Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Good cycle reversibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recycling method for graphite anode material from waste lithium-ion battery

InactiveCN105552468AReduce recycling costsHigh recovery rateWaste accumulators reclaimingBattery recyclingOxalateElectricity

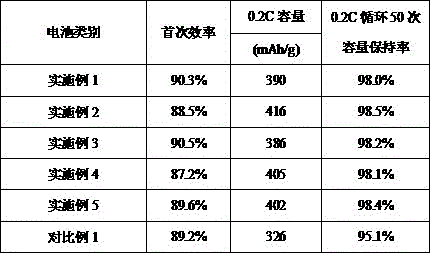

The invention discloses a recycling method for a graphite anode material from a waste lithium-ion battery, and belongs to the technical field of recovering of materials from the waste lithium-ion battery. According to the main points of the technical scheme, the method comprises the following steps: carrying out soaking pretreatment on the graphite material recovered from the waste lithium-ion battery; carrying out ball-mill mixing on pre-calcined and separated graphite powder and a ferrous oxalate or zinc oxalate or ferrous oxalate and zinc oxalate mixture evenly; and finally preparing the battery-grade graphite anode material through high-temperature treatment. The graphite anode material prepared by the method has excellent electrochemical activity and cyclic reversibility; the discharge capacity at 0.2C reaches over 400mAh / g; and the capacity retention rate after 50 cycles is greater than 98.0%. The recycling method can efficiently recover the graphite anode material from the waste lithium-ion battery, further improves the electrical property and achieves recycling of the graphite anode material.

Owner:河南环宇赛尔新能源科技有限公司

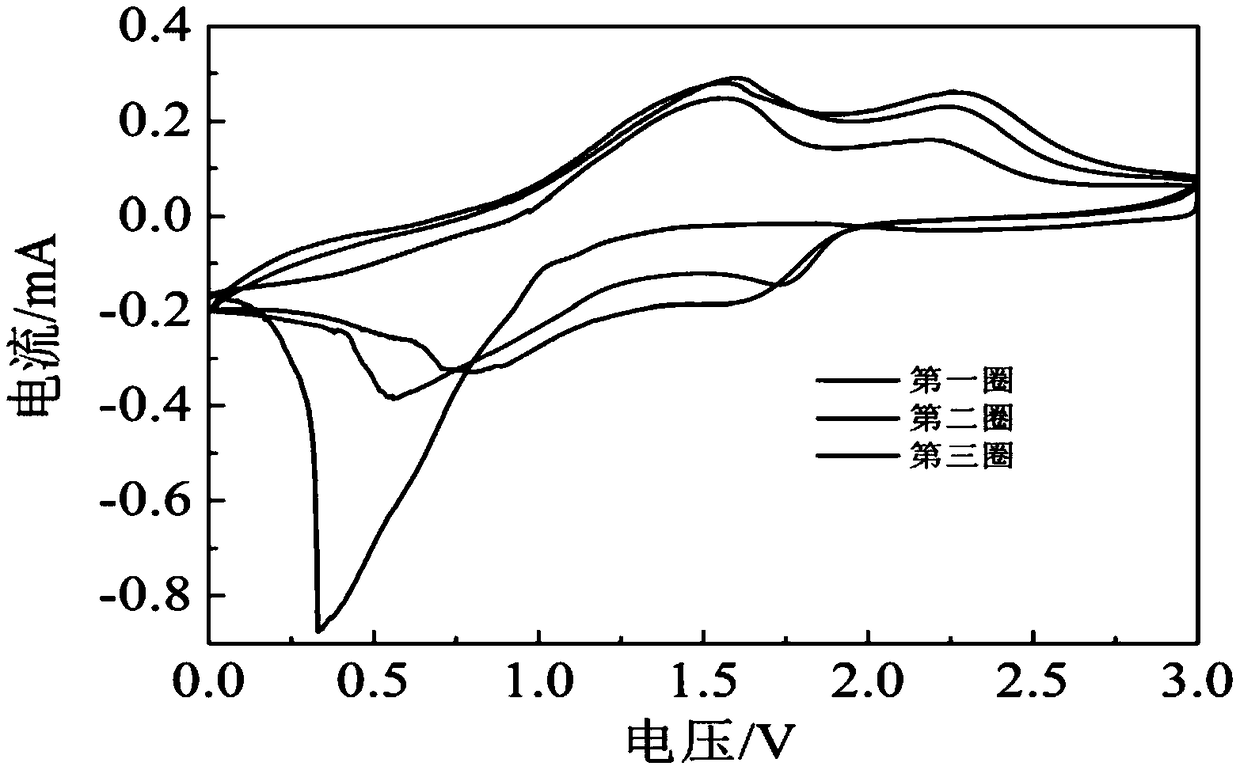

Vanadium disulfide/graphene composite material and preparation method therefor

InactiveCN105355865AImprove conductivityHigh chemical activityMaterial nanotechnologyCell electrodesVanadium disulfideNew energy

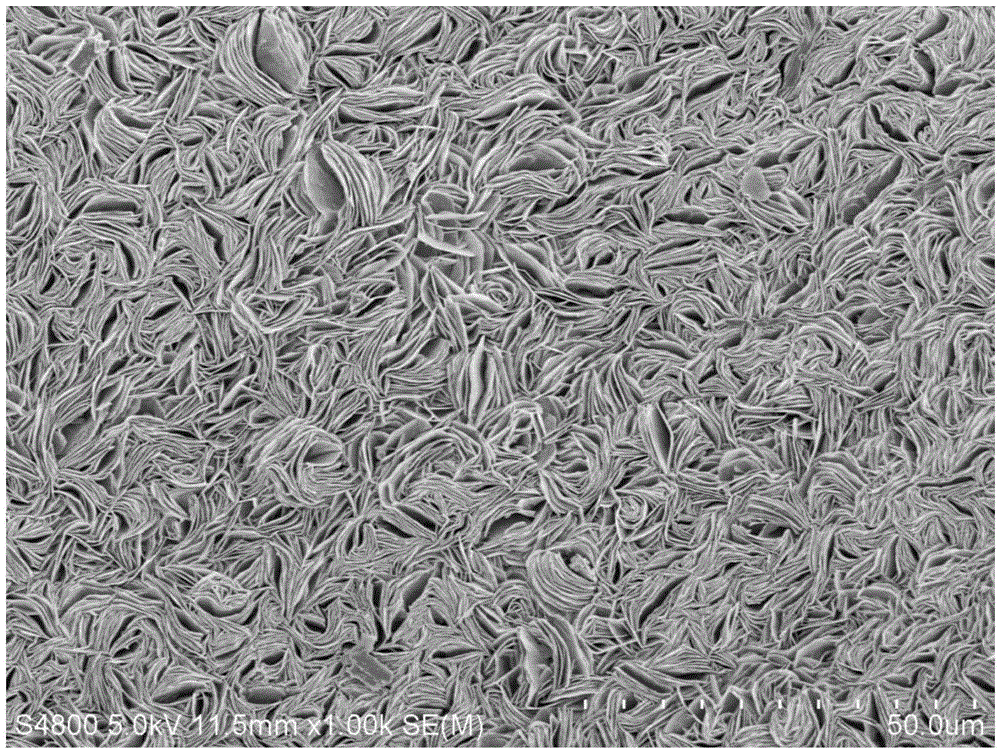

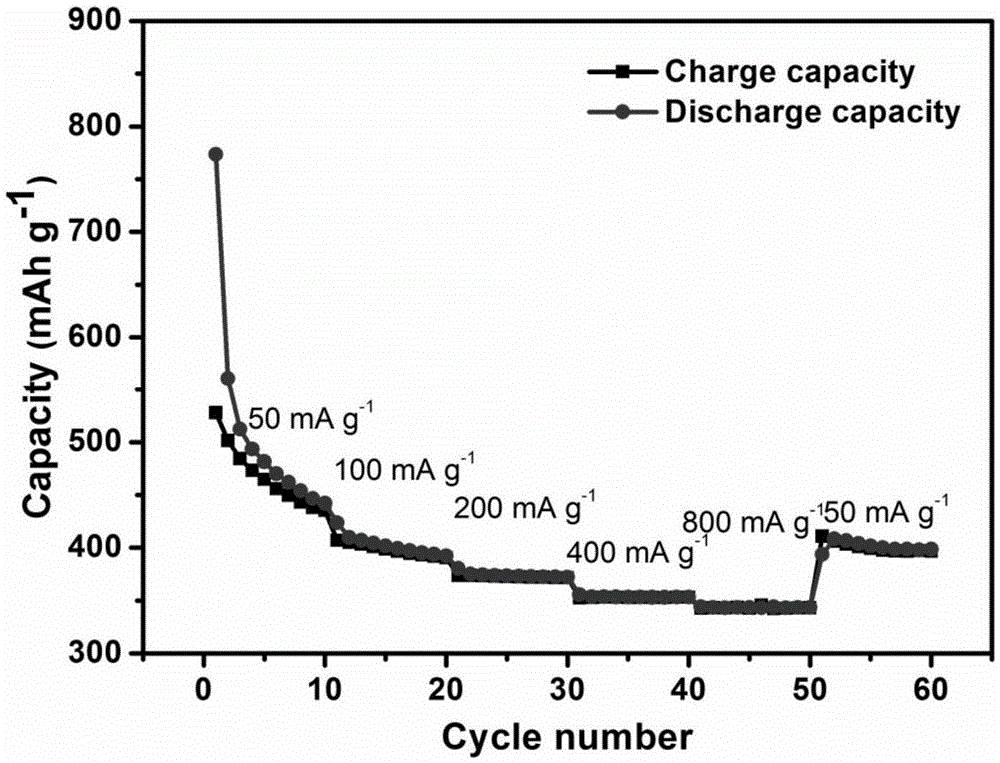

The invention relates to the technical field of new energy materials, and in particular to a vanadium disulfide / graphene composite material and a preparation method therefor. The preparation method comprises the following steps: dissolving a vanadium source into water and uniformly mixing with an excessive amount of sulfur source to obtain a mixed solution A, uniformly mixing graphene oxide with the mixed solution A, performing reaction at the temperature of 150-200 DEG C, and after the reaction to obtain the vanadium disulfide / graphene composite material. The preparation method is simple in process, mature in technology, available in equipment and quite good for the commercial promotion; according to the prepared vanadium disulfide / graphene composite material, the shortcomings of the vanadium disulfide and graphene are overcome by each other; the chemical activity of the material is improved, and the vanadium disulfide / graphene composite material can be used as the chemical active material to be applied to lithium ion battery negative electrodes; and the obtained lithium ion battery is quite good in circulation reversibility and relatively high in specific capacity.

Owner:DONGGUAN JOYSUN NEW ENERGY

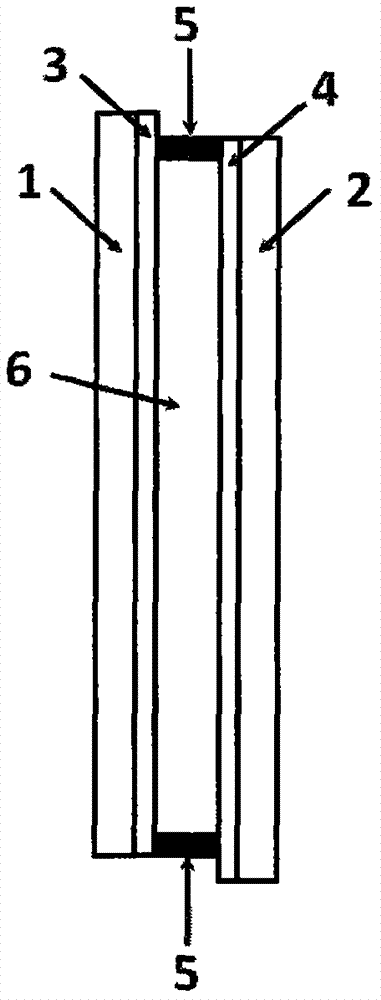

Lithium ion battery diaphragm, preparation method thereof and lithium ion battery

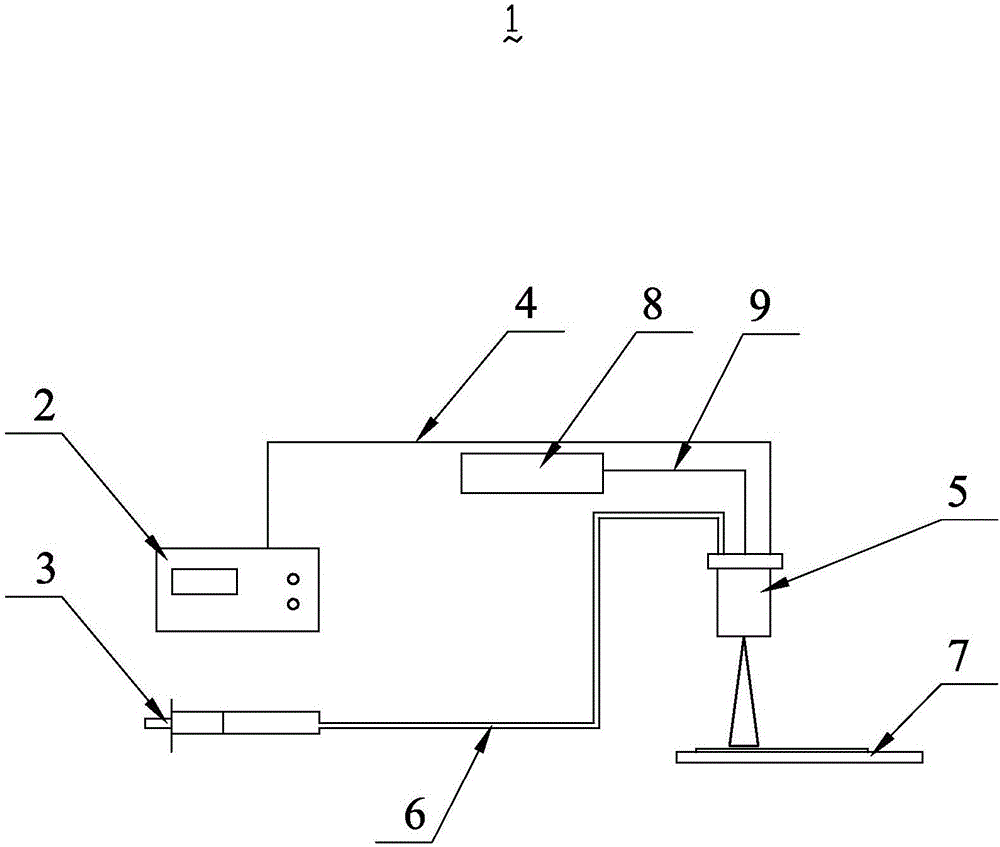

InactiveCN106299209AImprove ionic conductivityHigh porositySecondary cellsCell component detailsNon solventPorosity

The invention relates to the field of battery materials and preparation thereof, and particularly relates to a lithium ion battery diaphragm, a preparation method thereof and a lithium ion battery. The preparation method of the lithium ion battery diaphragm provided by the invention comprises the following steps: S1, providing a PVDF-HFP solution which is a mixed solution of PVDF-HFP, a solvent and a non-solvent; and S2, carrying out an ultrasonic atomization spaying process on the PVDF-HFP solution to form the diaphragm. The invention also provides the lithium ion battery diaphragm and the lithium ion battery. The lithium ion battery diaphragm provided by the invention cannot be dissolved into common electrolyte easily, and has the advantages of relatively high ionic conductivity and porosity and the like, and the lithium ion battery has relatively good electrochemical performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

