DVC thermal barrier coating and preparation method and application thereof

A thermal barrier coating and bottom layer technology, applied in coatings, metal material coating processes, sustainable transportation, etc., can solve the problems of lateral associated cracks in APSDVCTBCs, reduce long-term high-temperature fatigue oxidation, and improve high-temperature strain tolerance. , The effect of high coating porosity controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

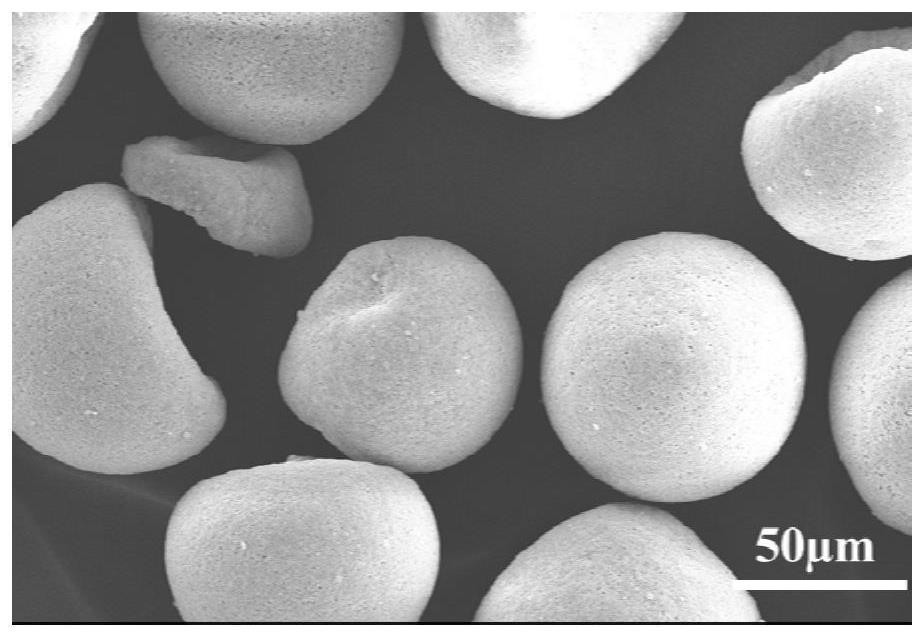

[0032] Using GH3128 / 3230 superalloy as the matrix, it is processed by wire cutting and polishing. The surface of the disc was sandblasted with 80-mesh white corundum, then fully ultrasonically cleaned with acetone, and dried. A 100 μm thick NiCrAlY or NiCoCrAlY metal bonding layer was prepared by low-pressure plasma spraying on the surface of the treated circular test piece. Then, a YSZ thermal barrier coating with a thickness of 250 μm was prepared on the surface of the adhesive layer by atmospheric plasma spraying. figure 2 shown), the total porosity of the coating is 20%, and the bond strength with the adhesive layer is 35 MPa. The spraying equipment is Oerlikon Metco Triplexpro210 high enthalpy plasma spray gun, the preheating temperature of the superalloy substrate is 380℃, the spraying distance is 75mm, the moving speed of the spray gun is 500mm / s, the working power is 50kW, and the working gas is: Ar45slpm, H 2 -5slpm, YSZ powder used (such as figure 1 shown) is sp...

