Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Effect of diffusion strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength weather resisting steel with Cu2-xS dispersed precipitates and manufacturing method thereof

ActiveCN101928894AReduce steelmaking costsInhibition of segregationTemperature control deviceManufacturing convertersChemical compositionHigh intensity

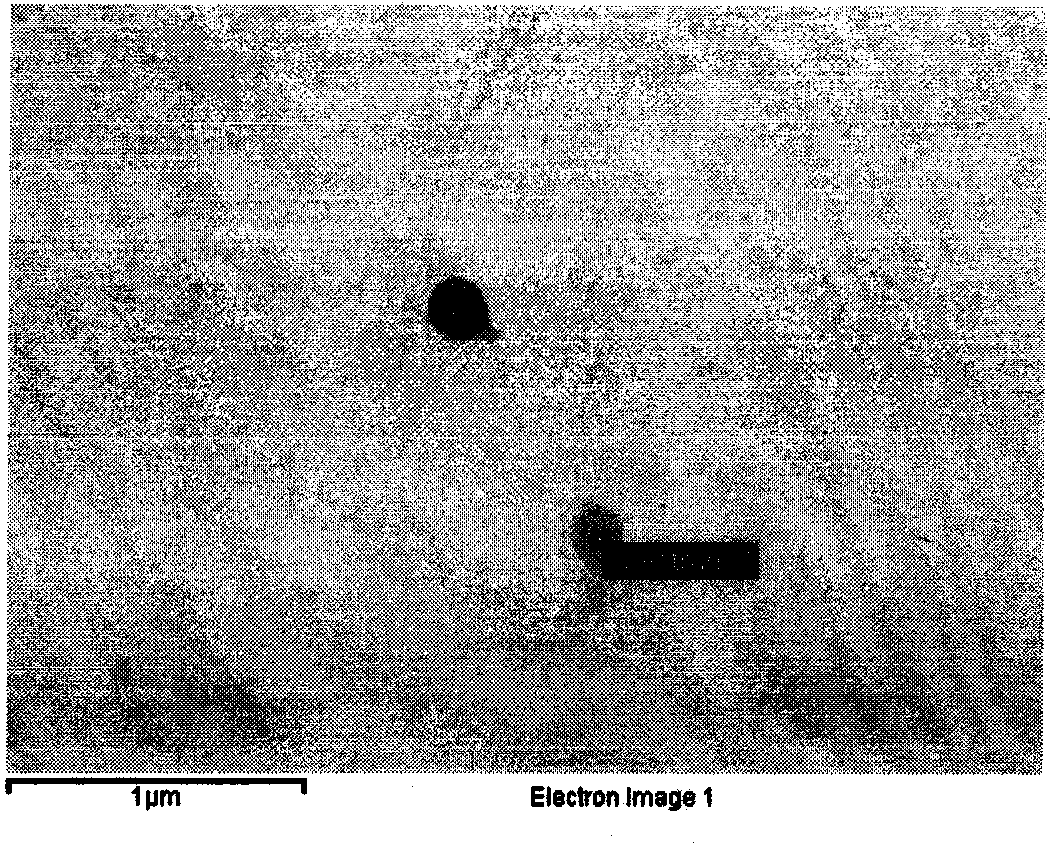

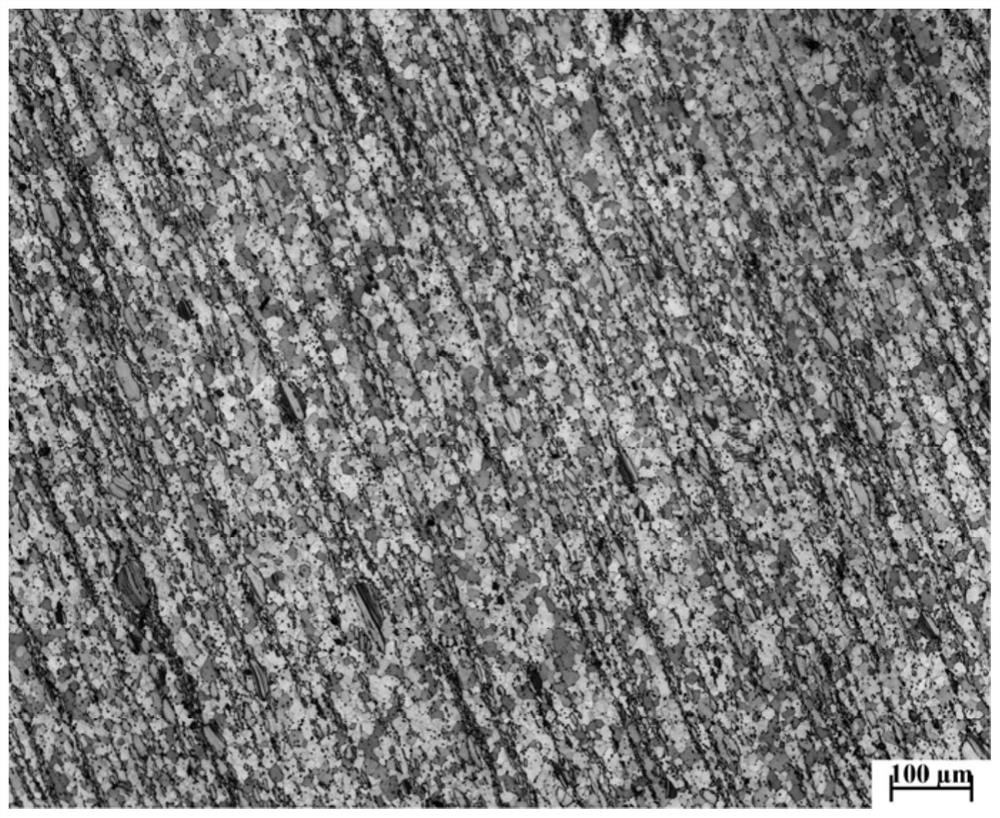

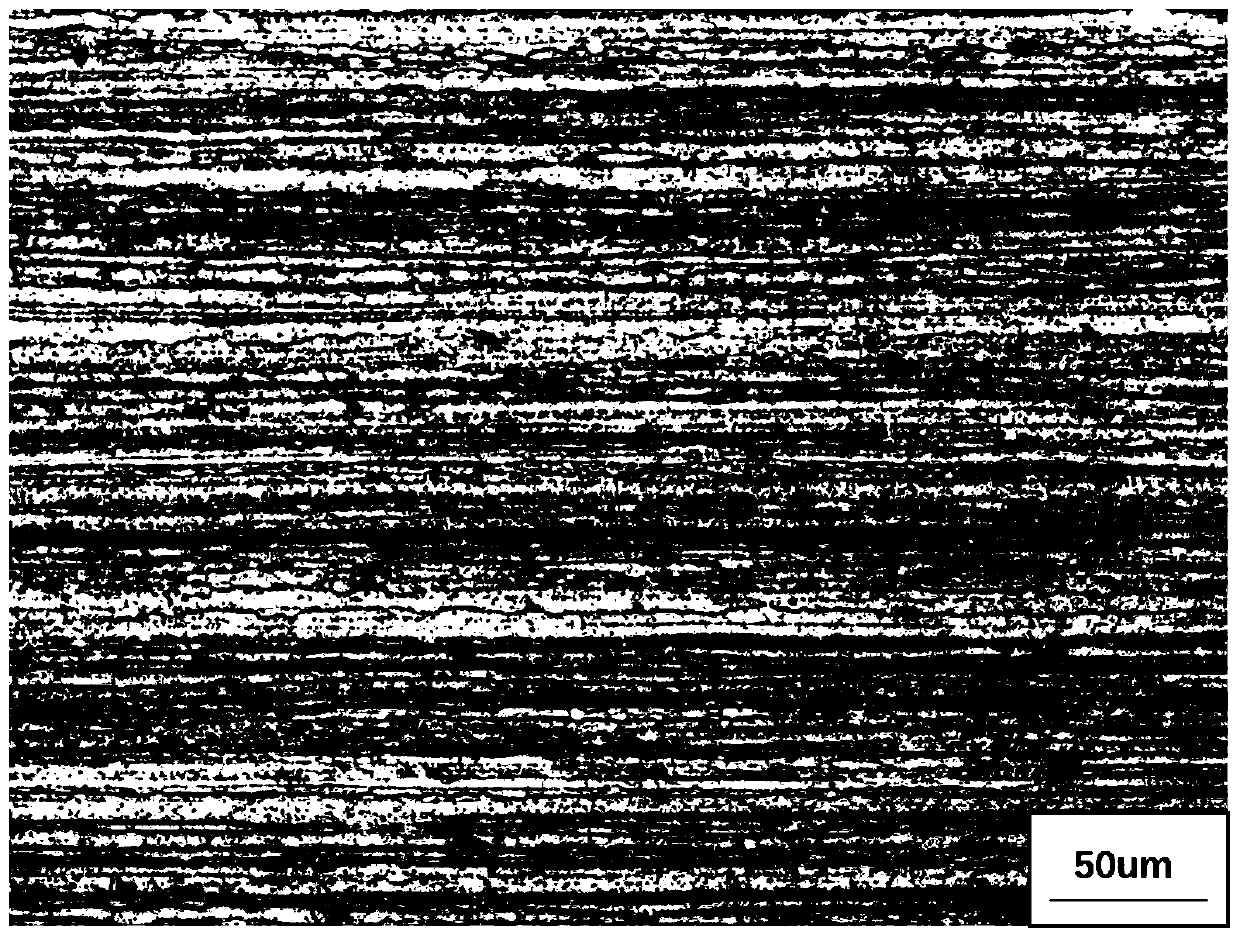

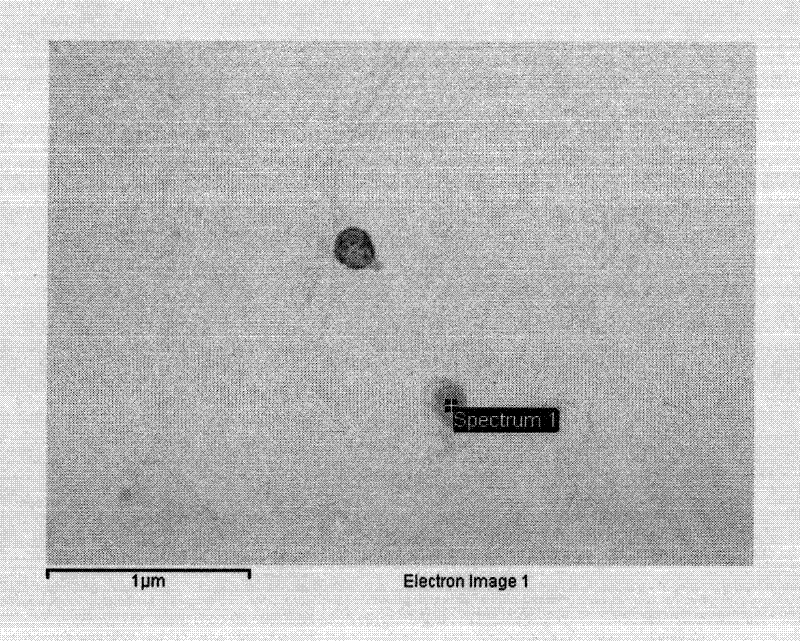

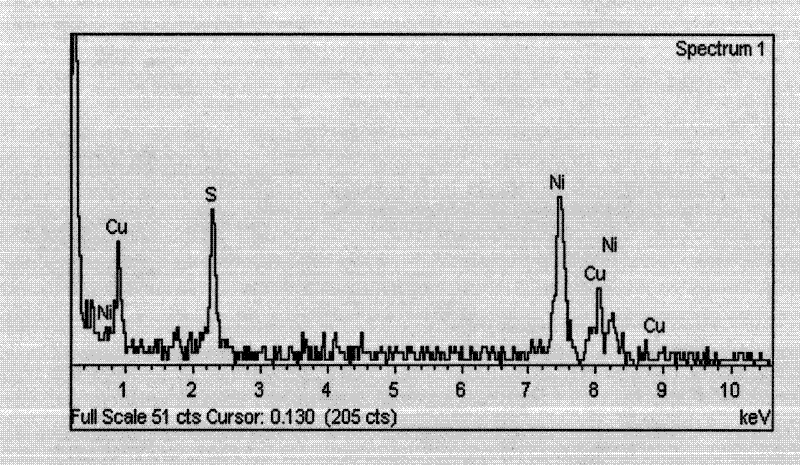

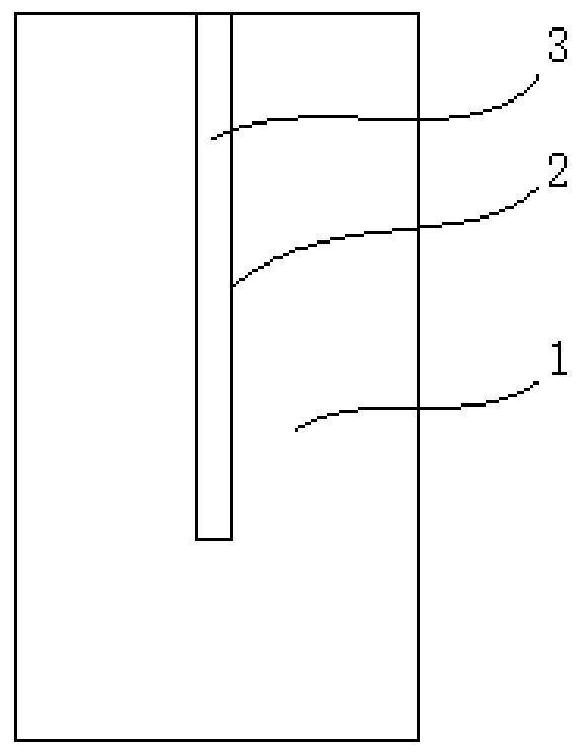

The invention relates to high-strength weather resisting steel with Cu2-xS dispersed precipitates, which comprises the following chemical components in percentage by weight: 0.04-0.08% of C, 0.20-0.40% of Si, 0.4-1.0% of Mn, 0.03-0.12% of P, not more than 0.2% of S, 0.01-0.06% of Al, 0.20-0.80% of Cu, 0.40-0.6% of Cr, 0.12-0.40% of Ni, 0.001-0.006% of Ca and the balance of Fe and inevitable impurities. The welding cold crack sensitivity coefficient Pcm is not more than 0.18%. A manufacturing method comprises the following steps of: acceleratedly cooling both sides of a cast belt formed by continuous casting by using a gas and adopting a thin belt continuous casting production technology, wherein the cooling rate is 150-200 DEG C / s; performing the entire double-roller continuous casting process in a closed chamber filled with protective atmosphere; and arranging one to two stands for online hot rolling, wherein the thickness of a finished steel belt reaches 0.6-2 mm. The desulfurization procedure in steel making process can be omitted, and the steel making cost is reduced. The segregation of copper elements is inhibited, meanwhile, a large quantity of dispersed Cu2-xS precipitates can be formed to achieve the effect of dispersion strengthening.

