Copper-base alloy/iron-base martensite alloy composite powder and method of preparing the same

A copper-based alloy and composite powder technology, which is applied in chemical instruments and methods, metal layered products, layered products, etc., can solve the problems of raw material loss, impossibility of obtaining iron-based martensitic phase, complex preparation process, etc. , to achieve a good effect of interface integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

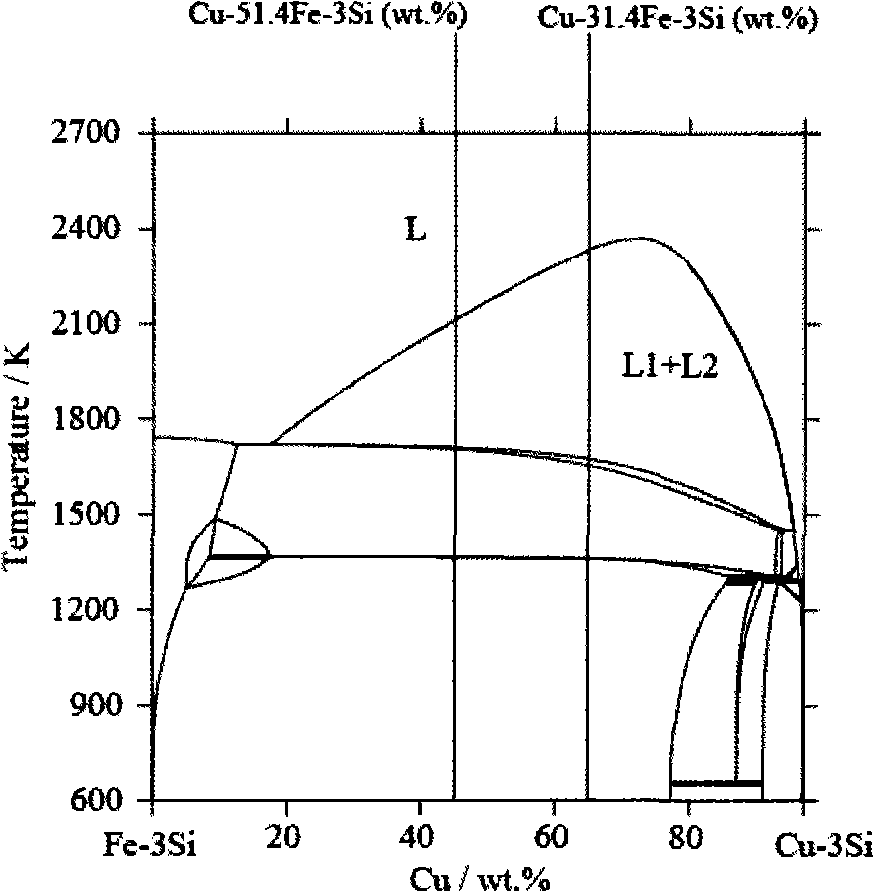

[0018] Embodiment 1: 456g pure copper (electrolytic copper, purity is 99.99wt.%), 514g pure iron (purity is 99.9wt.%), 30g pure silicon (purity is 99.9wt.%) is placed in alumina crucible , and then put the alumina crucible into the vacuum induction furnace (power supply voltage: 110V / 220V AC; power frequency: 50-60Hz; working frequency: 150-250KHz) built in the atomization equipment, close the furnace door and evacuate to Vacuum degree in vacuum induction furnace to 1×10 -3 Pa, increase the current until the above three pure metals are completely melted into liquid, and the composition of the obtained alloy liquid is Cu-51.4Fe-3Si (wt.%). Pour the molten alloy liquid (about 1kg) into the liquid receiving hopper, and blow it with nitrogen at the moment the liquid flows into the atomization chamber, and the copper-based alloy / iron-based martensite composite powder can be obtained at the bottom of the atomization chamber body. Close the nitrogen gas flow valve and reduce the cu...

Embodiment 2

[0019] Embodiment 2: 656g pure copper (electrolytic copper, purity is 99.99wt.%), 314g pure iron (purity is 99.9wt.%), 30g pure silicon (purity is 99.9wt.%) is placed in alumina crucible , and then put the alumina crucible into the vacuum induction furnace (power supply voltage: 110V / 220V AC; power frequency: 50-60Hz; working frequency: 150-250KHZ) built in the atomization equipment, close the furnace door and evacuate to Vacuum degree in vacuum induction furnace to 1×10 -3 Pa, increase the current until the above three pure metals are completely melted into liquid, and the composition of the obtained alloy liquid is Cu-31.4Fe-3Si (wt.%). Pour the molten alloy liquid (about 1kg) into the liquid receiving hopper, and blow it with argon when the liquid flows into the atomization chamber, and the iron-based martensitic alloy / copper-based alloy can be obtained at the bottom of the atomization chamber Composite powder. Close the argon gas flow valve and reduce the current value t...

Embodiment 3

[0020] Embodiment 3: 653g pure copper (electrolytic copper, purity is 99.99wt.%), 314g pure iron (purity is 99.9wt.%), 30g pure silicon (Si, purity is 99.9wt.%), 3g coke is placed in In an alumina crucible, the steps described in Example 2 were followed to obtain an iron-based martensitic alloy / copper-based alloy composite powder. Take 50g of the composite powder and seal it in the resin, after #80, #150, #400, #800, #1500, #2000 sandpaper water grinding treatment, and then polishing with polishing paste (diamond particles, about 10μm in diameter) , in the HV-1000 Vickers hardness tester (power supply: AC220V 50Hz; diamond regular pyramidal indenter; test force: 0.245N (25gf)), the relationship between the obtained hardness and the distance from the point to the interface is as follows Figure 6 shown. On the copper-rich phase (copper-based alloy), the average hardness value is close to 200HV; on the iron-based martensitic alloy phase, the hardness value is between 500 and 600H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com