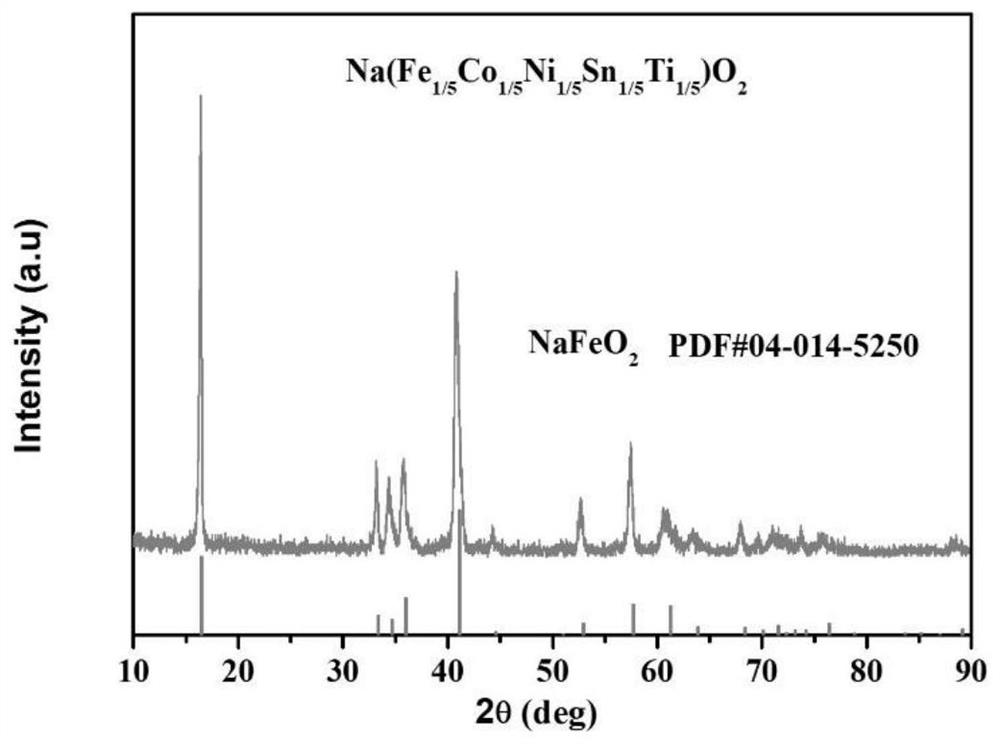

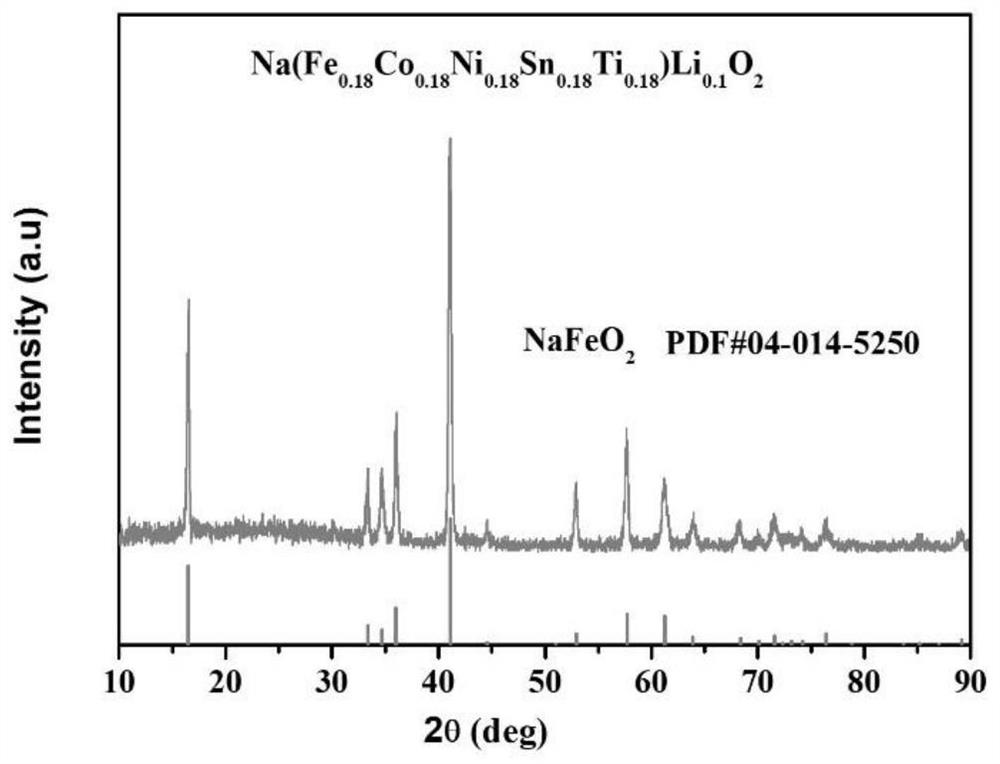

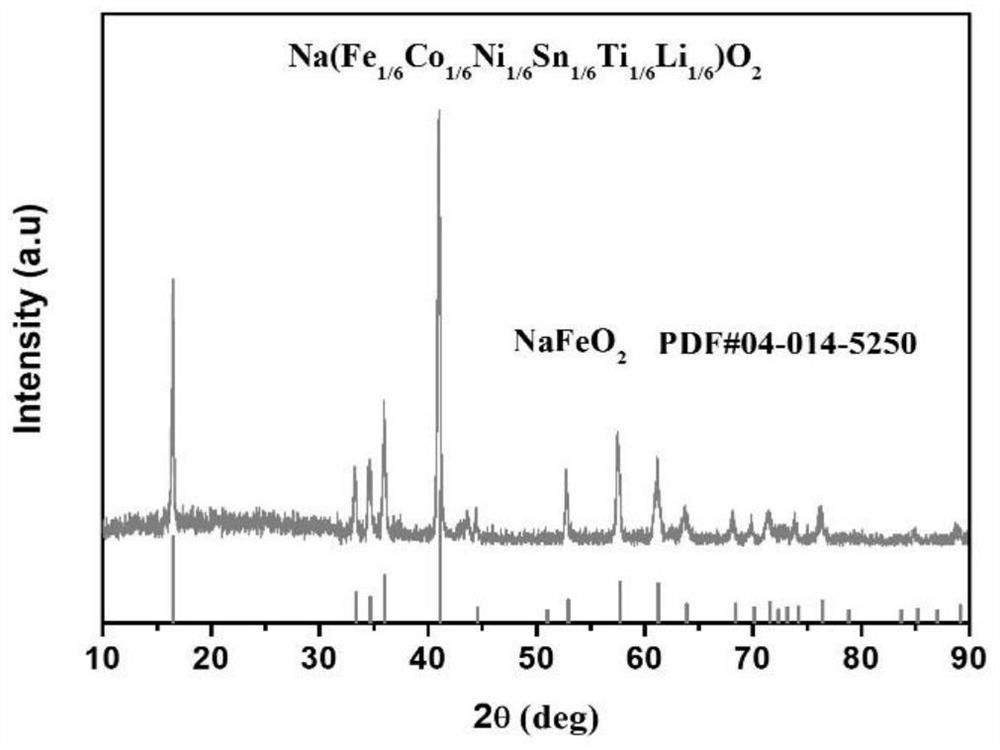

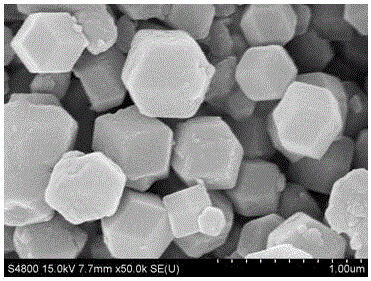

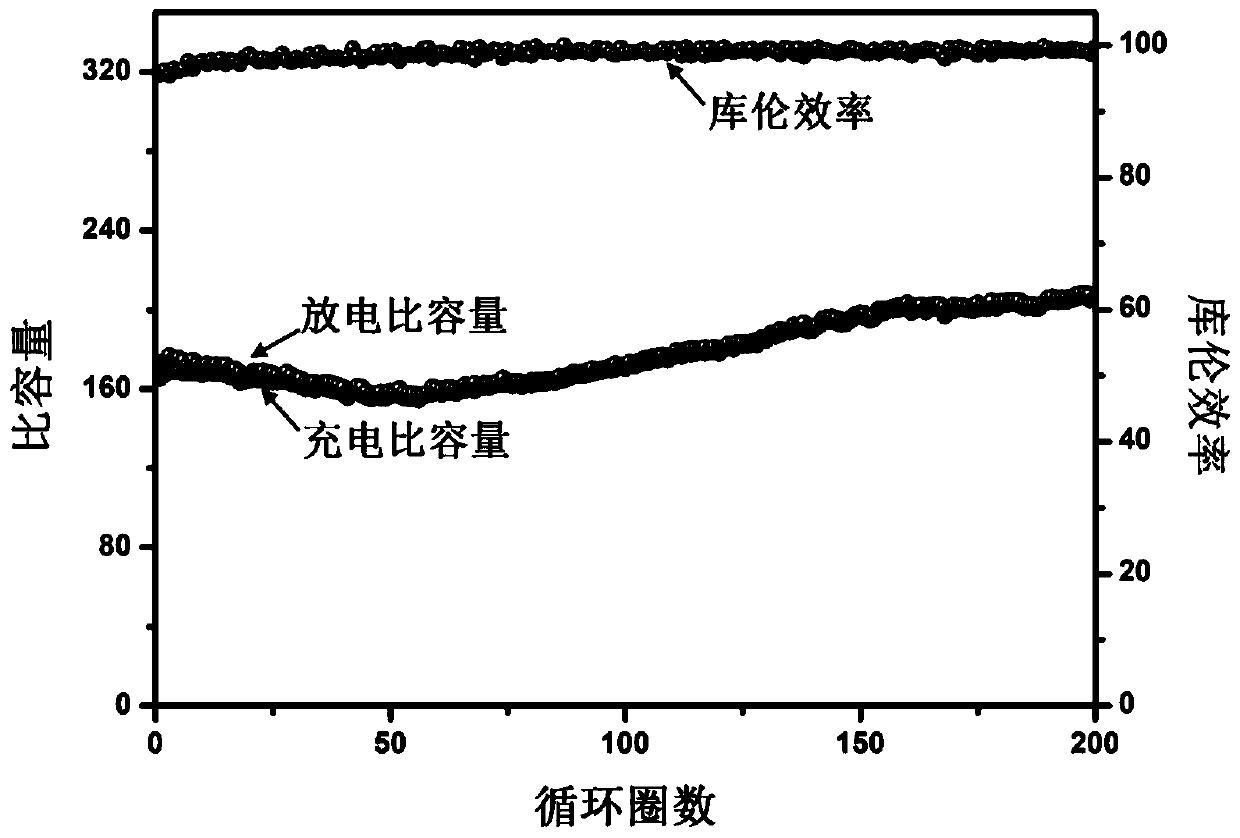

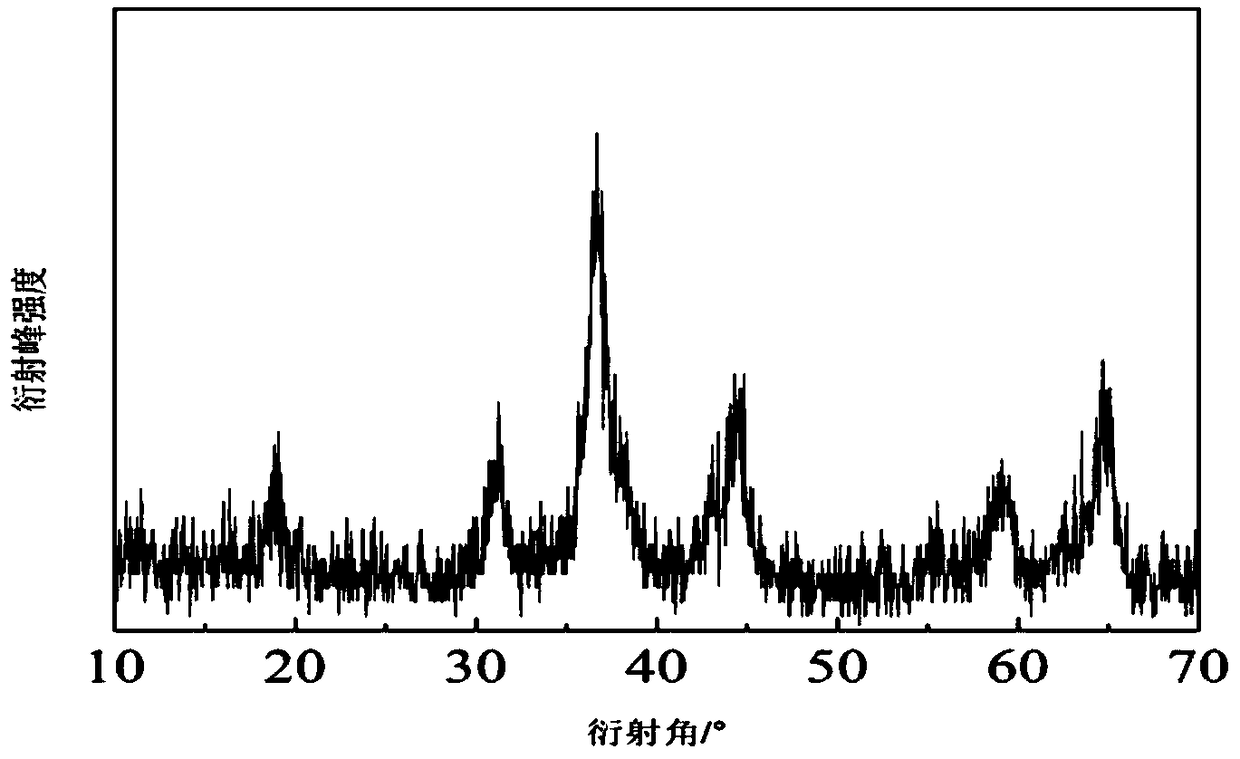

Preparation method and application of layered high-entropy oxide sodium ion battery positive electrode material

ActiveCN112467119AHigh crystallinityImprove electrochemical performanceSecondary cellsPositive electrodesChemical physicsSodium-ion battery

The invention discloses a preparation method and application of a layered high-entropy oxide sodium ion battery positive electrode material and belongs to the field of sodium ion battery positive electrode materials. The material is a Na (Fe(1-x) / 5Co(1-x) / 5Ni(1-x) / 5Sn(1-x) / 5Ti(1-x) / 5)LixO2 high-entropy oxide sodium ion battery positive electrode material, and x is equal to 0 or 0.1 or 1 / 6. The material prepared by the invention has the structural advantages of single phase, good crystallinity, small particle size, uniform distribution and the like, and by doping alkali metal elements, ionic and electronic conductivity of the material is effectively improved, the charge transfer impedance is greatly reduced, and the rate capability is improved. Under the current density of 10mA / g, the firstreversible specific capacity of the material is 80-120mAh / g; under the current density of 50 mA / g, the specific capacity reaches 40-100 mAh / g after 200 cycles, and the capacity retention ratio is larger than or equal to 58%.

Owner:东北大学秦皇岛分校

Method for recycling lithium iron phosphate positive electrode material in waste lithium ion battery

ActiveCN106992329ARealize resource reuseReduce recycling costsAlkaline accumulator electrodesWaste accumulators reclaimingLithium iron phosphateLithium-ion battery

The invention discloses a method for recycling a lithium iron phosphate positive electrode material in a waste lithium ion battery, belonging to the field of recovery technologies for lithium iron phosphate positive electrode materials in waste lithium ion batteries and the field of alkaline secondary batteries. According to a technical scheme in the invention, the lithium iron phosphate positive electrode material in the waste lithium ion battery is used as a raw material and uniformly mixed with a ferric salt and an organic additive so as to obtain a mixture; then the mixture is subjected to calcining in an inert atmosphere so as to prepare a lithium iron phosphate-based composite material; and the lithium iron phosphate-based composite material is used for preparation of the negative electrode of an alkaline secondary battery. The method provided by the invention can efficiently recycle waste lithium ion battery positive electrode materials and apply the recycled waste lithium ion battery positive electrode materials to the negative electrode of an alkaline secondary battery, so cyclic regeneration and utilization of the waste lithium iron phosphate material are realized.

