Carbon composite material modified by chalcogen compound and transition metal as well as preparation method and application of carbon composite material

A technology of chalcogenide and carbon composite materials, applied in chemical instruments and methods, chemical/physical processes, catalyst activation/preparation, etc., can solve problems such as hindering the development of fuel cells, expensive precious metals, and shortening of catalytic life of materials, etc. Ease of mass production, high current density, and controllable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

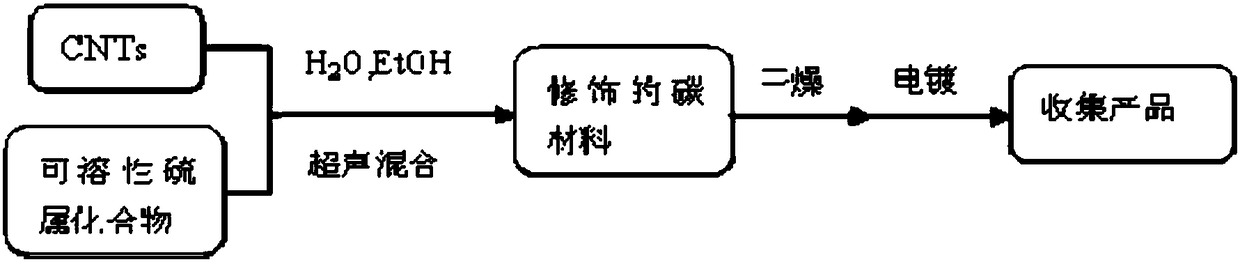

Method used

Image

Examples

Embodiment 1

[0034] Preparation of carbon composites modified with chalcogenides and transition metal tungsten (W x S y / CNTs)

[0035] (1) Electrode pretreatment: Take a glassy carbon electrode (Shanghai Chenhua, CHI104, diameter 3mm), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 30s in sequence.

[0036] (2) Preparation of glassy carbon electrodes modified with carbon nanotubes and sodium thiosulfate: add the mixture of arrayed carbon nanotubes (2 mg) and sodium thiosulfate (2 mg) to a mixture of ethanol and water at a volume ratio of 4:1 ( 1mL), form a suspension after ultrasonication for 2 hours, use a pipette to pipette a certain volume of the solution and drop it onto the surface of the electrode treated in step (1). Between every two times, the material must be dried naturally before adding dropwise. After the material is dry and a dense black film is formed, use a pipette gun to pipette a certain volume of naphthol ethanol solution (mass fraction is...

Embodiment 2

[0042] Carbon composites modified with chalcogenides and transition metal molybdenum (Mo x S y / CNTs)

[0043] (1) Electrode pretreatment: Take a glassy carbon electrode (Shanghai Chenhua, CHI104, diameter 3mm), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 30s in sequence.

[0044] (2) Preparation of glassy carbon electrodes modified with carbon nanotubes and sodium thiosulfate: add the mixture of arrayed carbon nanotubes (2 mg) and sodium thiosulfate (2 mg) to a mixture of ethanol and water at a volume ratio of 4:1 ( 1mL), form a suspension after ultrasonication for 2 hours, use a pipette to pipette a certain volume of the solution and drop it onto the surface of the electrode treated in step (1). Between every two times, the material must be dried naturally before adding dropwise. After the material is dry and a dense black film is formed, use a pipette gun to pipette a certain volume of naphthol ethanol solution (mass fraction is 0.2 %) was...

Embodiment 3

[0050] Carbon composites modified with chalcogenides and transition metal cobalt (Co x S y / CNTs)

[0051] (1) Electrode pretreatment: Take a glassy carbon electrode (Shanghai Chenhua, CHI104, diameter 3mm), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 30s in sequence.

[0052] (2) Preparation of glassy carbon electrodes modified with carbon nanotubes and sodium thiosulfate: add the mixture of arrayed carbon nanotubes (2 mg) and sodium thiosulfate (2 mg) to a mixture of ethanol and water at a volume ratio of 4:1 ( 1mL), form a suspension after ultrasonication for 2 hours, use a pipette to pipette a certain volume of the solution and drop it onto the surface of the electrode treated in step (1). Between every two times, the material must be dried naturally before adding dropwise. After the material is dry and a dense black film is formed, use a pipette gun to pipette a certain volume of naphthol ethanol solution (mass fraction is 0.2 %) was add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com