TB17 titanium alloy isothermal forging method

A technology of isothermal forging and titanium alloy, applied in the field of warm forging, it can solve the problem that strength and toughness cannot be effectively matched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment is for forging a nearly β-type TB17 titanium alloy forging with a phase transition point of 843°C.

[0020] The specific implementation process is as follows:

[0021] (1) Put the TB17 titanium alloy blank into the effective working area of the resistance furnace that has reached the set heating temperature of 790°C for heating and heat preservation. The heat preservation time is 80 minutes, and then heat up to 873°C with the furnace, and then heat preservation for 40 minutes;

[0022] (2) Step (1) After the heat preservation is completed, put the TB17 titanium alloy blank into the mold for isothermal forging, the deformation of the blank is controlled at 18%, the deformation rate of the blank is controlled at 0.35mm / s, and the temperature of the isothermal forging mold is set at 876 ℃;

[0023] (3) Step (2) After the forging is completed, the billet is taken out and cooled to room temperature at a cooling rate of 5.5°C / s.

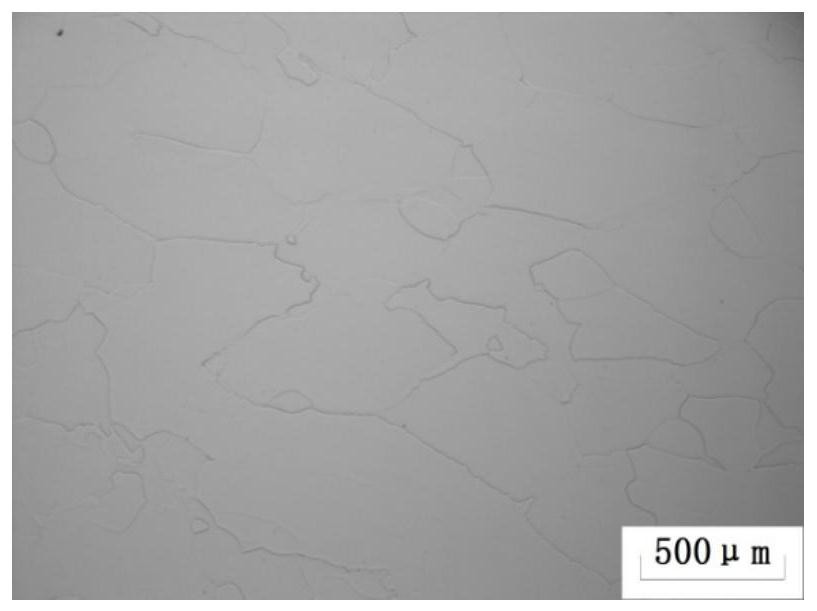

[0024] After carrying out s...

Embodiment 2

[0026] This embodiment is for forging a nearly β-type TB17 titanium alloy forging with a phase transition point of 843°C.

[0027] The specific implementation process is as follows:

[0028] (1) Put the TB17 titanium alloy billet into the effective working area of the resistance furnace that has reached the set heating temperature of 800°C for heating and heat preservation. The heat preservation time is 72 minutes, and then the temperature is raised to 870°C with the furnace, and then heat preservation is carried out for 36 minutes;

[0029] (2) Step (1) After the heat preservation is completed, put the TB17 titanium alloy blank into the mold for isothermal forging, the deformation of the blank is controlled at 23%, the deformation rate of the blank is controlled at 0.65mm / s, and the temperature of the isothermal forging mold is set at 870 ℃;

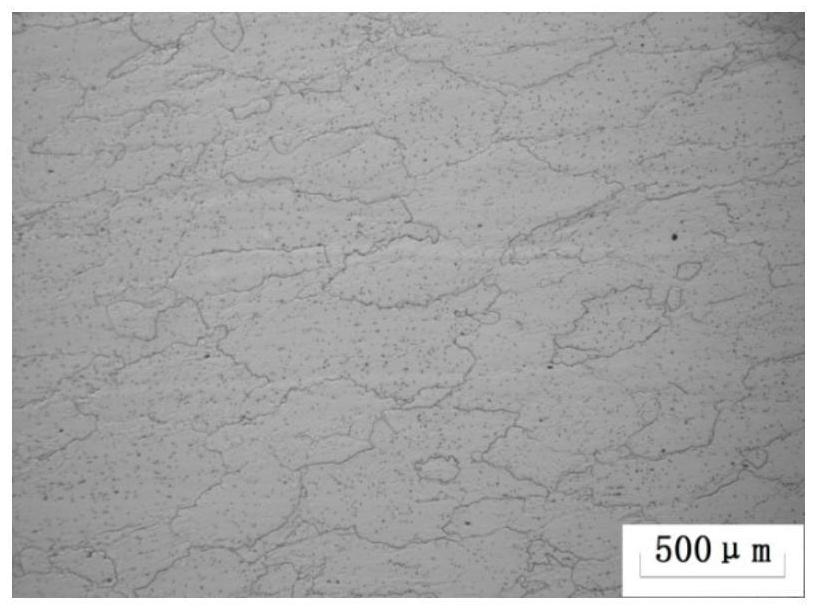

[0030] (3) Step (2) After the forging is completed, the billet is taken out and cooled to room temperature at a cooling rate of 2.5...

Embodiment 3

[0033] This embodiment is for forging a nearly β-type TB17 titanium alloy forging with a phase transition point of 843°C.

[0034] The specific implementation process is as follows:

[0035] (1) Put the TB17 titanium alloy billet into the effective working area of the resistance furnace that has reached the set heating temperature of 813°C for heating and heat preservation. The heat preservation time is 64 minutes, and then the temperature is raised to 858°C with the furnace, and then heat preservation is carried out for 32 minutes;

[0036] (2) Step (1) After the heat preservation is completed, put the TB17 titanium alloy blank into the mold for isothermal forging, the deformation of the blank is controlled at 15%, the deformation rate of the blank is controlled at 0.4mm / s, and the temperature of the isothermal forging mold is set at 860 ℃;

[0037] (3) Step (2) After the forging is completed, the billet is taken out and cooled to room temperature at a cooling rate of 1.1°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com