Owner:BAOSHAN IRON & STEEL CO LTD

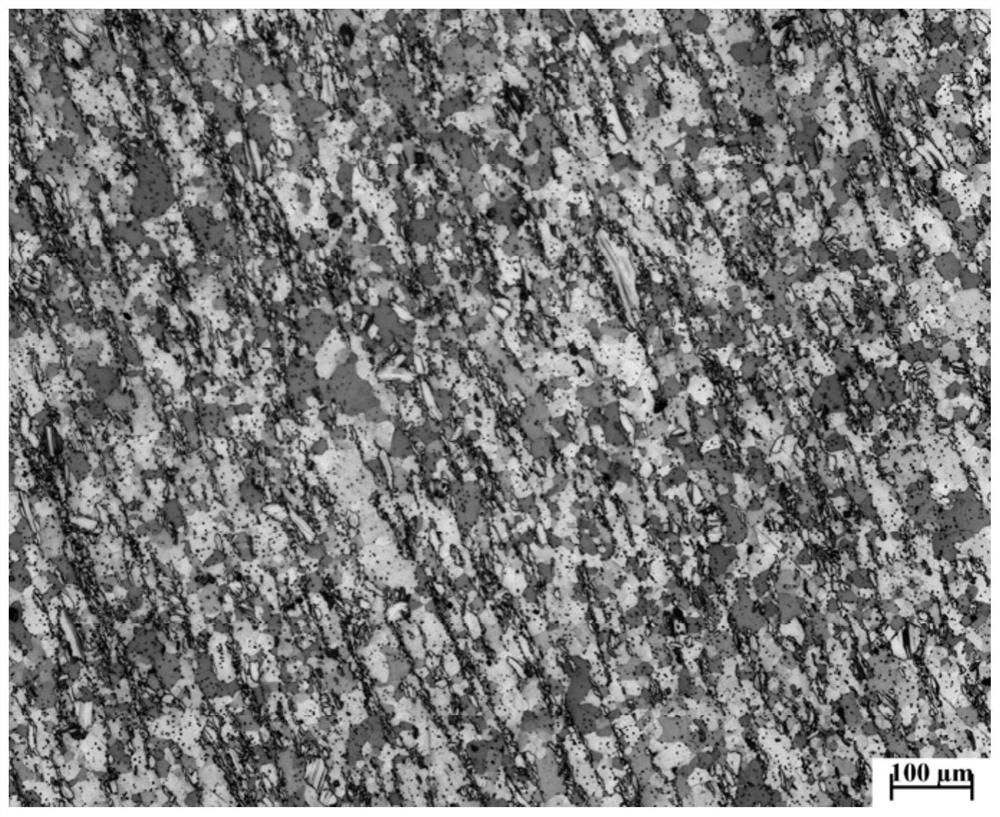

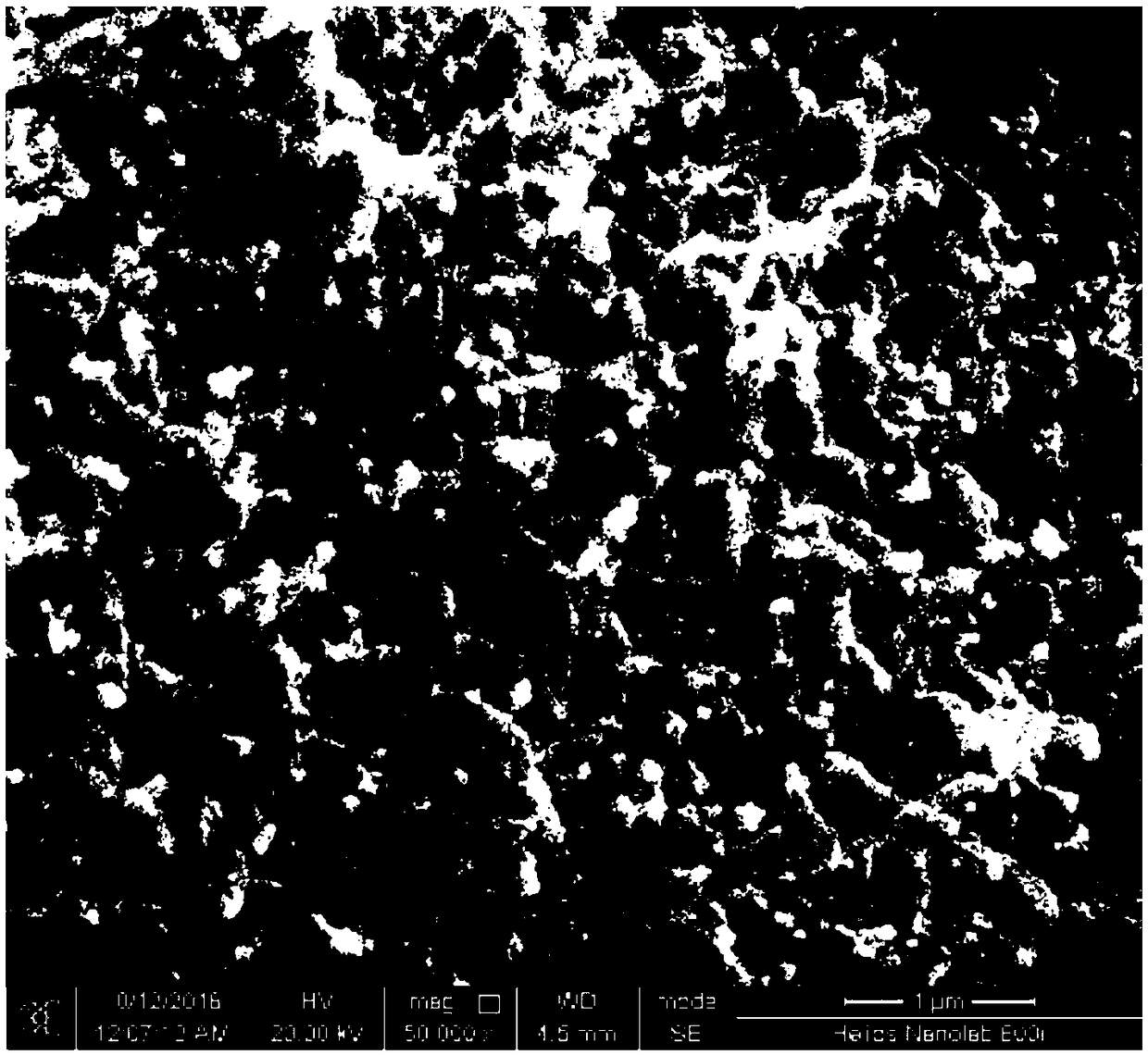

Multi-element composite reinforced molybdenum alloy and preparation method thereof

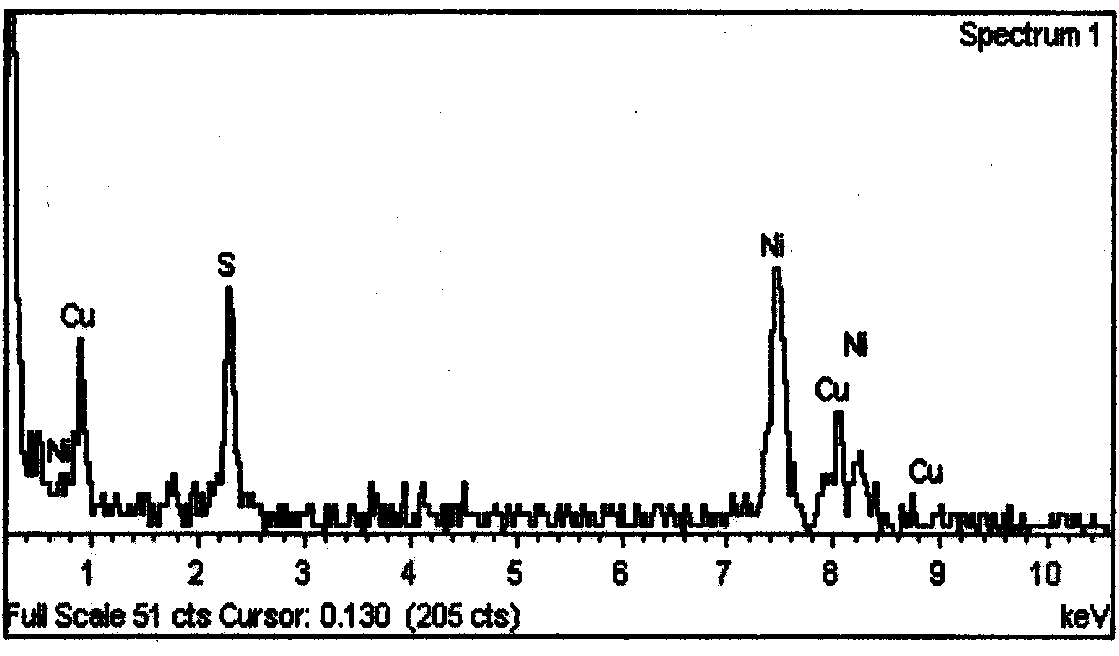

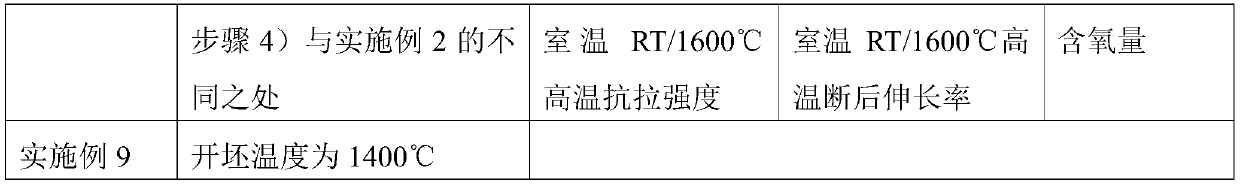

The invention relates to a preparation method of a multi-element composite reinforced molybdenum alloy. The preparation method sequentially comprises the following steps that the Mo source, the Ti source, the Zr source, the C source, the Hf source and the Re source are weighed according to a certain weight ratio, the raw materials are prepared and mixed to obtain the uniform molybdenum alloy powder; the molybdenum alloy powder is placed in a mold cavity of a mold and is subjected to compression forming treatment to obtain a forming blank; high-temperature sintering treatment on the formed blank is carried out under vacuum to obtain a sintered blank; forging or rolling deformation processing is carried out on the sintered blank to obtain a forged blank or a rolled blank; and annealing heattreatment on the forged blank or the rolled blank is carried out to obtain the molybdenum alloy plate or a rod material. According to the preparation method, the steps and the process conditions are reasonable in design and good in using effect, the prepared molybdenum alloy material has excellent performance, the tensile strength Ra is greater than or equal to 200 MPa at a high temperature of 1600 DEG C, the percentage elongation after fracture is larger than or equal to 20%, and the oxygen content is less than or equal to 100 ppm.

Owner:安泰天龙钨钼科技有限公司 +1

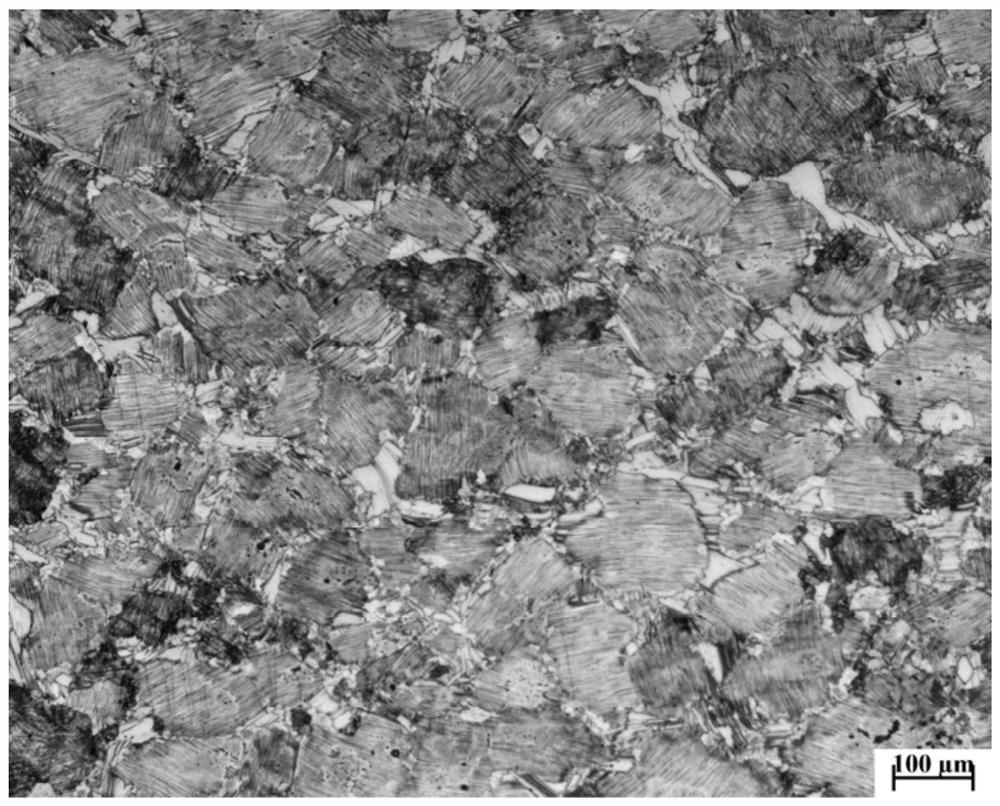

High-toughness rare earth heat-resistant magnesium alloy and preparation method thereof

