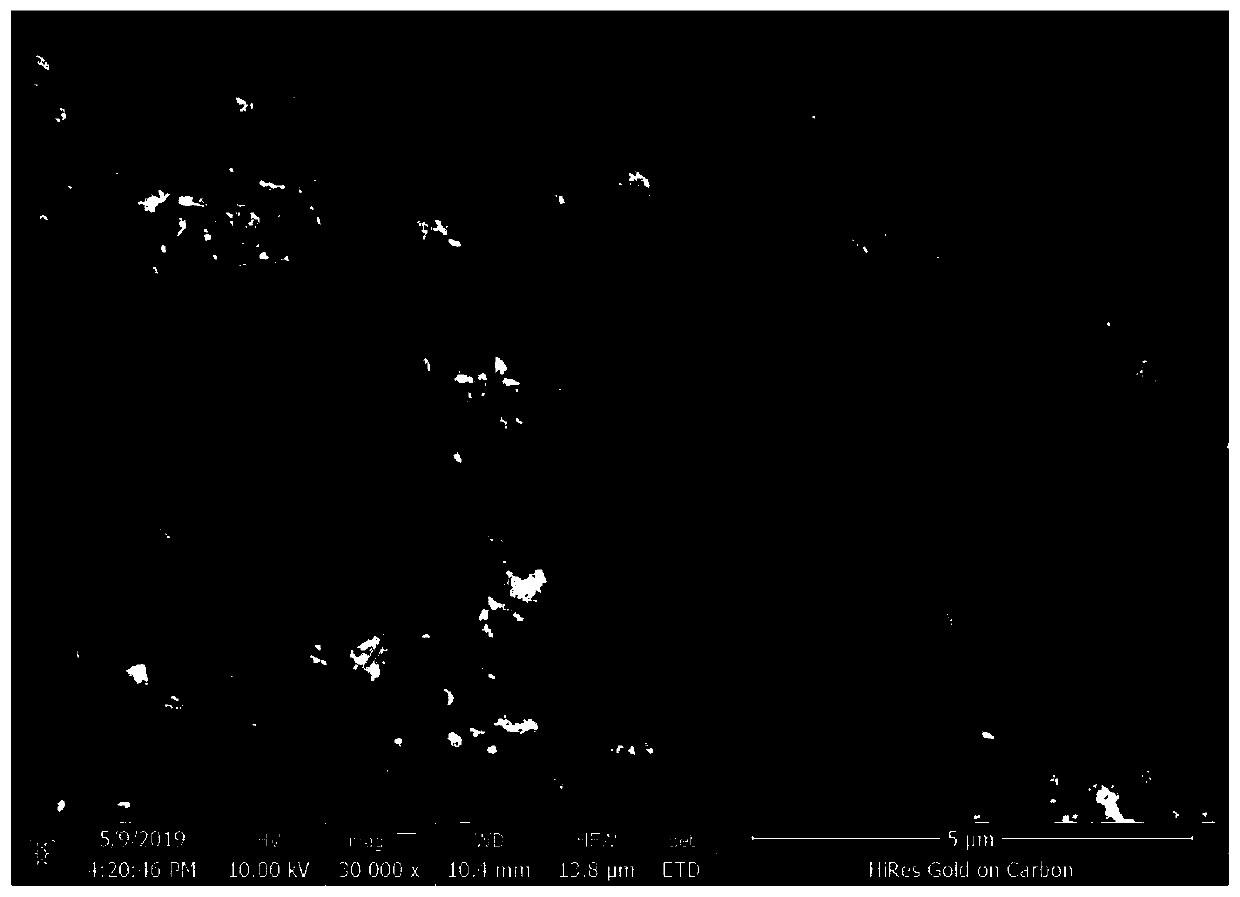

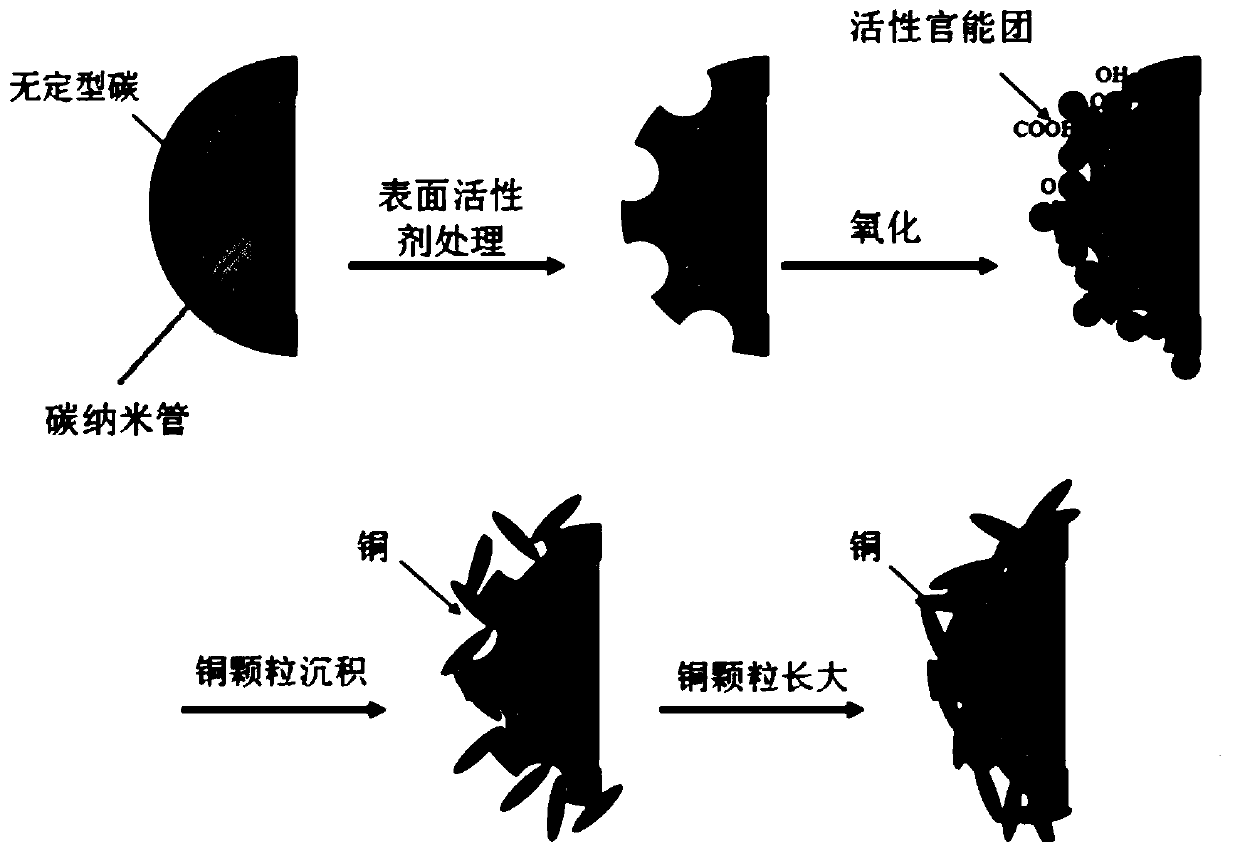

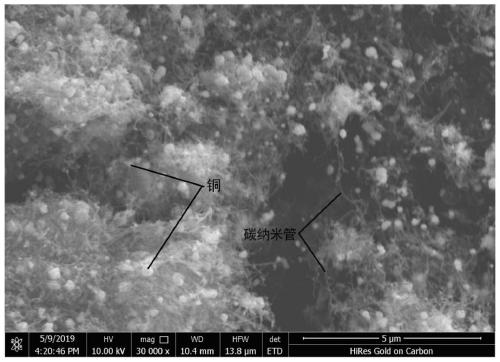

Low-melting-point metal-water-based conductive composite slurry and preparation method thereof

ActiveCN110189849AImprove performanceMix tightlyNon-conductive material with dispersed conductive materialCable/conductor manufactureChemical platingCarbon nanotube

The invention discloses low-melting-point metal-CNTS / Cu water-based conductive composite slurry. The low-melting-point metal-CNTS / Cu water-based conductive composite slurry comprises the following components in percentage by mass: 50-80% of a mixed conductive phase, 5-15% of tin powder or bismuth powder, 15-30% of a water-based carrier, 0.1-0.5% of an additive P and 0.1-4.5% of an additive Ga, wherein the total amount is 100%. The present invention further discloses a preparation method of low-melting-point metal-CNTS / Cu water-based conductive composite slurry. In the product and the preparation method thereof, the mixed conductive phase is prepared by employing a chemical plating method, so that the combination of the copper and a carbon nano tube is more compact and uniform; the low-melting-point metal tin or bismuth is used as a new bonding phase, so that the sintering temperature can be reduced, and the comprehensive performance of the slurry is improved; and the water-based carrier is environment-friendly, so that the cost is obviously reduced.

