Preparation method of ultrahigh-temperature anti-scouring thermal barrier coating

A thermal barrier coating, anti-scour technology, applied in the coating, superimposed layer plating, metal material coating process and other directions, can solve the problem that thermal barrier coating is difficult to have both ultra-high temperature resistance and anti-scour performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, for superalloy substrate 1 (see Figure 1-Figure 2 ) (that is, Hastelloy superalloy) for grinding, ultrasonic cleaning, and sandblasting pretreatment. The sandblasting process uses alumina with a particle size of 20-100 mesh to obtain a relatively uniform roughness.

[0032] In step 2, a metal bonding layer 2 is deposited on the superalloy substrate 1 by supersonic flame spraying (see Figure 1-Figure 2 ) (ie MCrAlY coating), wherein M is one or both of Ni and Co, and the thickness is about 200 μm.

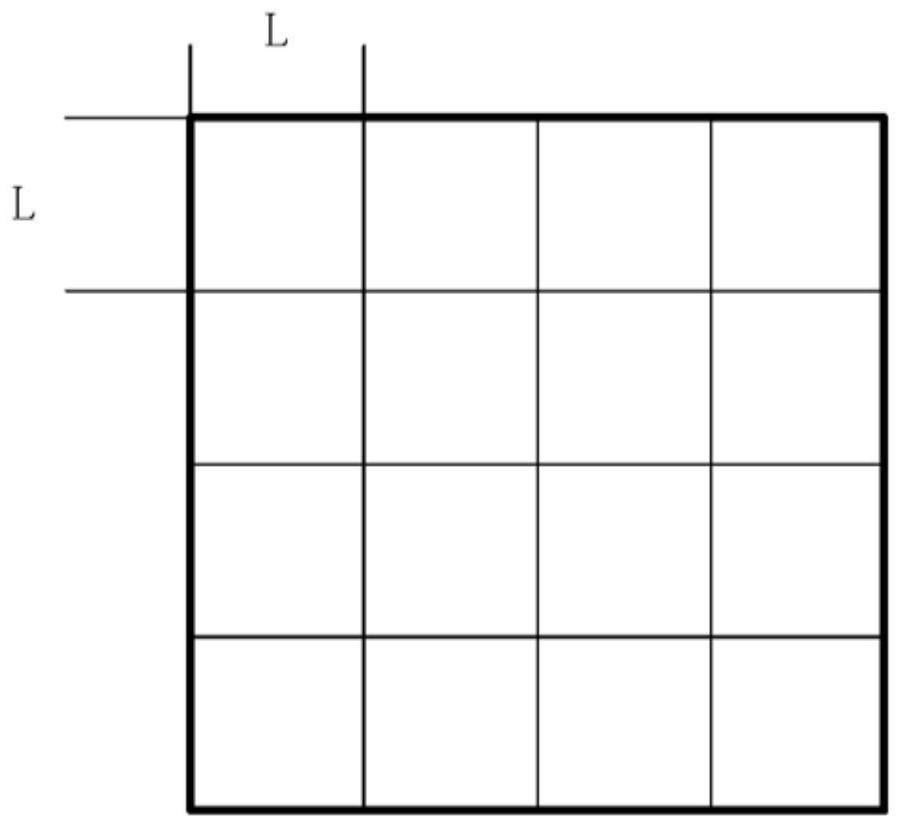

[0033] Step 3, using the laser engraving technology to introduce the grid bonding layer 3 with the same composition as the metal bonding layer 2 on the surface of the metal bonding layer 2 (see Figure 1-Figure 2 ) (ie MCrAlY mesh structure layer), the rated power of the fiber laser used is 1kW, the diameter of the laser beam spot is 0.9mm, the laser power is 120W, the scanning speed is 5mm / s, and the grid (ie, the grid bonding layer) The height h is 400 μm, and t...

Embodiment 2

[0038] Step 1, grinding, ultrasonic cleaning, and sandblasting pretreatment on the superalloy substrate 1 (ie, Ni-based single crystal superalloy).

[0039] In step 2, a metal bonding layer 2 (ie, a YHf micro-doped AlCrCoFeNi high-entropy bonding layer) is deposited on the superalloy substrate 1 by plasma spraying, with a thickness of about 200 μm, the atomic content of AlCrCoFeNi is 20%, and the doped YHf The atomic content is 0.2%.

[0040] Step 3, use laser engraving technology to introduce grid bonding layer 3 with the same composition as metal bonding layer 2 (ie, YHf micro-doped AlCrCoFeNi network structure layer) on the surface of metal bonding layer 2. The fiber laser used is rated for The power is 0.5 kW, the diameter of the laser beam spot is 0.3 mm, the laser power is 60 W, the scanning speed is 15 mm / s, the grid height h is 100 μm, and the grid width L is 900 μm.

[0041] In step 4, a layer of 8YSZ ceramic layer 4 with a thickness of about 500 μm is deposited on t...

Embodiment 3

[0045] Step 1, grinding, ultrasonic cleaning, and sandblasting pretreatment on the superalloy base 1 (ie, DZ125 superalloy).

[0046] Step 2, deposit a metal bonding layer 2 (ie, a YHf micro-doped AlCrCoFeNi high-entropy bonding layer) on the superalloy substrate 1 by plasma spraying, the thickness is about 100 μm, the Al atomic content is 10%, Cr, Co, Fe , Ni atomic content is 22.5%, and the doped YHf atomic content is 0.5%.

[0047] Step 3, use laser engraving technology to introduce grid bonding layer 3 with the same composition as metal bonding layer 2 (ie, YHf micro-doped AlCrCoFeNi network structure layer) on the surface of metal bonding layer 2. The fiber laser used is rated for The power is 0.8kW, the laser beam spot diameter is 0.6mm, the laser power is 90W, the scanning speed is 10mm / s, the grid height h is 150μm, and the grid width L is 600μm.

[0048] In step 4, a layer of 8YSZ ceramic layer 4 with a thickness of about 500 μm is deposited on the surface of the gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com