Owner:HENAN NORMAL UNIV

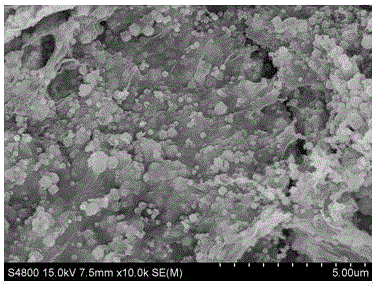

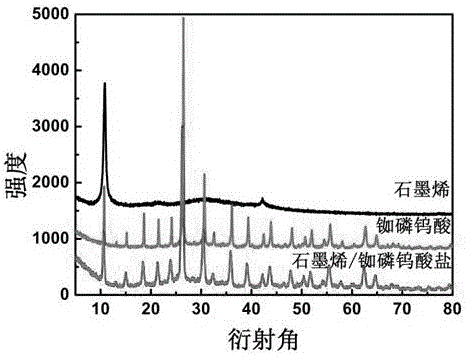

Method for preparing three-dimensional graphene-phosphotungstate

InactiveCN105870430ASmall sizeSolve the difficulty of embedding and detachmentCell electrodesSecondary cellsFreeze-dryingMolecular cluster

The invention discloses a method for preparing three-dimensional graphene-phosphotungstate, and belongs to the technical field of chemical batteries. The method comprises the following steps of: mixing a rubidium chloride solution and a phosphotungstic acid solution to react so as to obtain rubidium phosphowolframate; mixing the rubidium phosphowolframate and a graphene oxide solution, performing hydrothermal reaction, after the reaction is completed, cooling to the room temperature, taking out solid substances, and performing freeze-drying, thereby obtaining three-dimensional graphene-phosphotungstate. The method disclosed by the invention is simple, the prepared rubidium phosphowolframate is relatively small in size, uniform in morphology and beneficial to solve the problem that lithium ions are hard to embed and desorb from microcrystalline structures, and can be applied to cathode materials of lithium batteries, and conductivity of a heteropolyacid molecular cluster battery can be improved.

Owner:YANGZHOU UNIV

Method for making negative electrode material of lithium ion cell

InactiveCN1705150APrevent oxidationQuality assuranceElectrode manufacturing processesActive material electrodesLithiumRare earth

A method for preparing negative pole material of lithium cell, which contains putting silicon, carbon, doped 0.01 % rareearth oxide La2O5 and Nd2O5 in high power ball mill, protected by Ar or N2 for preventing oxidation, the C : Si = 3 :1 -5 : 1, checking the abrading grain size every 20 hr until to 50-100nm to obtain high specific capacity and fine safety nano negative pole material.

Owner:潘树明

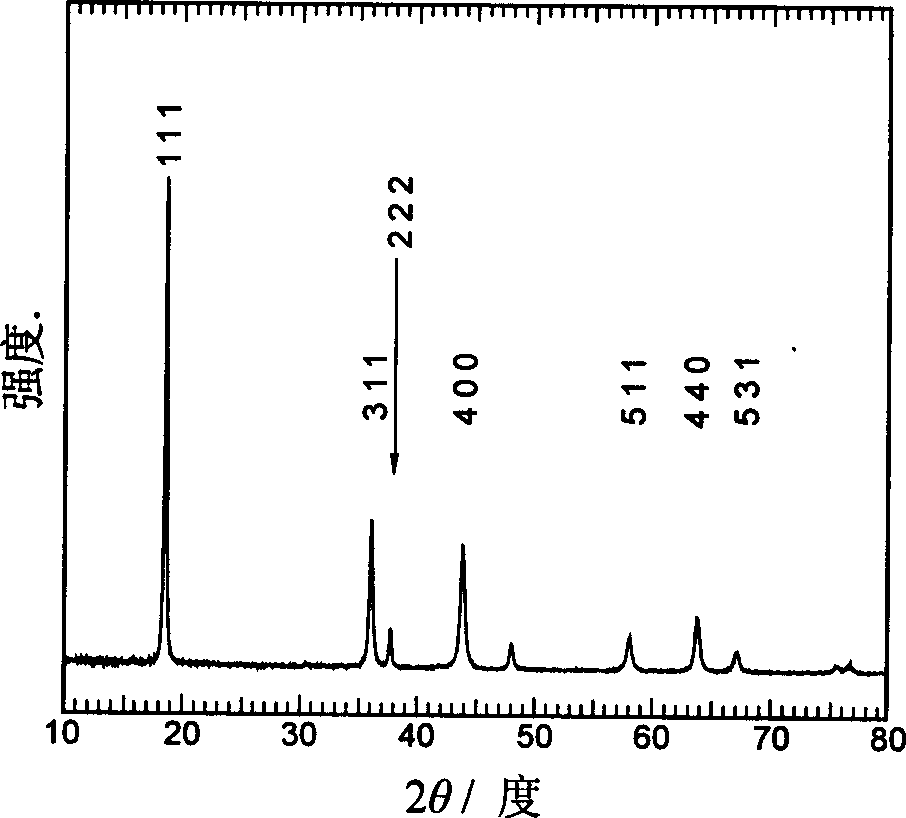

Anode material of lithium ion cell and its prepn method

InactiveCN1834022AEasy to wrapMicro stress reliefCell electrodesManganates/permanganatesLithiumElectrical battery

This invention discloses a method to prepare anode materials in lithium ion cells, which includes following steps: LiMxMn2-xO4 powder is adopted as substrate and mixed with low-melting-point salt powder to form a mixture. The melting point of low-melting-point salt is below 650 deg. C. In LiMxMn2-xO4, x is not less than 0.01 and not larger than 0.2 and M can be aluminium, cobalt, nickel or zincum. The metal amount in low-melting-point salt is 2~8wt% of LiMxMn2-xO4. The preceding mixture is pressed into blocks at a pressure of 4~8MPa. The blocks are kept first at 90~120 deg. C for 2~4.0 hours and then at 400~700 deg. C for 2~6.0 hours. Lithium ion cells which adopt anode materials prepared in this invention have relatively high capacitance and perform good circulative properties in wide potential ranges.

Owner:ZHEJIANG UNIV

Method for recycling waste lithium iron phosphate positive electrode material and applying recycled waste lithium iron phosphate positive electrode material to nickel-iron battery

ActiveCN106992328ARealize resource reuseReduce recycling costsAlkaline accumulator electrodesWaste accumulators reclaimingLithium iron phosphateLithium-ion battery

The invention discloses a method for recycling a waste lithium iron phosphate positive electrode material and applying the recycled waste lithium iron phosphate positive electrode material to a nickel-iron battery, belonging to the field of recovery technologies for lithium iron phosphate positive electrode materials in waste lithium ion batteries and the field of alkaline secondary batteries. According to a technical scheme in the invention, the waste lithium iron phosphate positive electrode material is used as a raw material; a saturated ferric salt solution is added into and uniformly mixed with the waste lithium iron phosphate positive electrode material; then the obtained mixture is subjected to calcining in an inert atmosphere so as to prepare a lithium iron phosphate-based composite material; and the lithium iron phosphate-based composite material is used for preparation of the negative electrode of the nickel-iron battery. The method provided by the invention can efficiently recycle the waste lithium iron phosphate positive electrode material and apply the recycled waste lithium iron phosphate positive electrode material to the negative electrode of the nickel-iron battery, so cyclic regeneration and utilization of the waste lithium iron phosphate positive electrode material are realized.