Owner:扬州虹运电子材料有限公司

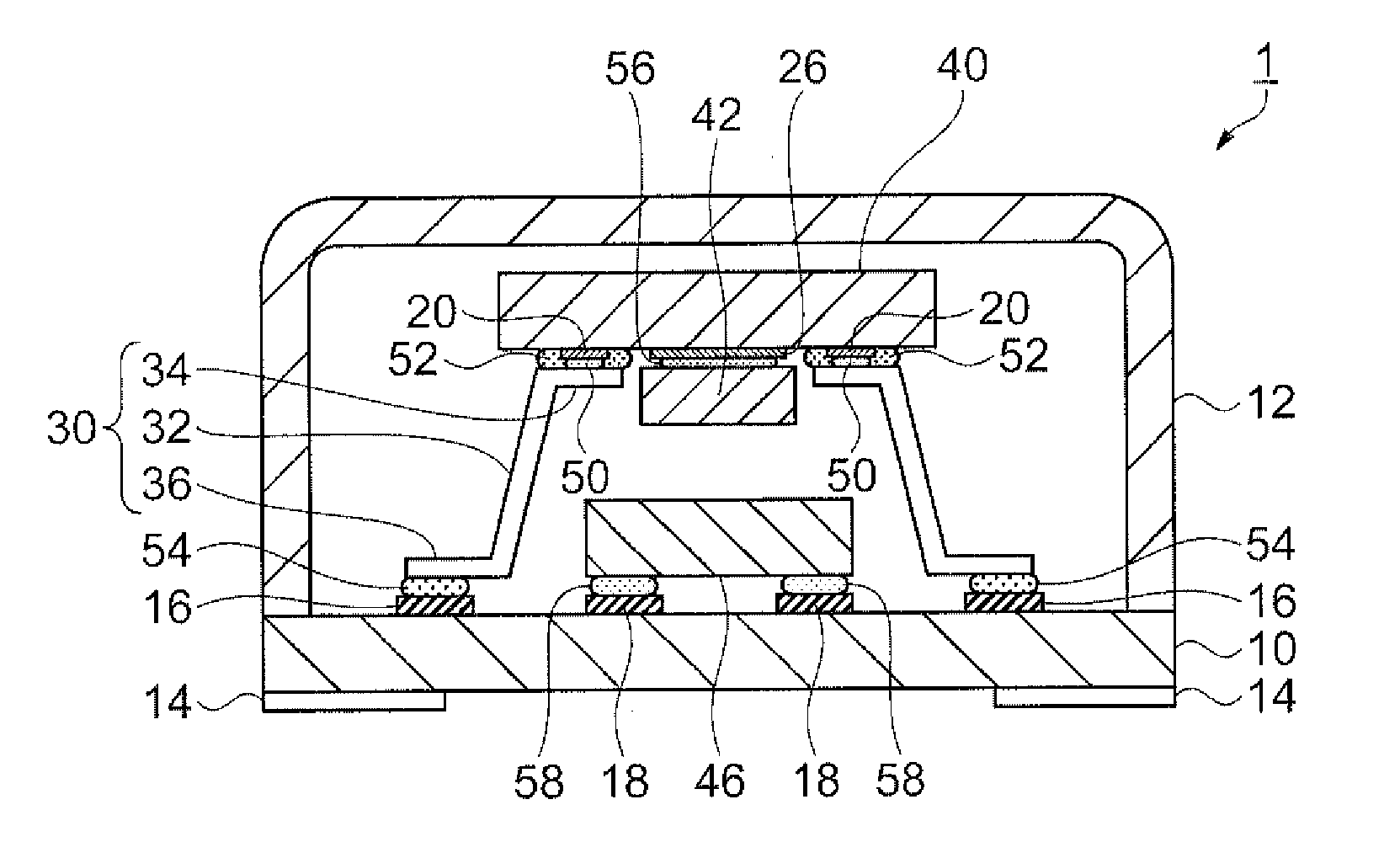

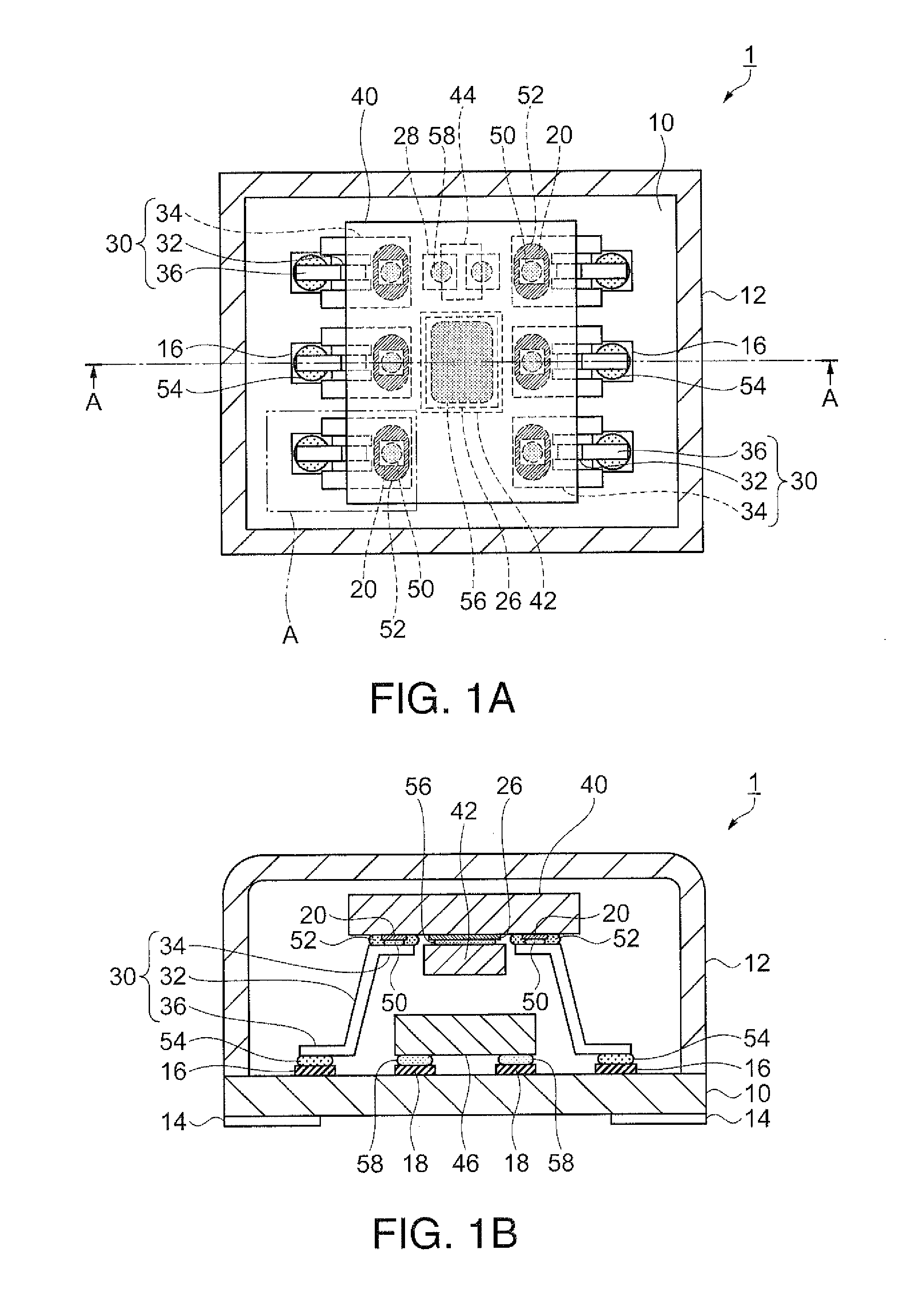

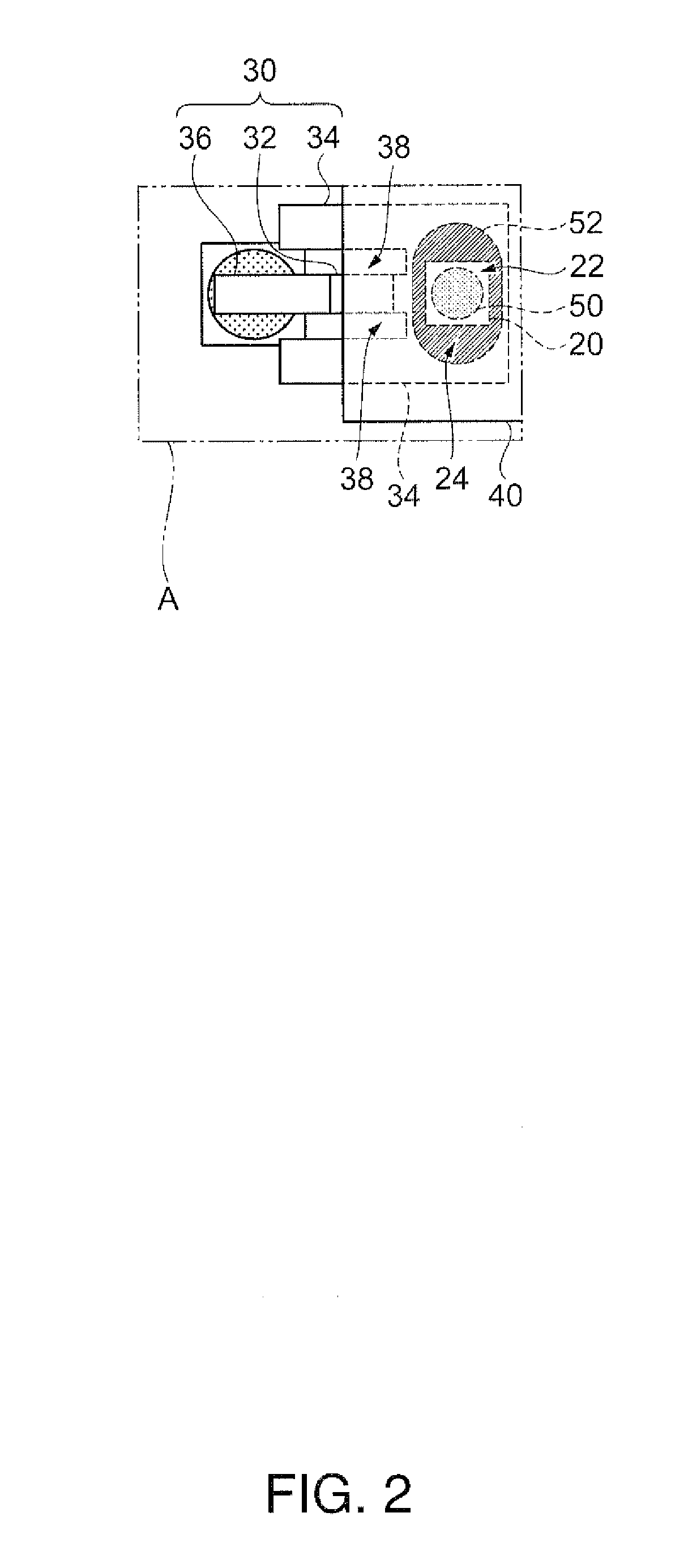

Electronic device, electronic apparatus, moving object, and method for manufacturing electronic device

ActiveUS20140292421A1Efficient conductionReduce power consumptionLine/current collector detailsImpedence networksEngineeringElectronic component

An electronic device includes: a support member including a first terminal, a second terminal, and a support portion extending from the first terminal and coupling the first terminal with the second terminal; an electronic component; and a bonding member connecting the first terminal with the electronic component. In a plan view along a direction in which the first terminal and the electronic component overlap each other, a portion of the first terminal is adjacent to the support portion with a notch portion therebetween and protrudes toward the extending direction side of the support portion. The support portion is bent at a portion adjacent to the protruding portion of the first terminal along the overlapping direction.

Owner:SEIKO EPSON CORP

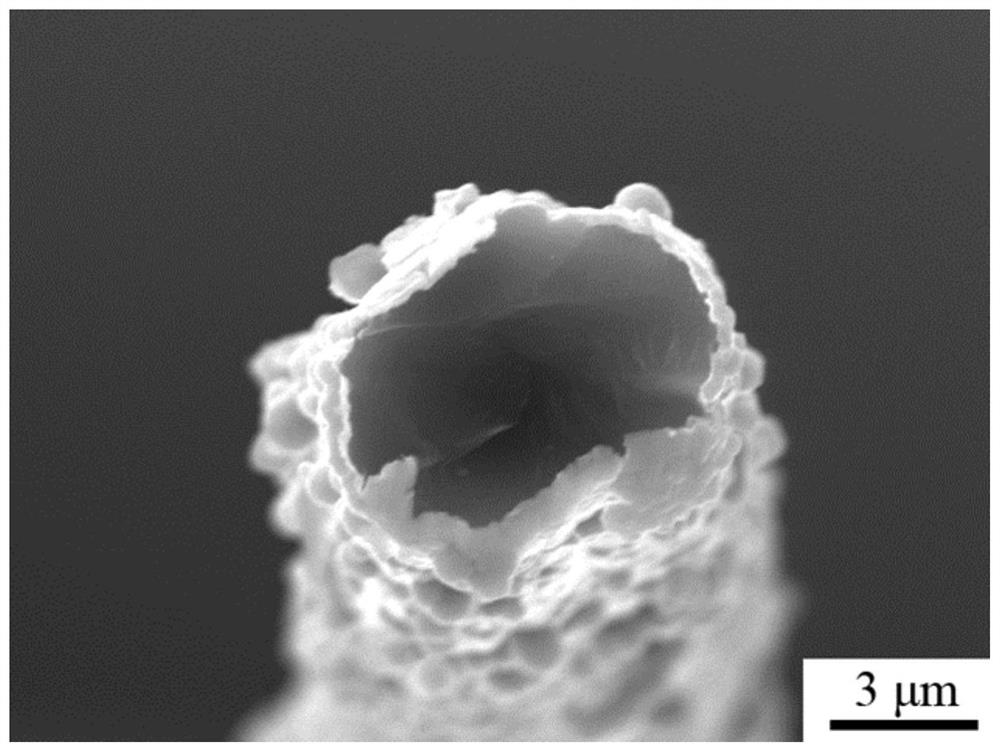

Preparation method of enhanced hollow polyvinylidene fluoride fiber membrane

ActiveCN103432916BImprove mechanical propertiesExtended service lifeSemi-permeable membranesEnhanceosomePolyvinylidene difluoride

The invention discloses a preparation method of an enhanced hollow polyvinylidene fluoride fiber membrane. The preparation method comprises the following steps: (1) preparation of an enhanceosome: braiding polyacrylonitrile fiber into a hollow braided pipe by adopting a two-dimensional braiding technology; (2) preparation of separation layer casting film liquor: respectively dissolving 5-25wt% polyvinylidene fluoride resin and 5-30wt% of additive into a solvent, stirring and dissolving under the condition of 70-90 DEG C, conducting vacuum defoaming to obtain the separation layer casting film liquor; (3) surface pretreatment of the enhanceosome: cleaning and drying the enhanceosome with a neutral detergent, and then infiltrating the enhanceosome with slight polar organic liquid; and (4) preparation of the enhanced hollow polyvinylidene fluoride fiber membrane: evenly coating the separation layer casting film liquor obtained from the step (2) on the surface of the enhanceosome treated in the step (3), and curing to obtain the enhanced hollow polyvinylidene fluoride fiber membrane. The binding strength of a separation layer on the surface of the enhanced hollow polyvinylidene fluoride fiber membrane prepared by adopting the method and the enhanceosome is high, and the separation layer and the enhanceosome are unlikely to strip, and high-pressure backflushing can be conducted.