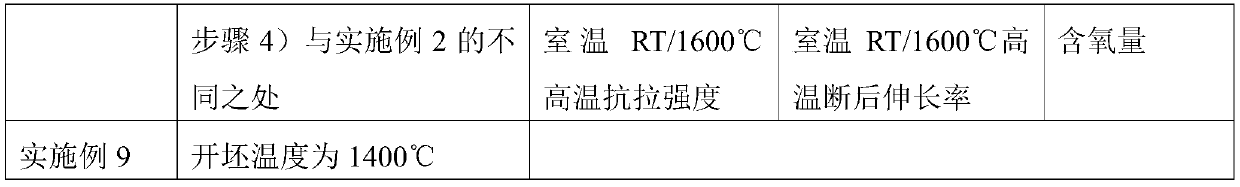

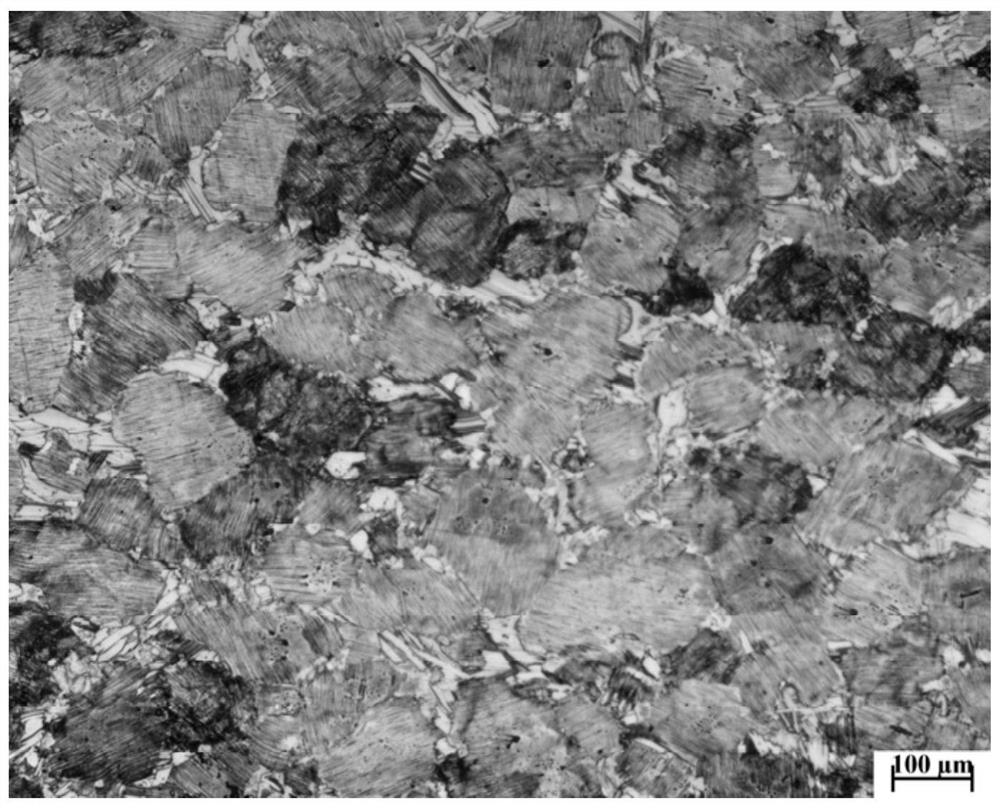

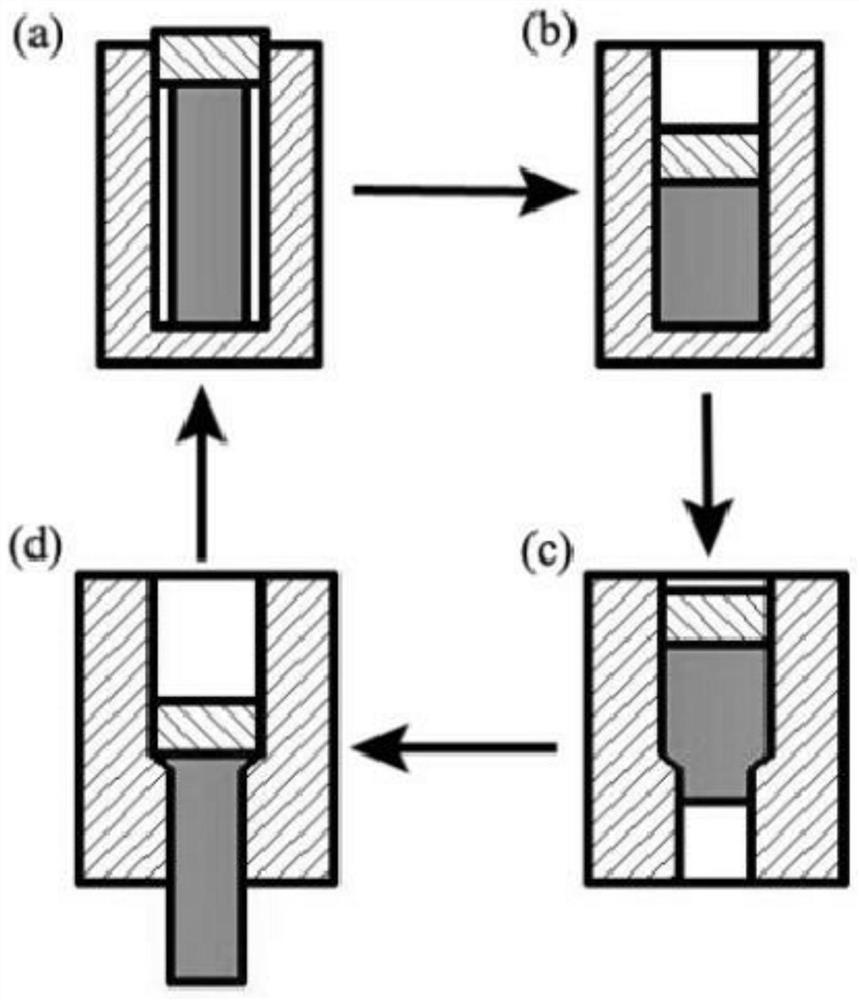

The invention discloses a high-toughness rare earth heat-resistant magnesium alloy. The high-toughness rare earth heat-resistant magnesium alloy comprises the following chemical components of, in percentage by mass, 8.0%-10.8% of Gd, 3.1%-4.0% of Y, 1.8%-2.2% of Zn, 0.4%-0.5% of Zr and the balance magnesium and inevitable impurity elements, the invention further discloses a preparation method of the high-toughness rare earth heat-resistant magnesium alloy, the preparation method sequentially comprises the following steps of (1) preparing a magnesium alloy casting rod; (2) homogenization of the bar, specifically, heating a magnesium alloy bar and preserving heat by adopting a grading homogenization system, then heating and reheating, preserving heat and carrying out homogenization treatment; (3) upsetting-extruding composite deformation, specifically, putting the bar into a heated upsetting-extruding composite die, and obtaining a high-toughness deformation state rare earth heat-resistant magnesium alloy material after multiple times of cyclic upsetting-extruding. (4) solid solution and aging treatment, specifically, enabling heat treatment to adopt solid solution and aging treatment and heat preservation, adopting hot water quenching after discharging, and after cooling to room temperature, conducting aging and preserving heat. The magnesium alloy prepared by the solution is good in quality, and has more obvious high tensile strength and high elongation compared with common magnesium alloys in the market.

Owner:ZHONGBEI UNIV

Wear-resisting and high-hardness flux core wire

InactiveCN107252994AHigh hardnessHigh strengthWelding/cutting media/materialsSoldering mediaSilicon alloyRare earth

The invention discloses a wear-resisting and high-hardness flux core wire. The wear-resisting and high-hardness flux core wire is composed of a flux core and a low-carbon cold-rolling steel tape sheath wrapped on the outer side of the flux core. The flux core comprises, by weight, 20-25 parts of low-carbon ferrochromium, 1.5-3 parts of titanium powder, 1-2 parts of nickel powder, 5-8 parts of calcium-silicon alloys, 2-4 parts of magnesium-aluminum alloys, 3-5 parts of electrolytic manganese, 1-2 parts of ferromolybdenum, 2.5-4 parts of ferroniobium, 1-2 parts of ferrovanadium, 3-5 parts of rare earth iron alloys, 3-5 parts of carbonate, 3-4 parts of graphite, 120-150 parts of iron powder, 0.5-1.5 parts of tungsten powder and 2-4 parts of calcium fluoride. The wear-resisting and high-hardness flux core wire has good welding performance, deposited metal tissue is compact, air holes and cracks are avoided, combination with base metal is good, performance is stable, and deposited metal has good wear resistance, corrosion resistance, high hardness and other performance.

Owner:天长市通联焊业有限公司

High-strength Mg-Gd-Y-Zn-Zr rare-earth magnesium alloy and preparation method thereof

The invention discloses a high-strength Mg-Gd-Y-Zn-Zr rare-earth magnesium alloy. The high-strength Mg-Gd-Y-Zn-Zr rare-earth magnesium alloy comprises the following chemical components in percentage by mass: 10.8%-13.6% of Gd, 4.0%-4.6% of Y, 1.8%- 2.2% of Zn, 0.4%-0.6% of Zr and the balance of magnesium and inevitable impurity elements. The invention further discloses a preparation method of the high-strength Mg-Gd-Y-Zn-Zr rare-earth magnesium alloy. The preparation method sequentially comprises the following steps: (1) preparing a magnesium alloy cast bar; (2) homogenization of the bar: heating the magnesium alloy bar and preserving heat by adopting a grading homogenization system, then heating and reheating, preserving heat and carrying out homogenization treatment; and (3) upsetting-extruding composite deformation: putting the bar into a heated upsetting-extruding composite die, and obtaining a high-toughness deformed-state heat-resistant rare-earth magnesium alloy material after multiple times of circulating upsetting-extruding; (4) solid solution and aging treatment: adopting solid solution and aging treatment for heat treatment, and preserving heat, and quenching by adopting hot water after discharging; and after cooling to room temperature, aging and preserving heat. The magnesium alloy prepared through the preparation method is high in quality, and particularly can keep high mechanical performance at a temperature of 300 DEG C.

Owner:ZHONGBEI UNIV

Method for assisting brazing by carbon nanotube reinforced type three-dimensional middle layer

ActiveCN106346100AReduce residual stressHigh joint strengthSoldering apparatusChemical vaporsBrazing

The invention discloses a method for assisting brazing by a carbon nanotube reinforced type three-dimensional middle layer, and relates to a method for brazing ceramic and metal, which aims at solving the problems of larger residual stress and insufficient high-temperature property in the existing ceramic and metal brazing connection process. The method comprises the following steps of 1, preparing soaked foam metal; 2, putting the soaked foam metal into a plasma reinforced type chemical vapor depositing vacuum device, and increasing temperature at certain pressure and hydrogen atmosphere; 3, preparing nanotube reinforced type foam metal; 4, preparing surface impurity-removed metal, surface impurity-removed brazing material foil and surface impurity-removed ceramic; 5, sequentially overlapping the surface impurity-removed to-be-brazed metal, the carbon nanotube reinforced type foam metal, the surface impurity-removed brazing material foil and the surface impurity-removed ceramic, so as to obtain a to-be-brazed part; brazing the to-be-brazed part, and cooling to room temperature. The method disclosed by the invention is used for assisting the brazing by the carbon nanotube reinforced type three-dimensional middle layer.

Owner:哈尔滨工大特种连接高新科技发展股份有限公司

Novel nano-particle reinforced active tungsten argon arc welding method

InactiveCN103008845AImprove ultimate tensile strengthPromote nucleation and crystallizationArc welding apparatusWelding/cutting media/materialsAcetoneCrystallite

The invention discloses a novel nano-particle reinforced active tungsten argon arc welding method, and belongs to the active welding technology. The method is characterized by comprising the following steps of: before welding, mixing oxide activator powder and nano ceramic particles in proportion, and then adding acetone into the mixture so that the mixture is in pasty; then uniformly coating the pasty activator on the surface of samples by a flat brush, wherein the coating width is about 40mm, and the average coating amount is 5.mg.cm<-2>; and carrying out tungsten argon arc welding after the acetone is volatilized. The external waviness of the welding joints obtained by adopting the nano-particle reinforced active tungsten argon arc welding is smooth; compared with the welding joints obtained by the traditional tungsten argon arc welding, the fusion depth is increased by 110%; the crystal particles of the welding joint fusion region are obviously reduced compared with the active tungsten argon arc welding; and the tensile property of the welding joint is improved by 64.6% compared with the active tungsten argon arc welding. The problems that the tungsten argon arc welding fusion depth of magnesium alloy is shallow and the crystal particles of the active tungsten argon arc welding are thick are solved.

