SiHfOC ceramic material and preparation method thereof

A ceramic material and gel technology, applied in the field of SiHfOC ceramic materials and their preparation, can solve the problems of performance degradation, limit the high temperature resistance performance and high temperature application of SiOC ceramics, etc. The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

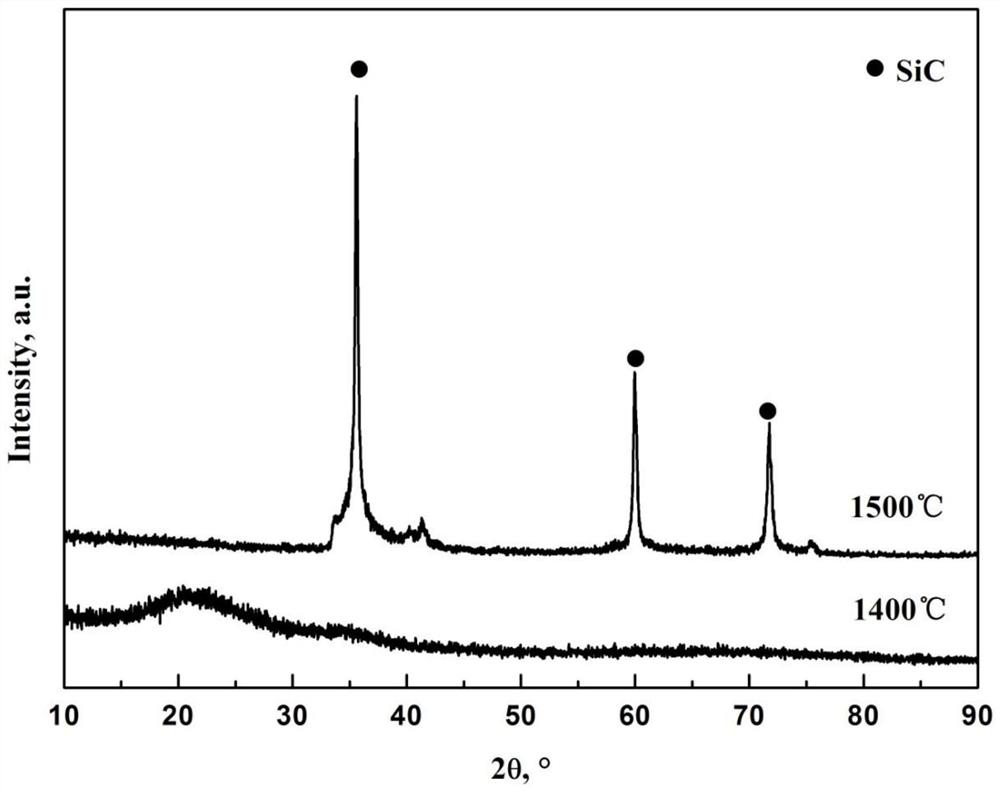

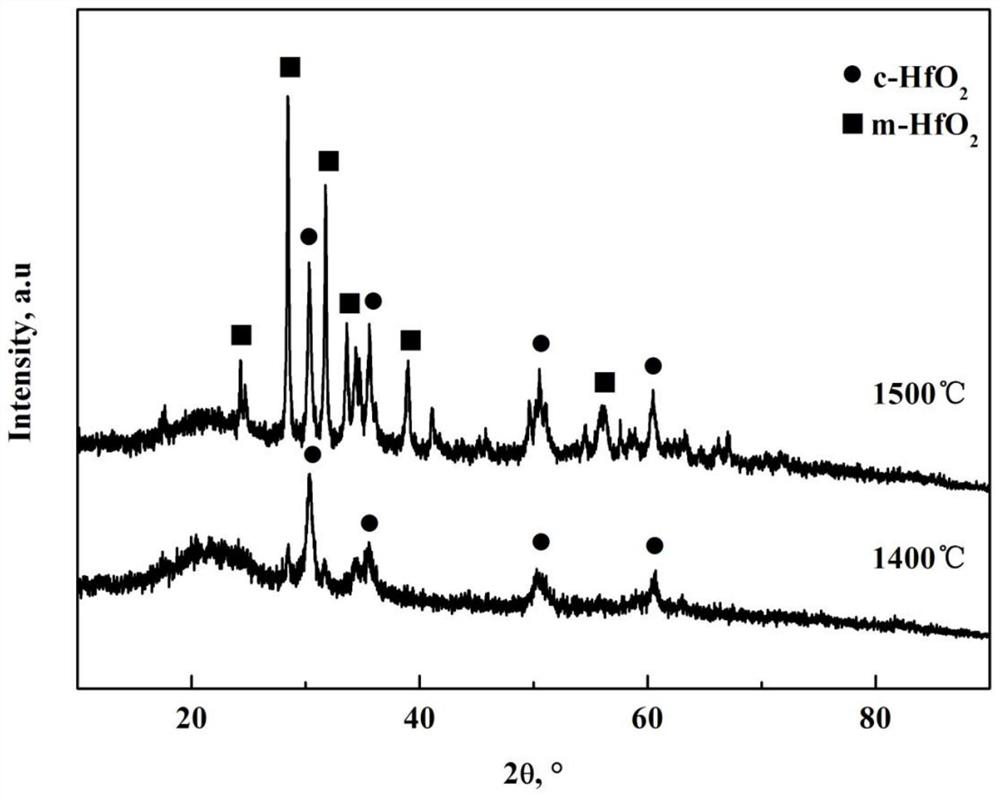

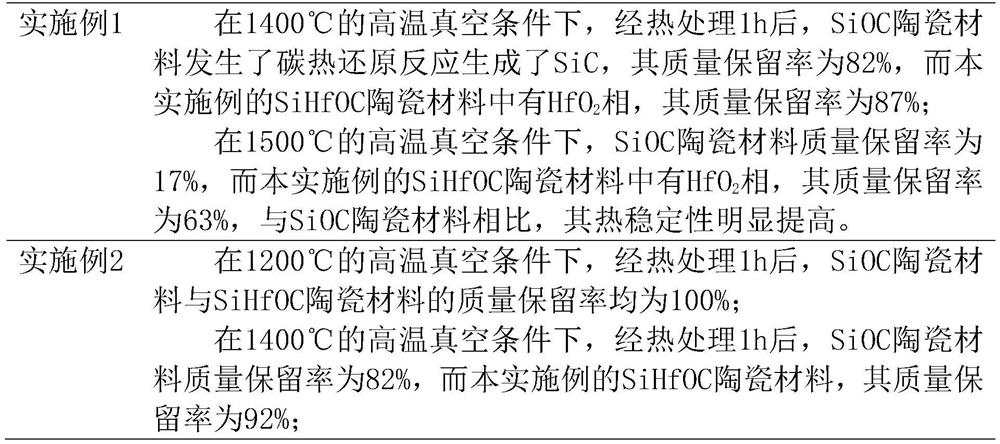

Embodiment 1

[0024] A preparation method of SiHfOC ceramic material, comprising the following steps:

[0025] 1) Preparation of hafnium sol:

[0026] At room temperature, take 6g HfOCl 2 ·8H 2 O was dissolved in 20g ethanol, after adding 6g acetylacetone therein, magnetically stirred for 20min to obtain hafnium sol;

[0027] Take 30g of MK silicone resin and dissolve it in 30g of ethanol to prepare a 50% MK silicone resin ethanol solution;

[0028] 2) Preparation of gel: Mix the prepared MK silicone resin ethanol solution and hafnium sol, dry at room temperature and let stand for 9 hours to form a gel;

[0029] 3) Preparing the precursor: heating the obtained gel to 150° C. in a drying oven, and drying for 20 hours to obtain a hafnium-modified polysiloxane precursor;

[0030] 4) Preparation of SiHfOC ceramic material by precursor conversion method: the obtained hafnium-modified polysiloxane precursor was placed in an inert gas atmosphere at 1000°C for cracking, and the cracking time wa...

Embodiment 2

[0034] A preparation method of SiHfOC ceramic material, comprising the following steps:

[0035] 1) Preparation of hafnium sol:

[0036] At room temperature, 4g HfOCl 2 ·8H 2 O was dissolved in 15g ethanol, after adding 1g acetylacetone therein, magnetically stirred for 10min to obtain hafnium sol;