Owner:TIANJIN POLYTECHNIC UNIV

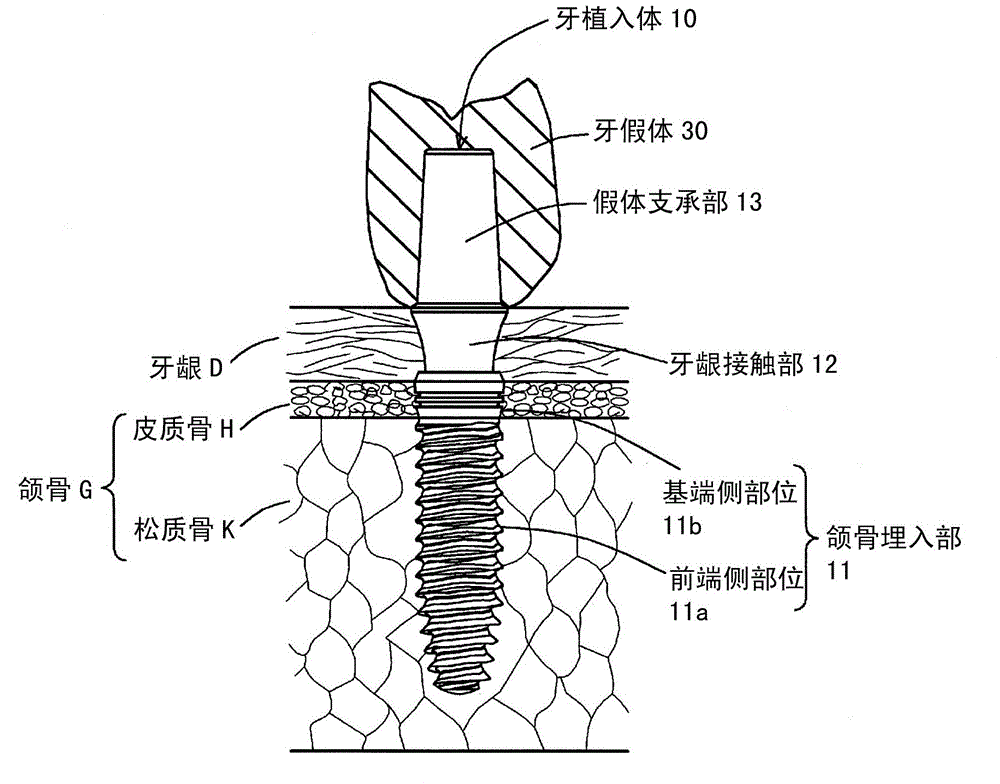

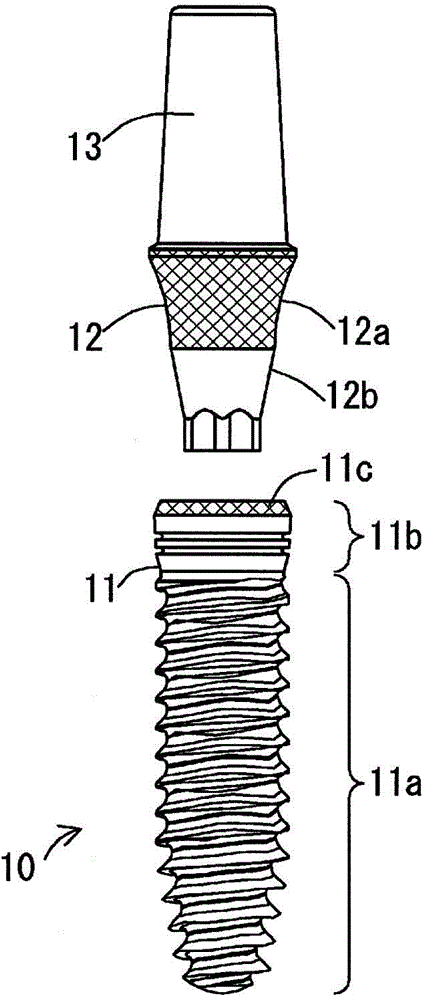

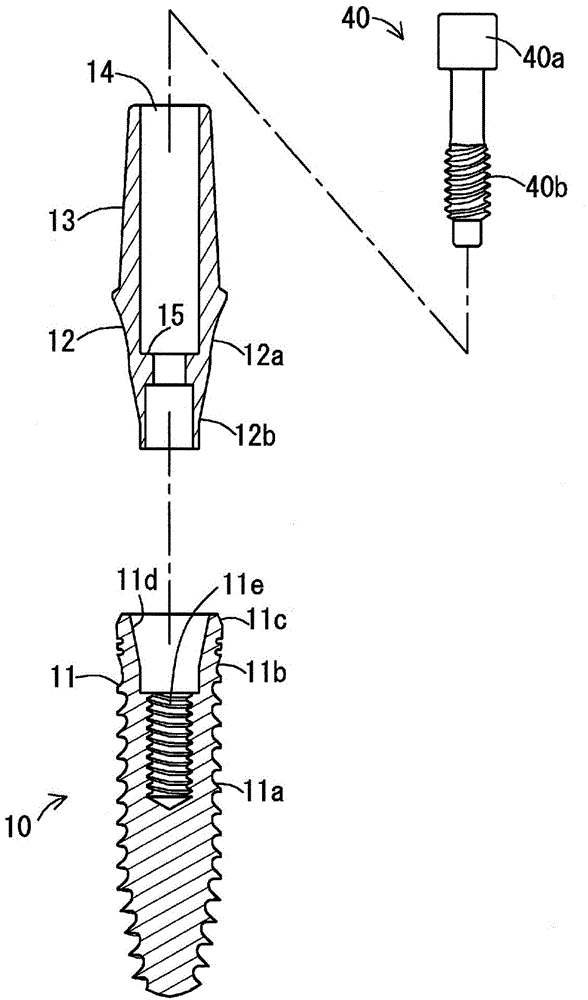

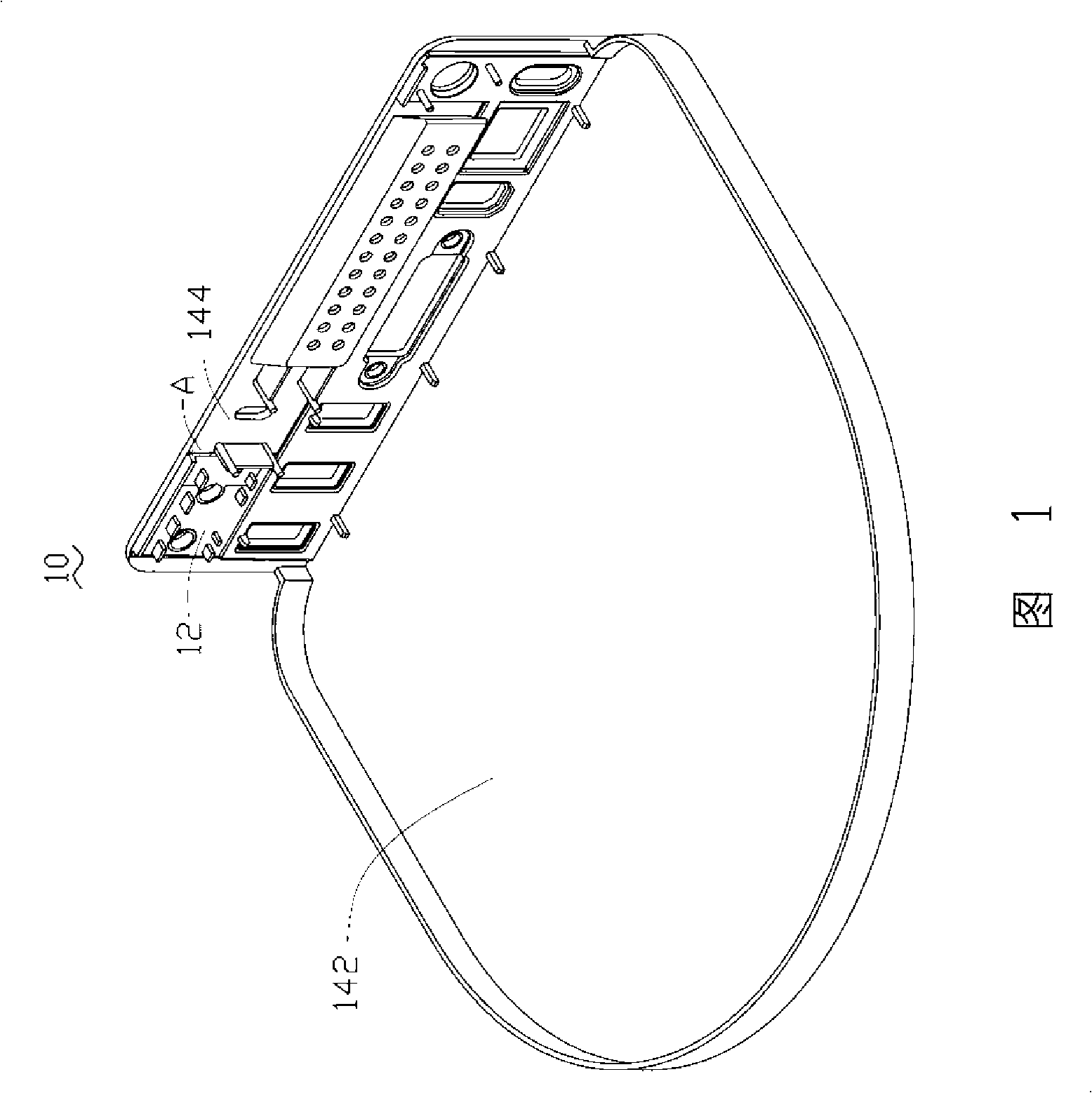

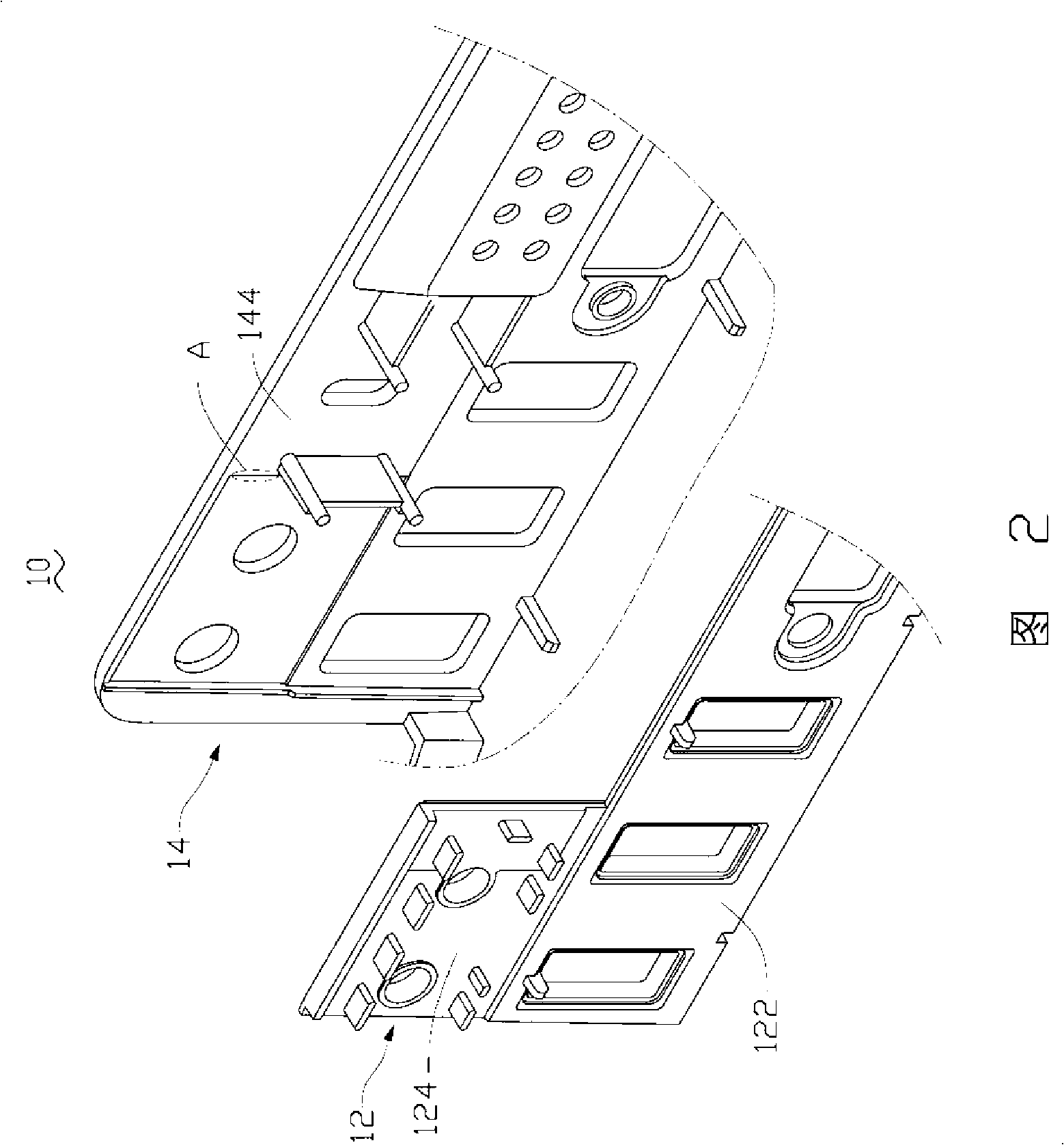

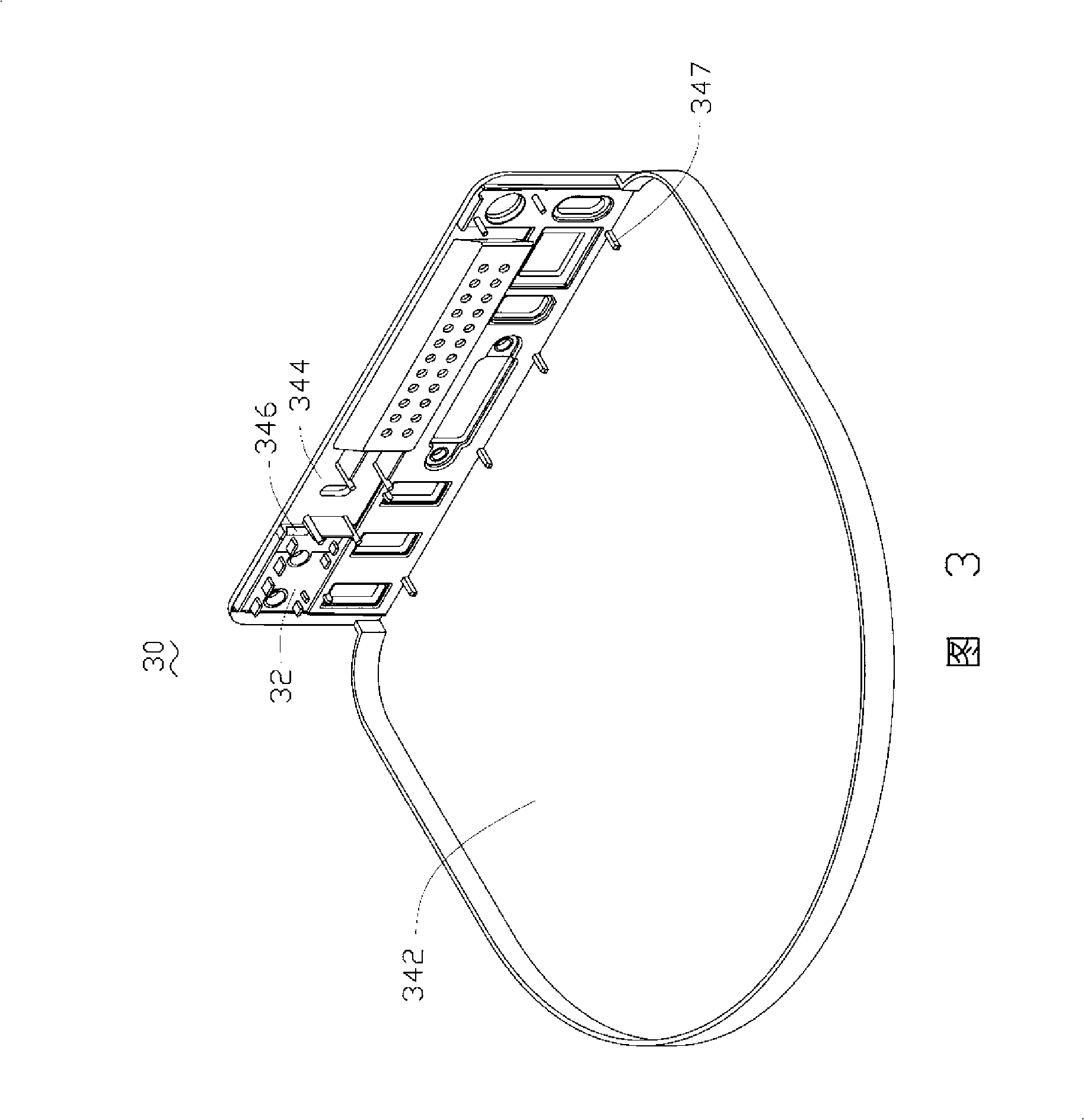

Dental implant

InactiveCN104349743APrevent intrusionInhibition of reproductionDental implantsJaw bonePeri implant disease

The present invention relates to a dental implant which can prevent peri-implant diseases, and of which the affinity of a jaw bone implantation part that is to be implanted into a jaw bone for a jaw bone is not inhibited. In the dental implant (10), at least a region (12a), which is a region to be in contact with a gum (D), of a gum contact part (12) is anti-bacterially treated, and the region (12a) has an arithmetic average roughness (Ra) of 2 mum or less. At least the region (12a) of the gum contact part (12) is imparted with an anti-bacterial property, and has a surface shape onto or on which bacteria rarely adhere or remain and which can contact closely with a gum (D).

Owner:KYOCERA MEDICAL CORP

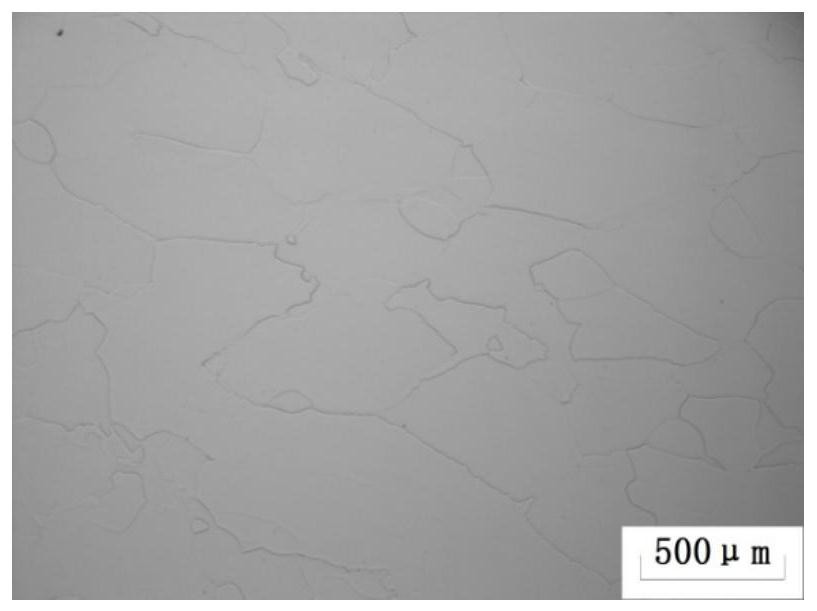

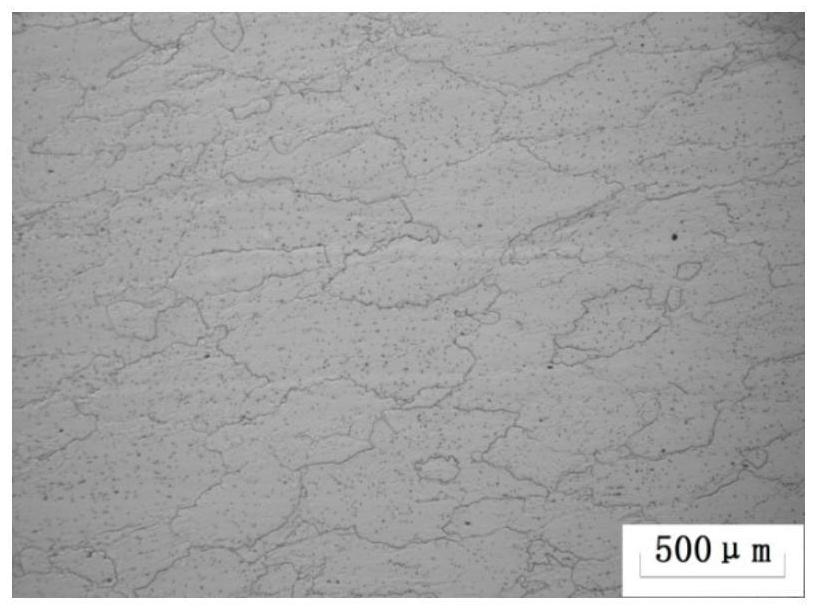

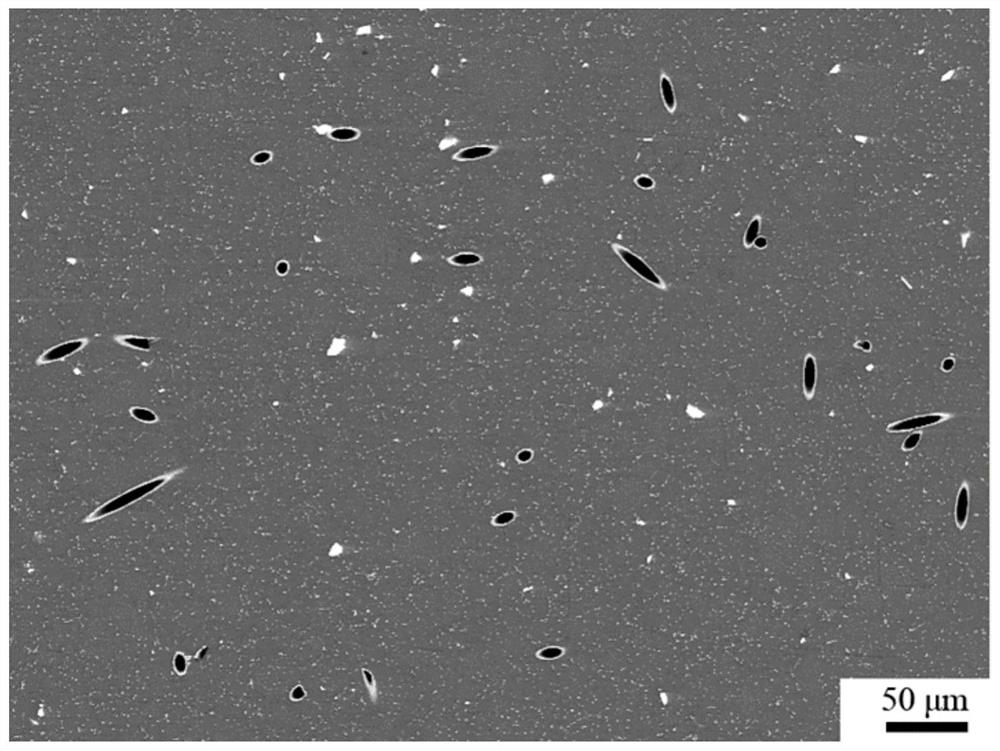

TB17 titanium alloy isothermal forging method

ActiveCN114226616AReduced germinationIncrease heightMetal-working apparatusHeat conservationTitanium alloy

The invention discloses an isothermal forging process of a TB17 titanium alloy, and belongs to the technical field of material science. The method mainly comprises the steps that (1) a titanium alloy blank is placed in an effective working area of a resistance furnace with the set heating temperature being 785-815 DEG C for heating and heat preservation, the heat preservation time is 45-125 min, and then the titanium alloy blank is heated to 850-890 DEG C along with the furnace and then subjected to heat preservation for 25-60 min; (2) after heat preservation in the step (1) is finished, a titanium alloy blank is put into a die to be subjected to isothermal forging, the deformation amount of the blank is controlled to range from 10% to 29%, and the deformation rate of the blank is controlled to range from 0.3 mm / s to 1.25 mm / s; and (3) after forging in the step (2) is completed, the blank is taken out and cooled to the room temperature at the cooling speed of 0.5 DEG C / s-35 DEG C / s. The comprehensive mechanical property of the titanium alloy forge piece treated by the isothermal forging process can be remarkably improved, and the tensile strength and fracture toughness of the forge piece are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Display device

A display device has a display panel having a first substrate for displaying an image that is observed from a front surface of the first substrate. A translucent substrate covers the display panel from the front surface of the first substrate. The translucent substrate has a rear surface and a first light shielding portion on a periphery of the rear surface. A photo-curable translucent adhesive integrally bonds a front surface of the first substrate and the rear surface of the translucent substrate to each other. A first light reflecting portion is formed on the first light shielding portion of the translucent substrate. A second light reflecting portion is formed on a surface of the first substrate so as to oppose the first light reflecting portion through the photo-curable translucent adhesive.