Owner:CHONGQING UNIV

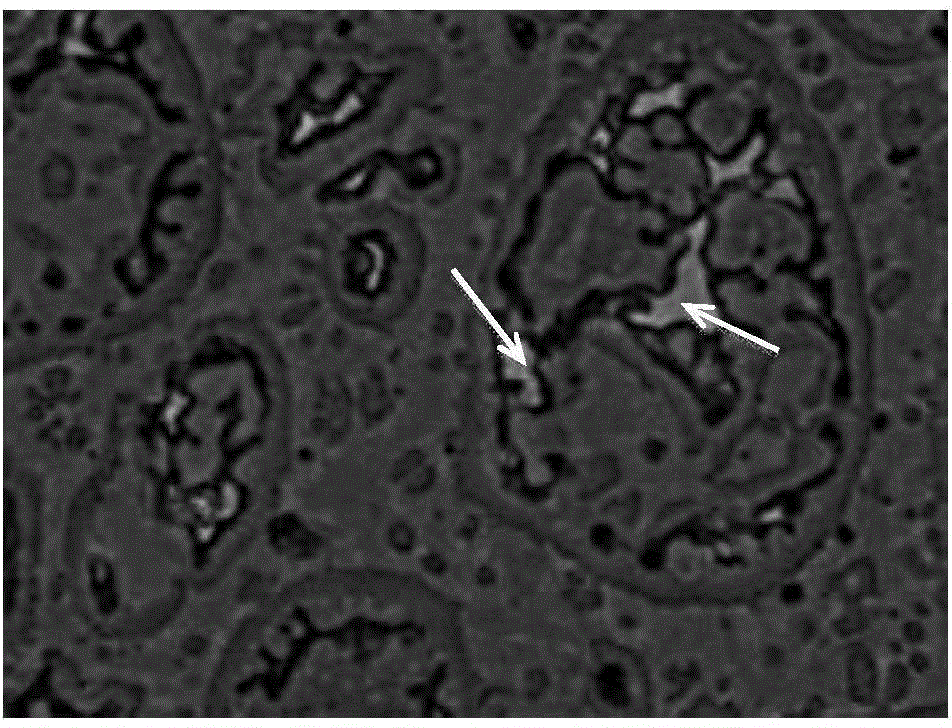

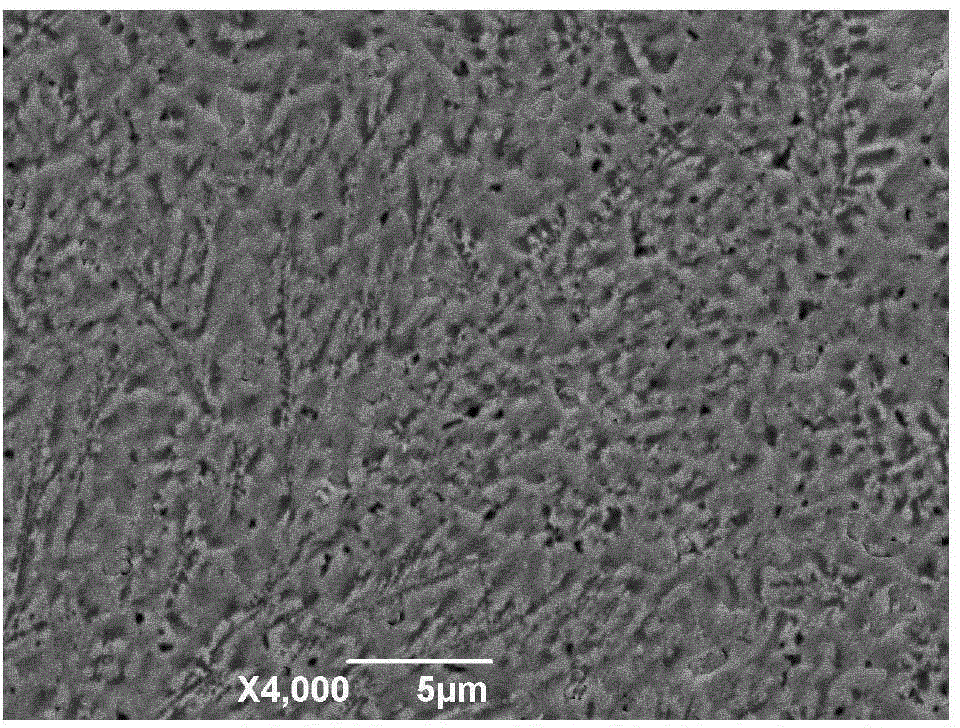

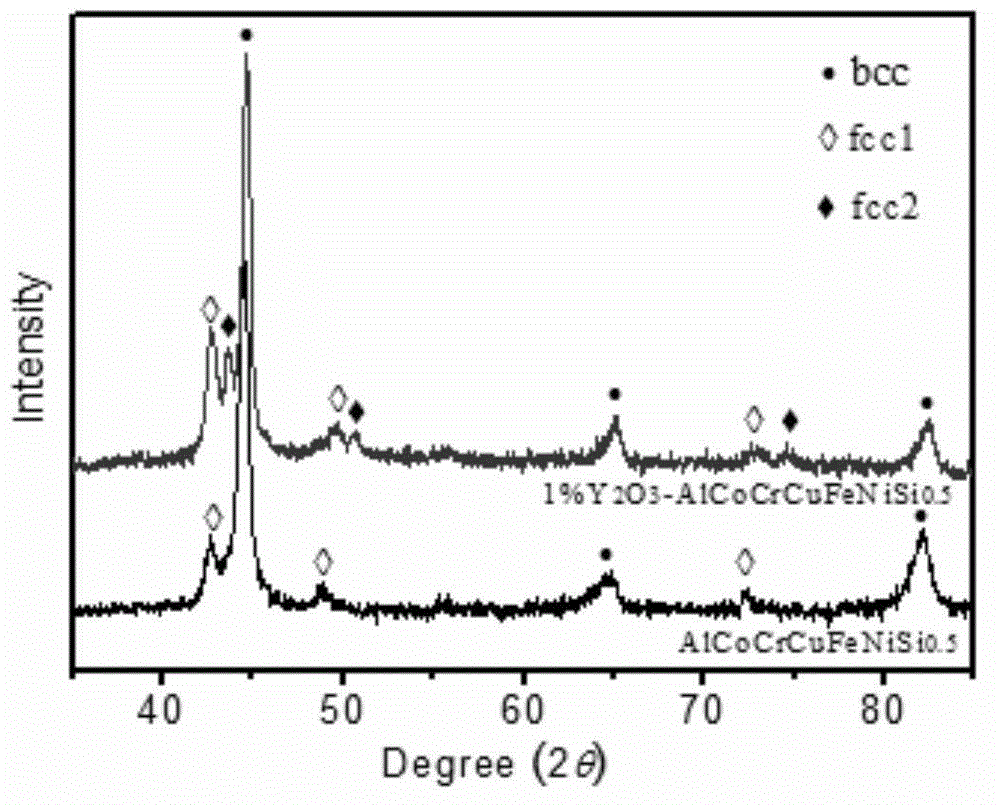

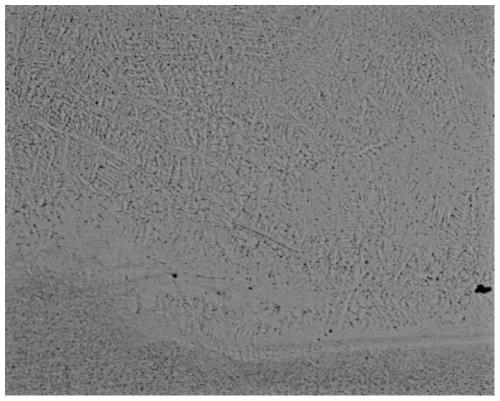

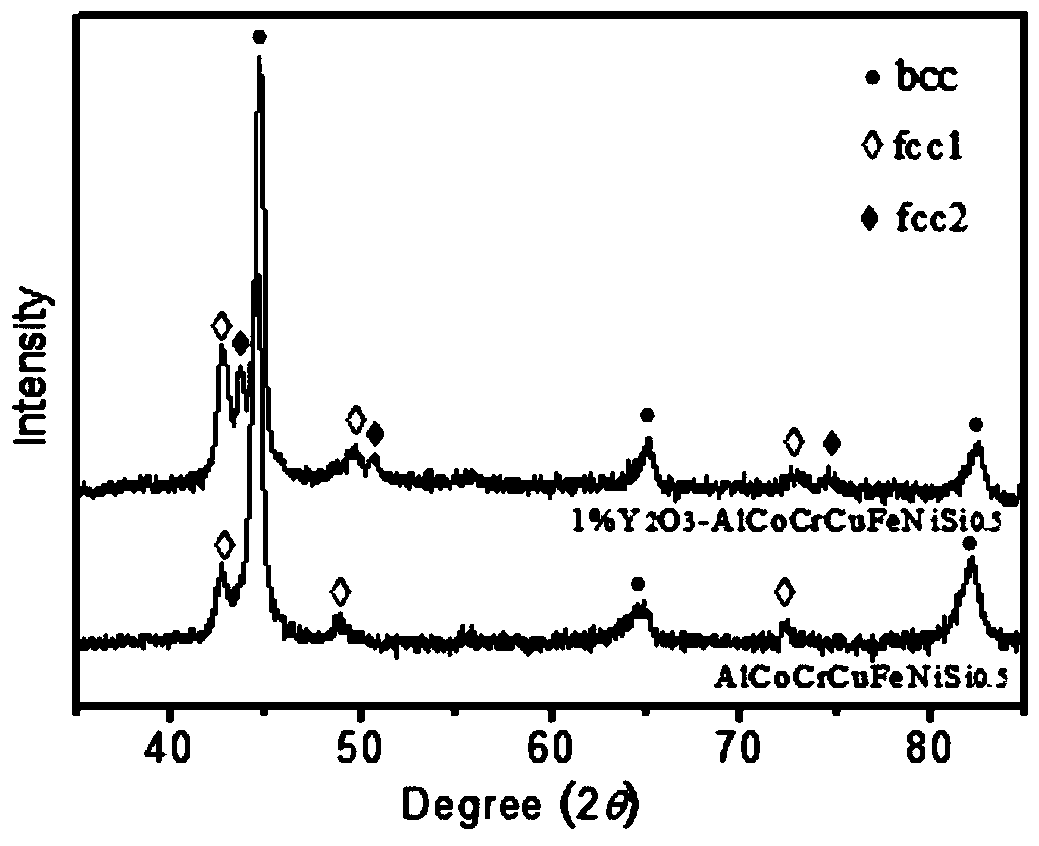

Cu-containing high-entropy alloy coating with liquid phase separation tissue and preparation method thereof

ActiveCN104911581AOptimize the preparation processChange the single-phase structureMetallic material coating processesHigh entropy alloysSingle phase

The invention discloses a Cu-containing high-entropy alloy coating with liquid phase separation tissue and a preparation method thereof, and belongs to the field of alloy material design. According to the invention, a small amount of nano Y2O3 (mass fraction of 0.5-3%) is added to the Cu-containing high-entropy alloy composition, and can promote laser cladding of the Cu-containing high-entropy alloy coating and formation of liquid phase separation tissue. The Cu-containing high-entropy alloy is composed of five or more metallic or non-metallic elements, and the compulsory Cu element accounts for 15-35% of the total moles of the high-entropy alloy composition. The nano Y2O3 has a large surface effect and small size effect, can promote separation of liquid copper from the alloy melt in the laser cladding of Cu-containing high-entropy alloy coating; and a large number of copper-rich particles in dispersed distribution grow in situ on the coating solidified matrix tissue, thus changing the single-phase structure of the coating, and providing a novel method for designing complex phase tissue and expanding capability of the high-entropy alloy by liquid phase separation.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

TiAl-based abrasion-resistant laser cladding coating powder and preparation method thereof

InactiveCN109750290AGood macroscopic appearanceHigh hardnessMetallic material coating processesHardnessTitanium alloy

The invention relates to TiAl-based abrasion-resistant laser cladding coating powder and a preparation method thereof, and belongs to the technical field of laser cladding metal material surface modification. The TiAl-based abrasion-resistant laser cladding coating powder is composed of the following components of, by mass, 60.5%-86.5% of TiAl intermediate alloy powder, 10%-20% of Si powder, 1%-10% of HfO2 powder, 1%-5% of La2O3 powder, 1%-3% of B powder and 0.5%-1.5% of CeO2 powder. A coating which has high hardness and high abrasion resistance and is metallurgically bonded with a substrate is prepared on the titanium alloy substrate.

Owner:KUNMING UNIV OF SCI & TECH

Moderate-temperature Zr-based brazing filler metal special for Ti2AlNb-based alloy identical or different material brazing and preparation method and brazing process of brazing filler metal

ActiveCN111702281AImprove wettabilityImprove liquidityWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalRaw material

The invention belongs to the field of welding and particularly relates to moderate-temperature Zr-based brazing filler metal special for Ti2AlNb-based alloy identical or different material brazing anda preparation method and a brazing process of the brazing filler metal. According to weight percentage, the brazing filler metal comprises 5%-30% of Fe, 1%-15% of Nb or 1%-20% of Cu, <=5% of oligoelements including one or two or more of Al, B, Co, Cr, Mn, Mg, Ni, Ag, and Zn, <=2% of microelements including one or two or more of Ti, Hf, V, Ta, Mo, W, Au, Si, Sn, Pd and Ga, and the balance of Zr elements and unavoidable impurity elements. The preparation method of the brazing filler metal comprises the steps that firstly, raw materials are weighed; secondly, mother alloy of the brazing filler metal is smelted; and thirdly, the smelted mother alloy is subjected to quenching melt-spinning, and then the brazing filler metal is obtained. The brazing filler metal is used for brazing according tothe brazing process of 960 DEG C to 1,030 DEG C and 0-120min. Compared with existing brazing filler metal, the prepared brazing filler metal has an appropriate melting point, excellent wettability and high-temperature mechanical properties, and brazing filler metal preparation and the brazing process are simple.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

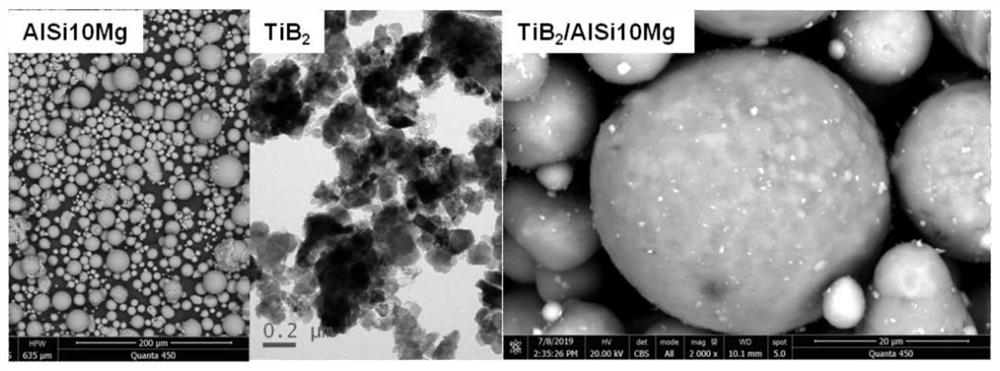

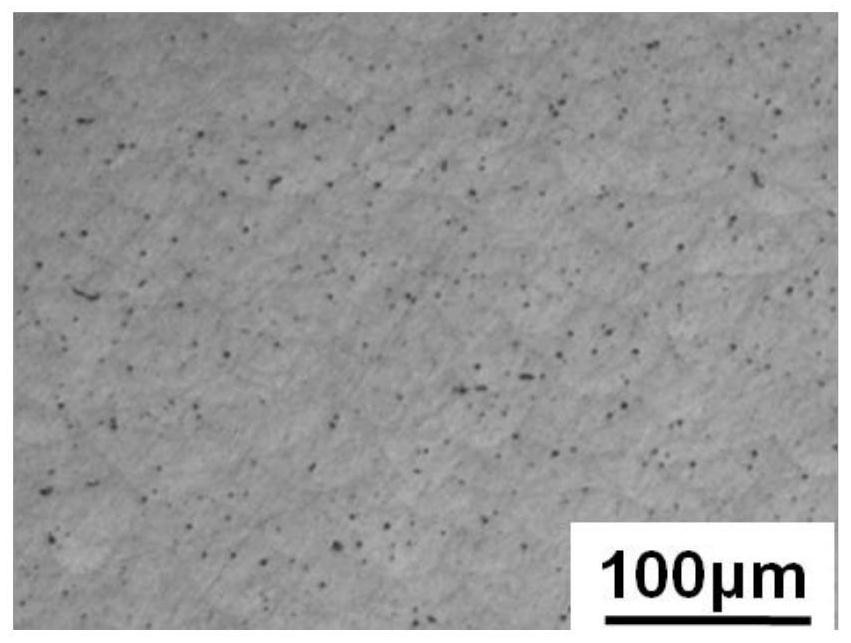

Preparation method of selective laser melting formed nano TiB2 reinforced aluminum-based composite material

InactiveCN112695220AEnhances the uniform dispersion of particlesEvenly dispersedAdditive manufacturingMaterial nanotechnologySelective laser meltingAluminum matrix composites

The invention provides a nano TiB2 reinforced aluminum-based composite material prepared through selective laser melting and a method thereof. The method comprises the following steps of (1) selecting high-purity spherical AlSi10Mg powder with the purity greater than 99.9% and a particle size of 15-53 microns, and irregular structure TiB2 powder with the purity greater than 99.9% and a particle size of 50-100 nm, (2) mechanically mixing the two kinds of powder, and uniformly mixing the two kinds of powder under the condition that the original characteristics of matrix powder are not damaged; and (3) preparing a high-density composite material forming sample with reinforced phase particles uniformly distributed on an aluminum alloy matrix by adopting a selective laser melting forming technology. By adding the nano-reinforced particles into the aluminum alloy matrix, the comprehensive mechanical properties of the aluminum alloy can be effectively improved under the synergistic strengthening action of fine grain strengthening and dispersion strengthening.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Machining method for improving abrasion and corrosion resistance of valve

InactiveCN107385433AImprove mechanical propertiesImprove fatigue resistanceMetallic material coating processesProcess optimizationSand blasting

The invention discloses a machining method for improving abrasion and corrosion resistance of a valve. The machining method comprises the following steps that firstly, the valve is arranged in activation liquid to be immersed, then the valve is washed to be neutral, grinding is conducted, then washing is conducted, drying is conducted, and a material A is obtained; secondly, the material A is subjected to sand blasting treatment, and a material B is obtained; thirdly, the material B is subjected to plasma cladding treatment, and a material C is obtained; and fourthly, the material C is subjected to heat treatment. According to the provided machining method for improving abrasion and corrosion resistance of the valve, through process optimization, a plating material and a base body are tightly combined, distribution is uniform, the high temperature resistance, corrosion resistance and creeping resistance of the valve are effectively improved, and the service life of the valve is effectively prolonged.

Owner:ANHUI WODE VALVE MFG

Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate and preparation method thereof

The invention discloses a preparation method of an Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate. The Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate is prepared from the alloy components: 3.0-4.0% of Zn, 1-2% of Mg, 0.2-0.4% of Mn, 0.1-0.3% of Cr, 0.1-0.3% of Zr, 0.1-0.3% of Er, 0.1-0.5% of Si, less than 0.01% of Cu and the balance of Aland other impurities, and the content of single impurity is not more than 0.1%. The preparation process includes the steps that an alloy prepared according to the composition design is smelted, casted and poured into an ingot with a diameter of 300 mm to 500 mm, the temperature is directly raised to 460 DEG C without homogenization heat treatment after stress relief annealing of the ingot is completed at 220 DEG C to 300 DEG C, after temperature is kept for 3 to 6 hours, hot extruding is carried out, and an aluminum alloy plate with a thickness of 6 to 10 mm is prepared under the condition that the extrusion ratio exceeds 16, wherein the extruded aluminum alloy plate has the tensile strength of more than 350 Mp, the yield strength of more than 300 Mp, the elongation of more than 15% and the ISSRT of less than 0.03 at normal temperature after solid solution aging treatment.

Owner:YANTAI NANSHAN UNIV

High-tenacity anti-cracking aluminum alloy welding stick

InactiveCN107175424AGood casting performanceImprove welding effectWelding/cutting media/materialsSoldering mediaArc stabilityBonding strength

The invention discloses a high-tenacity anti-cracking aluminum alloy welding stick. The high-tenacity anti-cracking aluminum alloy welding stick comprises components including, by mass percent, Mg, Be, Si, Mn, Cr, Cu, Ti, Sr, Mo, W, V, Nb, Zr, Nd, Sc, Ce, Eu, Y and the balance Al and inevitable impurities. The provided high-tenacity anti-cracking aluminum alloy welding stick is reasonable in formula, arc stability is good, welding line forming is attractive, strength is high, low-temperature resistance and impact resistance are good, the bonding strength between the welding stick and a mother material is large, and performance is stable.