Owner:河南省恒明新能源有限公司

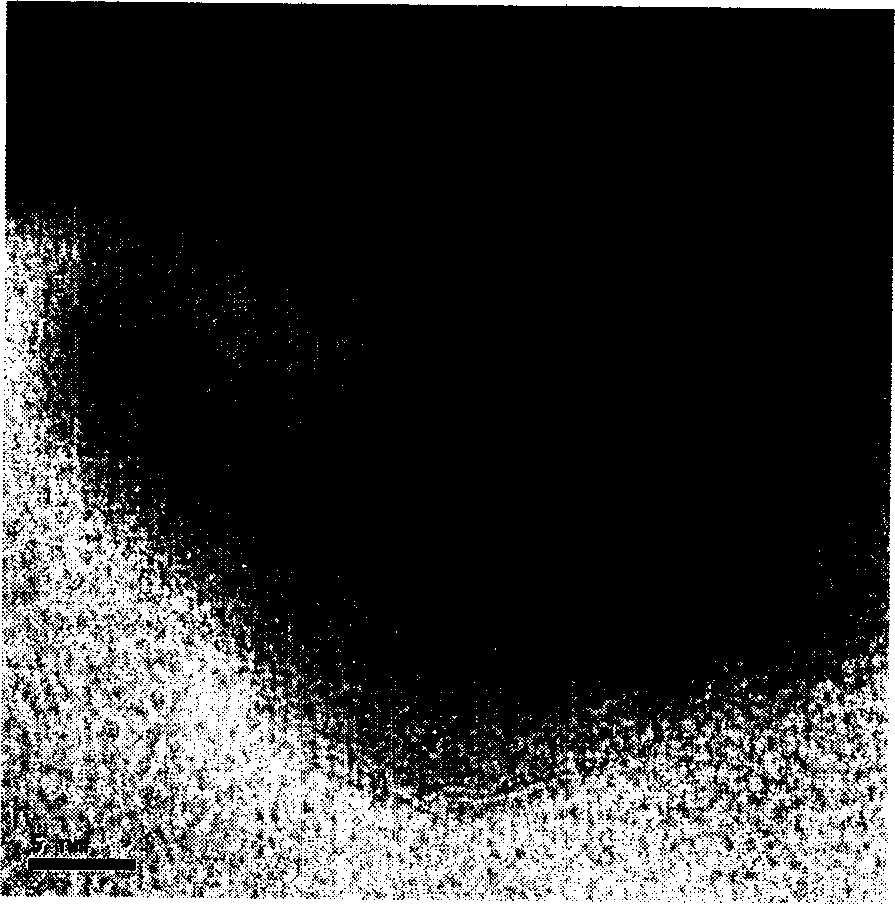

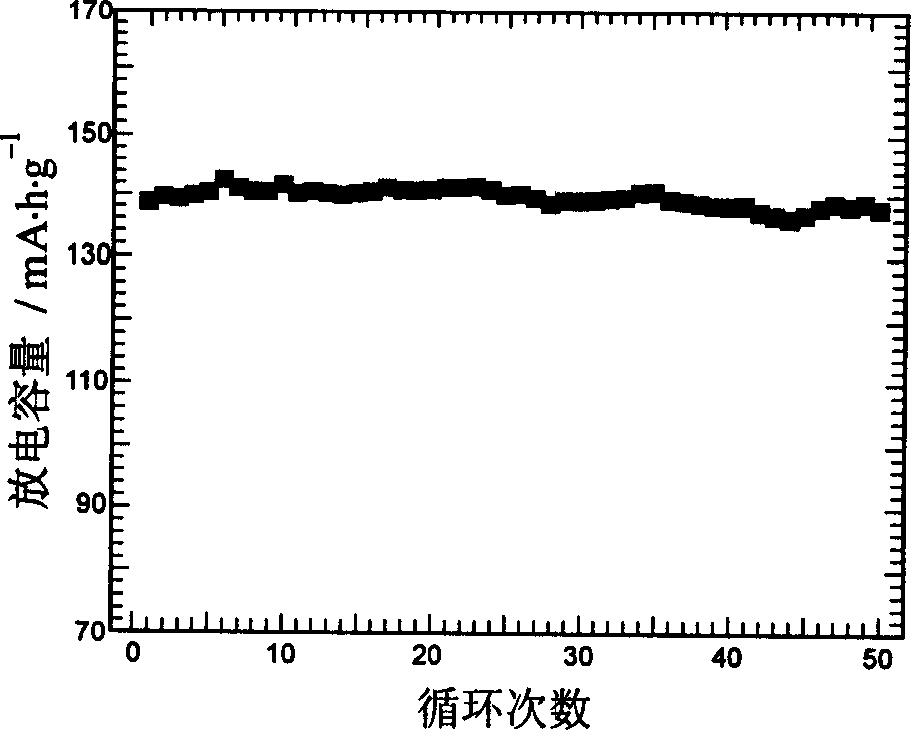

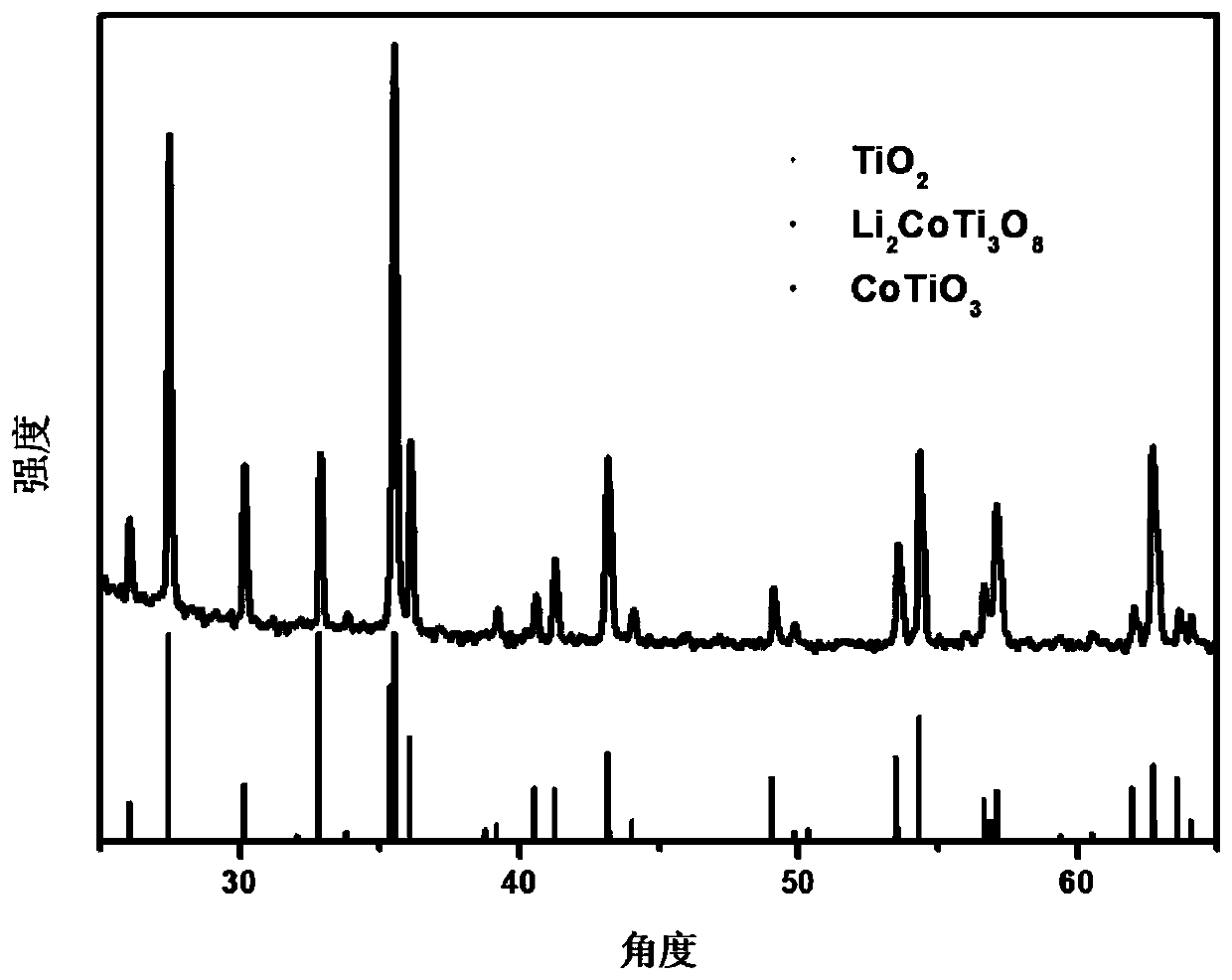

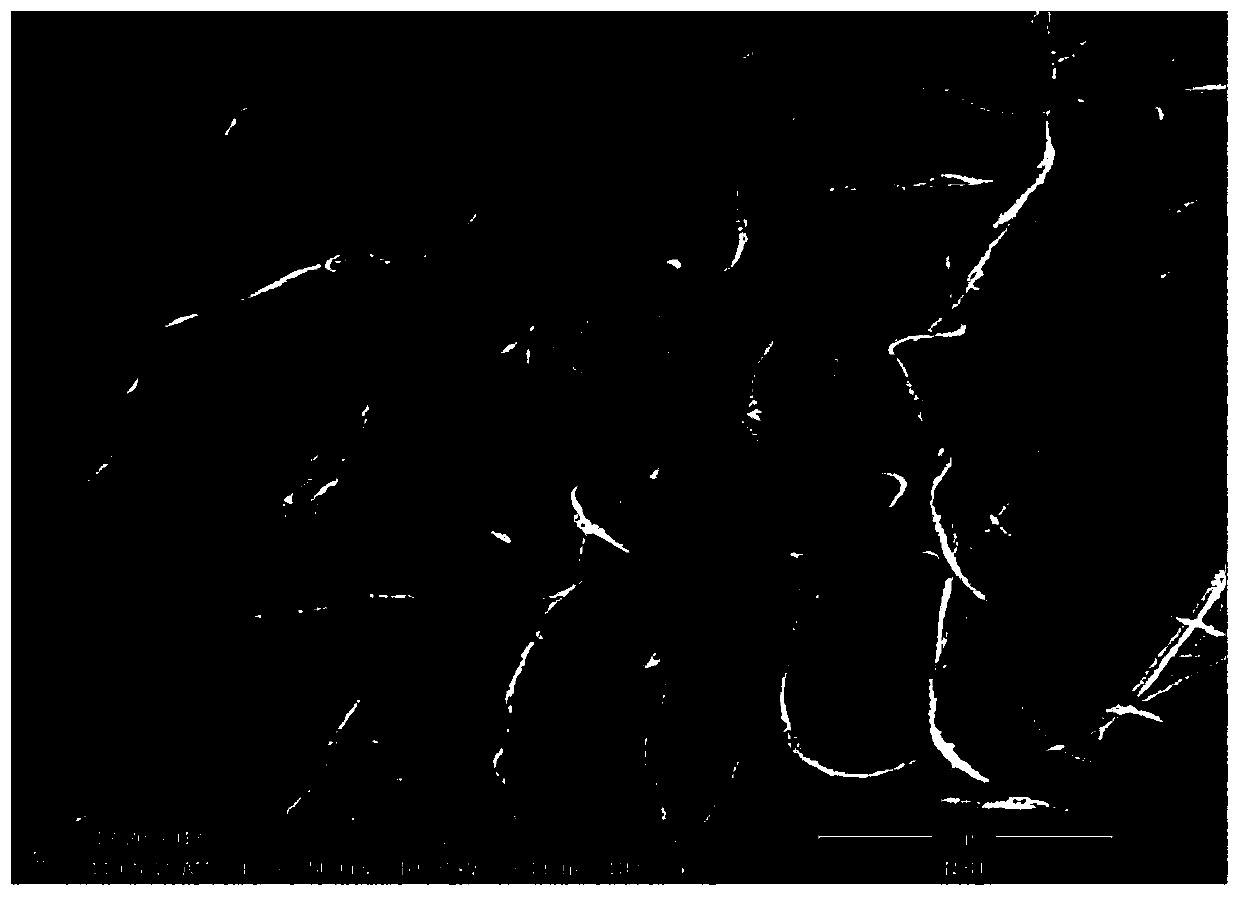

Titanate and titanium dioxide composite nanowire and preparation method thereof

ActiveCN110079895ALarge aspect ratioGrowth inhibitionInorganic material artificial filamentsAir atmosphereNanowire

The invention discloses a titanate and titanium dioxide composite nanowire and a preparation method thereof. The preparation method provided by the invention comprises the following steps: dissolvingtetrabutyl titanate, cobalt acetate tetrahydrate and lithium acetate in a mixed solvent of N, N-dimethylformamide, ethanol and acetic acid by using an electrospinning technology; adding polyvinylpyrrolidone and stirring to obtain a precursor mixture solution; electrospinning under a certain voltage, flow rate, temperature and certain relative humidity atmosphere; collecting and sintering electrospinning products in a muffle furnace under an air atmosphere to obtain the titanate and titanium dioxide composite nanowire provided by the invention. The composite nanowire is excellent in electrochemical performance, applicable to electrode materials of lithium ion batteries, and simple to operate, low in raw material and low in equipment investment in the whole preparation process, and suitablefor mass production.

Owner:NINGBO UNIV

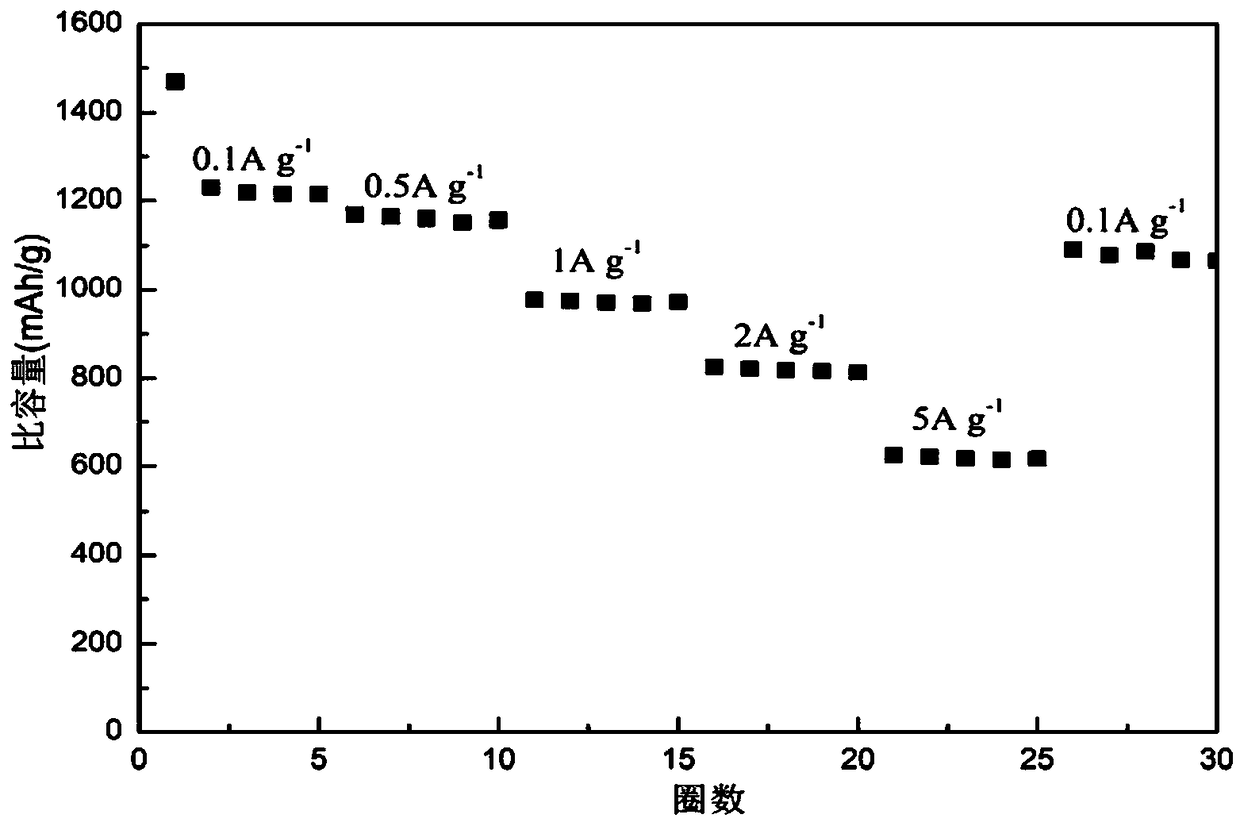

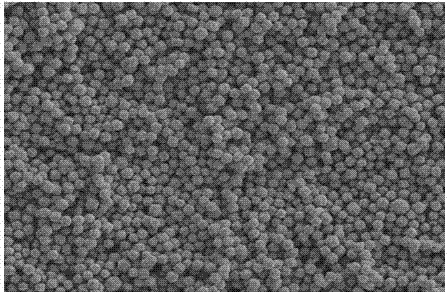

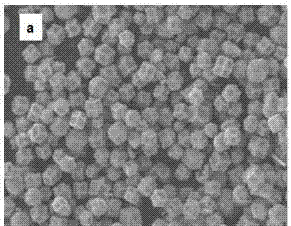

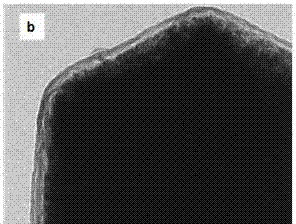

Preparation method and applications of nickel cobaltate

InactiveCN108933255ASolve the problem of poor rate characteristicsSignificant technological progressCell electrodesSecondary cellsNickel saltCobalt salt

The invention discloses a preparation method of nickel cobaltate. The preparation method comprises following steps: at a stoichiometric ratio, a nickel salt, a cobalt salt, a precipitating agent, anddeionized water are mixed; an obtained mixed solution is introduced into a reaction kettle, reaction temperature is controlled to be 100 to 125 DEG C for 6 to 8 h, and washing and drying are carried out so as to obtain a powdery mixed precursor; the powdery mixed precursor is subjected to heat treatment in the air so as to obtain the NiCo2O4 material. The NiCo2O4 material can be used for preparation of lithium ion battery anodes, and increasing of lithium battery rate capability.

Owner:SHANGHAI INST OF TECH

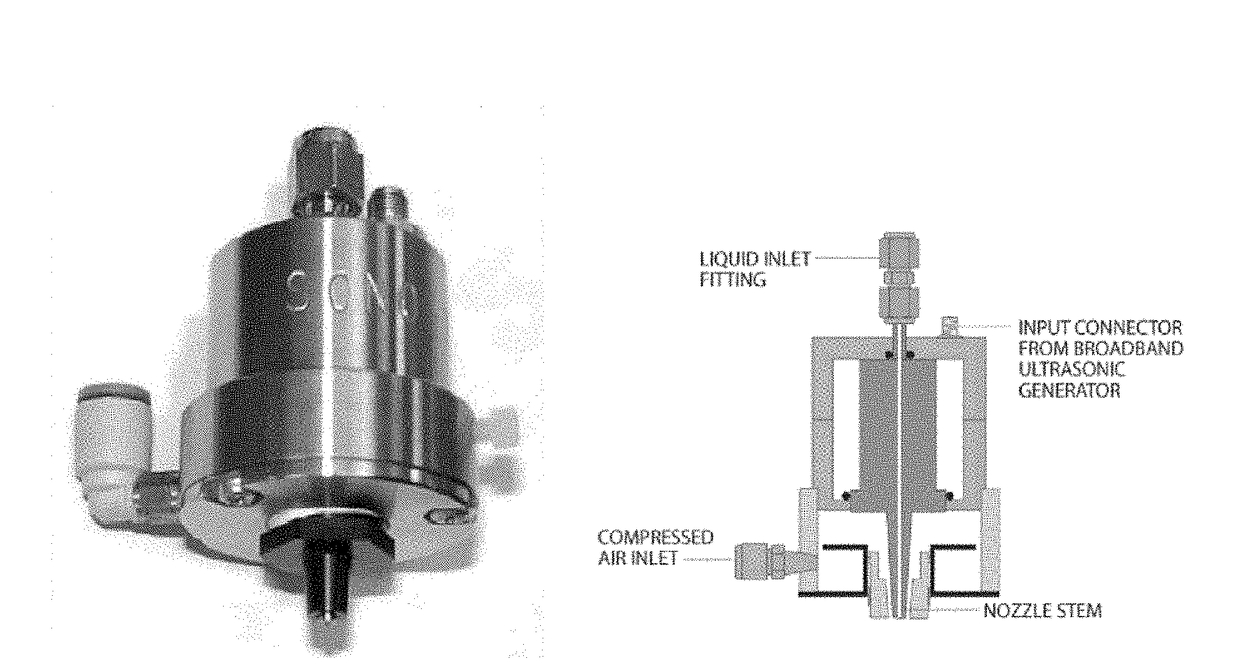

Improved process of ultrasonic spray pyrolysis deposition of one or more electrochromic and/or electrolytic films on a substrate

ActiveUS20170363928A1High layer uniformityEasy to coverEnergy inputOxide conductorsElectricityElectrolysis