Owner:DAWNCREST IP LLC

Preparation method of modified carbon fiber and zirconium carbide reinforced aluminum-based composite material

PendingCN112501523AImprove uniformityImprove mechanical propertiesLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a preparation method of a modified carbon fiber and zirconium carbide reinforced aluminum-based composite material. The preparation method comprises the following steps: carrying out degumming, roughening, sensitization, activation and reduction pretreatment on carbon fibers with the diameter of 6-7 [mu]m and the length of 0.5-2 mm; 2, a layer of metal nickel is plated on the surface of the carbon fiber by adopting a chemical plating method to obtain a nickel-plated carbon fiber; 3, ball-milling and mixing are performed on zirconium carbide and aluminum alloy powder, and nickel-plated carbon fibers are mechanically stirred to obtain mixed powder; and 4, spark plasma sintering is performed on the mixed powder, cooled and demolded to obtain the modified carbon fiber and zirconium carbide reinforced aluminum matrix composite material. The prepared modified carbon fiber and zirconium carbide reinforced aluminum matrix composite is good in mechanical property, high in hardness and good in wear resistance.

Owner:XI AN JIAOTONG UNIV +1

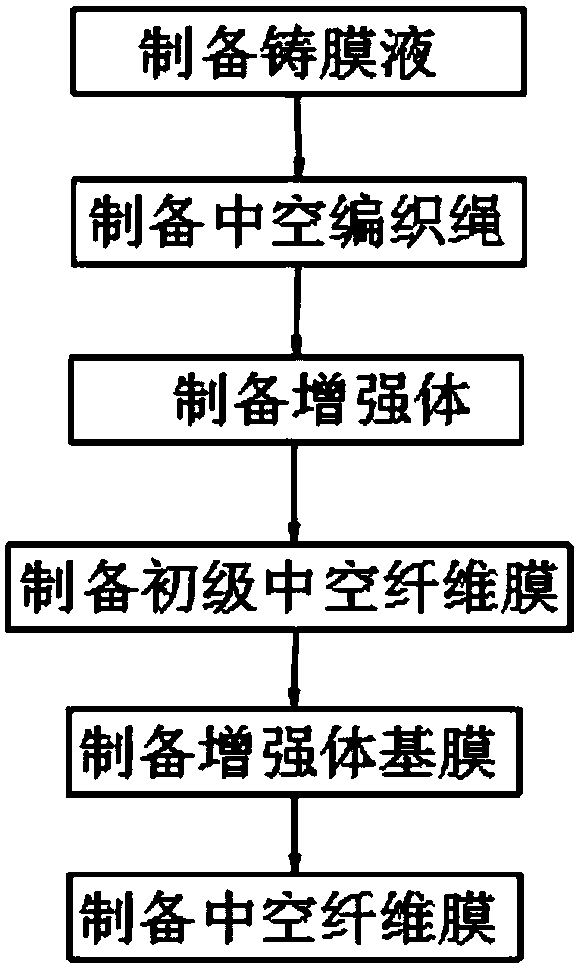

Preparation method for reinforced polyvinylidene fluoride hollow fiber membrane

InactiveCN109806777AImprove corrosion resistanceImprove heat resistanceSemi-permeable membranesPolymer sciencePollution

The invention discloses a preparation method for a reinforced polyvinylidene fluoride hollow fiber membrane. The preparation method comprises the following steps of preparing a casting solution, preparing a hollow braided rope, preparing a reinforcing body, preparing a primary hollow fiber membrane body, preparing a reinforced body base membrane body and preparing the hollow fiber membrane. The method has the advantages of being simple in process and high in efficiency, meanwhile, the prepared membrane has excellent corrosion resistance, heat resistance, cold resistance, oxidation resistance and weather resistance, pollutants can be selectively blocked, irreversible deposition of the pollutants on the surface of the membrane can be prevented or reduced, and the anti-pollution performance of the membrane is improved; and the problem that the skin layer is prone to fall off in the using process of a hollow fiber membrane can be solved, a polyacrylonitrile filament which has the co-solvent characteristic with a polyvinylidene fluoride surface separation layer is adopted and is woven into hollow tubular fabric to serve as the reinforced body of the membrane, the casting solution has agood wettability on the reinforcing body and partially permeates into fiber gaps of the reinforcing body, the mechanical bonding strength is improved, the possibility of filament breaking and pollutant blockage can be lowered, and the service life of the membrane is prolonged.

Owner:乐清腾祥膜技术有限公司

Shaped inlay part and its making method

InactiveCN101262748AImprove yieldIncrease flow spaceInstrument housingDomestic articlesEngineeringUltimate tensile strength

The invention discloses an insert molding, which comprises an insert and a plastic piece. The insert comprises a main body part and an extended part; the extended part extends outwards horizontally from one end at one side of the main body part; the extended part is provided with a protruding part at a place near the side of the center of the main body part and far away from the outside periphery; part of the plastic piece wraps the insert, and a bulged part is formed on the plastic piece at a side opposite to the protruding part. The invention also provides a method for manufacturing the insert molding. The insert molding has relatively high mechanical strength, which prevents cracks during assembly.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Low-melting-point SnBi alloy-copper composite electronic slurry and preparing and printing methods

ActiveCN109994250APrevent oxidationSave steps in advance surface preparationApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialAlloySlurry

The invention discloses low-melting-point SnBi alloy-copper composite electronic slurry, which comprises the following components by weight: 55-85% of mixed conductive phase, 5-15% of tin-bismuth alloy powder, 10-25% of organic carrier, and additives consisting of 0-0.5% of La and 0-4.5% of Ga, with the total percent being 100%. The invention also discloses a preparing method of the low-melting-point SnBi alloy-copper composite electronic slurry and a printing method of the low-melting-point SnBi alloy-copper composite electronic slurry. The low-melting-point SnBi alloy-copper composite electronic slurry and the preparing and printing applications thereof have the advantages of simple process route, easy availability of raw materials, low production cost, no lead and cadmium components, and no pollution.

Owner:扬州虹运电子材料有限公司

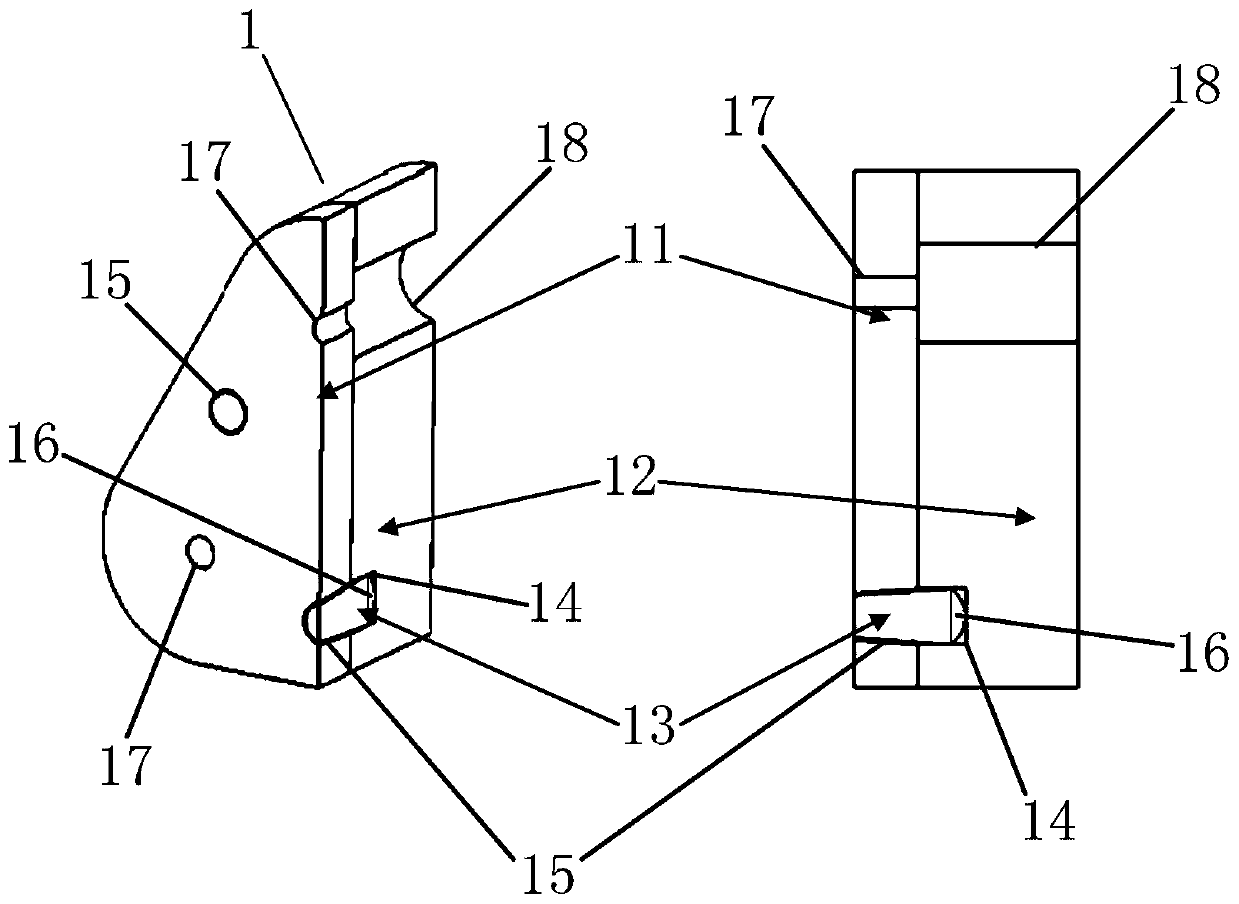

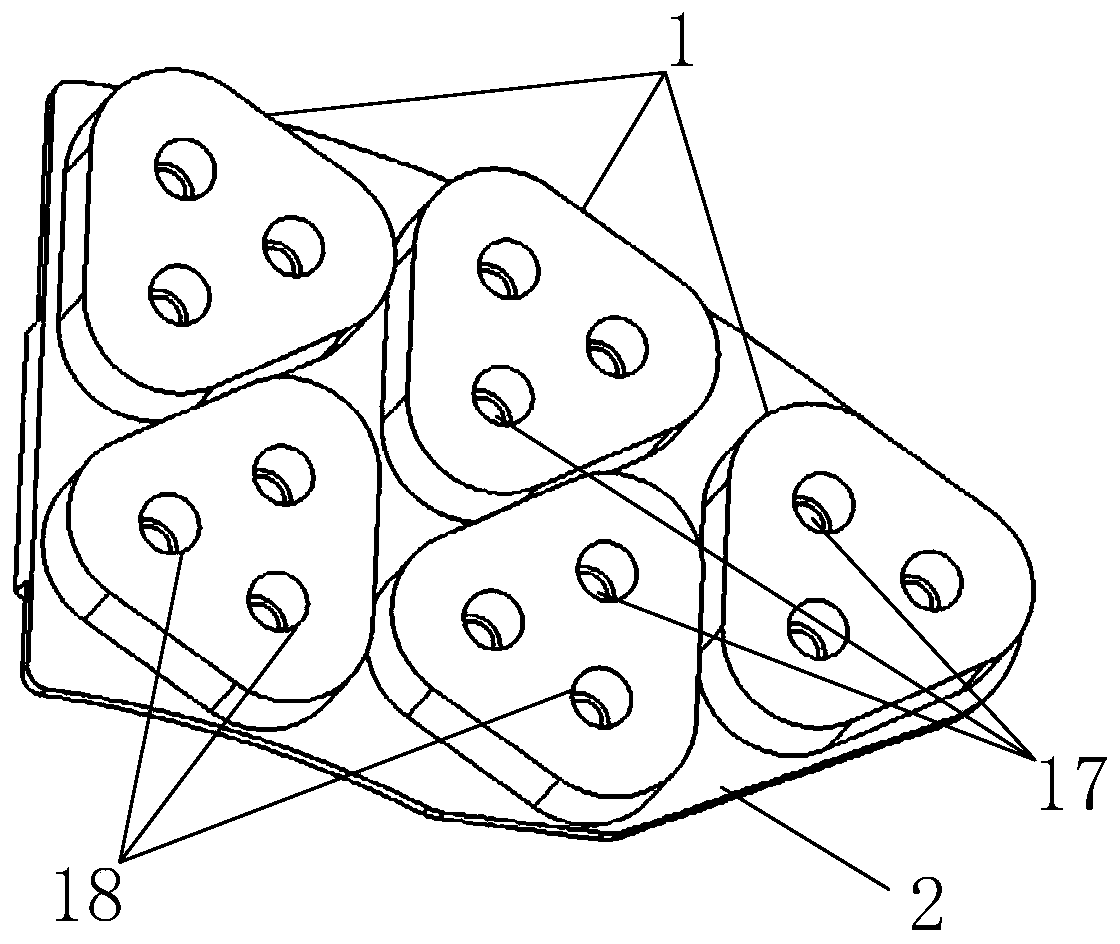

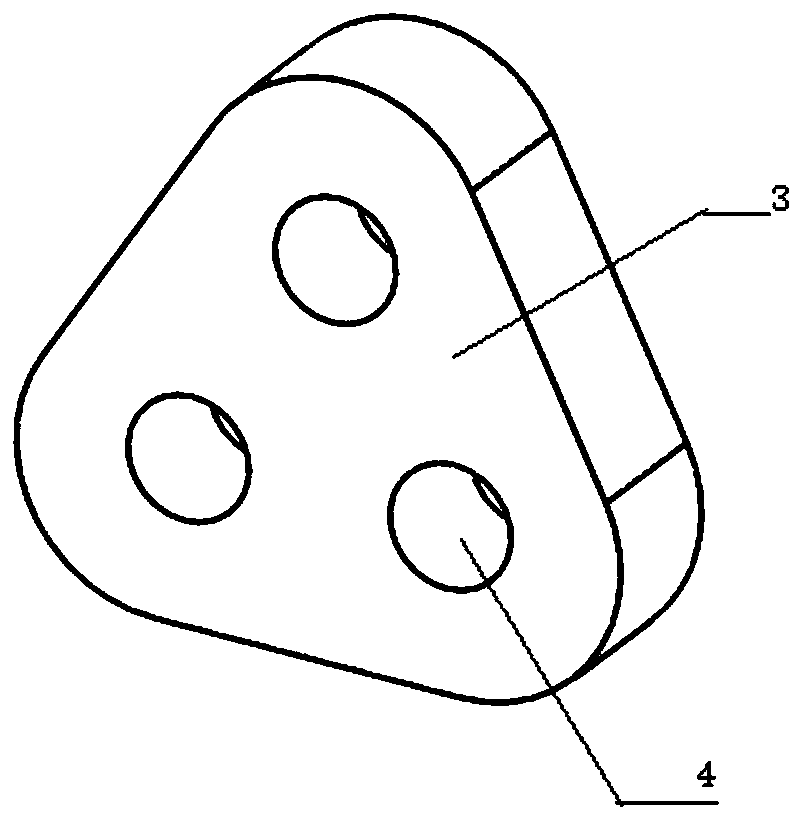

Brake pad for high-speed train

PendingCN111022536AImprove mechanical bond strengthImprove shear resistanceOther chemical processesFriction liningBrake padBlind hole

The invention discloses a brake pad for a high-speed train. The brake pad comprises a brake pad steel backing and a friction block; the friction block comprises a friction block steel backing, a pressing blank and a reinforcing pin; a blind hole is formed in the pressing blank; a through hole communicated with the blind hole is formed in the friction block steel backing; the two ends of the reinforcing pin are fixedly clamped in the blind hole and the through hole respectively, the pressing blank is fixedly connected with the friction block steel backing, the brake pad steel backing is fixedlyconnected with the friction block steel backing, the mechanical bonding strength of the friction block steel backing and the pressing blank is enhanced through the reinforcing pin, and the shear resistance and the impact resistance of the bonding surface between the pressing blank and the friction block steel backing are enhanced. The brake pad can be used to solve the problem that in the prior art, the shear resistance and the impact resistance of the bonding surface between the pressed blank and the friction block steel backing are weak due to the fact that pores are inevitably formed in the bonding surface between the pressing blank and the friction block steel backing.