Embodiment 2

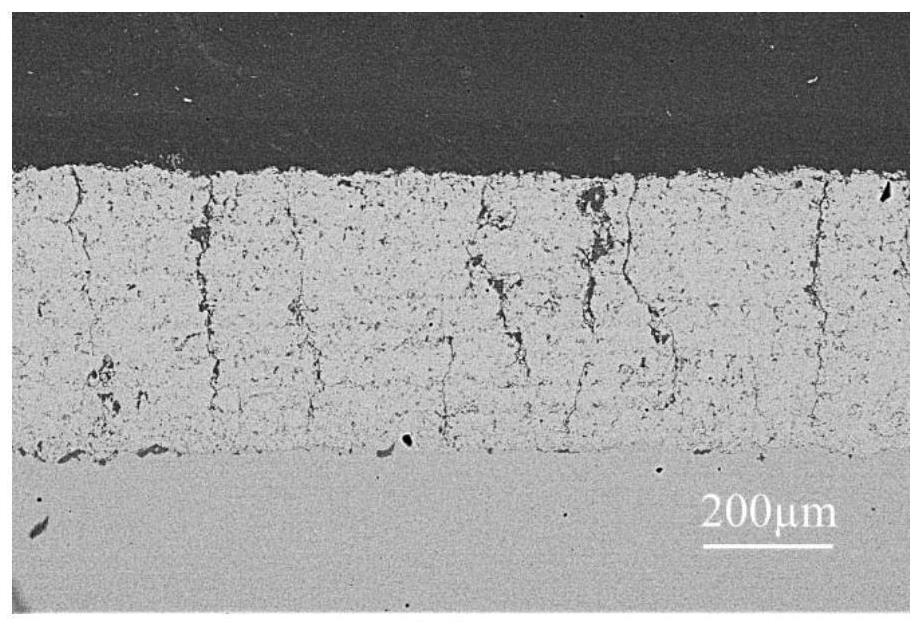

[0036] Using directionally solidified nickel-based superalloy DZ125 as the matrix, it is processed by wire cutting and polishing. The surface of the disc was sandblasted with 120-mesh white corundum, then fully ultrasonically cleaned with acetone, and dried. A NiCoCrAlYHf metal bonding layer with a thickness of 150 μm was prepared by supersonic flame spraying on the surface of the treated circular test piece. Then, a low-porosity and dense YSZ bottom layer with a thickness of 60-150 μm was prepared on the surface of the adhesive layer by atmospheric plasma spraying with a porosity of 3%, and a DVC structure YSZ top layer was prepared on the surface of the layer with a thickness of ~300-1500 μm, vertical Crack density is ~7cracks / mm, see Image 6 , the total porosity of the coating is 10%, and the interface bonding strength with the adhesive layer is 60MPa. The spraying equipment is Oerlikon Metco Triplexpro210 high enthalpy plasma spray gun, in which: (1) the 60-150μm botto...

Embodiment 3

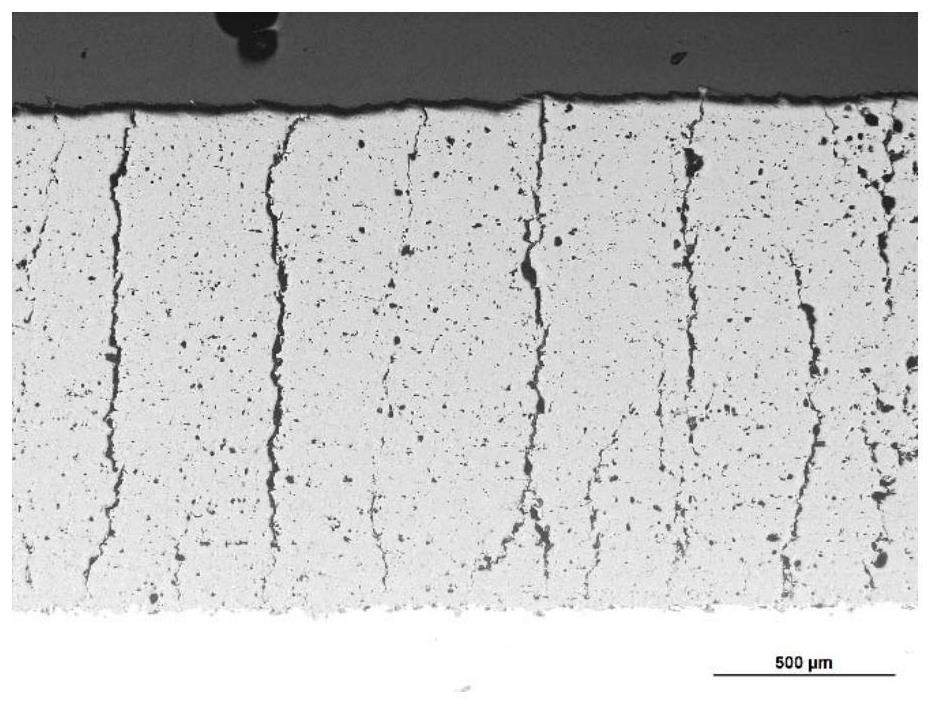

[0039] Using the third generation nickel-based single crystal superalloy DD10 as the base, it is processed by wire cutting and polishing. The surface of the disc was sandblasted with 240-mesh white corundum, and then fully ultrasonically cleaned with acetone and dried. A 200 μm thick NiCoCrAlYTa metal bonding layer was prepared by low-pressure plasma spraying on the surface of the treated circular test piece. Then, a DVC structure YSZ bottom layer with a thickness of 60-500 μm was prepared on the surface of the bonding layer by atmospheric plasma spraying, the vertical crack density was ~1cracks / mm, the total porosity was ~5%, and the associated transverse crack length / vertical crack length was about ~3%. Then, 250-1500μm thick DVC structure YSZ+5.8wt.%Gd was prepared on the surface of this layer 2 O 3 +6.2wt.%Yb 2 O 3 layer or Gd 2 Zr 2 O 7 +20wt.%Yb 2 O 3 layer, the vertical crack density is ~5cracks / mm, the associated transverse crack length / vertical crack length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com