Owner:安徽飞弧焊业股份有限公司

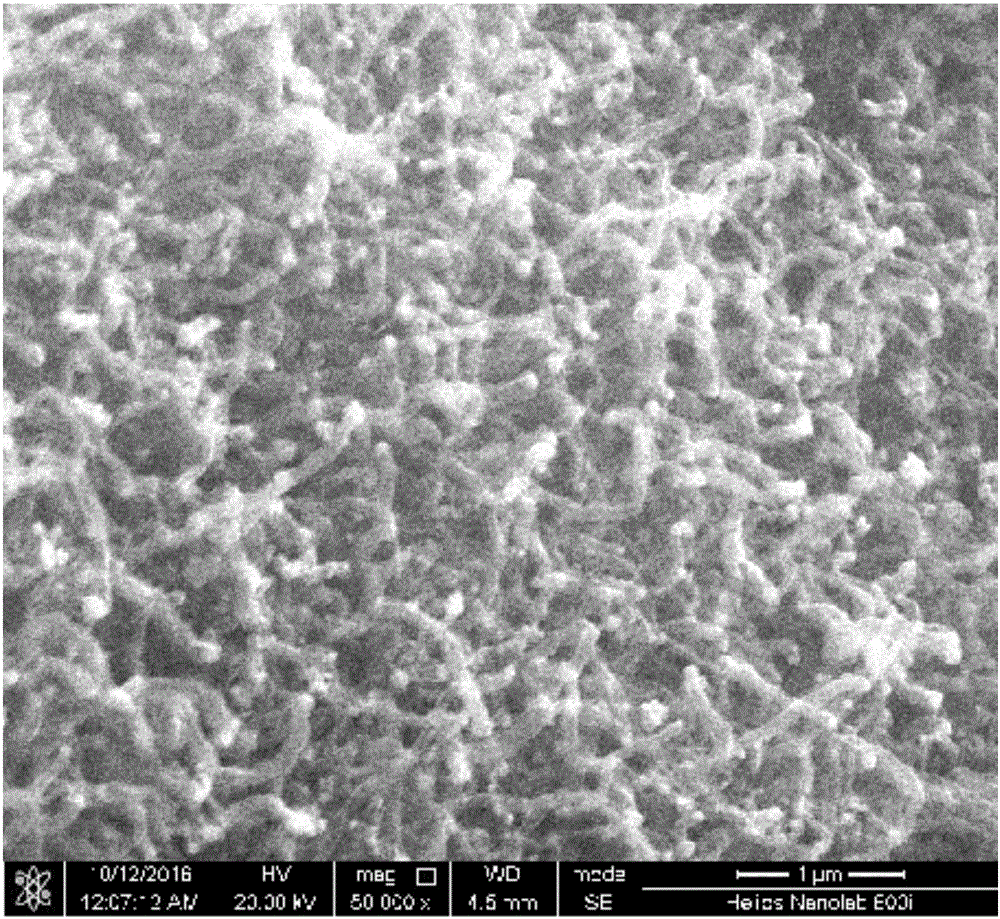

A method for assisting brazing of carbon nanotube reinforced three-dimensional structure intermediate layer

InactiveCN106346100BEvenly distributedEffect of diffusion strengtheningSoldering apparatusHydrogen atmosphereGas phase

The invention discloses a method for assisting brazing by a carbon nanotube reinforced type three-dimensional middle layer, and relates to a method for brazing ceramic and metal, which aims at solving the problems of larger residual stress and insufficient high-temperature property in the existing ceramic and metal brazing connection process. The method comprises the following steps of 1, preparing soaked foam metal; 2, putting the soaked foam metal into a plasma reinforced type chemical vapor depositing vacuum device, and increasing temperature at certain pressure and hydrogen atmosphere; 3, preparing nanotube reinforced type foam metal; 4, preparing surface impurity-removed metal, surface impurity-removed brazing material foil and surface impurity-removed ceramic; 5, sequentially overlapping the surface impurity-removed to-be-brazed metal, the carbon nanotube reinforced type foam metal, the surface impurity-removed brazing material foil and the surface impurity-removed ceramic, so as to obtain a to-be-brazed part; brazing the to-be-brazed part, and cooling to room temperature. The method disclosed by the invention is used for assisting the brazing by the carbon nanotube reinforced type three-dimensional middle layer.

Owner:哈尔滨工大特种连接高新科技发展股份有限公司

High-plasticity high-strength cast aluminum alloy containing nickel and copper and preparation method of high-plasticity high-strength cast aluminum alloy

The invention discloses a high-plasticity high-strength cast aluminum alloy containing nickel and copper and a preparation method of the high-plasticity high-strength cast aluminum alloy. The alloy comprises the following components in percentage by weight: 3.0%-6.0% of Ni, 0.01%-2% of Cu, 0.2%-1.0% of Ce, 0.2%-0.7% of Mn, 0.01%-0.04% of Ti and less than 0.2% of Fe, with the balance being Al and other inevitable impurities. According to the preparation method, nickel is added, so a fine and dispersed columnar Al3Ni phase can be formed on a matrix, and dispersion strengthening effect is achieved; a second phase can be refined by adding Ce; and meanwhile, Ce and Cu can be combined in a matrix to form fine precipitated phases which are distributed in a dispersed mode, so dislocation is effectively pinned, and strength is improved.