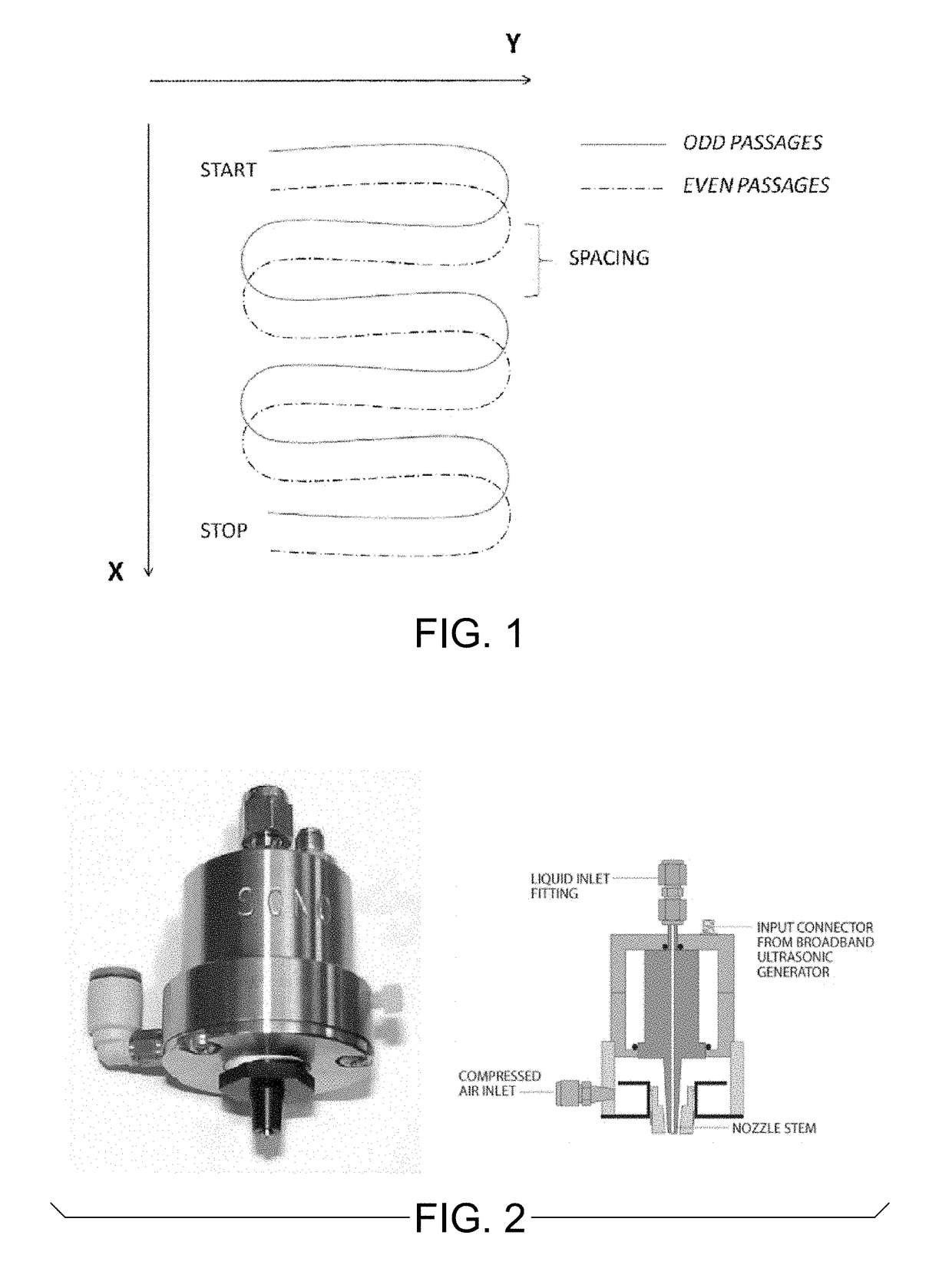

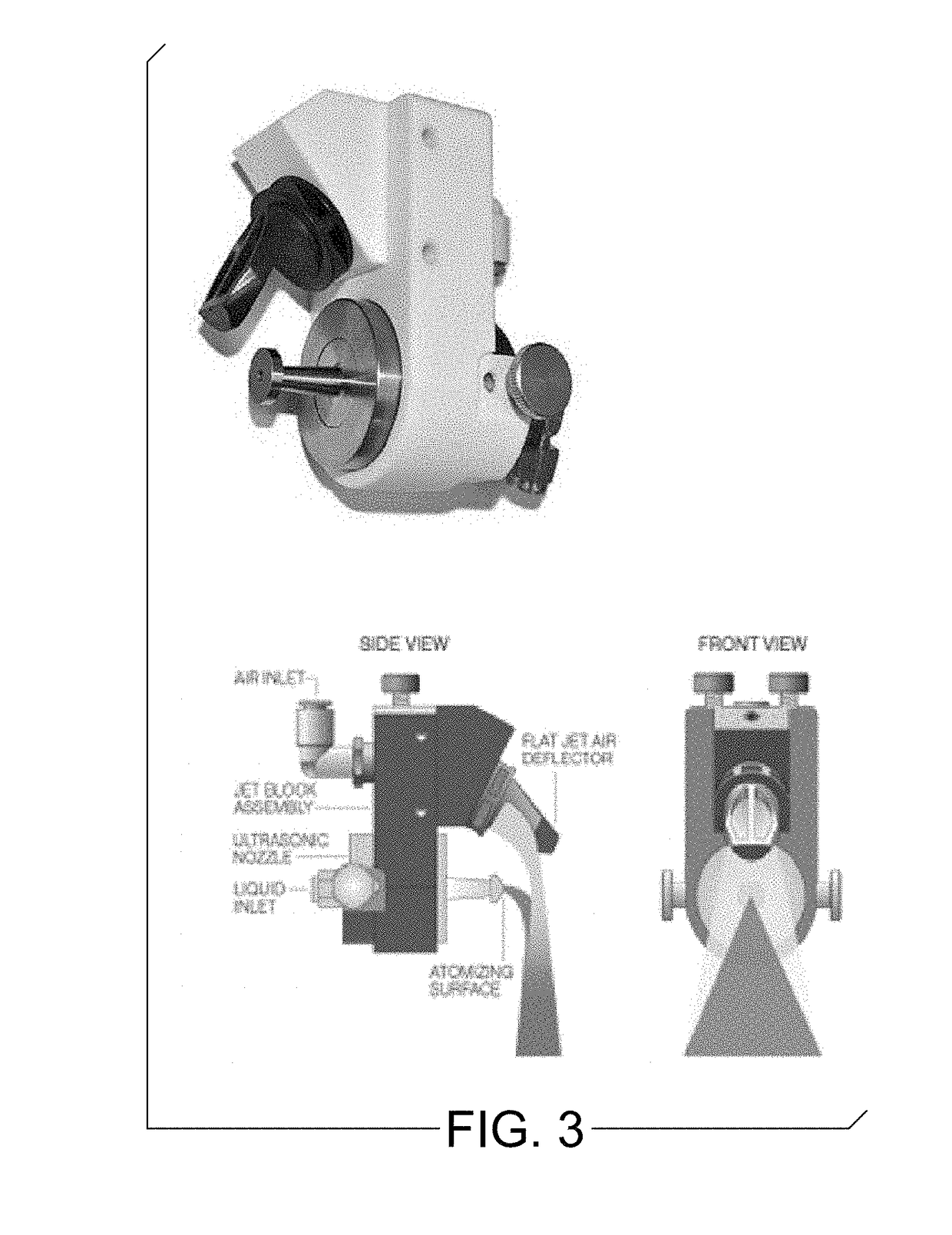

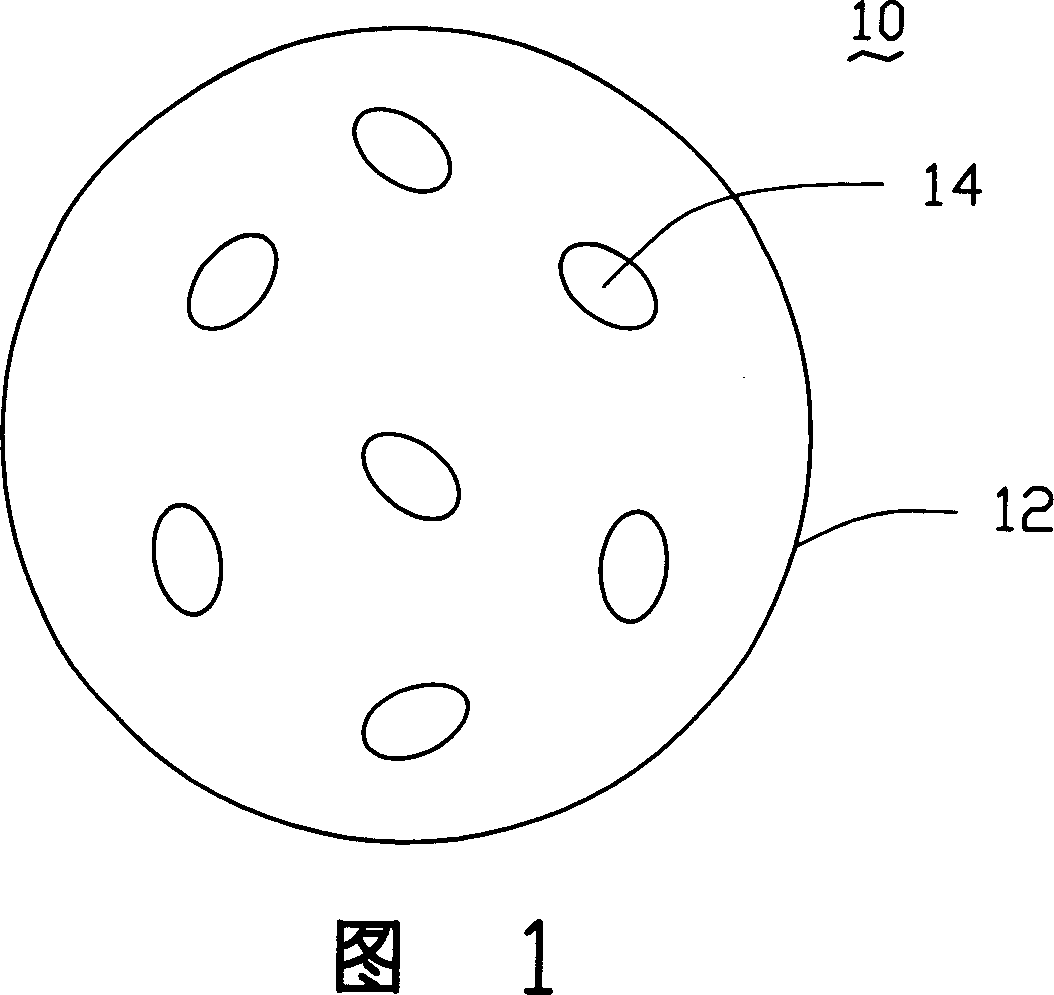

A process of making an electrochromic or an electrolytic film by Ultrasonic Spray Pyrolysis (USP) deposition on a substrate comprising:mixing a surfactant to an aqueous precursor solution comprising an electrochromic component or an electrolytic component to provide a spray solution;introducing the spray solution into an ultrasonic spray deposition nozzle at a constant flow rate between 0.1 mL / min and 2 mL / min and applying an ultrasonic frequency between 80 and 120 kHz to generate atomized droplets of the precursor solution;entraining the atomized droplets with a controlled jet of air as gas carrier at a pressure between 0.50 to 2.0 psi, onto a pre-heated substrate at a temperature of 200 to 450° C.;thermally converting the atomized droplets when depositing onto the pre-heated substrate to generate an electrochromic or an electrolytic film.

Owner:INISMA +1

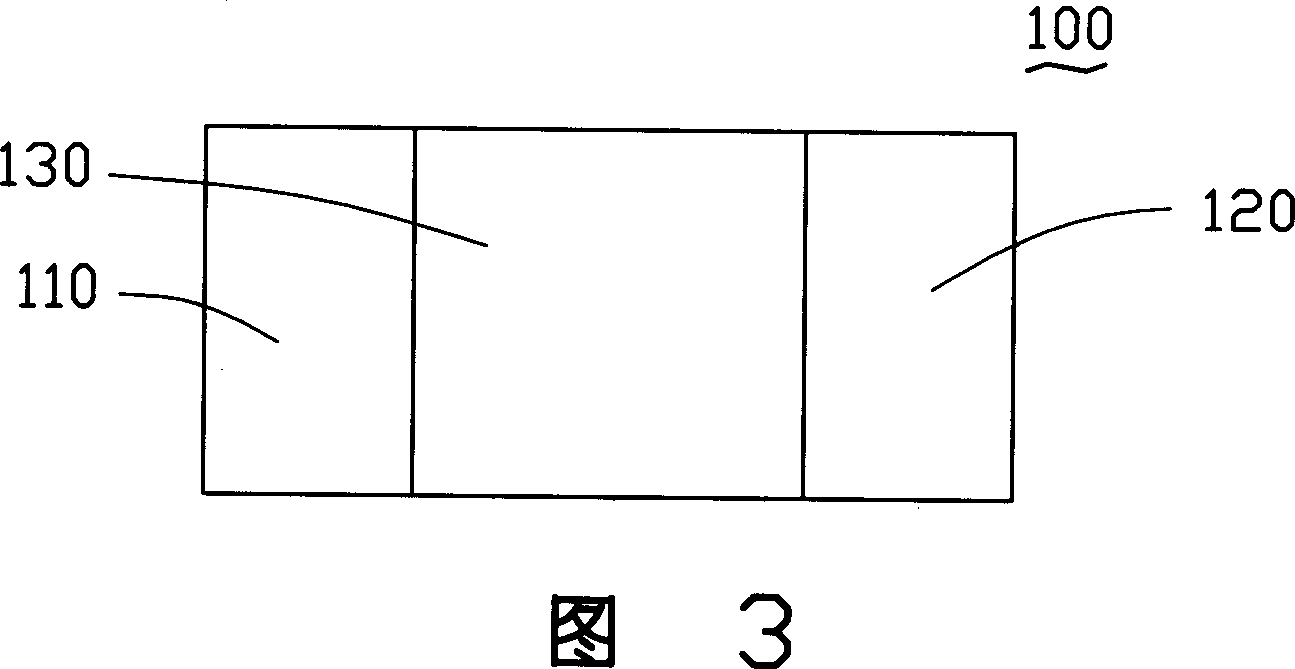

Lithium secondary anode, its preparing method and lithium secondary anode using same

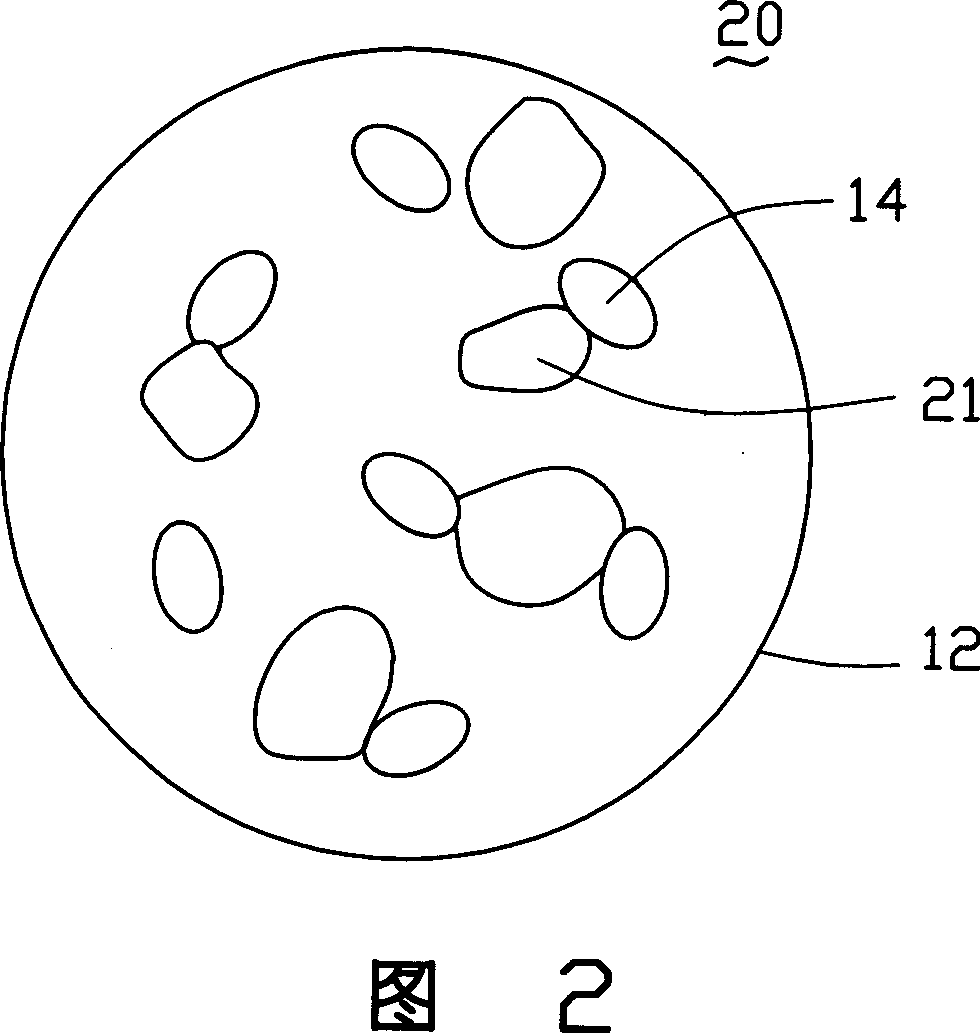

InactiveCN1925191AIncrease capacityGood high temperature cycle lifeElectrode manufacturing processesFinal product manufactureLithiumAnode

This invention provides one lithium secondary battery anode and its process method, which comprises secondary anode composed of one base and two different compounds coating on different areas. The process method comprises the following steps: coating one compound onto anode base surface area different to basic materials; coating other compound different to basic materials on other part of the base surface to get lithium secondary battery anode of different basic material two compounds. This invention provides one lithium secondary battery composed of one anode, one cathode and one transmission isolation film.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Lithium-lanthanum-titanium-doped modified electrostatic spinning supercapacitor diaphragm material

InactiveCN106544786AIncrease liquid absorptionImprove thermal stabilityHybrid capacitor separatorsNon-woven fabricsEngineeringLanthanum

The invention discloses a lithium-lanthanum-titanium-doped modified electrostatic spinning supercapacitor diaphragm material. The lithium-lanthanum-titanium-doped modified electrostatic spinning supercapacitor diaphragm material is prepared from the following raw materials in parts by weight: 80-83 parts of polyvinylidene fluoride, 20-22 parts of polymethyl methacrylate, a proper amount of DMF, 2-3 parts of nano boehmite, 0.8-1 part of a silane coupling agent KH550, a proper amount of deionized water, 1.5-2 parts of lanthanum trioxide, 1.5-2 parts of lithium carbonate, 2-3 parts of titanium dioxide, 8-9 parts of polyimide and a proper amount of absolute ethyl alcohol. The lanthanum trioxide, the lithium carbonate and the titanium dioxide are compounded by a certain chemical process to obtain a dopant with certain electric conductivity, the dopant is added in preparation of the diaphragm material, the mechanical property of electrolyte can be enhanced, and the conductivity can also be improved remarkably. The diaphragm material has a fibrous duct structure with good connectivity, and has good electrolyte absorbing property and good electrochemical performance; the process facilitates industrial production; and the lithium-lanthanum-titanium-doped modified electrostatic spinning supercapacitor diaphragm material is suitable for a supercapacitor.

