A preparation method of powder metallurgy friction material

A friction material and powder metallurgy technology, which is applied in the field of powder metallurgy friction material preparation, can solve the problems of poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

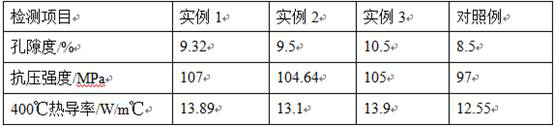

Examples

example 1

[0034] Take copper powder, iron powder, modified resin, friction filler, and lubricating component, mix copper powder, iron powder, modified resin, friction filler, and lubricating component, and stir at a high speed of 1000r / min for 6h, that is A precursor is obtained; the precursor is subjected to compression molding to obtain a green body, and the green body is subjected to heat preservation treatment and cooled to room temperature to obtain a powder metallurgy friction material. The modified resin preparation steps are: get epoxy resin, butadiene rubber, benzoyl peroxide, cerium oxide, lanthanum stearate, calcium carbonate whiskers, UVP-327; Benzoyl, cerium oxide, lanthanum stearate, calcium carbonate whiskers and UVP-327 were mixed and placed in an open mill, and kneaded for 2 hours at a stirring speed of 400r / min to obtain a blend, and the blend After vulcanization treatment, the modified resin can be obtained. The preparation steps of the friction filler are as follows...

example 2

[0036] Take copper powder, iron powder, modified resin, friction filler, and lubricating component, mix copper powder, iron powder, modified resin, friction filler, and lubricating component, and stir at a high speed of 1500r / min for 8h, that is A precursor is obtained; the precursor is subjected to compression molding to obtain a green body, and the green body is subjected to heat preservation treatment and cooled to room temperature to obtain a powder metallurgy friction material. The modified resin preparation steps are: get epoxy resin, butadiene rubber, benzoyl peroxide, cerium oxide, lanthanum stearate, calcium carbonate whiskers, UVP-327; Benzoyl, cerium oxide, lanthanum stearate, calcium carbonate whiskers and UVP-327 were mixed and placed in an open mixer, and kneaded for 2 hours at a stirring speed of 450r / min to obtain a blend, and the blend After vulcanization treatment, the modified resin can be obtained. The preparation steps of the friction filler are as follow...

example 3

[0038] Take copper powder, iron powder, modified resin, friction filler, and lubricating component, mix copper powder, iron powder, modified resin, friction filler, and lubricating component, and stir at a high speed of 2000r / min for 10h, that is A precursor is obtained; the precursor is subjected to compression molding to obtain a green body, and the green body is subjected to heat preservation treatment and cooled to room temperature to obtain a powder metallurgy friction material. The modified resin preparation steps are: get epoxy resin, butadiene rubber, benzoyl peroxide, cerium oxide, lanthanum stearate, calcium carbonate whiskers, UVP-327; Benzoyl, cerium oxide, lanthanum stearate, calcium carbonate whiskers and UVP-327 were mixed and placed in an open mixer, and kneaded for 3 hours at a stirring speed of 500r / min to obtain a blend, and the blend After vulcanization treatment, the modified resin can be obtained. The preparation steps of the friction filler are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com