Owner:BEIJING BEI MO GAO KE FRICTION MATERIAL

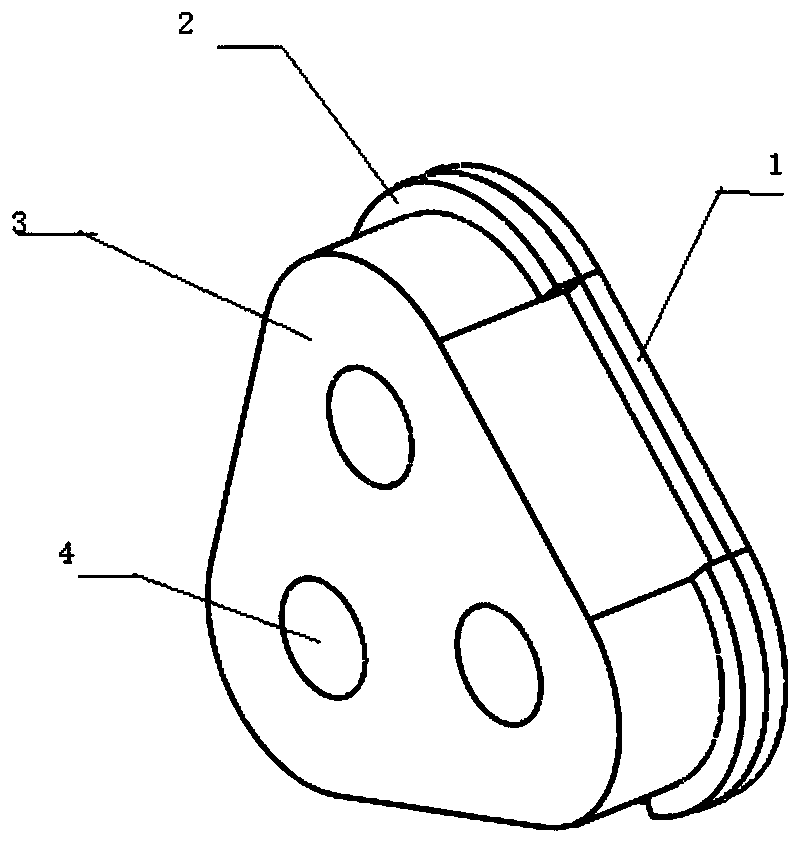

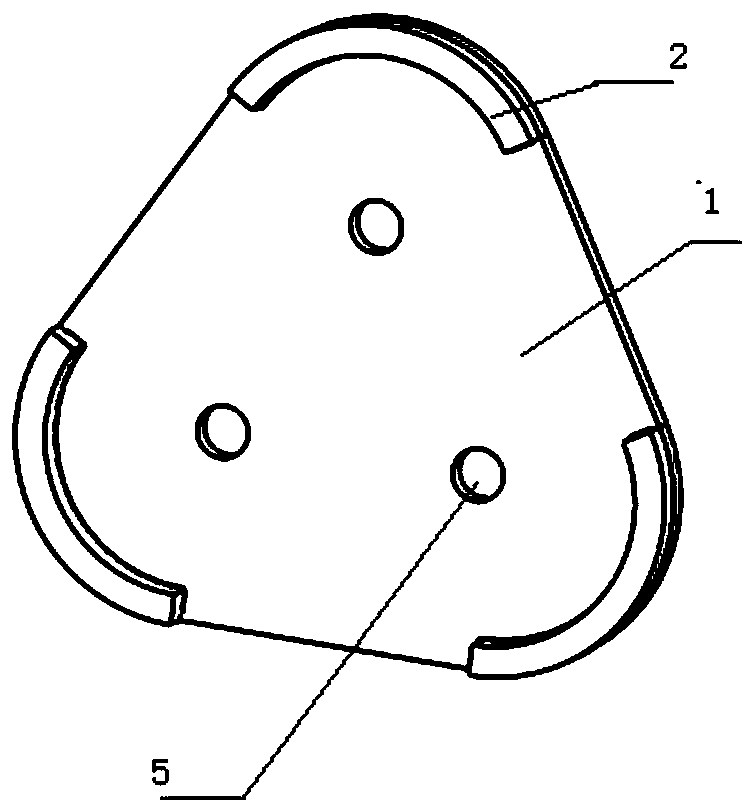

Externally-wrapped friction block for high-speed train brake

PendingCN111075864ASafe and reliable workImprove shear resistanceBraking membersSlack adjustersControl theoryBrake pad

The invention belongs to the technical field of train braking, and particularly relates to an externally-wrapped friction block for a high-speed train brake. The externally-wrapped friction block forthe high-speed train brake comprises a friction block steel back bottom plate, friction block steel back arc claws, a friction block compact blank, first through holes and second through holes. The friction block adopts the externally-wrapped structure, the friction block compact blank is buckled tightly, the firmer effect is realized, the shear resistance and the shock resistance between a friction block steel back and a bonding surface of a friction material layer are enhanced, the phenomena of falling and chipping of the friction material layer can be avoided, and thus a brake pad works more safely and reliably.

Owner:BEIJING BEI MO GAO KE FRICTION MATERIAL

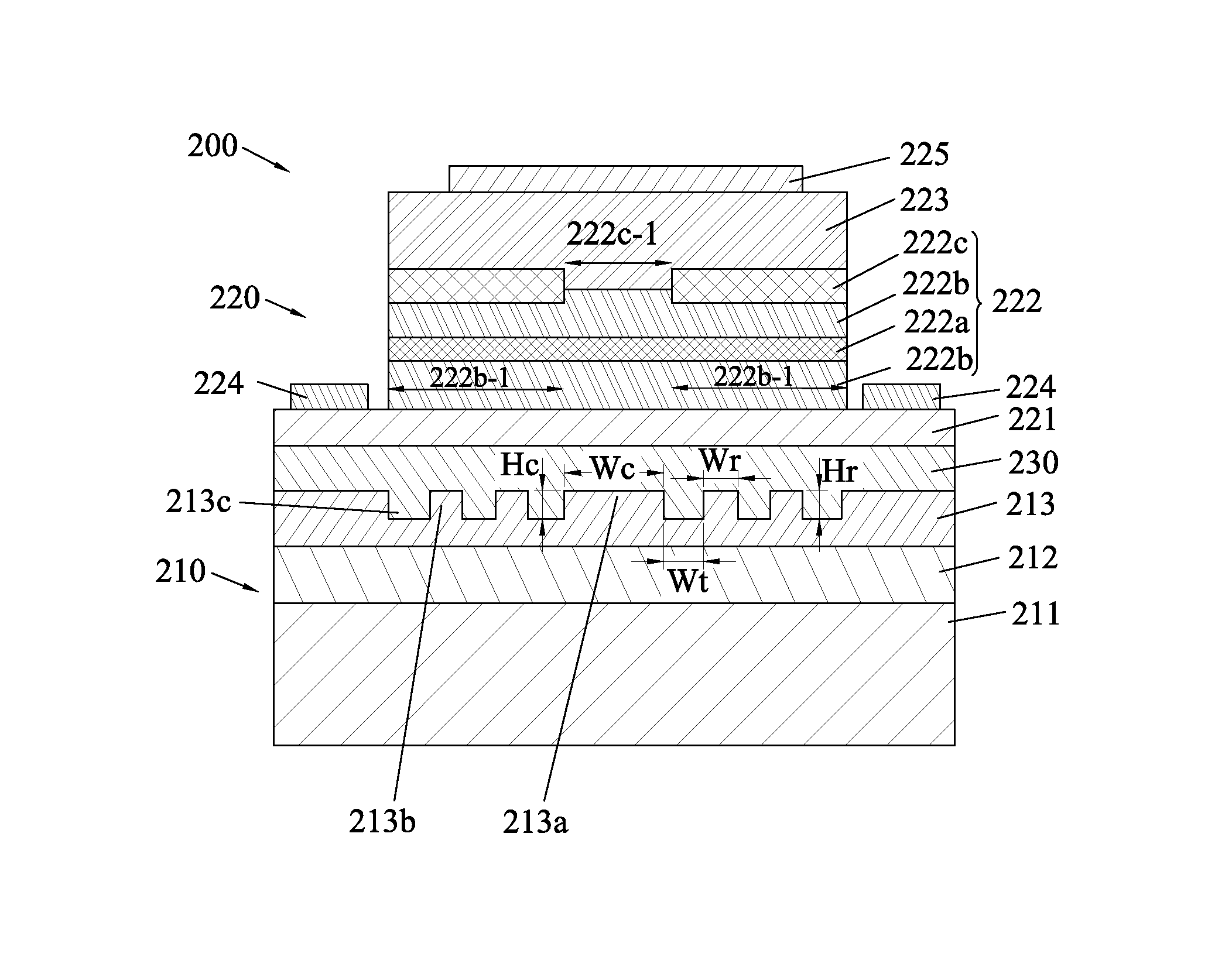

Semiconductor laser apparatus and manufacturing method thereof

ActiveUS9484711B2Low propagation lossEfficient heat dissipationLaser detailsLaser optical resonator constructionSingle mode laserMechanical bond

A semiconductor laser apparatus includes a silicon-on-insulator assembly and an edge-emitting semiconductor laser assembly integrated on the silicon-on-insulator assembly. The silicon-on-insulator assembly includes an optical waveguide at the top which is bonded to the edge-emitting semiconductor laser assembly and configured to couple a laser light emitted from the edge-emitting semiconductor laser assembly, and the optical waveguide includes a core portion located in the middle of the optical waveguide; and at least one vertical rib configured on two sides of the core portion respectively, with a width narrower than that of the core portion. The apparatus obtains a single mode laser operation and has low propagation loss and high mechanical bond strength.

Owner:CLOUD LIGHT TECH LTD

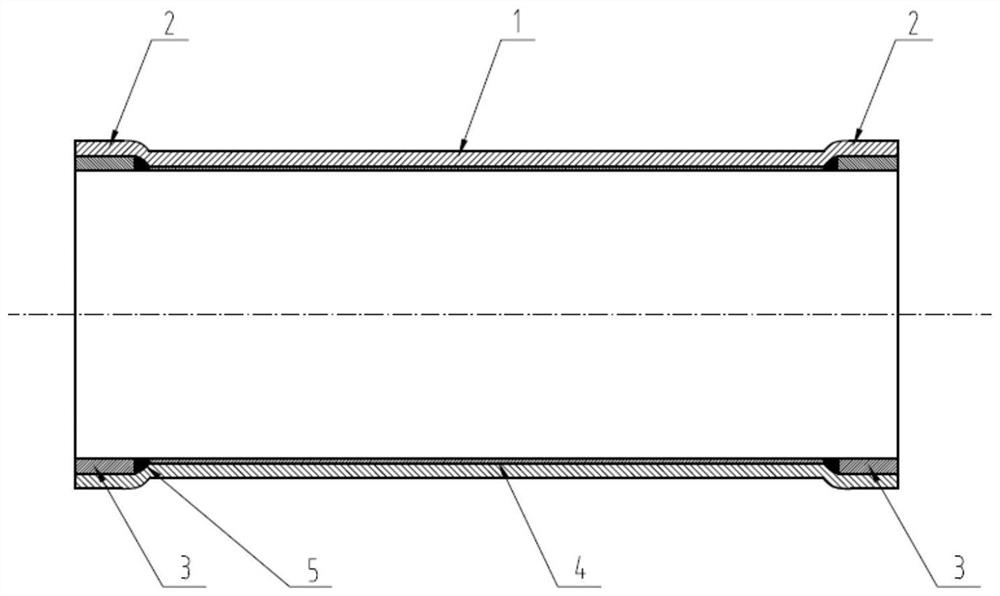

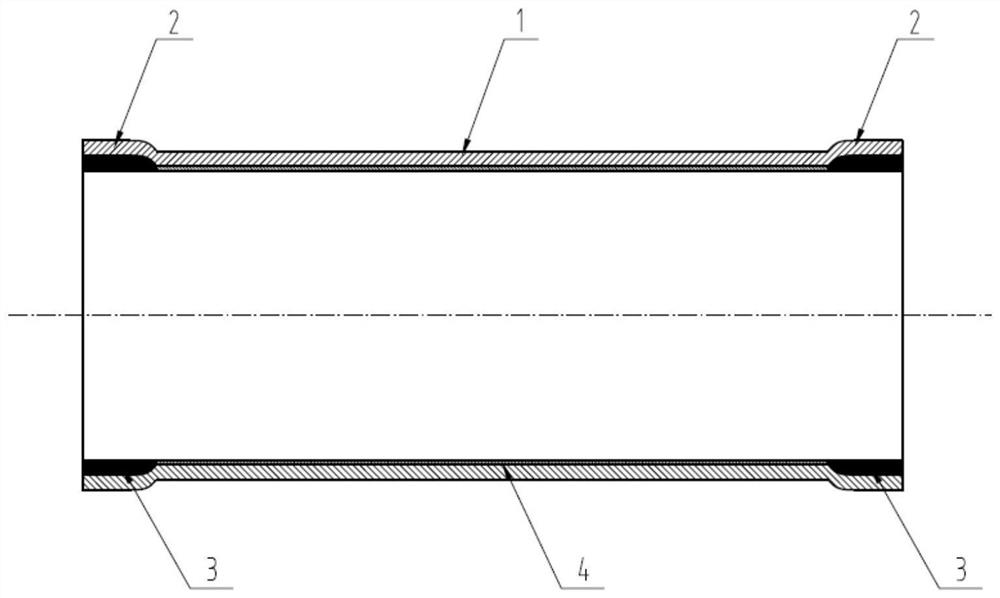

Mechanical bimetal composite pipe with thickened pipe end lining layer and preparation method thereof

PendingCN113028154AThickening achievedIncreasing the thicknessRigid pipesNon-disconnectible pipe-jointsPipeBimetal

The invention discloses a mechanical bimetal composite pipe with a thickened pipe end lining layer. The mechanical bimetal composite pipe comprises a base pipe and a liner pipe assembled in the base pipe, the two ends of the base pipe both exceed the liner pipe, and the exceeding parts of the base pipe are all expanded sections. A thickening layer is arranged between the expanded sections and the liner pipe, and the inner diameter of the thickening layer is equal to that of the liner pipe. The sum of the wall thicknesses of the expanded sections and the thickening layer is greater than the sum of the wall thicknesses of the liner pipe and the base pipe. The invention further discloses a method for preparing the mechanical bimetal composite pipe with the thickened pipe end lining layer. The method comprises the steps that firstly, the mechanical bimetal composite pipe is assembled and prepared; secondly, an expanding process is designed; thirdly, a liner pipe blank is cut off and expanded, and the thickening layer is prepared; and fourthly, subsequent treatment is conducted. According to the mechanical bimetal composite pipe with the thickened pipe end lining layer and the preparation method thereof, the two ends, exceeding the liner pipe, of the base pipe in the composite pipe are arranged to be the expanded sections, the thickening layer is further arranged, thickening of the liner layer at the pipe end is achieved, and the problems that the bimetal composite pipe is large in welding technology difficulty and the quality is difficult to guarantee are solved. The preparation process is simple, the preparation efficiency is high, and cost is low.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

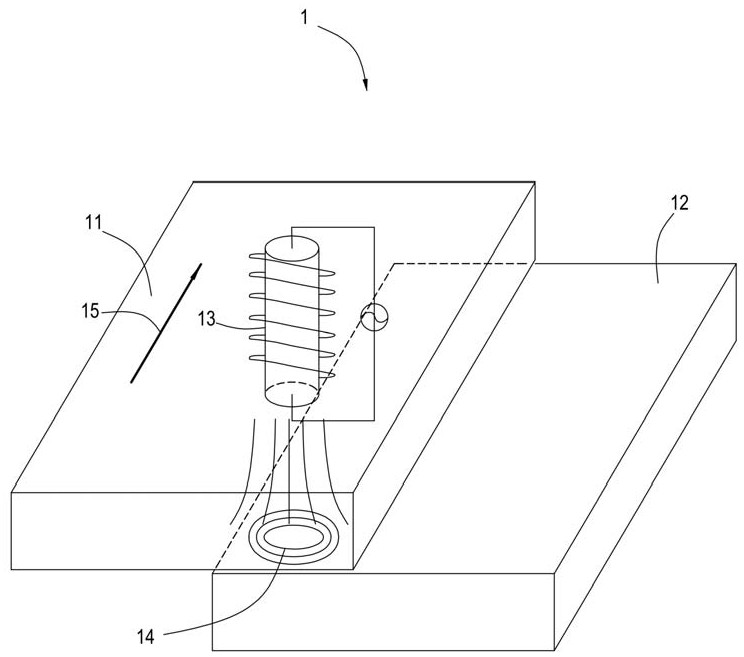

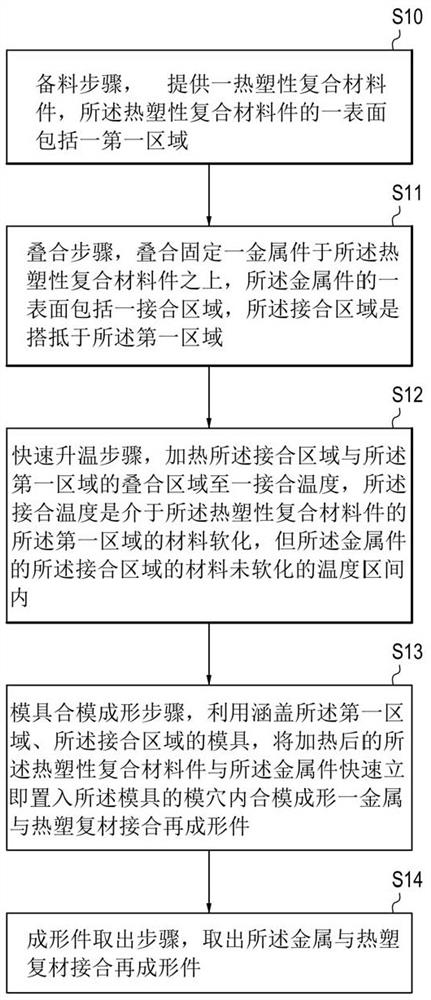

Metal and thermoplastic composite joining and reshaping methods

ActiveCN109910274BMinimize and simplify the design processShorten heating timePolymer scienceCompressive strength

The invention discloses a method for joining and reshaping a metal and a thermoplastic composite material. The steps include: providing a thermoplastic composite material piece, one surface of which includes a first region; laminating and fixing a metal piece on the thermoplastic composite material piece In the above, the metal part includes a joint area that is placed on the first area; the superimposed area of the joint area and the first area is rapidly heated to a joint temperature; the heated thermoplastic composite material part and the metal part are quickly inserted into the first The molds in the area and the joint area are molded together to form metal and thermoplastic composite joint reshaped parts; then take out the metal and thermoplastic composite joint reshaped parts from the mold; when the heating source is a light source, it can A heat-adjusting partition wall is set between the pair of metal parts to adjust the heating heat of the metal parts; according to this, the metal and the thermoplastic composite material are joined and formed to improve the local mechanical properties of the fiber-reinforced composite material, improve the compression strength, and Wear and overall dimensional accuracy stability.