Owner:TONGLING CITY START ELECTRONICS MFG

Compound electrostatic spun diaphragm material with added dopamine modified aluminum sulfate

InactiveCN106328388AIncrease liquid absorptionImprove thermal stabilityHybrid capacitor separatorsHybrid/EDL manufacturePorosityPolymethyl methacrylate

The invention discloses a compound electrostatic spun diaphragm material with added dopamine modified aluminum sulfate. The compound electrostatic spun diaphragm material is made from, by weight, 80-83 parts of polyvinylidene fluoride, 20-22 parts of polymethyl methacrylate, an appropriate amount of DMF, 2-3 parts of nanometer boehmite, 0.8-1 part of silane coupling agent KH550, an appropriate amount of deionized water, an appropriate amount of trihydroxymethyl aminomethane, 2-3 parts of dopamine and 1-1.3 parts of aluminum sulfate. The dopamine solution reacts with aluminum sulfate, dopamine aggregates on the surface of aluminum sulfate, small and compact particles are formed on the surface of the aluminum sulfate, in this way, the porosity of the diaphragm is increased, a good hydrophilic property is achieved, and imbibing efficiency is further improved. The made diaphragm material has rich pore canals, conductive ions pass through the diaphragm material easily and especially transfer under high-magnification charging and discharging conditions, and the high-property superconductor diaphragm material is obtained.

Owner:ANHUI JIANGWEI PRECISION IND

Method for recycling waste lithium iron phosphate cathode materials in iron-nickel batteries

ActiveCN106992328BRealize resource reuseReduce recycling costsAlkaline accumulator electrodesWaste accumulators reclaimingLithium iron phosphateLithium-ion battery

Owner:河南省恒明新能源有限公司

A method for recycling and reusing waste lithium ion battery lithium iron phosphate cathode material

ActiveCN106992329BRealize resource reuseReduce recycling costsAlkaline accumulator electrodesWaste accumulators reclaimingLithium iron phosphateLithium-ion battery

The invention discloses a method for recycling a lithium iron phosphate positive electrode material in a waste lithium ion battery, belonging to the field of recovery technologies for lithium iron phosphate positive electrode materials in waste lithium ion batteries and the field of alkaline secondary batteries. According to a technical scheme in the invention, the lithium iron phosphate positive electrode material in the waste lithium ion battery is used as a raw material and uniformly mixed with a ferric salt and an organic additive so as to obtain a mixture; then the mixture is subjected to calcining in an inert atmosphere so as to prepare a lithium iron phosphate-based composite material; and the lithium iron phosphate-based composite material is used for preparation of the negative electrode of an alkaline secondary battery. The method provided by the invention can efficiently recycle waste lithium ion battery positive electrode materials and apply the recycled waste lithium ion battery positive electrode materials to the negative electrode of an alkaline secondary battery, so cyclic regeneration and utilization of the waste lithium iron phosphate material are realized.

Owner:HENAN NORMAL UNIV

Preparation technique of composite film electrode used for a super capacitor

InactiveCN101533716ASolve power problemsSolve large capacityCapacitor electrodesCapacitancePolymer capacitor

The invention discloses a preparation technique of a composite film electrode used for a super capacitor; the preparation technique is characterized by comprising the following steps: pre-processing on high-purity metal tantalum foil with the purity of more than 99.95 percent: grinding and roughening, grinding and polishing, removing oil and cleaning to the metal tantalum foil; 2) electrodeposition technique; and 3) heat processing to the composite film electrode. The composite film electrode prepared by adopting the technique can reduce the using amount of noble metal ruthenium on the basis of guaranteeing capacitance characteristic, thus reducing the cost.

Owner:CENT SOUTH UNIV

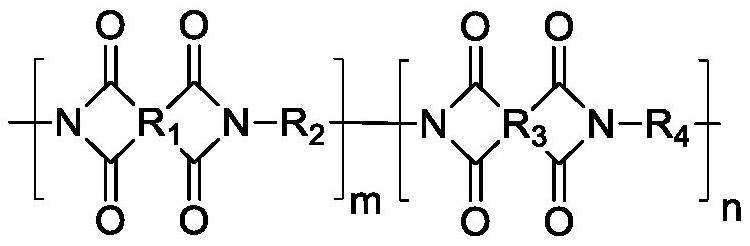

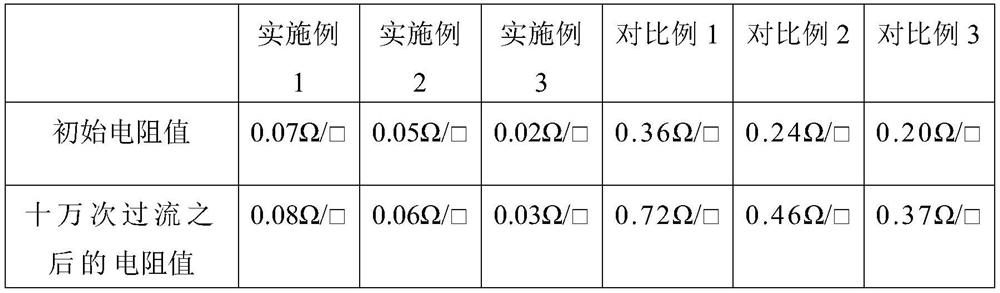

Cross-linked network-shaped silicon-carbon negative electrode binder and silicon-carbon negative electrode plate

InactiveCN112018391AHigh tensile strengthImprove cycle reversibilityNegative electrodesSecondary cellsPolyvinyl alcoholLithium-ion battery

The invention provides a cross-linked network-shaped silicon-carbon negative electrode binder and a silicon-carbon negative electrode plate. The binder is obtained by thermal crosslinking of polyimideand polyvinyl alcohol, so that the binder has the advantages of high tensile strength of polyimide and strong capacity of inhibiting expansion of active substances, and can effectively improve the cycle reversibility of the charge-discharge lithium ion battery when being used for a silicon-carbon negative plate.

Owner:浙江中科玖源新材料有限公司

Graphene heating ink, preparation method and application thereof

ActiveCN112521796AGood film formingImprove basic performanceInksHeating element materialsPolymer scienceResin matrix

The invention discloses graphene heating ink, a preparation method and application thereof. The graphene heating ink comprises a resin matrix, conductive filler, an assistant and a solvent, wherein the conductive filler comprises graphene, the resin matrix is composed of an organic polymer and polysilazane in a mass ratio of 1:0.08-1.5, and the graphene heating ink further comprises a cross-linking agent; the preparation method comprises the following steps of: stirring and dispersing graphene in a powder form and polysilazane in a polysilazane solution form for fully mixing, and then adding the rest raw materials under stirring to obtain the graphene heating ink. The invention also relates to an electric heating film prepared from the ink, on the premise that excellent conductivity at a low temperature is guaranteed, the characteristic that the resistance is greatly improved at a high temperature is achieved, then self-temperature-limiting is achieved, meanwhile, when the electric heating film returns to a normal temperature, the resistance value of a material is not greatly changed, and reversibility is good, therefore, the recycling performance and the safety of the electric heating film are improved.

Owner:SU ZHOU CSTAR MATERIAL TECH CO LTD

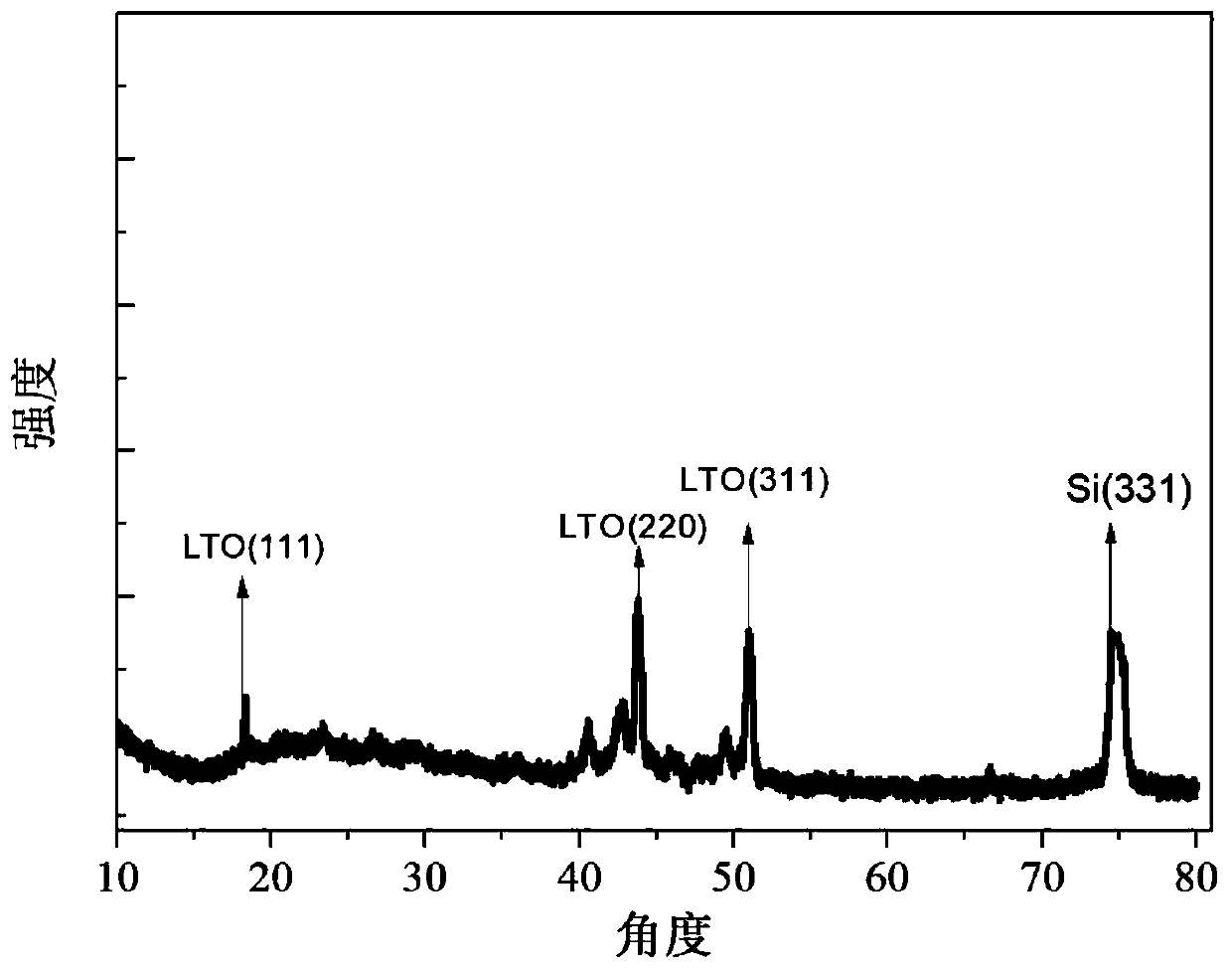

Composite lithium titanate thin film as well as preparation method and application thereof

InactiveCN110176586AImprove structural stabilityStable chemical propertiesHybrid capacitor electrodesCell electrodesLithiumSide reaction

The invention provides a composite lithium titanate thin film as well as a preparation method and an application thereof. The preparation method of the composite lithium titanate thin film comprises the following steps of carrying out co-sputtering treatment on a lithium titanate target material and an energy density contribution main body element target material in an inert atmosphere, and growing the composite lithium titanate thin film on a substrate. According to the preparation method of the composite lithium titanate thin film, the lithium titanate target material and the energy densitycontribution main body element target material are directly deposited and formed by adopting a co-sputtering method. Therefore, the grown composite lithium titanate thin film has a rich channel structure and is stable in structure, so that high lithium ion transmission rate can be provided, and high cycling reversibility and relatively high specific capacity are maintained; and meanwhile, the direct contact of an electrolyte and a nano-scale energy density contribution main body element is effectively prevented, the irreversible side reaction between the electrolyte and the energy density contribution main body can be reduced and blocked, and the generation of a solid electrolyte membrane (SEI) is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Modified positive pole material of magnesium secondary battery and preparing method thereof

ActiveCN102136573AImprove and refine electrochemical performanceImprove electrochemical performanceElectrode manufacturing processesHeteropoly acidShielding gas

The invention relates to modified positive pole material of a magnesium secondary battery and a preparing method thereof. The positive pole material adopts quadrivalent magnesium molybdate modified by heteropoly acid, and the content of the quadrivalent magnesium molybdate is 85 percent to 99 percent and the content of the heteropoly acid is 1 percent to 15 percent according to mass percent. The chemical structural formula of the quadrivalent magnesium molybdate is Mg1 plus xMoO3, wherein x is larger than 0 and smaller than or equal to 0.1; and the preparing method of the positive pole material comprises the steps as follows: magnesium compound, molybdic compound and active carbon are adopted as raw materials, argon is taken as protective gas, quadrivalent magnesium molybdate powder is prepared after a high-temperature solid phase reaction method, and then the powder is modified through heteropoly acid, so that the positive pole material of the magnesium secondary battery is obtained.The positive pole material has good electrochemical charge-discharge behaviors, and compared with the ideal positive pole material Mo3S4 of the prior magnesium secondary battery, the preparing methodhas the advantages that the preparing method is simple, the cost is low, and the preparing method has high specific capacity, good circulating performance, reversibility, and obvious practical value and economic benefit.

Owner:SHANGHAI JIAO TONG UNIV

Lithium iron phosphate composite and preparation method thereof

InactiveCN108110237APromote circulationImprove electronic conductivityPhosphatesCell electrodesLithium iron phosphateNitrogen

The invention provides a lithium iron phosphate composite and a preparation method thereof. The preparation method of the lithium iron phosphate composite comprises the following steps of weighing a certain quantity of sodium benzene sulfonate, putting the sodium benzene sulfonate in a three-necked flask, thoroughly dissolving the sodium benzene sulfonate with 100ml deionized water, weighing a proper quantity of LiFe-PO4 and 1ml pyrrole, adding the LiFe-PO4 and the pyrrole in the three-necked flask, performing ultrasonic mixing for 1-3h, adding a proper quantity of Fecl3 solution under ice bath and nitrogen protection, performing electromagnetic stirring reaction for 6h, centrifugally washing an obtained product with the deionized water and ethanol for many times sequentially, and performing vacuum drying for 12h at the temperature of 60 DEG C to obtain the PPY / LiFePO4 composite. The lithium iron phosphate composite is high in tapping density, and thus the specific volumetric capacityof the LiFePO4 is increased.