Owner:长三角先进材料研究院

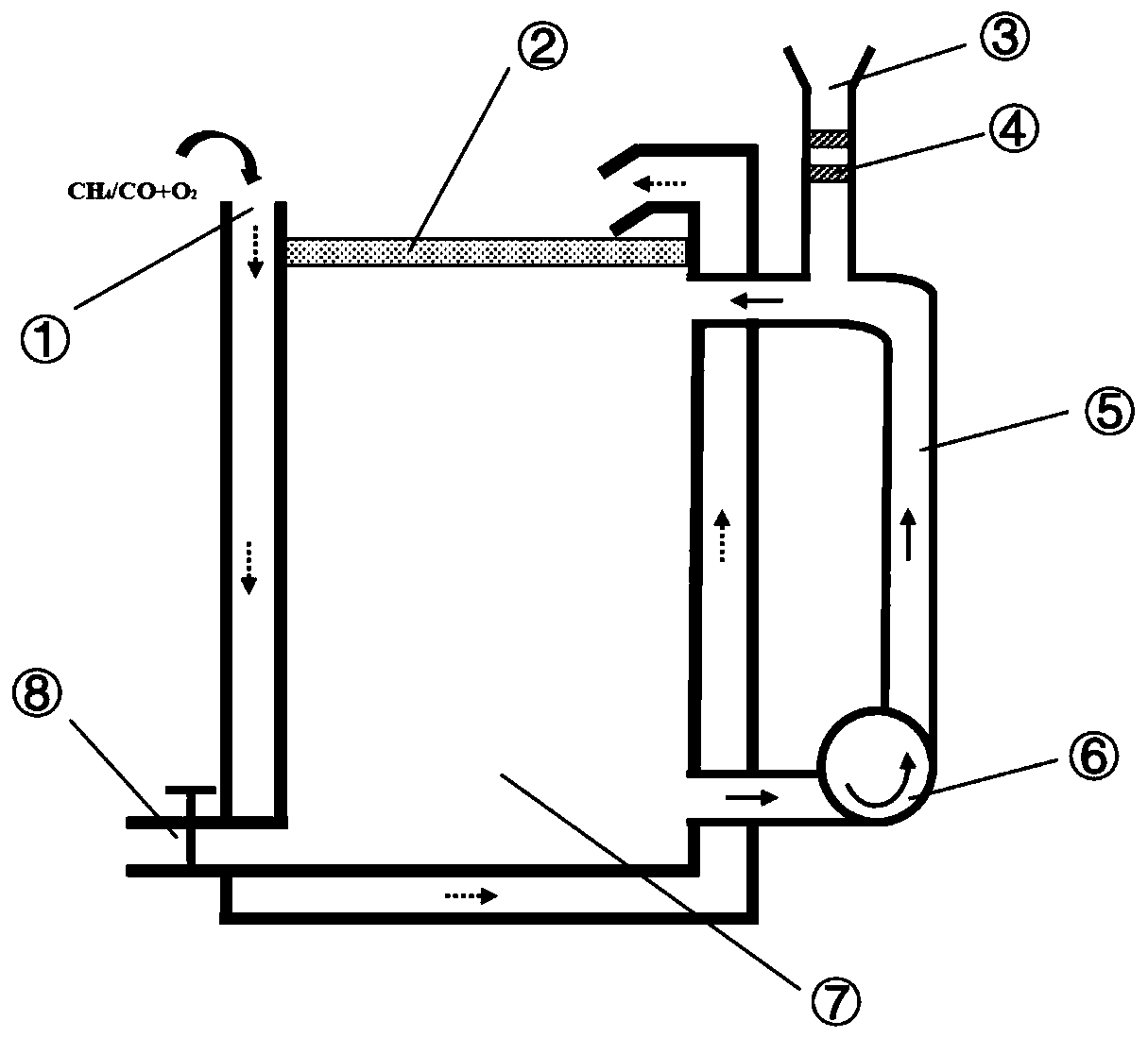

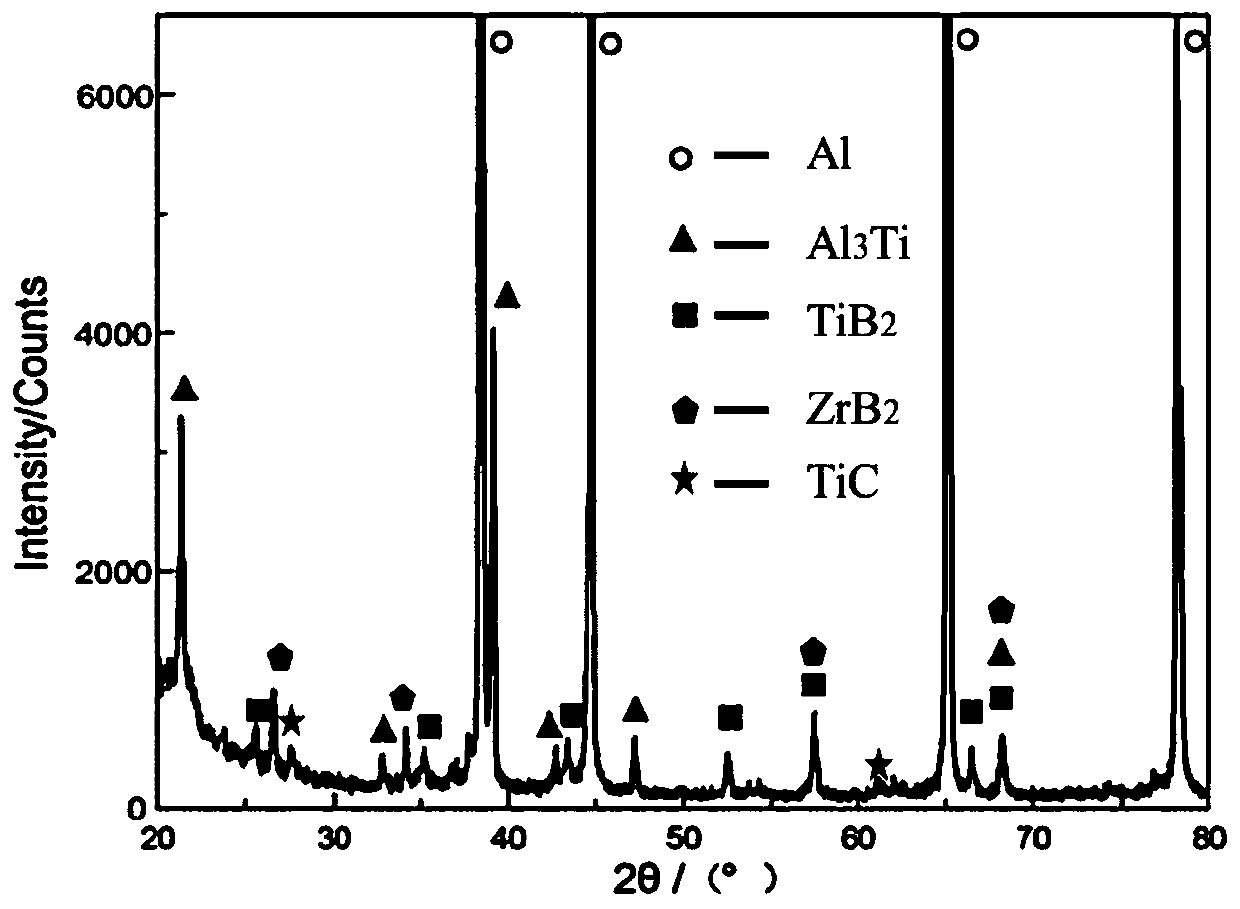

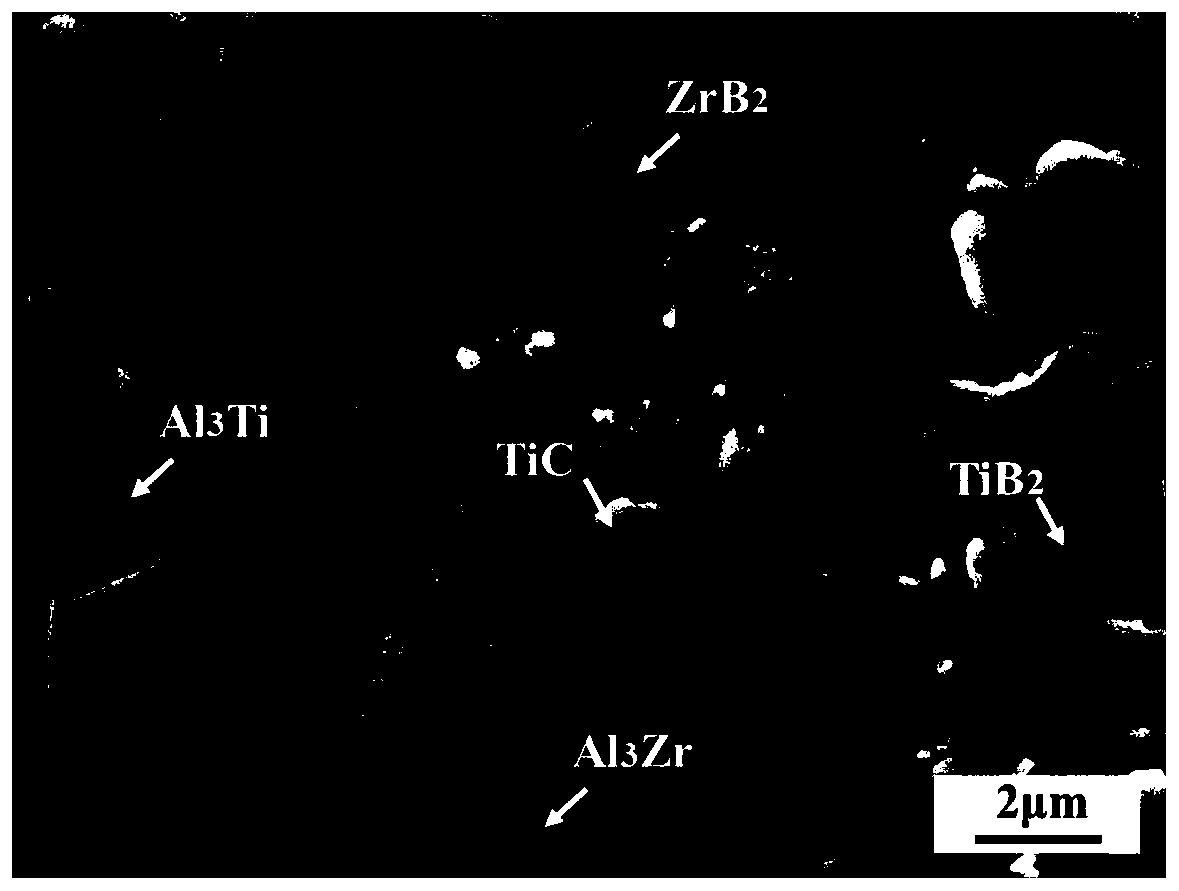

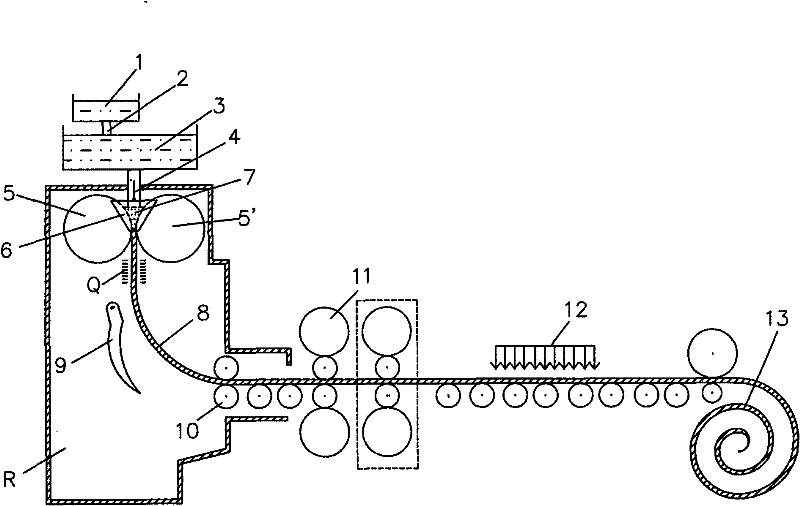

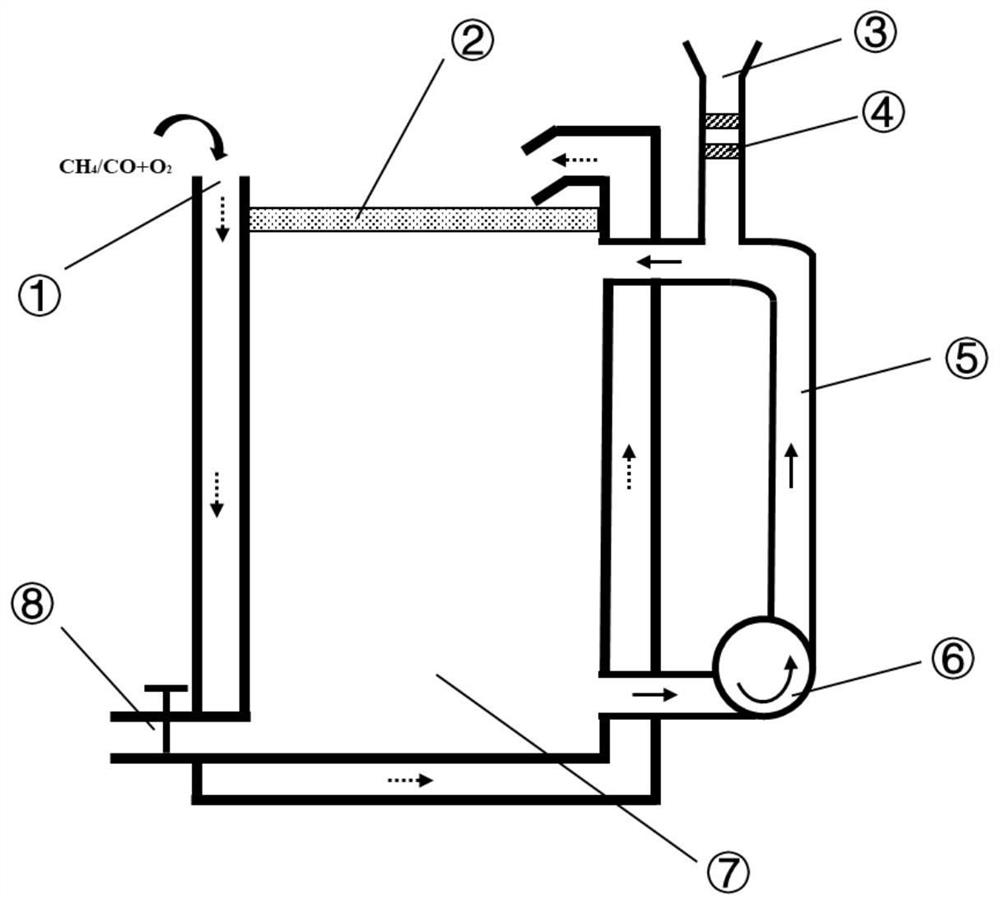

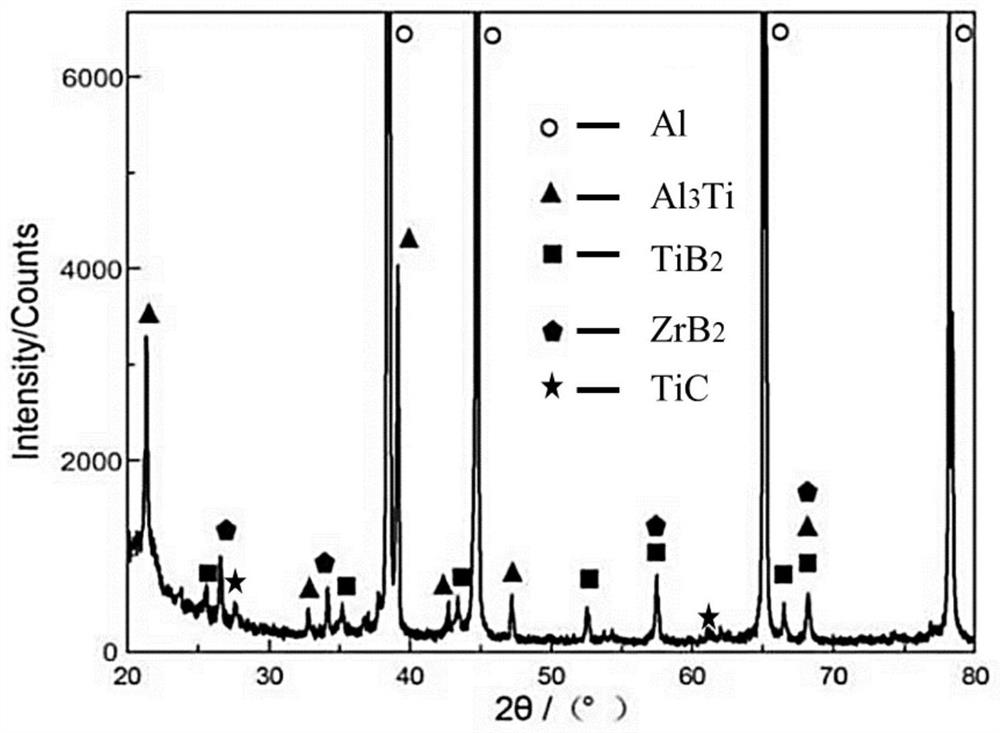

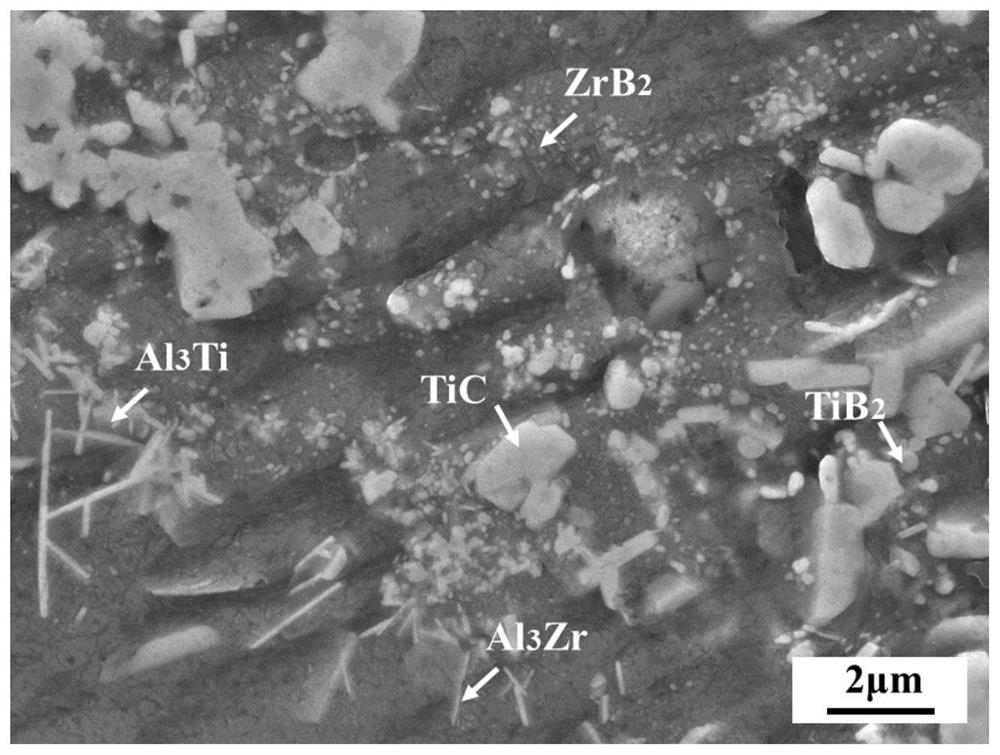

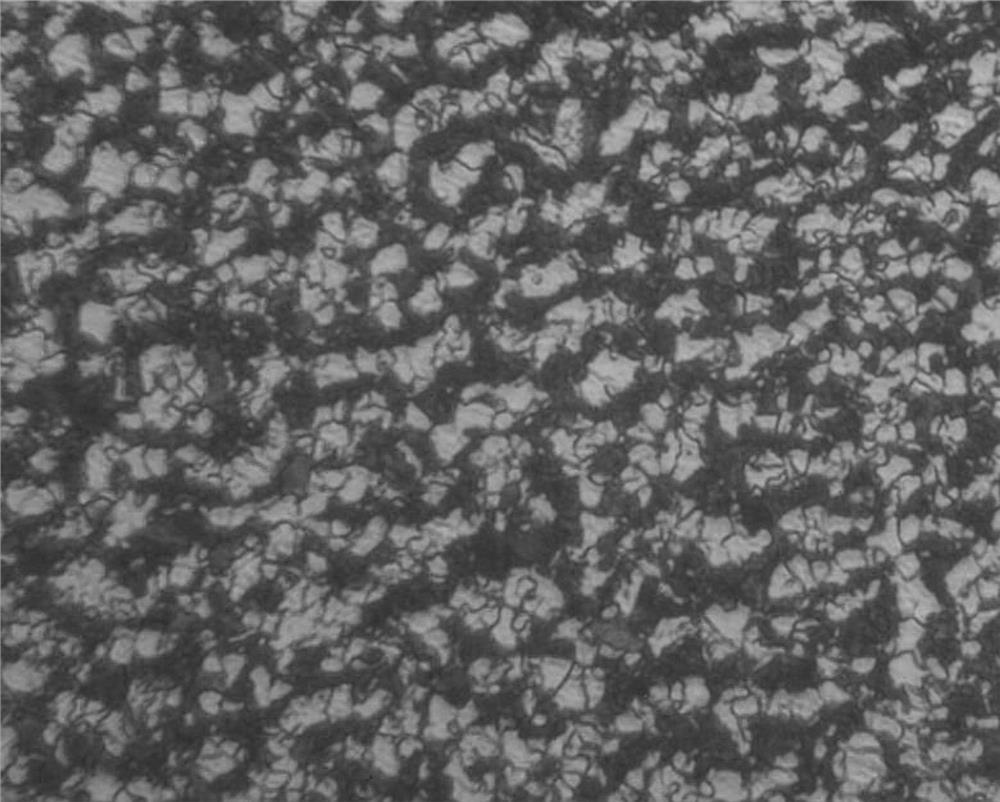

Aluminum alloy compound refining and reinforcing agent and preparing method and device thereof

The invention belongs to the field of metal materials, and particularly discloses an aluminum alloy compound refining and strengthening agent and a preparing method and device thereof. Firstly, pure aluminum is placed into a smelting furnace crucible to be melted to a certain temperature, the top of an aluminum melt goes beyond an inlet of the upper portion of an electromagnetic circulating devicein the crucible, an aluminum alloy covering agent is added into the top of the crucible, weighing is conducted, preprocessed Ti, B2O3, Zr and C powder or dust is added into a feed port of the electromagnetic circulating device, then the electromagnetic circulating device is started, and the required compound refining and strengthening agent is obtained through a certain period of circulating reacting and compounding. The prepared compound refining and strengthening agent has the advantages of efficient refining of a traditional Al-Ti-B system and long-acting refining of an Al-Ti-C system. Moreover, the compound refining and strengthening agent contains a large amount of sub-micron and nanoscale TiB2, ZrB2, TiC and ZrC reinforcement particles, improves the refining effect and is finally dispersed in an alloy base body to have a dispersion strengthening effect.

Owner:JIANGSU UNIV

A multi-component composite strengthened molybdenum alloy and its preparation method

The invention relates to a preparation method of a multi-element composite reinforced molybdenum alloy. The preparation method sequentially comprises the following steps that the Mo source, the Ti source, the Zr source, the C source, the Hf source and the Re source are weighed according to a certain weight ratio, the raw materials are prepared and mixed to obtain the uniform molybdenum alloy powder; the molybdenum alloy powder is placed in a mold cavity of a mold and is subjected to compression forming treatment to obtain a forming blank; high-temperature sintering treatment on the formed blank is carried out under vacuum to obtain a sintered blank; forging or rolling deformation processing is carried out on the sintered blank to obtain a forged blank or a rolled blank; and annealing heattreatment on the forged blank or the rolled blank is carried out to obtain the molybdenum alloy plate or a rod material. According to the preparation method, the steps and the process conditions are reasonable in design and good in using effect, the prepared molybdenum alloy material has excellent performance, the tensile strength Ra is greater than or equal to 200 MPa at a high temperature of 1600 DEG C, the percentage elongation after fracture is larger than or equal to 20%, and the oxygen content is less than or equal to 100 ppm.