[0037] Dissolve 20g of silicone resin in 30g of absolute ethanol to prepare a 40% MK silicone resin ethanol solution;

[0038] 2) Gel preparation: the prepared MK silicone resin ethanol solution and hafnium sol were mixed, dried at room temperature and allowed to stand for 17 hours to form a gel;

[0039] 3) Preparing the precursor: heating the obtained gel to 220° C. in the air, and drying for 4 hours to obtain a hafnium-modified polysiloxane precursor;

[0040] 4) Preparation of SiHfOC ceramic material by precursor conversion method: the obtained hafnium-modified polysiloxane precursor was placed in a high-temperature inert gas atmosphere at 1200°C for pyrolysis for 30 minut...

Embodiment 3

[0043] A preparation method of SiHfOC ceramic material, comprising the following steps:

[0044] 1) Preparation of hafnium sol:

[0045] At room temperature, 8g HfOCl 2 ·8H 2 O was dissolved in 20g ethanol, after adding 8g acetylacetone therein, magnetically stirred for 30min to obtain hafnium sol;

[0046] Dissolve 40g of silicone resin in 20g of absolute ethanol to prepare a 60% MK silicone resin ethanol solution;

[0047] 2) Preparation of gel: The prepared MK silicone resin ethanol solution and hafnium sol were mixed, dried at room temperature and left to stand for 12 hours to form a gel;

[0048] 3) Preparing the precursor: heating the obtained gel to 250° C. in air, and drying for 10 hours to obtain a hafnium-modified polysiloxane precursor;

[0049] 4) Preparation of SiHfOC ceramic material by precursor conversion method: the obtained hafnium-modified polysiloxane precursor was placed in a high-temperature inert gas atmosphere at 1100 ° C for 120 minutes to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com