High-strength NiW alloy composite baseband with cube texture and preparation method thereof

A composite baseband and cubic texture technology, which is applied in chemical instruments and methods, metal layered products, layered products, etc., can solve the problems of many pores on the surface of the composite baseband, complex operation process, and expensive sintering equipment, so as to avoid Cracking between layers, easy cubic texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

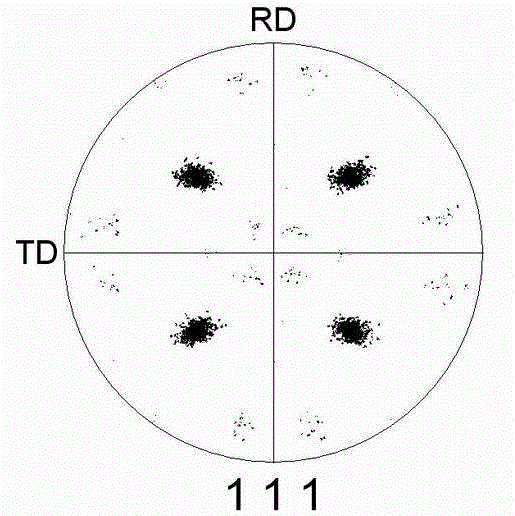

Embodiment 1

[0017] The NiW alloy rod with a W atomic percentage of 6% obtained by vacuum induction melting is machined into a through hole to obtain a NiW alloy tube with an outer diameter of 20mm, an inner diameter of 10mm, and a length of 24mm, which is used as the outer layer of the composite ingot , the NiW alloy solid rod with a W atomic percentage of 9% prepared by vacuum induction melting was used as the core layer of the composite billet, with a diameter of 10mm and a length of 24mm, and the core NiW solid alloy rod was inserted into the outer NiW In the alloy tube; the mechanically combined composite billet is subjected to high-temperature hot-rolling treatment, the hot-rolling temperature is 1300 ° C for 10 hours, the deformation of each pass of hot rolling is 15% to 25%, and the total deformation is 70% to 80%. The initial composite ingot before cold rolling with large deformation is obtained; the composite ingot obtained by hot rolling is cold-rolled, the deformation of each pa...

Embodiment 2

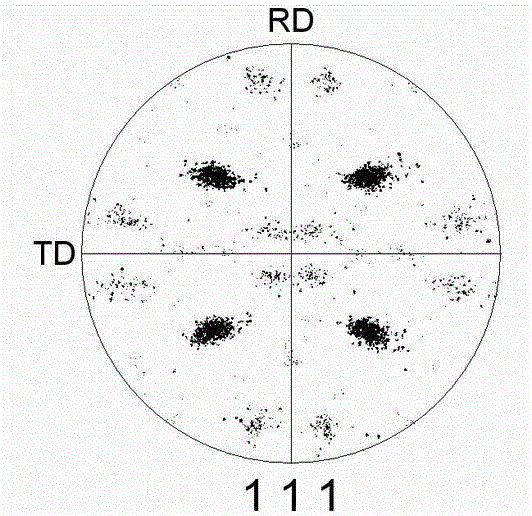

[0020] A NiW alloy rod with a W atomic percentage of 6.5% obtained by vacuum induction melting is machined into a through hole to obtain a NiW alloy tube with an outer diameter of 20mm, an inner diameter of 10mm, and a length of 24mm, which is used as the outer layer of the composite ingot , the NiW alloy solid rod with a W atomic percentage of 9% prepared by vacuum induction melting is used as the core layer of the composite ingot, with a diameter of 10mm and a length of 24mm, and the core NiW alloy solid rod is inserted into the outer NiW In the alloy tube; the mechanically combined composite ingot is subjected to hot rolling treatment, the hot rolling temperature is 1300 ° C for 10 hours, the deformation of each pass of hot rolling is 15% to 25%, and the total deformation is 70% to 80%. The initial composite ingot before cold rolling with large deformation; the composite ingot obtained by hot rolling is cold-rolled, the deformation of each pass is 1%~3%, and the total deform...

Embodiment 3

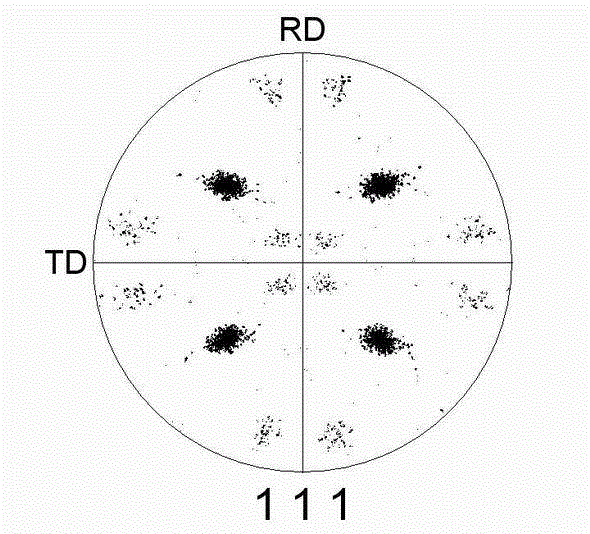

[0023] A NiW alloy rod with a W atomic percentage of 7% obtained by vacuum induction melting is machined into a through hole to obtain a NiW alloy tube with an outer diameter of 20mm, an inner diameter of 10mm, and a length of 24mm, which is used as the outer layer of the composite ingot , the NiW alloy solid rod with a W atomic percentage of 9% prepared by vacuum induction melting is used as the core layer of the composite ingot, with a diameter of 10mm and a length of 24mm, and the core NiW alloy solid rod is inserted into the outer NiW In the alloy tube; the mechanically combined composite ingot is subjected to hot rolling treatment, the hot rolling temperature is 1300 ° C for 10 hours, the deformation of each pass of hot rolling is 15% to 25%, and the total deformation is 70% to 80%. The initial composite ingot before cold rolling with large deformation; the composite ingot obtained by hot rolling is cold-rolled, the deformation of each pass is 1%~3%, and the total deformat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com