Owner:METAL INDS RES & DEV CENT

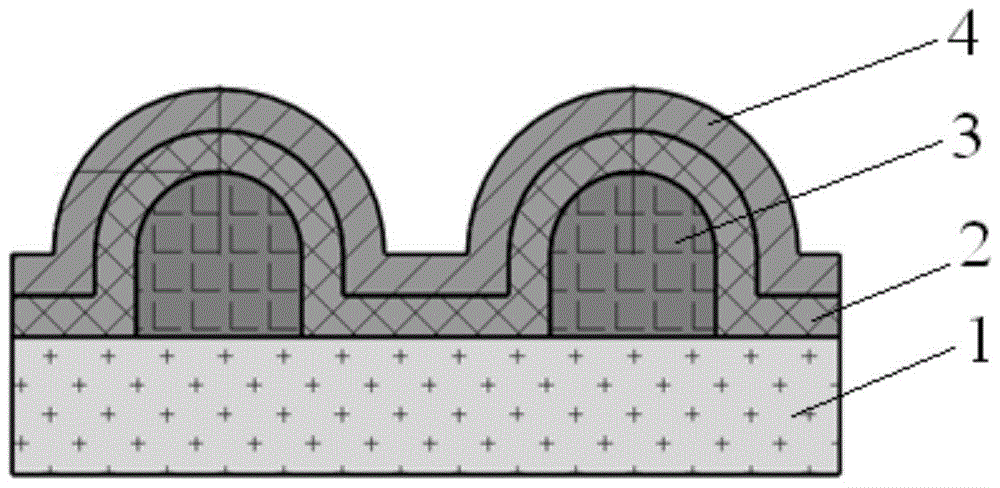

Preparation method of ultrahigh-temperature anti-scouring thermal barrier coating

PendingCN114540738AIncrease service temperaturePrevent peelingAdditive manufacturing apparatusMolten spray coatingLaser engravingSuperalloy

The invention relates to a preparation method of an ultrahigh-temperature anti-scouring thermal barrier coating. The preparation method comprises the following steps: providing a high-temperature alloy matrix; depositing a metal bonding layer on the high-temperature alloy matrix; a grid bonding layer with the same components as the metal bonding layer is introduced to the metal bonding layer through the laser engraving technology or the laser coaxial powder feeding 3D printing technology, the grid bonding layer is composed of rectangular grid structures with regular shapes and protrudes out of the metal bonding layer, and the side length of each rectangular grid ranges from 100 micrometers to 900 micrometers; the height of the grid bonding layer is between 100 microns and 400 microns; and depositing a ceramic layer on the grid bonding layer. According to the preparation method of the ultrahigh-temperature anti-scouring thermal barrier coating, the continuous grid layer with the regular shape is introduced between the bonding layer and the ceramic layer, the roughness of an interface between the bonding layer and the ceramic layer is increased, the mechanical bonding strength of the interface is enhanced, and therefore the service temperature of the thermal barrier coating is increased.

Owner:EAST CHINA UNIV OF SCI & TECH +3

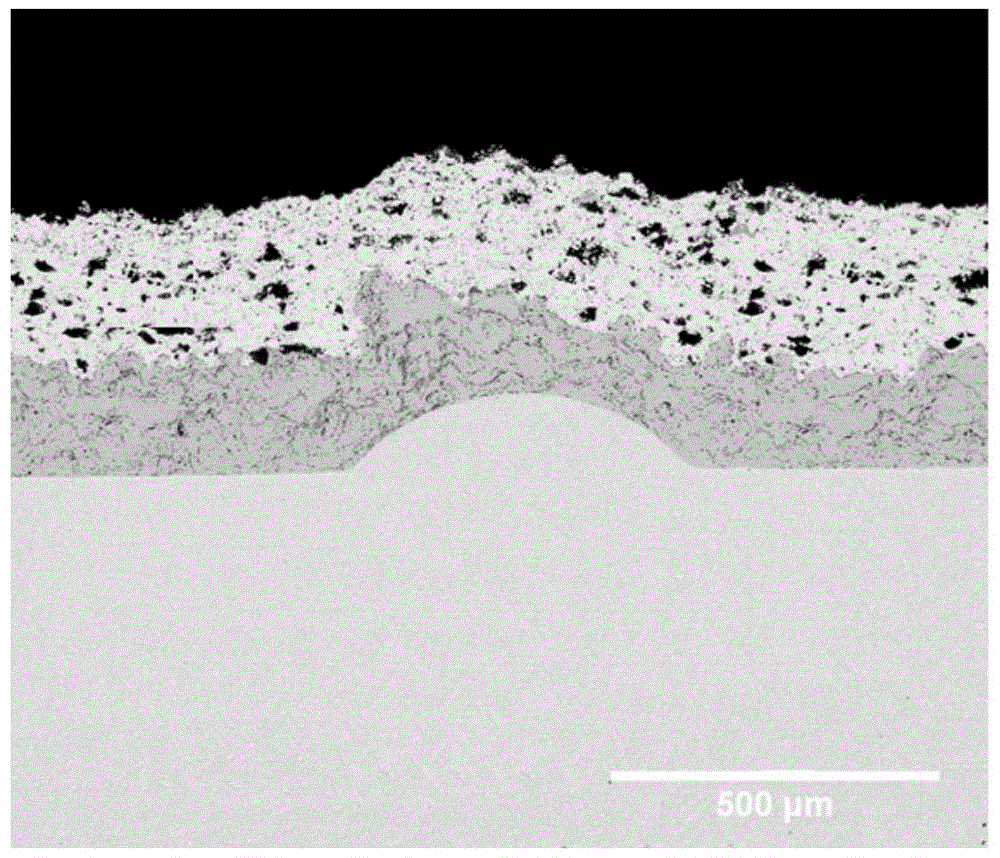

A Laser Powder Deposition Method for Controlling the Interface Morphology of Thermal Barrier Coatings

ActiveCN104451672BExtended service lifeImprove mechanical bond strengthMolten spray coatingEfficient propulsion technologiesElectron beam physical vapor depositionAbrasive blasting

The invention relates to a laser powder deposition method for regulating and controlling the interface morphology of a thermal barrier coating. The laser powder deposition method comprises the following steps: performing rust removal on a metal base body, degreasing and performing abrasive blasting pretreatment; preparing a metal bonding layer on the upper surface of the metal base body by plasma spraying or hypersonic flame spraying; depositing laser powder on the metal bonding layer to introduce a grid layer with a regular shape and controllable parameters; and spraying the outer side of the grid layer by utilizing the plasma spraying or electronic beam physical vapor deposition to prepare a ceramic coating. Compared with the prior art, the laser powder deposition method for regulating and controlling the interface morphology of the thermal barrier coating has the advantages that the grid layer is introduced to a traditional thermal barrier coating structure by adopting a laser powder deposition technique, so that the mechanical bond performance of adjacent coatings is improved, the horizontal expansion of horizontal cracks is limited, and vertical cracks in the ceramic coating are uniformly distributed; and therefore, the performance of the thermal barrier coating is remarkably improved, and the service life is remarkably prolonged.

Owner:SHANGHAI JIAOTONG UNIV

Copper coated grid-type graphene and preparation method thereof

ActiveCN109267049AControl the ambient temperatureReduce sizeLiquid/solution decomposition chemical coatingCopper platingFiltration

The invention discloses copper coated grid-type graphene, and further discloses a preparation method of the copper coated grid-type graphene. The preparation method comprises the steps that 1, the surfaces of graphene nanosheets are desensitized and inactivated, and the graphene nanosheets are punched in a vacuum punching bin of a transmission electron microscope, so that grids are formed; 2, trisodium citrate, sodium tetraborate and EDTA are added into a copper sulfate solution, and the pH value is adjusted to obtain a main salt mixed solution; 3, a catalyst, a reducing agent and a buffer agent are added into the main salt mixed solution, and the pH value is adjusted to obtain a mixed plating solution; 4, the grid-type graphene nanosheets are placed in the mixed plating solution, then, anadditive is added, the pH value is controlled to be 10-15, magnetic stirring, ultrasonic dispersion and filtration are conducted, and the grid-type graphene nanosheets are taken out; the grid-type graphene nanosheets are washed with deionized water to be neutral, drying is conducted, and the copper coated grid-type graphene is prepared. By means of the method, the plating effect and the electrical conductivity are obviously improved.

Owner:黑龙江省墨砾新型材料有限责任公司

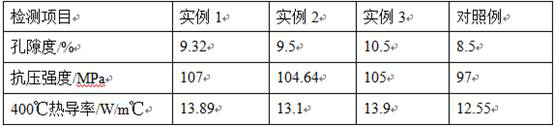

A preparation method of powder metallurgy friction material

The invention relates to a preparation method of a powder metallurgy friction material, which belongs to the technical field of friction materials. In the present invention, the bonding between copper-coated silicon carbide particles and the substrate is tight, and silicon carbide has outstanding advantages such as low density, small thermal expansion coefficient, high strength, high elastic modulus, high melting point and stable chemical properties, and can be used in high-energy braking processes. Keep the friction performance of the material stable, and its good thermal conductivity can also accelerate the conduction of friction heat on the friction surface of the material during the high-energy braking process; the present invention adopts butadiene resin and rare earth element modified epoxy resin, because rubber with low surface energy tends to Adsorbed on the surface of rare earth particles with high surface energy, this adsorption can improve the strength of rubber, and under the action of stress, it can slide on the surface of rare earth particles, redistribute the stress in the material, avoid stress concentration, and improve the modification. The mechanical properties of the resin improve the wear resistance of the powder metallurgy friction material.

Owner:青岛方冠摩擦材料有限公司 +1

A kind of copper-plated grid graphene and preparation method thereof

ActiveCN109267049BControl the ambient temperatureReduce sizeLiquid/solution decomposition chemical coatingPtru catalystCopper plating

The invention discloses copper coated grid-type graphene, and further discloses a preparation method of the copper coated grid-type graphene. The preparation method comprises the steps that 1, the surfaces of graphene nanosheets are desensitized and inactivated, and the graphene nanosheets are punched in a vacuum punching bin of a transmission electron microscope, so that grids are formed; 2, trisodium citrate, sodium tetraborate and EDTA are added into a copper sulfate solution, and the pH value is adjusted to obtain a main salt mixed solution; 3, a catalyst, a reducing agent and a buffer agent are added into the main salt mixed solution, and the pH value is adjusted to obtain a mixed plating solution; 4, the grid-type graphene nanosheets are placed in the mixed plating solution, then, anadditive is added, the pH value is controlled to be 10-15, magnetic stirring, ultrasonic dispersion and filtration are conducted, and the grid-type graphene nanosheets are taken out; the grid-type graphene nanosheets are washed with deionized water to be neutral, drying is conducted, and the copper coated grid-type graphene is prepared. By means of the method, the plating effect and the electrical conductivity are obviously improved.

Owner:黑龙江省墨砾新型材料有限责任公司

Low melting point snbi alloy-copper composite electronic paste and its preparation and printing method

ActiveCN109994250BPrevent oxidationSave steps in advance surface preparationApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialAlloySlurry

The invention discloses low-melting-point SnBi alloy-copper composite electronic slurry, which comprises the following components by weight: 55-85% of mixed conductive phase, 5-15% of tin-bismuth alloy powder, 10-25% of organic carrier, and additives consisting of 0-0.5% of La and 0-4.5% of Ga, with the total percent being 100%. The invention also discloses a preparing method of the low-melting-point SnBi alloy-copper composite electronic slurry and a printing method of the low-melting-point SnBi alloy-copper composite electronic slurry. The low-melting-point SnBi alloy-copper composite electronic slurry and the preparing and printing applications thereof have the advantages of simple process route, easy availability of raw materials, low production cost, no lead and cadmium components, and no pollution.

Owner:扬州虹运电子材料有限公司

A kind of low-melting-point metal-water-based conductive composite slurry and preparation method thereof

ActiveCN110189849BImprove performanceMix tightlyNon-conductive material with dispersed conductive materialCable/conductor manufactureChemical platingCarbon nanotube

The invention discloses low-melting-point metal-CNTS / Cu water-based conductive composite slurry. The low-melting-point metal-CNTS / Cu water-based conductive composite slurry comprises the following components in percentage by mass: 50-80% of a mixed conductive phase, 5-15% of tin powder or bismuth powder, 15-30% of a water-based carrier, 0.1-0.5% of an additive P and 0.1-4.5% of an additive Ga, wherein the total amount is 100%. The present invention further discloses a preparation method of low-melting-point metal-CNTS / Cu water-based conductive composite slurry. In the product and the preparation method thereof, the mixed conductive phase is prepared by employing a chemical plating method, so that the combination of the copper and a carbon nano tube is more compact and uniform; the low-melting-point metal tin or bismuth is used as a new bonding phase, so that the sintering temperature can be reduced, and the comprehensive performance of the slurry is improved; and the water-based carrier is environment-friendly, so that the cost is obviously reduced.