Owner:DALIAN ZINTELLIGENCE TECH

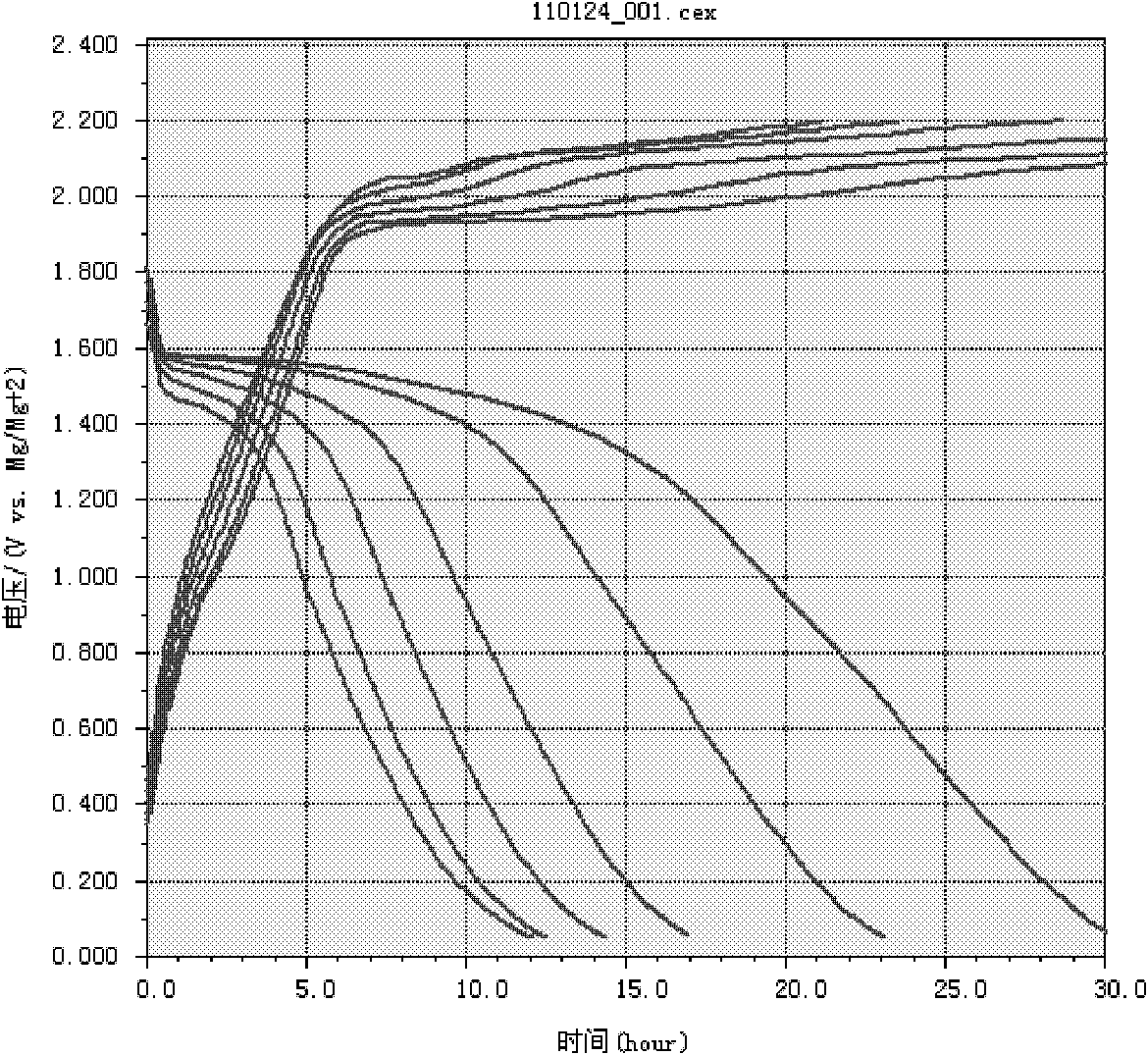

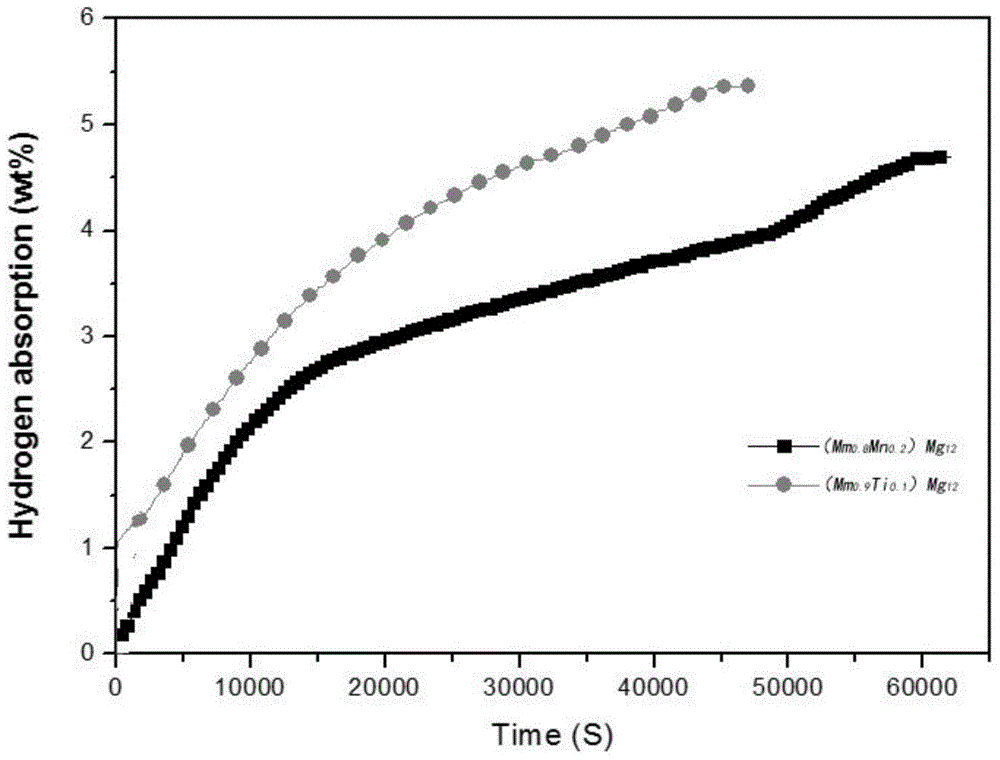

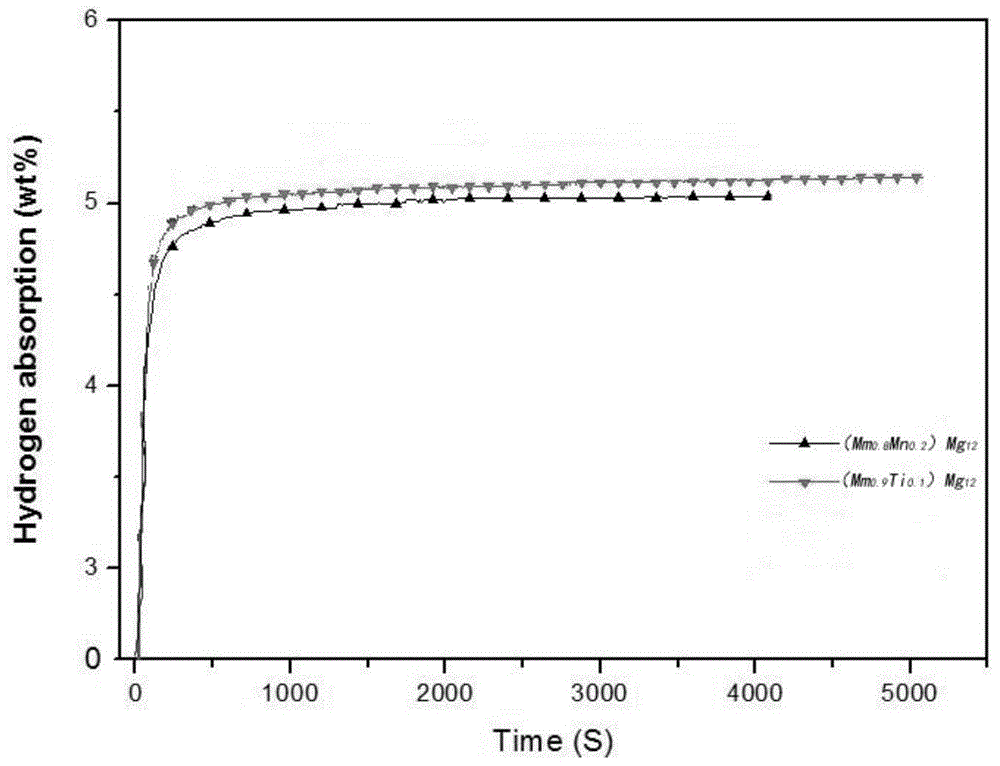

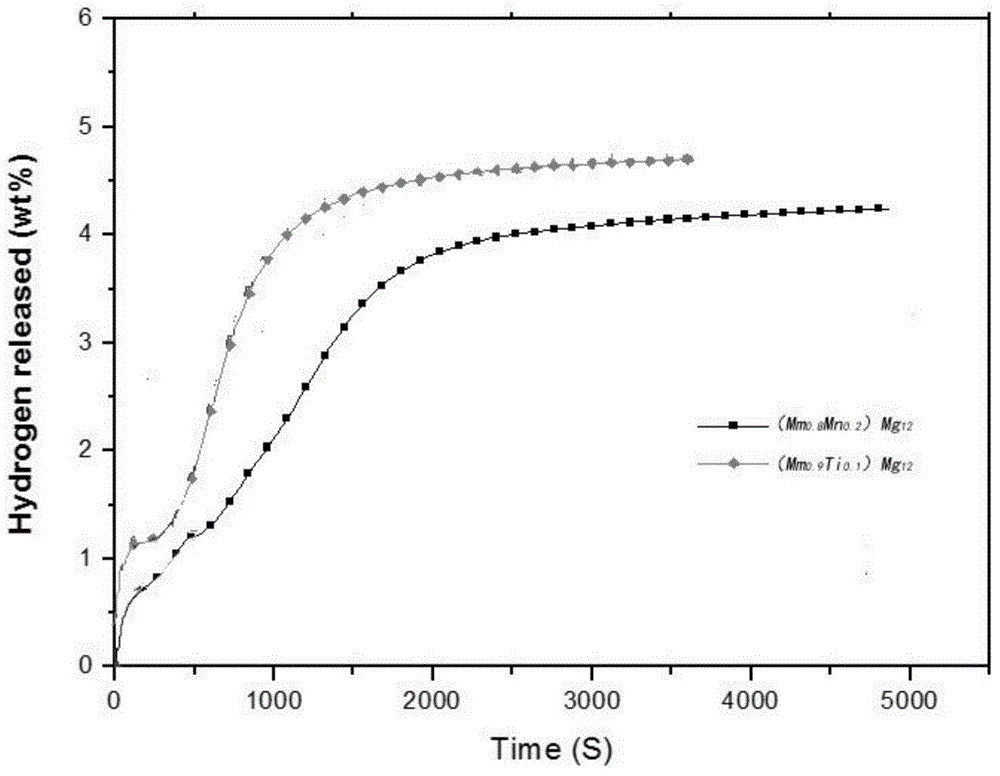

Mixed rare earth-magnesium metal hydride high-temperature heat storage material for solar heat collection power generation

InactiveCN104831138AImproved activation performanceShorten activation timeHeat-exchange elementsMagnesiumHydride

The invention provides a mixed rare earth-magnesium metal hydride high-temperature heat storage material for solar heat collection power generation, which is characterized in that the composition is (Mm[1-y]Ay)Mgx, wherein Mm is cerium-rich mixed rare earth, A is one or two or more of Mn, Ca, Ti and B, 7<=x<=17, and 0<y<=0.2. Compared with the existing pure magnesium heat storage material, the novel mixed rare earth-magnesium heat storage material has the advantages of obviously improved activation property, obviously shorter activation time, excellent hydrogen absorption dynamic property, high hydrogen absorption rate and favorable hydrogen desorption dynamic property, and can ensure free hydrogen absorption and hydrogen desorption in the use process, thereby achieving the goal of energy storage. Compared with the existing pure magnesium heat storage material, the hydrogen absorption platform pressure of the material is lower under the condition of the same temperature, the 400-DEG C maximum hydrogen absorption amount is approximate to the hydrogen absorption amount of MgH2, and the platform hysteresis quality is not high. The mixed rare earth-magnesium metal hydride high-temperature heat storage material has favorable loop reversibility.

Owner:UNIV OF SCI & TECH BEIJING

Super capacitor diaphragm by using polyoxyethylene polyoxypropylene for raising imbibition rate

InactiveCN106567190AIncrease liquid absorptionImprove thermal stabilityHybrid capacitor separatorsNon-woven fabricsFiberPolymethyl methacrylate

The invention discloses a super capacitor diaphragm by using polyoxyethylene polyoxypropylene for raising imbibition rate, and the material comprises the raw materials by parts of weight: 80-83 parts of polyvinylidene fluoride, 20-22 parts of polymethyl methacrylate, proper amount of DMF, 2-3 parts of nanometer boehmite, 0.8-1 part of silane coupling agent KH550, proper amount of deionized water, 4-5 parts of glycerin, 2-3 parts of hydrogenated siloxanes; 4-5 parts of glycidyl ether; 3-4 parts of poly (ethylene oxide, propylene oxide), proper amount of toluene, and 0.2-0.3 part of chloroplatinic acid. The prepared fiber diaphragm material has the advantages that the internal tunnel connectivity is good; the composition is uniform; the void fraction is high; a polyoxyethylene- polyoxypropylene extended chain is formed on the skeleton surface and in the tunnel; the strong interacting between the electrolyte and the groups are helpful for raising the absorbing capacity and stability of the electrolyte in the tunnel.

Owner:TONGLING CITY START ELECTRONICS MFG

Preparation method of carbon-coated potassium phosphotungstate microcubic composite

A preparation method of a carbon-coated potassium phosphotungstate microcubic composite belongs to the technical field of chemical batteries. The preparation method comprises: firstly preparing potassium phosphotungstate microcubes, then dispersing the potassium phosphotungstate microcubes in a mixed solution of ethanol and deionized water; adding ammonia water, tetraethyl orthosilicate, resorcinol and formaldehyde, carrying out a stirring reaction, and after the reaction is finished, washing and drying, and roasting the dried solid powder under nitrogen protection; next, etching the roasted solid powder in HF acid to remove silicon dioxide; and centrifuging and drying the solid phase to obtain the carbon-coated potassium phosphotungstate microcubic composite. The potassium phosphotungstate microcubes prepared by the simple preparation method and simple and convenient operations are small in size and uniform in morphology, thereby being conducive to solving the problem of difficult insertion and extraction of lithium ions in and from a microcrystalline structure. The potassium phosphotungstate microcubes is coated with carbon to obtain the composite which has high electrical conductivity and has good cyclic reversibility and stability and high specific discharge capacity in electrochemistry.

Owner:YANGZHOU UNIV

Composite electrostatic spinning fiber diaphragm material with doped zirconia and compounded polyurethane

InactiveCN106367895AIncrease liquid absorptionImprove thermal stabilityConjugated synthetic polymer artificial filamentsNon-woven fabricsFiberPolyethylene glycol

The invention discloses a composite electrostatic spinning fiber diaphragm material with doped zirconia and compounded polyurethane. The composite electrostatic spinning fiber diaphragm material is prepared from, by weight parts, 80-83 parts of polyvinylidene difluoride, 20-22 parts of polymethyl methacrylate, an appropriate amount of DMF, 2-3 parts of nano boehmite, 0.8-1 part of silane coupling agent KH550, an appropriate amount of deionized water, 2-3 parts of graphite oxide, 2-3 parts of nano zirconia, 3-4 parts of polyethylene glycol, 0.8-1 part of polyvinylpyrrolidone and 2-3 parts of polyurethane. Nano zirconia, graphite oxide and polyurethane and the like are compounded and added into spinning solution, a fiber membrane is obtained through electrostatic spinning, the composite electrostatic spinning fiber diaphragm material has good breaking strength and electrochemical stability, and the hydrophilicity and permeability of the fiber membrane are greatly improved. The fiber membrane can serve as a capacitor diaphragm material, is safe and hydrophilic, has wettability, is high in liquid absorption rate, can meet the high-performance capacitor requirements, and is good in stability.