Owner:安泰天龙钨钼科技有限公司 +1

High-strength weather resisting steel with Cu2-xS dispersed precipitates and manufacturing method thereof

ActiveCN101928894BReduce steelmaking costsInhibition of segregationTemperature control deviceManufacturing convertersChemical compositionHigh intensity

Owner:BAOSHAN IRON & STEEL CO LTD

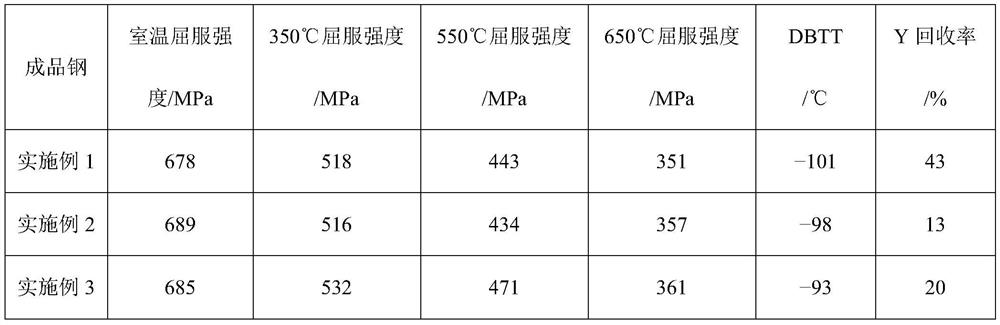

Oxide-strengthened low-activation steel, electroslag remelting slag system and smelting method

ActiveCN111876609BHigh yieldIncrease the number ofIncreasing energy efficiencyElectro-slag remeltingYttrium

The invention discloses an oxide-strengthened low-activation steel, an electroslag remelting slag system and a smelting method. The electroslag remelting slag system includes A slag and B slag, and the components of the A slag include: CaF 2 :40~55 copies, Y 2 o 3 : 30 to 35 parts, CaO: 20 to 30 parts; the composition of the B slag includes CaF 2 : 55-65 parts, CaO: 30-40 parts, MgO: 2-5 parts, SiO 2 : 3 to 7 parts; during smelting, a blind hole is processed inward from the upper end of the consumable electrode, filled with yttrium in the blind hole, the upper end of the consumable electrode is welded to the dummy electrode, and the consumable electrode Fix it at the smelting position, add slag A into the water-cooled crystallizer, and start arcing to make slag; start smelting after arcing, and add B slag after smelting to the designated position of the consumable electrode, and continue smelting until the end. The horizontal position corresponding to the bottom of the blind hole on the consumable electrode. The electroslag remelting slag of the present invention does not contain Al 2 o 3 , The smelting method can make full use of the electroslag remelting system of the present invention, improve the Y yield, and obtain a new oxide-strengthened low-activation steel.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

a ti 2 Medium-temperature ZR-based brazing filler metal for Alnb-based alloy homogeneous or dissimilar materials and its preparation method and brazing process

ActiveCN111702281BImprove wettabilityImprove liquidityWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalHigh heat

The invention belongs to the field of welding, in particular to a Ti 2 The invention relates to a medium-temperature Zr-based solder special for brazing of the same material or different materials of AlNb-based alloys, a preparation method thereof, and a brazing process. In terms of weight percentage, the composition and content of the solder are: Fe 5% to 30%, Nb 1% to 15% or Cu 1% to 20%, choose one of the two, and a small amount of elements Al, B, Co, Cr , one or more of Mn, Mg, Ni, Ag and Zn≤5%, one or more of trace elements Ti, Hf, V, Ta, Mo, W, Au, Si, Sn, Pd, Ga≤ 2%, the rest is Zr element and unavoidable impurity elements. The preparation method of brazing material: 1. Weighing the raw materials; 2. Melting the master alloy of the brazing material; The brazing material of the present invention is brazed according to the brazing process of 960 DEG C to 1030 DEG C and 0 to 120 minutes. Compared with the existing solder, the brazing filler metal prepared by the invention has suitable melting point, excellent wettability and high-temperature mechanical properties, and the brazing filler metal preparation and brazing process are simple.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-impedance high-strength illuminating bus slot

InactiveCN108866361AHigh strengthImprove impact resistanceTotally enclosed bus-bar installationsEmbedded systemRare-earth element

The invention discloses a low-impedance high-strength illuminating bus slot, and relates to the technical field of electrical equipment. The bus slot comprises an upper cover plate, a lower cover plate, two side plates and a bus. A bus containing cavity is defined by the upper cover plate, the lower cover plate and the two side plates, the bus is arranged in the bus containing cavity, and the upper cover plate, the lower cover plate and the two side plates are each prepared from, by mass, 0.35-0.68% of C, 2.26-2.52% of Cr, 0.95-1.18% of Si, 0.66-0.73% of Zn, 2.34-2.58% of Cu, 0.13-0.18% of W,0.35-0.52% of Mn, 0.93-1.27% of Mg, 1.56-1.88% of rare earth elements and the balance Al and inevitable impurities. The strength of the low-impedance high-strength illuminating bus slot is higher thanthat of an existing bus slot, the bus impedance is low, energy can be saved, heat emitted during bus working is reduced, and the service life of the bus slot is effectively prolonged.

Owner:荣马电器有限公司

An aluminum alloy composite refiner, strengthening agent and its preparation method and device

The invention belongs to the field of metal materials, and particularly refers to a composite thinning and strengthening agent for aluminum and aluminum alloys, a preparation method and a device. First, put pure aluminum in the crucible of the melting furnace and melt it to a certain temperature, make the top of the aluminum melt exceed the upper entrance of the electromagnetic circulation device in the crucible, and add an aluminum alloy covering agent to the top of the crucible, and put the weighed and pretreated Ti , B 2 o 3 , Zr, C powder or shavings are added from the feeding port of the electromagnetic circulation device, and then the electromagnetic circulation device is started, and after a period of cycle reaction compounding, the required compound refinement and strengthening agent are obtained. The composite thinning and strengthening agent prepared by the present invention not only has the characteristics of traditional Al-Ti-B series high-efficiency thinning and Al-Ti-C series long-term thinning, but also contains a large amount of submicron and nanometer TiB 2 , ZrB 2 , TiC, ZrC reinforcement particles, while improving the refinement effect, are finally dispersed in the alloy matrix to achieve the effect of dispersion strengthening.

Owner:JIANGSU UNIV

A kind of low V microalloying superfine dispersed phase high-strength steel and its preparation method

ActiveCN113755762BStrong economic applicabilityImprove strong plasticityProcess efficiency improvementIngotHeating furnace

The invention belongs to the technical field of ultra-fine dispersed precipitated phase high-strength steel and its preparation method, specifically a low V microalloyed ultra-fine dispersed precipitated phase high-strength steel and its preparation method, which solves the technical problems in the background technology, the preparation method In order to obtain steel slabs after mixing the various element components according to the nominal composition ratio, the smelted steel slabs are then processed by conventional heating furnace process or direct rolling process. After the treatment, the steel ingots cooled to room temperature are heated and heated at a certain temperature Holding for a certain period of time allows V to completely dissolve into the steel ingot, and then cooling at a certain temperature and holding for a certain period of time allows V to be completely precipitated, forming V (C, N) uniformly dispersed and fine precipitates to provide low V microalloyed super Fine dispersed precipitate phase high strength steel. This method exerts the precipitation strengthening effect of the V(C, N) precipitates, so that the precipitates can be uniformly dispersed in the matrix to achieve the effect of dispersion strengthening, and prepare high-strength and high-plasticity high-strength steel.

Owner:TAIYUAN UNIV OF TECH

Diesel engine valve coating technology

InactiveCN107365995AHigh hardnessHigh strengthMetallic material coating processesDiesel engineCorrosion

The invention discloses a diesel engine valve coating technology. The diesel engine valve coating technology comprises the steps of pretreatment before coating and plasma cladding treatment. The diesel engine valve coating technology specifically comprises the following process that the portion, needing to be coated, of a diesel engine valve is soaked in an activating solution, cleaned and dried; mixed powder is uniformly applied to the surface of the portion, needing to be coated, of the diesel engine valve obtained after pretreatment before coating, plasma cladding treatment is conducted, cooling is conducted, a material A is obtained, and then heat treatment is conducted. According to the diesel engine valve coating technology, a coating material and a substrate are combined closely and distributed uniformly through the optimized technology, therefore, the high temperature resistance, the corrosion resistance and the fatigue resistance of the diesel engine valve are effectively improved, ad the service life of the diesel engine valve is effectively prolonged.

Owner:ANHUI WODE VALVE MFG

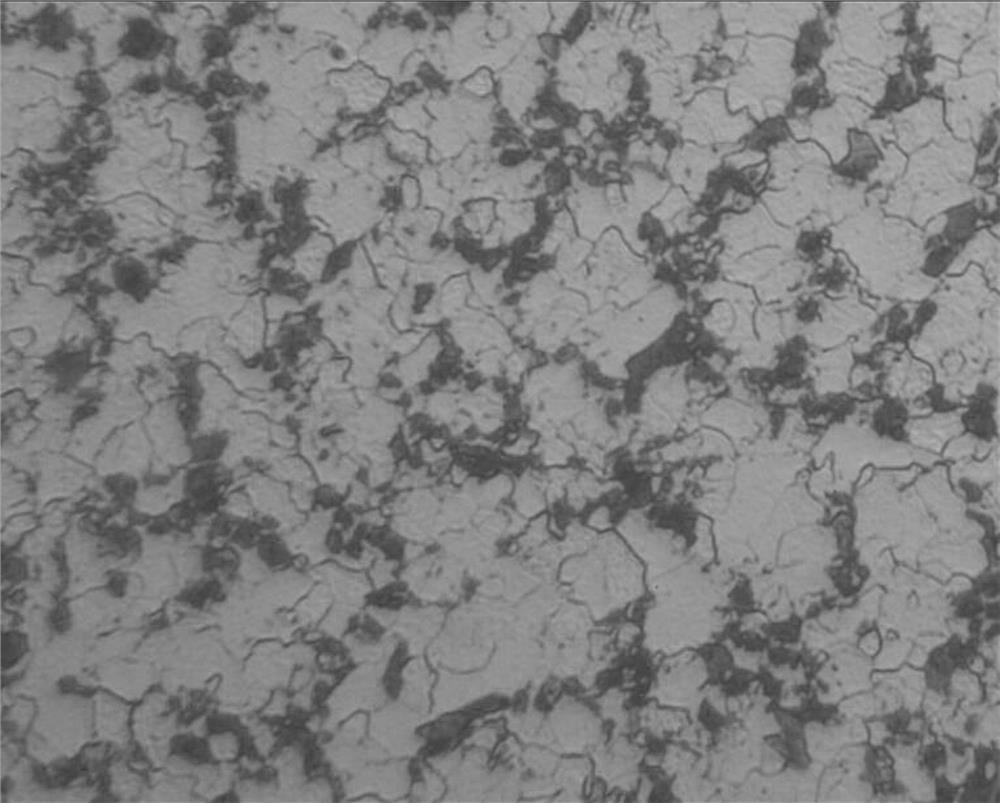

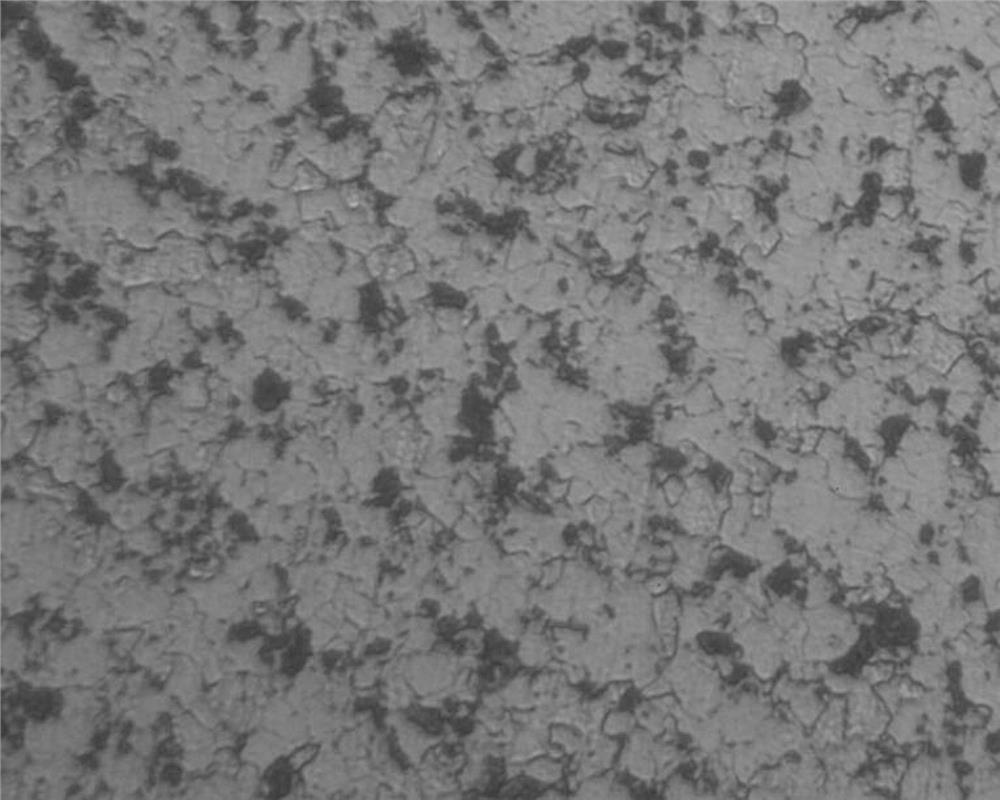

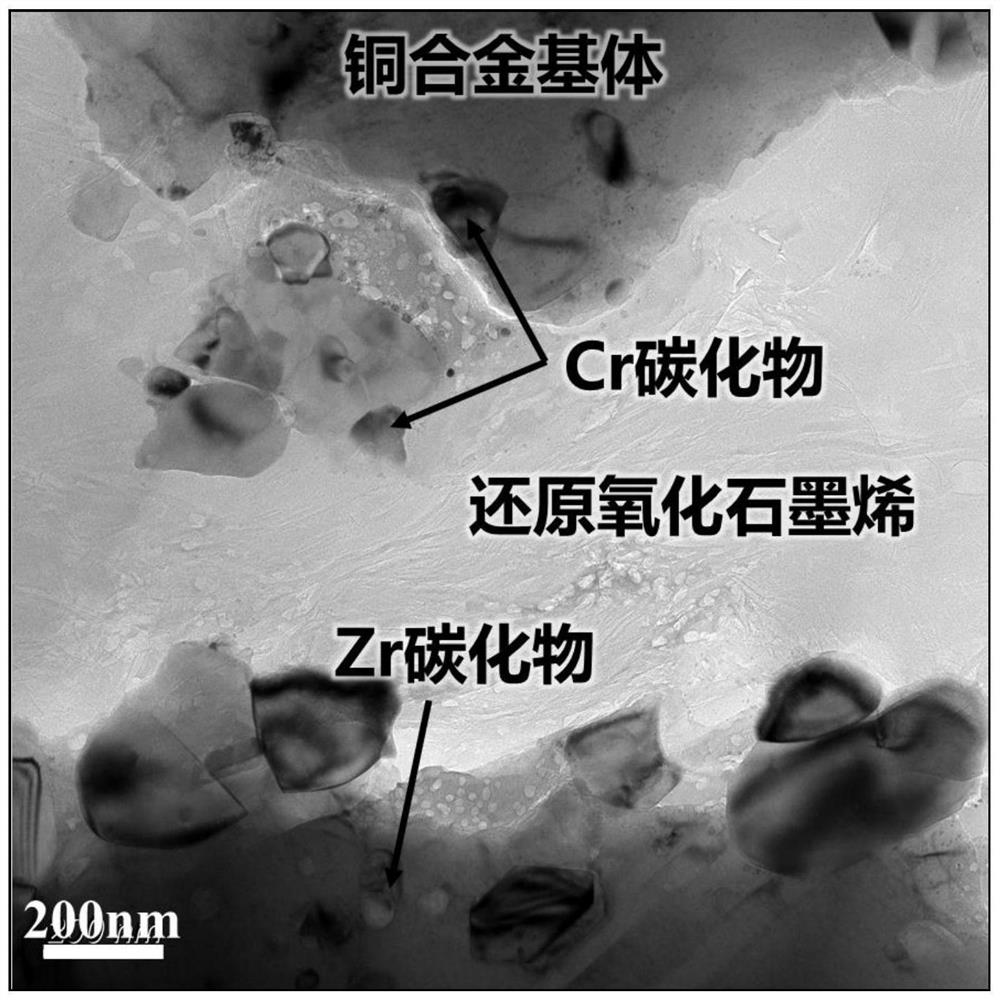

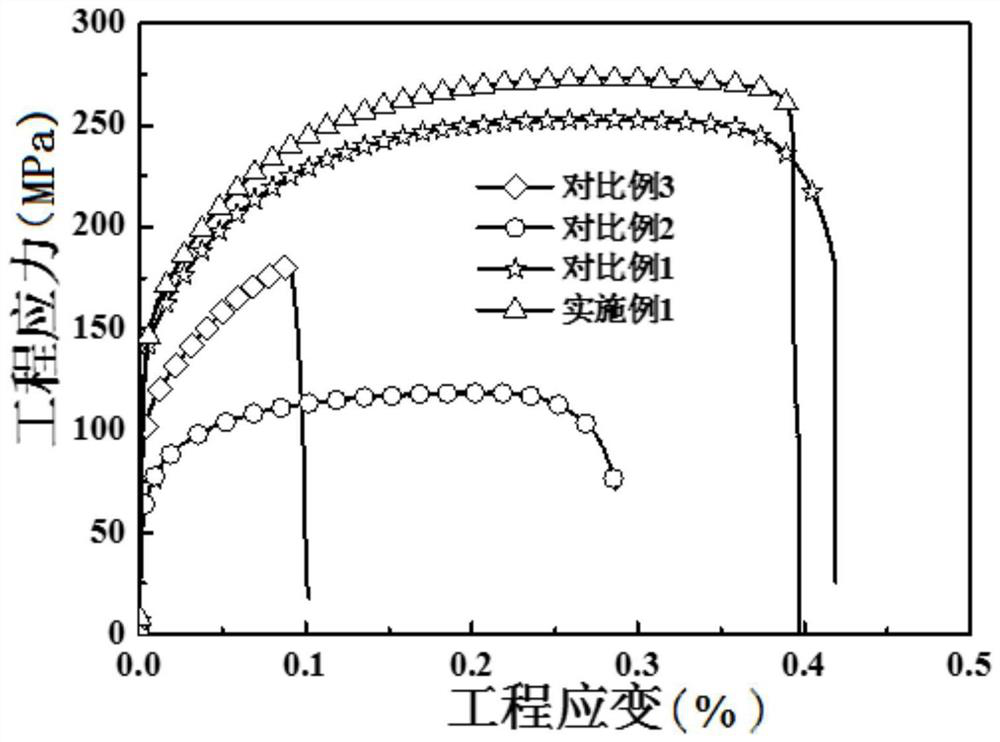

Method for improving strength and conductivity matching of copper-based composite material based on in-situ reaction