Owner:扬州虹运电子材料有限公司

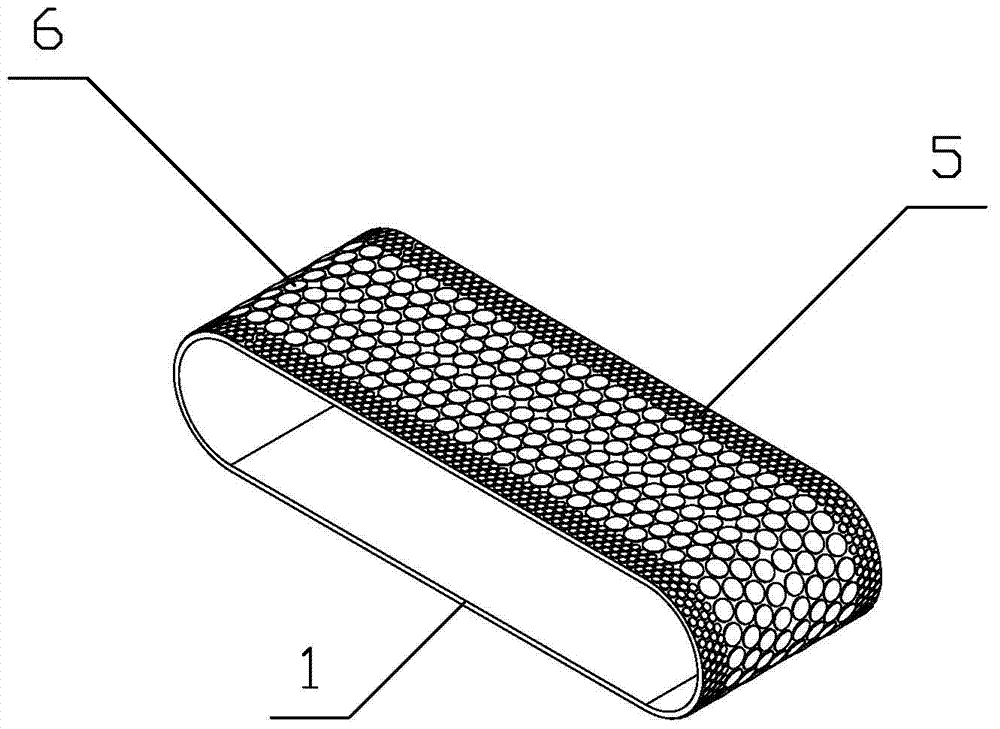

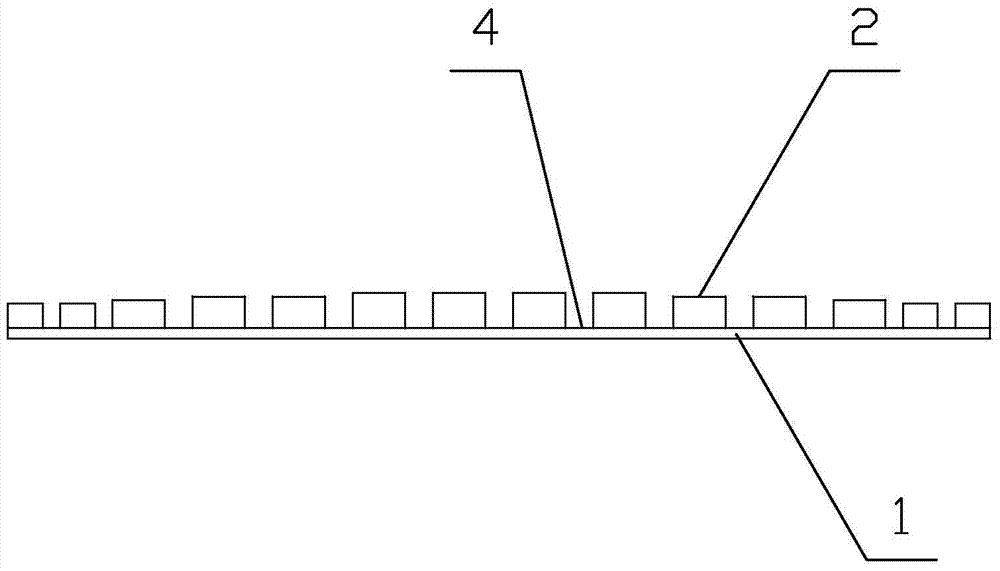

A kind of diamond flexible abrasive belt with equal wear structure and manufacturing method thereof

ActiveCN105458945BImprove mechanical bond strengthUniform wearAbrasion apparatusMetal coatingGalvanic deposition

The invention discloses a diamond flexible abrasive belt with an equal-abrasion structure. The diamond flexible abrasive belt is in head-to-tail connection to form an annular belt shape and comprises a base body and a grinding work layer; the surface of the base body and the interiors of thin holes formed in the surface of the base body are subject to electro-deposition to form an electro-deposition metal coating; the grinding work layer is composed of a plurality of super-hard thin particles fixedly connected to the surfaces of the left edge and the right edge of the electro-deposition metal coating and super-hard rough particles on the surface of the middle portion, and a convex distribution structure with the two dense small-thickness edges and the sparse large-thickness middle is formed; and the surface of the electro-deposition metal coating on the base body and the grinding work layer are mechanically embedded and combined together. In the using process of the diamond flexible abrasive belt, the grinding work layer can achieve uniform abrasion, the possibility that a grinding unit on the grinding work layer falls off is avoided, and the service life is prolonged.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

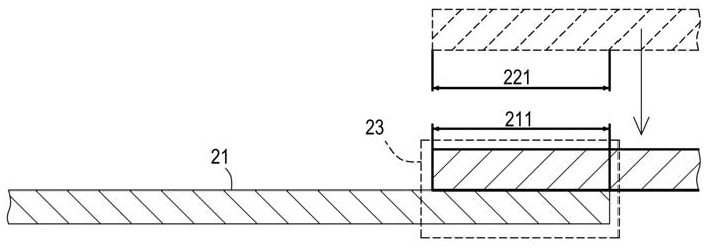

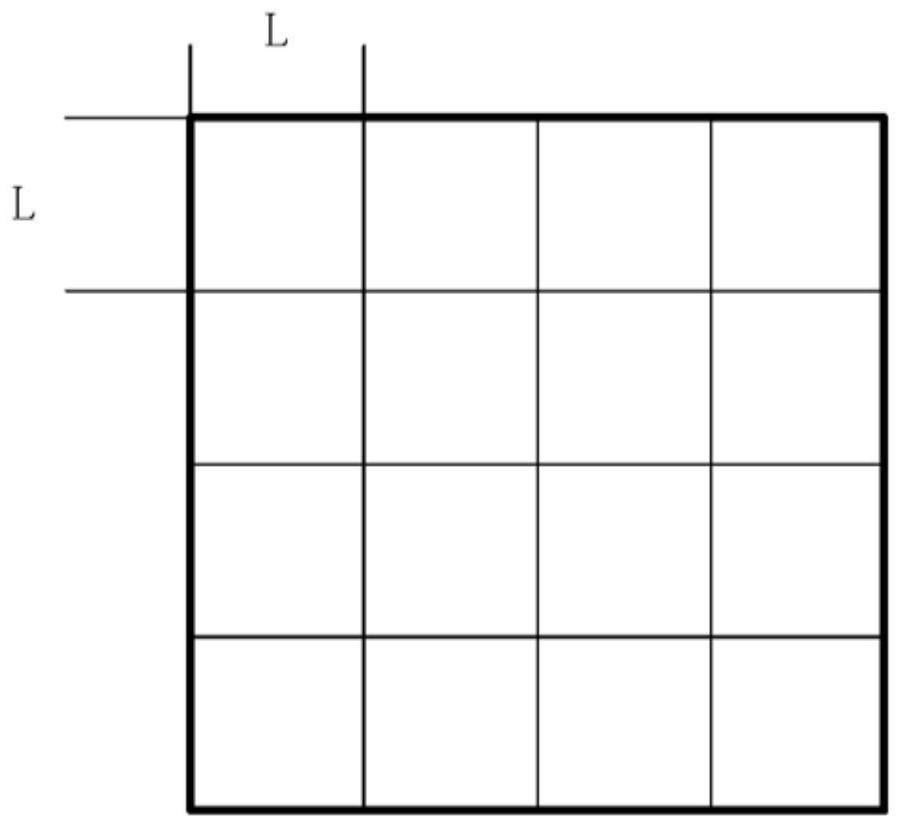

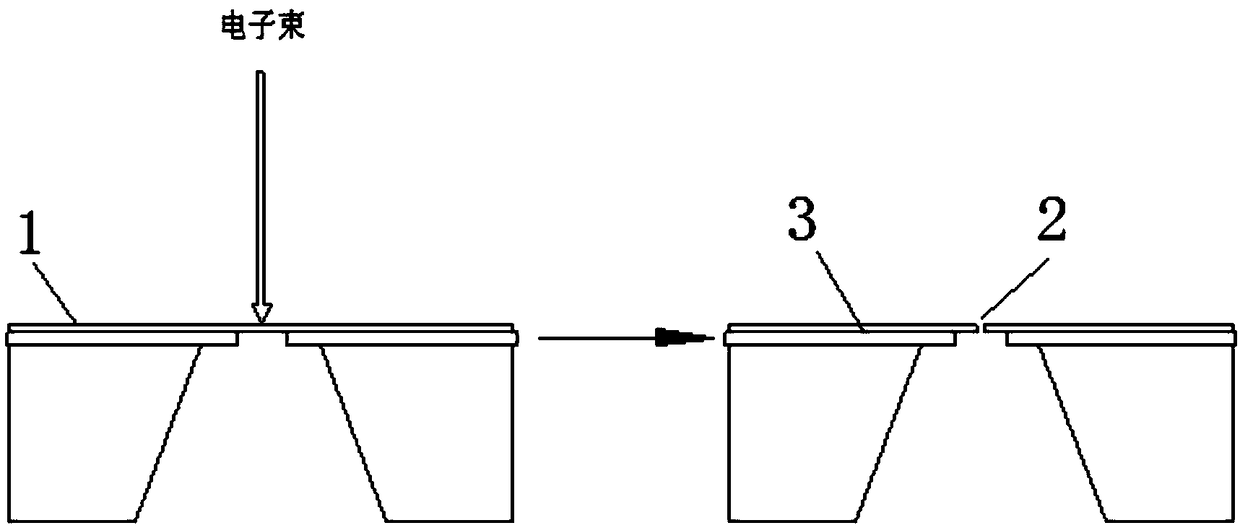

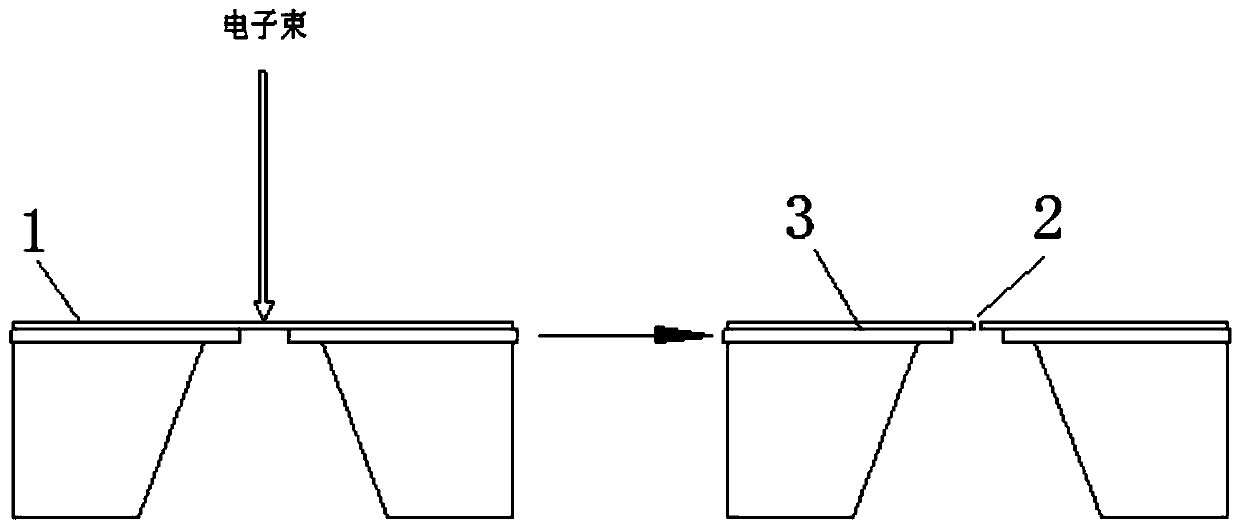

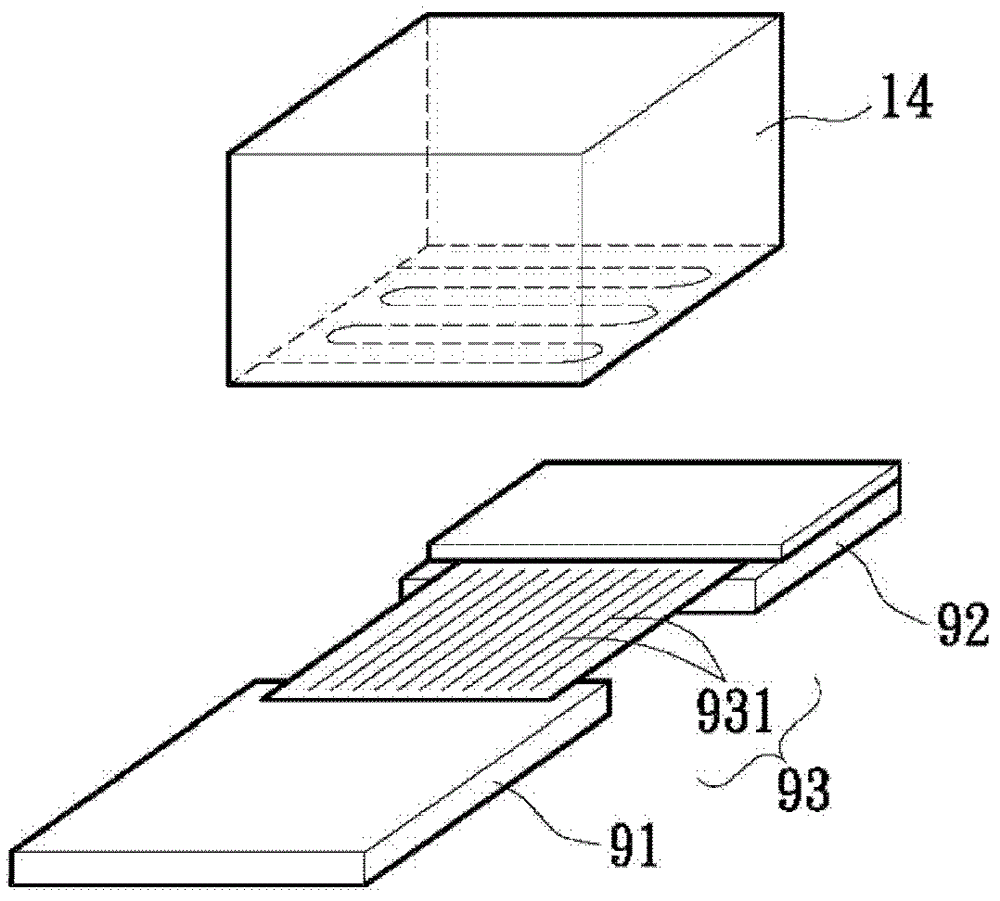

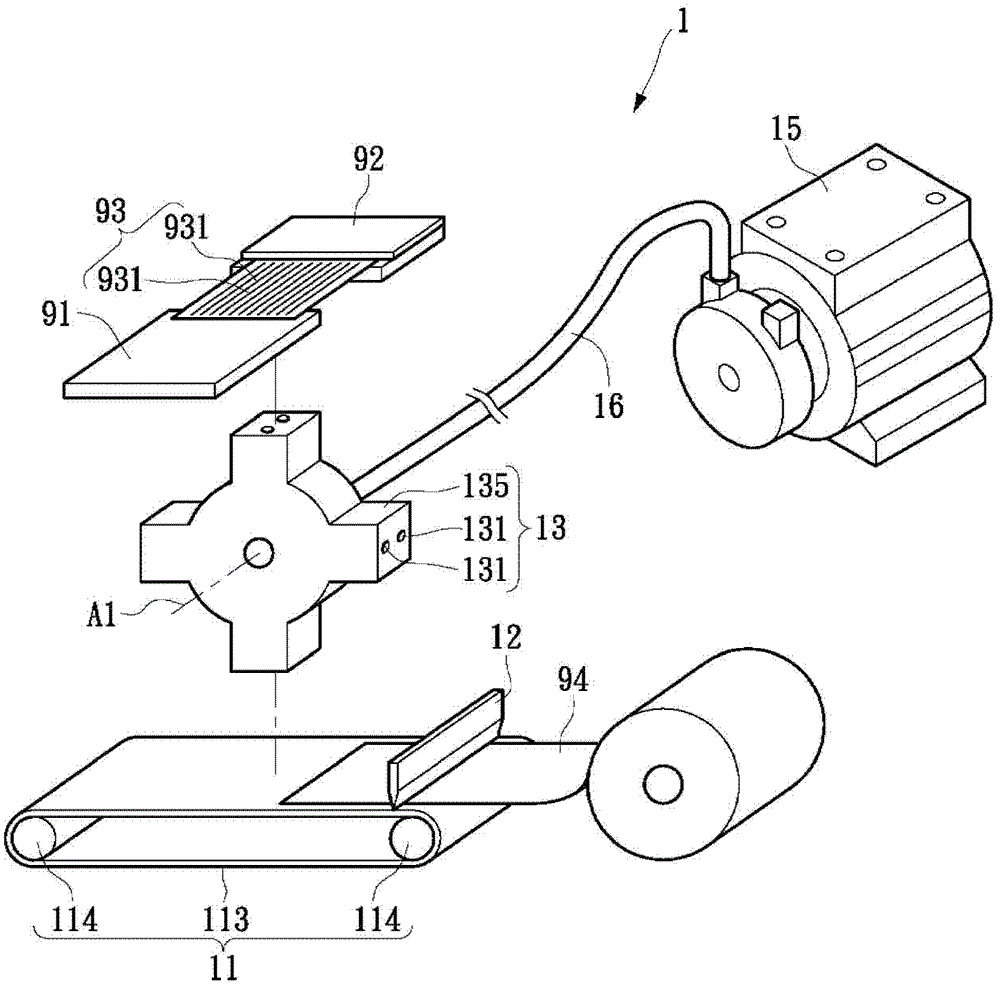

Adhesive film bonding equipment and adhesive film bonding method

InactiveCN103171231BImprove mechanical bond strengthLaminationLamination apparatusThermal compressionEngineering

The present invention provides adhesive film bonding equipment and an adhesive film bonding method using the same, used for bonding an adhesive film to a circuit board. The adhesive film bonding equipment comprises a conveying unit, a cut-off tool, a rotary headstock, and a hot-press headstock; wherein the conveying unit is used for conveying the adhesive film, the cut-off tool is arranged at a periphery of the conveying unit and used for cutting off the adhesive film through repeated movement; the rotary headstock comprises at least one suction hole, the suction hole is arranged at a side edge of the rotary headstock, the rotary headstock enables the suction hole to be selectively adjacent to the periphery of the circuit board and the cut-off adhesive film; the hot-press headstocknis arranged at the periphery of the circuit board, when the suction hole is arranged at the periphery of the circuit board, the hot-press headstock heats the adhesive film. When the circuit board is produced and assembled, mechanical bonding strength between a hot melting film and the circuit board or other electronic component can be enhanced, so as to overcome easy dropping and stripping conditions of the hot melting film, thus the adhesive film bonding equipment is very practical.