Owner:TONGLING CITY START ELECTRONICS MFG

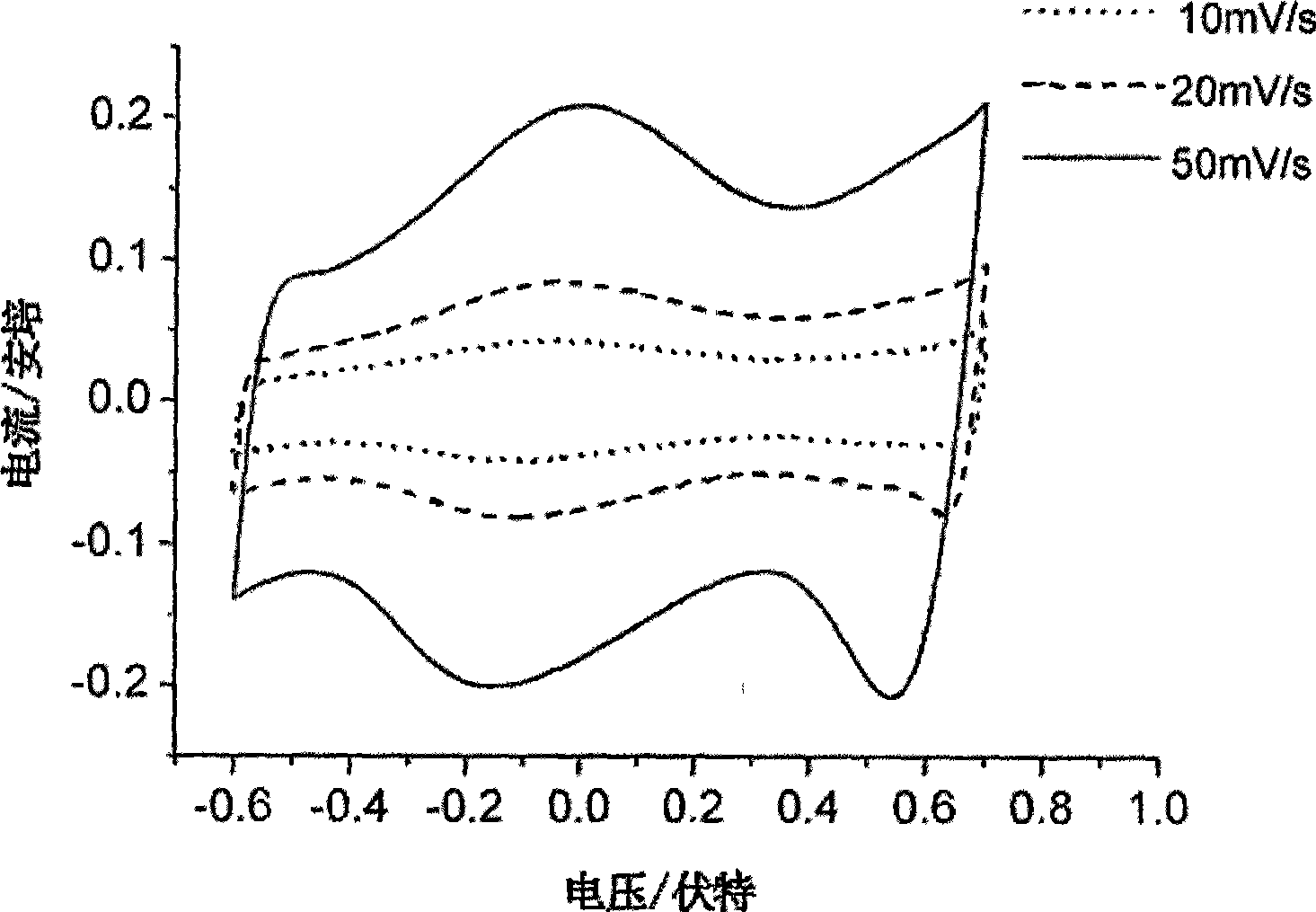

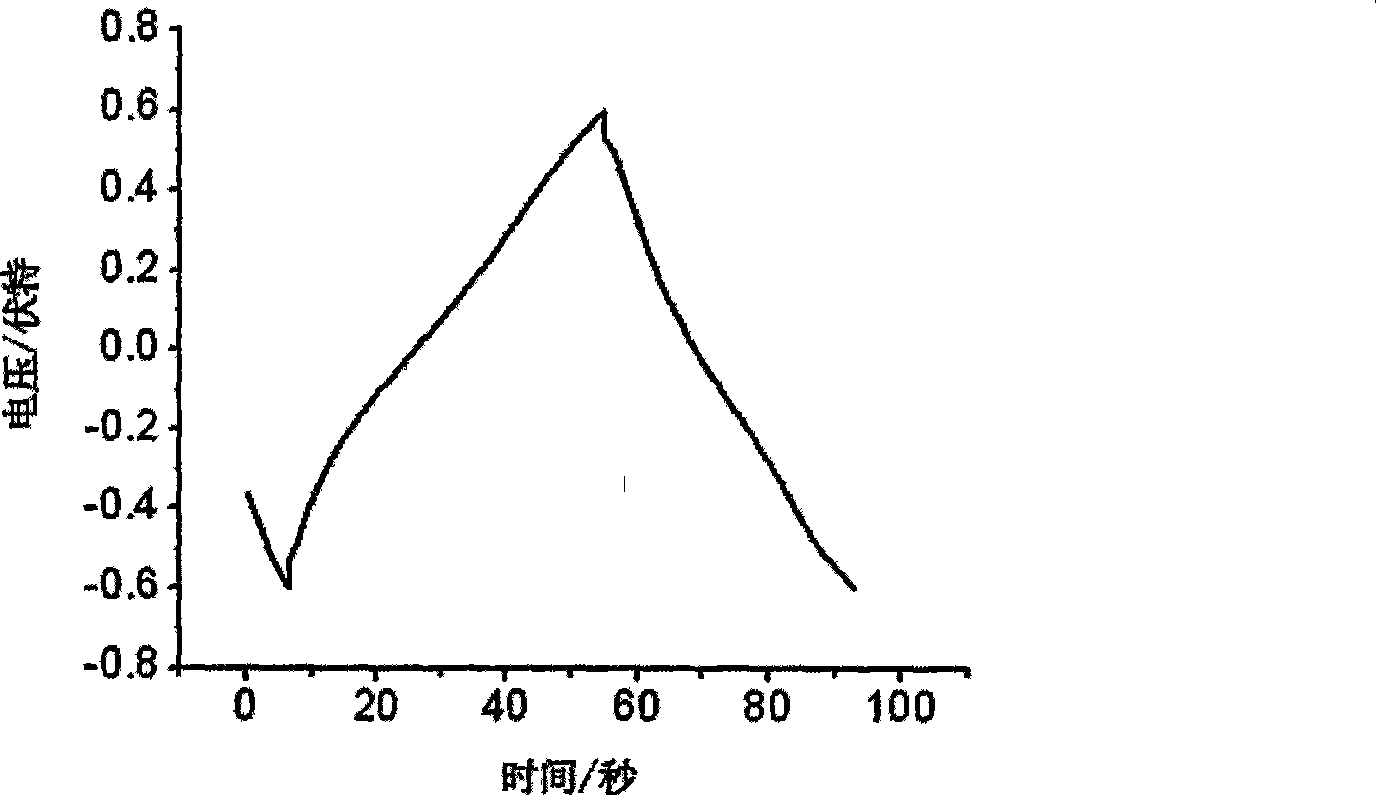

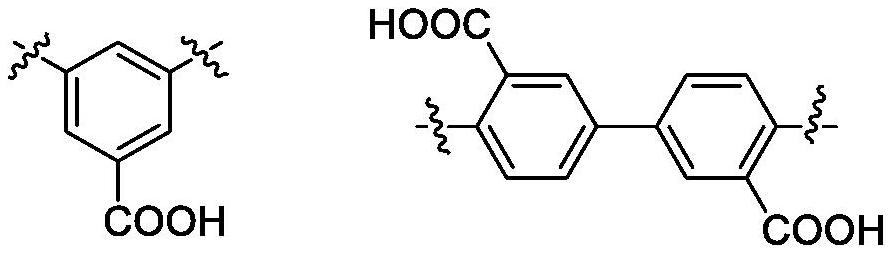

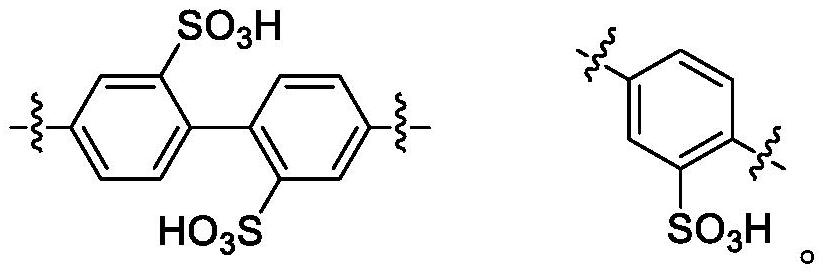

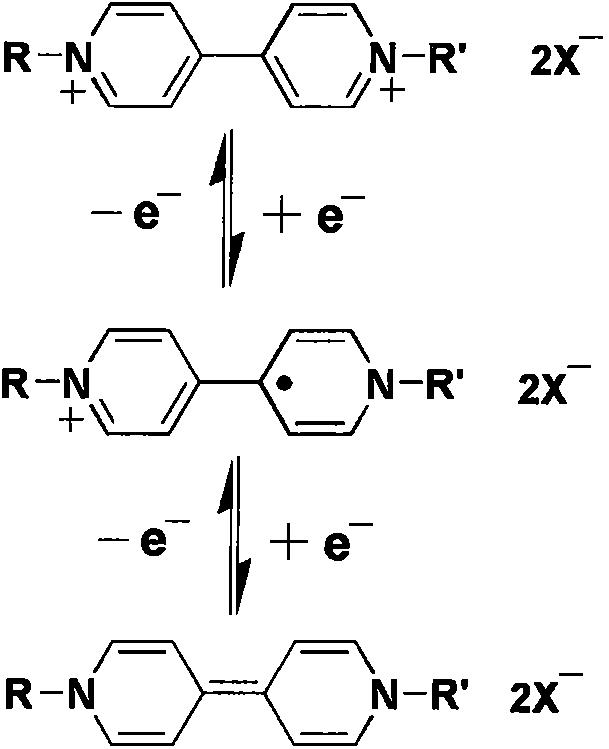

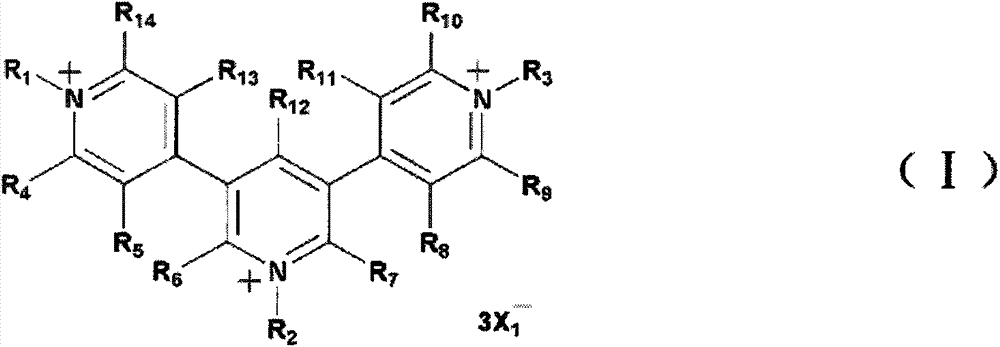

Cathodic electrochromic compound, and relevant medium and device thereof

InactiveCN106916582AGood cycle reversibilityImprove stabilityOrganic chemistryTenebresent compositionsChemistryElectricity

The invention discloses a cathodic electrochromic compound, and a relevant medium and a device thereof. The device is an electrochromic device containing the electrochromic medium, and the electrochromic medium comprises the cathodic electrochromic compound containing three or four quaternized pyridine rings. The voltage applied to the electrochromic device produced in the invention is adjusted to realize change among various colors.

Owner:NINGBO MI RUO ELECTRONICS TECH CO LTD

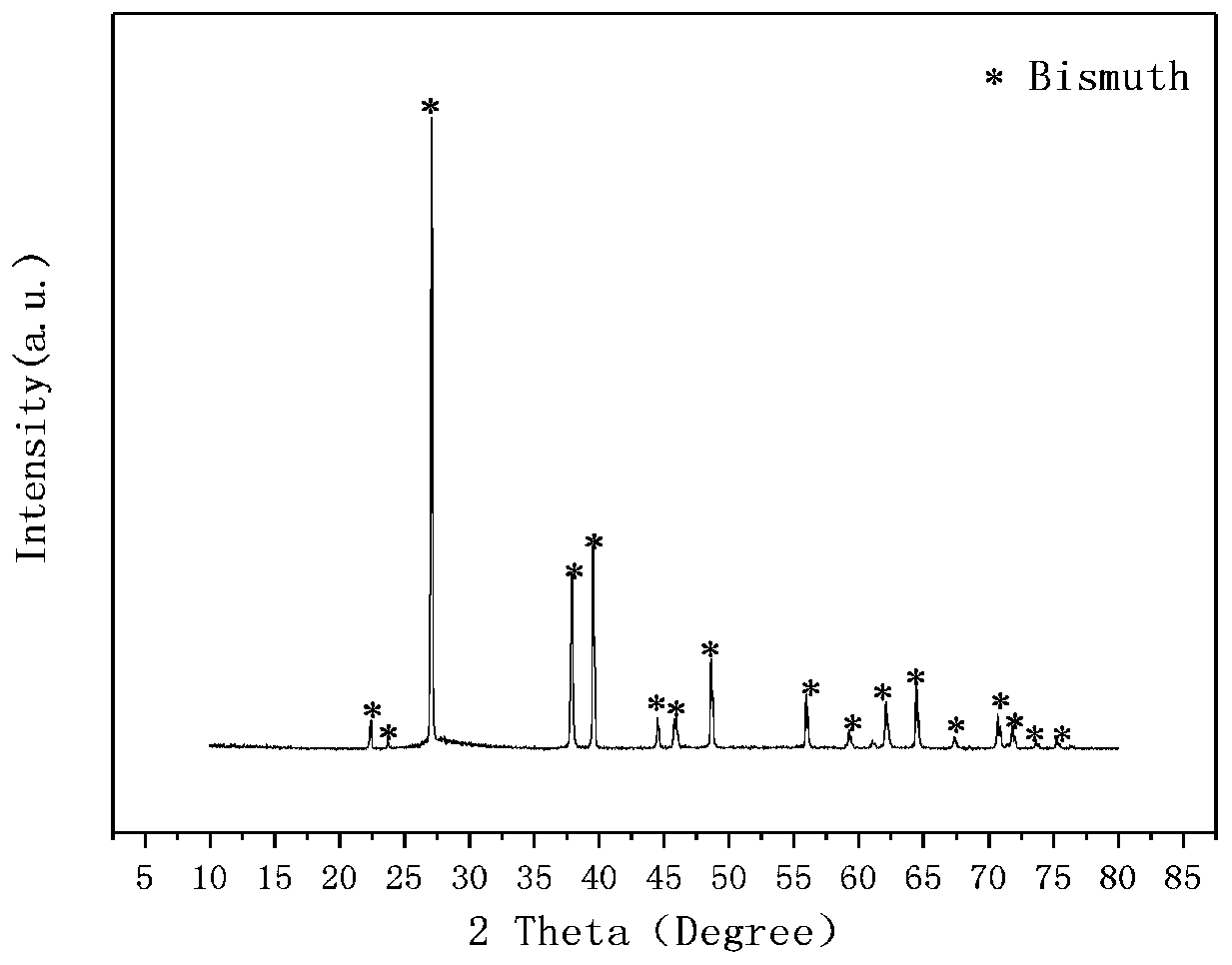

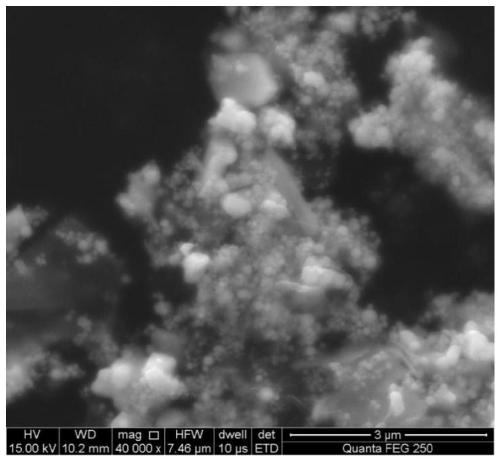

C@Bi/rGO electro-adsorption composite active material, preparation and applications thereof

ActiveCN110357221AImprove adsorption capacityGood choiceDispersed particle separationWater/sewage treatment apparatusHalogenWastewater

The invention belongs to the field of wastewater treatment, and specifically discloses a C@Bi / rGO electro-adsorption composite active material, which comprises reduced graphene oxide and carbon-coatedbismuth elemental particles compounded on the surface of the reduced graphene oxide in situ. The invention further discloses preparation and applications of the composite active material. The invention further relates to an electrode compounded with the C@Bi / rGO, and preparation thereof, and applications in brine. According to the present invention, the composite active material can effectively solve the problems of poor stability, poor reversibility and the like of the material, and can effectively improve the high-adsorption capacity to halogens, excellent circulation stability and excellent regeneration stability in electro-adsorption of halogens.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com