Owner:KINPO ELECTRONICS +1

Preparation method of aluminum blades used in oil skimmer loaded with oleophilic and hydrophobic composite materials

ActiveCN109094043BImprove performanceEasy to prepareMaterial nanotechnologyGrapheneMechanical bondGraphene

The invention discloses a method for preparing aluminum blades used in an oil receiving machine with oil-wet and hydrophobic composite materials. According to the method, ultrafine graphene nanosheetsare prepared by a microwave expansion method, and polytetrafluoroethylene-graphene nanosheet composite material powder is prepared; then the composite material powder is subjected to compression moulding forming and the surface chemical reduction to obtain polytetrafluoroethylene-graphene composite material slices; and finally, the polytetrafluoroethylene-graphene composite material slices and aluminum sheets are bonded with fluorine resin primer, and after drying is completed, the aluminum blades used in the oil receiving machine with the oil-wet and hydrophobic composite materials are prepared. The method for preparing the aluminum blades used in the oil receiving machine with the oil-wet and hydrophobic composite materials is simple, simple and convenient to operate and low in cost, the prepared aluminum blades used in the oil receiving machine with the oil-wet and hydrophobic composite materials have good oil-wet and hydrophobic performance, high oil-receiving efficiency, high mechanical bond strength and high corrosion resistance, and the recovery and disposal of oil slick can be greatly promoted.

Owner:蓝鲸海洋溢油净化工程秦皇岛有限公司

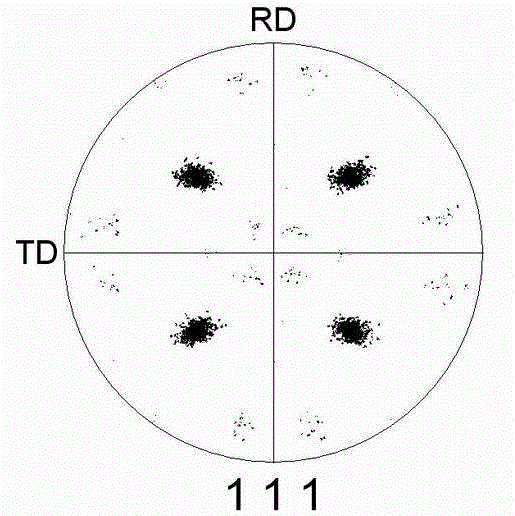

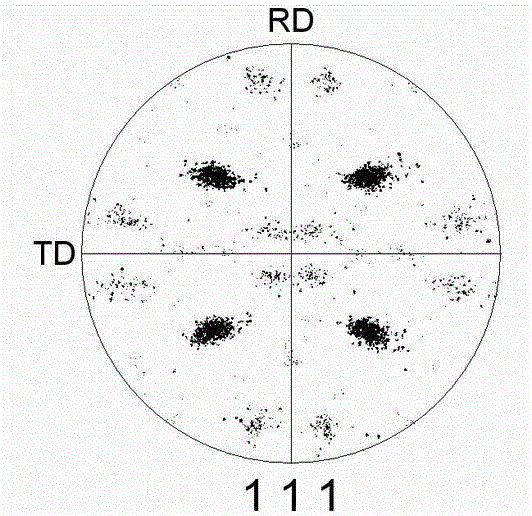

High-strength NiW alloy composite baseband with cube texture and preparation method thereof

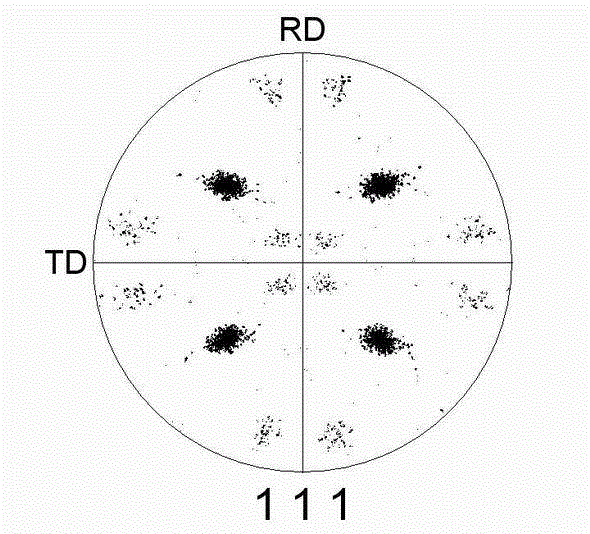

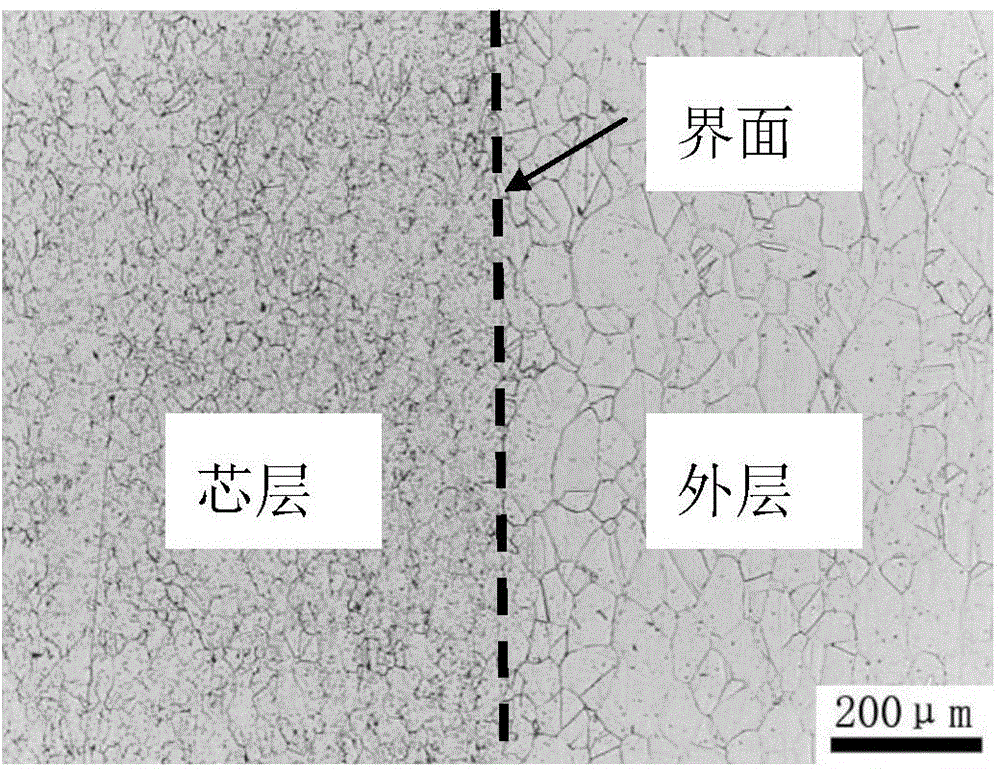

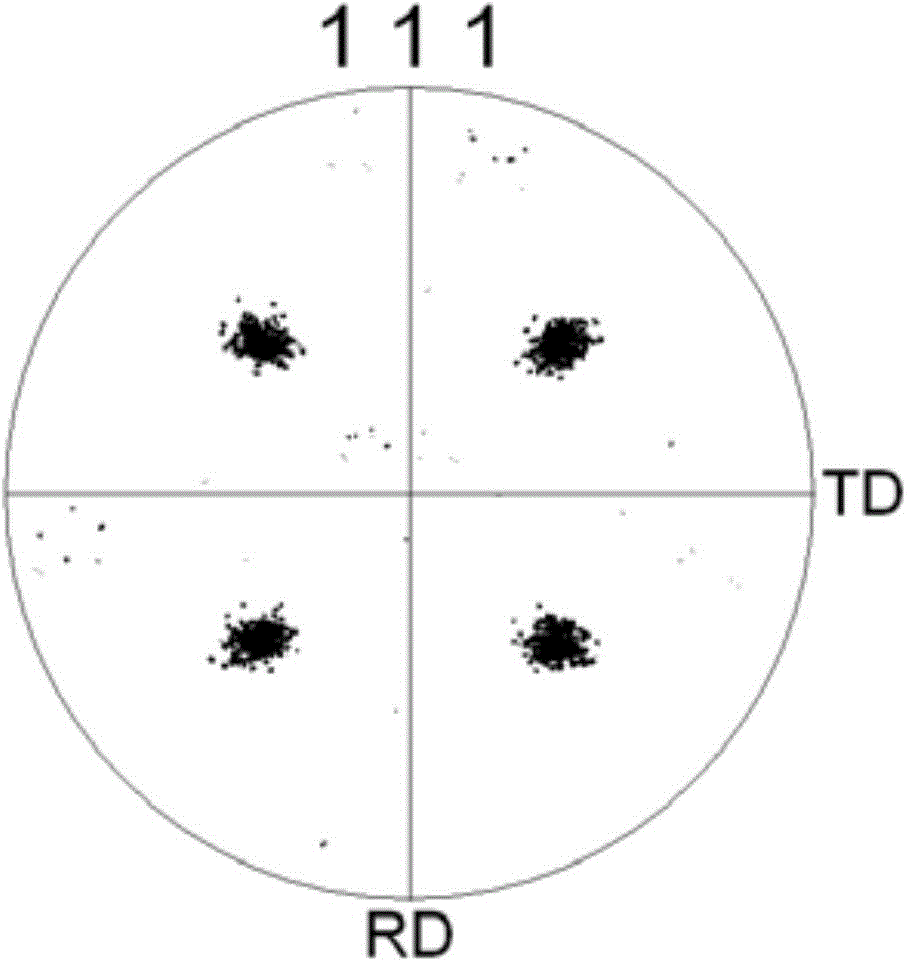

InactiveCN103498121BImprove mechanical bond strengthAvoid crackingMetal layered productsAlloy compositeUltimate tensile strength

The invention discloses a high-strength NiW alloy composite baseband with a cube texture and a preparation method thereof. The key points of the technical scheme of the invention are as follows: the composite baseband is formed by compositing an outer layer and a core, wherein the initial material of the outer layer of the composite baseband is a NiW alloy which is obtained by vacuum induction melting and has W atom percentage of 6-7%; the initial material of the core of the composite baseband is a NiW alloy which is obtained by vacuum induction melting and has W atom percentage of 9%. The invention also discloses the preparation method of the high-strength NiW alloy composite baseband with the cube texture. The NiW alloy composite baseband prepared by the preparation method is good in interface bonding and has strong cube texture and high mechanical strength.

Owner:HENAN NORMAL UNIV

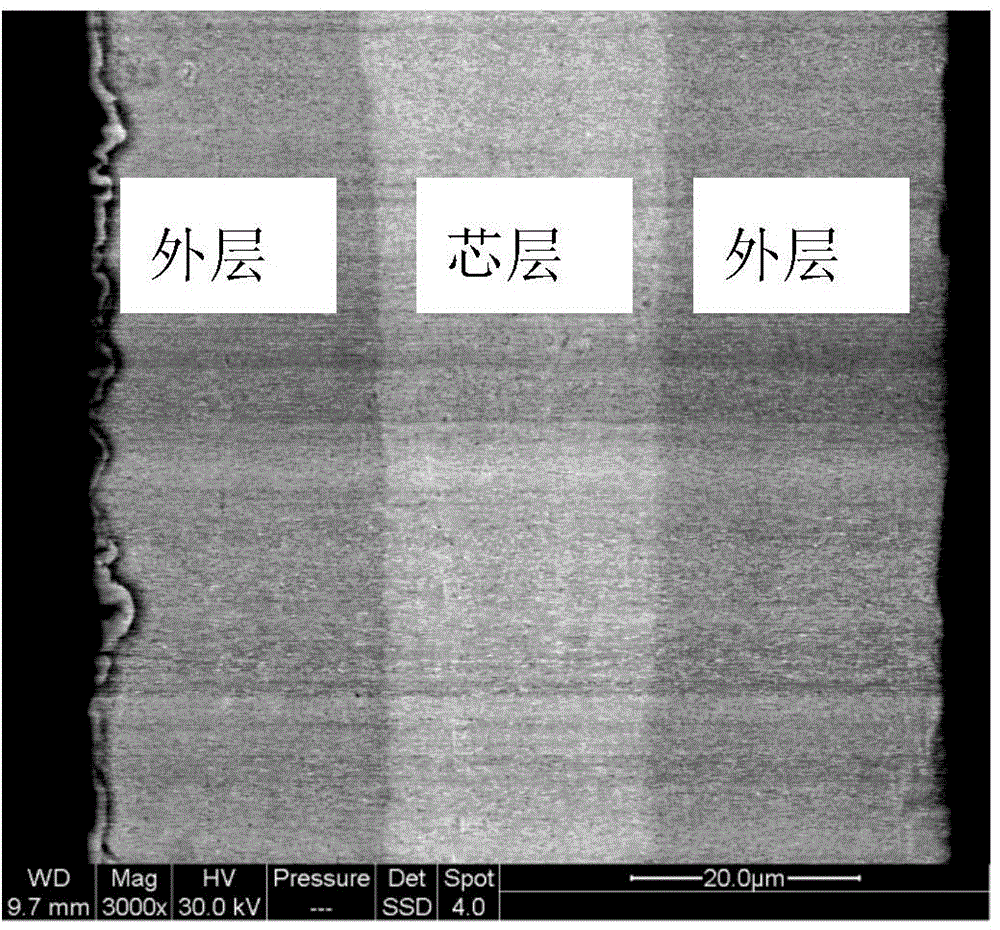

A kind of preparation method of initial composite billet for non-magnetic Cu-based composite base tape

The invention discloses a preparation method of a composite billet for a Cu-based alloy composite baseband. According to the Cu-based alloy initial composite billet provided by the invention, the surface layer is made of Cu-Ni alloy in which the atomic percent of Ni is 40-46% and the core layer is made of Ni-W alloy in which atomic percent of W is 9-10%. The preparation method of the Cu-based alloy initial composite billet comprises the following steps of: sand blasting the surface of the Cu-Ni alloy (marked with A) of which the atomic percent of Ni is 40-46%, wherein the Cu-Ni alloy is prepared by means of melting; placing the sand-blasted Cu-Ni alloy and the Ni-W mixed powder (marked with B) in which the atomic percent of W is 9-10% in a mold according to the sequence of A-B-A, simultaneously pressing and sintering the Cu-Ni alloy and the Ni-W mixed powder by means of discharge plasma sintering technology to obtain the composite billet, and hot pressing the composite billet to obtain the initial composite billet with large deformation before cold rolling, wherein the deformation of the first pass is 30-40%, the deformation of each subsequent pass is 3-5%, and the total deformation is 50-60%. The initial composite billet is good in interfacial bonding and can be applied to preparation of the initial billet for high-temperature coating superconductive enhanced ductile basebands.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com