InactiveCN113322390AImprove interfacial wettabilityImprove the bonding strength of the interfaceConductive materialMetal/alloy conductorsChromium carbideUltimate tensile strength

The invention discloses a method for improving strength and conductivity matching of a copper-based composite material based on an in-situ reaction. The method comprises the steps that firstly, graphene oxide powder and chromium-containing copper-based alloy powder are taken as raw material powder, and the raw material powder is uniformly mixed in a grinding manner to obtain mixed powder; and secondly, the mixed powder obtained in the first step is subjected to plasma sintering, so that the mixed powder generates the in-situ reaction, and the copper-based composite material with strength and conductivity matched is obtained through cooling. Graphene oxide is used as a reinforcing phase, a chromium-containing copper-based alloy system is used as a matrix, through grinding and plasma sintering, carbon atoms in the graphene oxide and chromium in the chromium-containing copper-based alloy are subjected to the in-situ reaction to form chromium carbide, the chromium carbide and the alloy matrix form a coherent or semi-coherent interface, the interface strength between the graphene oxide and the chromium-containing copper-based alloy is improved, and meanwhile the prepared copper-based composite material keeps good conductivity in combination with high dispersion of the graphene oxide in the alloy matrix.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Oxide-reinforced low-activation steel, electroslag remelting slag system and smelting method

ActiveCN111876609APreventing failure of arc initiation and slag formationIncrease reaction rateIncreasing energy efficiencySmelting processOxide

The invention discloses oxide-reinforced low-activation steel, an electroslag remelting slag system and a smelting method. The electroslag remelting slag system comprises slag A and slag B, the slag Acomprises the following components including, by mass, 40-55 parts of CaF2, 30-35 parts of Y2O3 and 20-30 parts of CaO, the slag B comprises the following components including, by mass, 55-65 parts of CaF2, 30-40 parts of CaO, 2-5 parts of MgO and 3-7 parts of SiO2; in the smelting process, a blind hole is machined inwards from the end face of the upper end of a consumable electrode, the blind hole is filled with yttrium, the upper end of the consumable electrode is welded to a fake electrode, the consumable electrode is fixed to a smelting position, the slag A is added into a water-cooling crystallizer, and arcing slagging is conducted; and smelting is started after arcing, the slag B is added after smelting to a designated position of the consumable electrode, smelting continues to be carried out until smelting is finished, and the designated position is a horizontal position corresponding to the bottom of the blind hole in the consumable electrode. The electroslag remelting slag system does not contain Al2O3, the smelting method can fully utilize the electroslag remelting slag system, the yield of Y is increased, and the new oxide-reinforced low-activation steel is obtained.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A Cu-containing high-entropy alloy coating with liquid phase separation structure and preparation method thereof

ActiveCN104911581BEasy to separateChange the single-phase structureMetallic material coating processesHigh entropy alloysAlloy coating

The invention discloses a Cu-containing high-entropy alloy coating with a liquid phase separation structure and a preparation method thereof, belonging to the field of alloy material design. The invention adds a small amount (mass fraction of 0.5-3%) nanometer Y2O3 to the Cu-containing high-entropy alloy composition, which can promote the laser cladding Cu-containing high-entropy alloy coating to form a liquid phase separation structure. The copper-containing high-entropy alloy is composed of 5 or more metal or non-metallic elements, and the content of the Cu element that must be added accounts for 15-35% of the total moles of the high-entropy alloy components. In the present invention, due to the large surface effect and small size effect of nano-Y2O3, it can promote the separation of liquid phase copper from the alloy melt when the laser cladding copper-containing high-entropy alloy coating is fused, and the in-situ self-generation on the solidified matrix structure of the coating A large number of dispersed copper-rich phase particles change the single-phase structure of the coating, providing a new method for designing multi-phase structures and expanding properties of high-entropy alloys through liquid phase separation.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

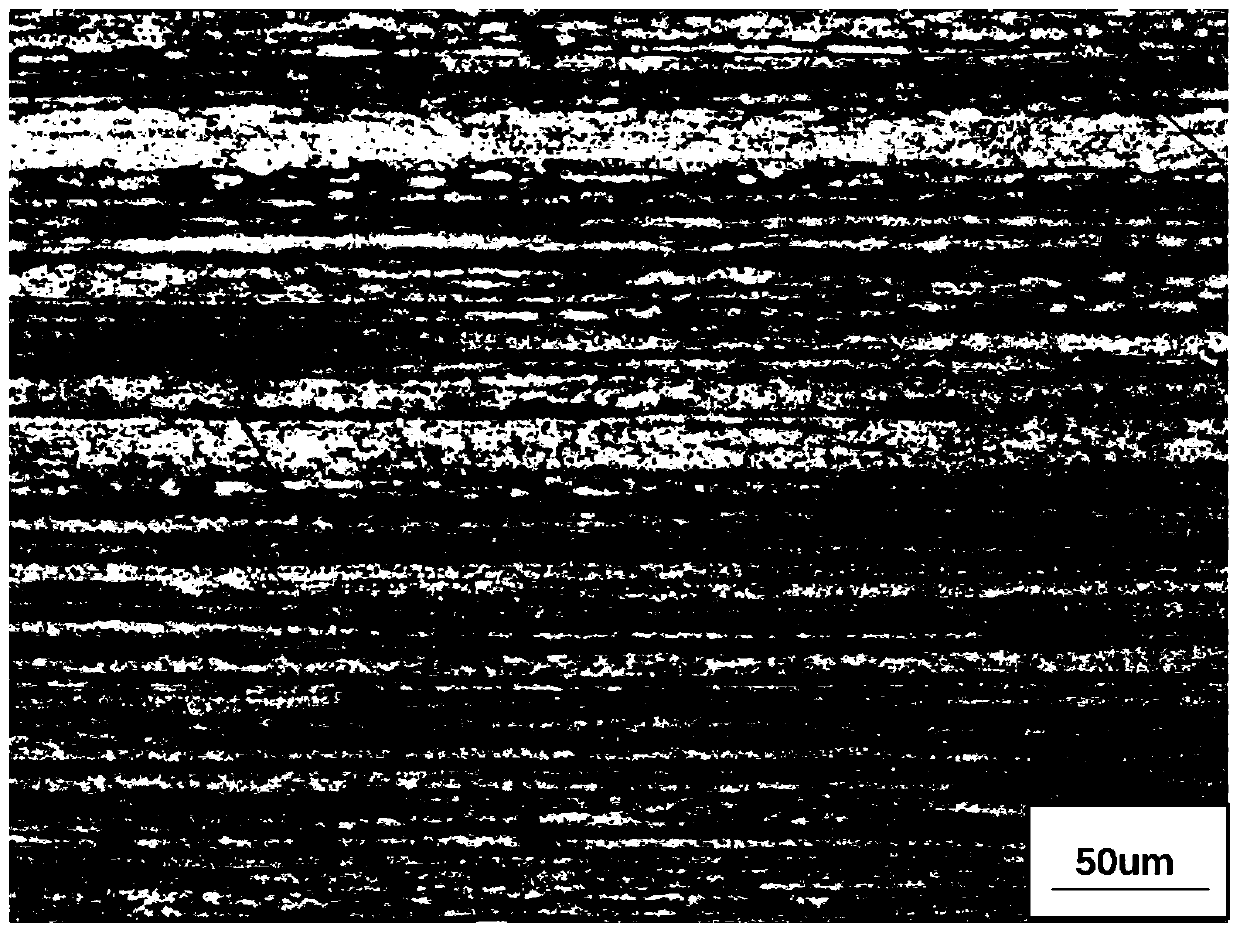

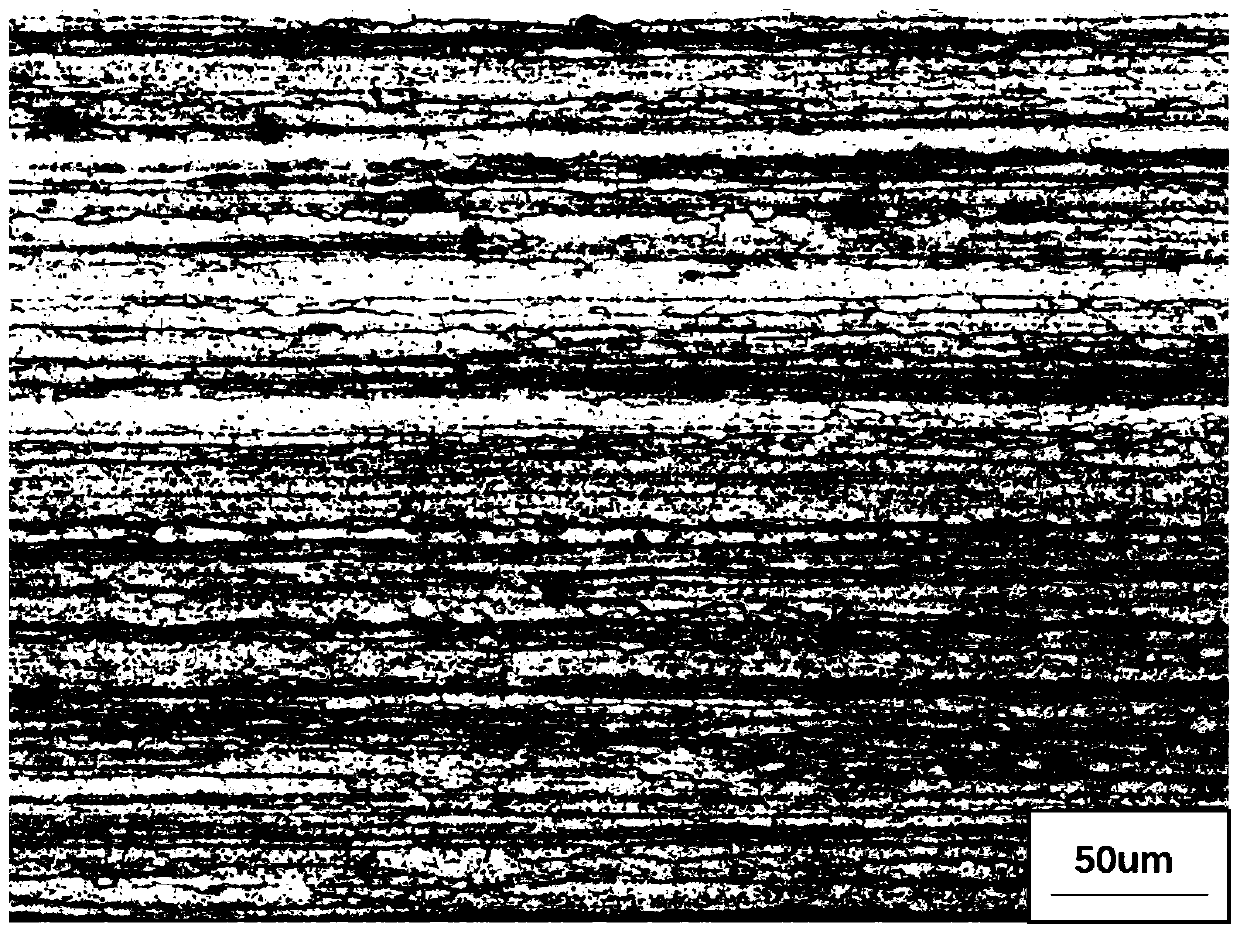

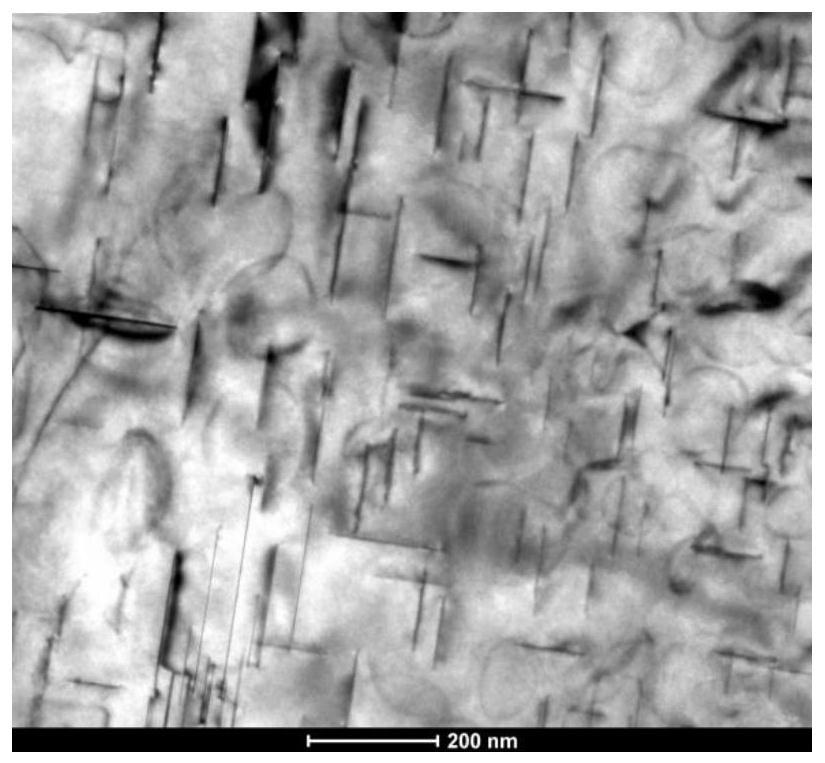

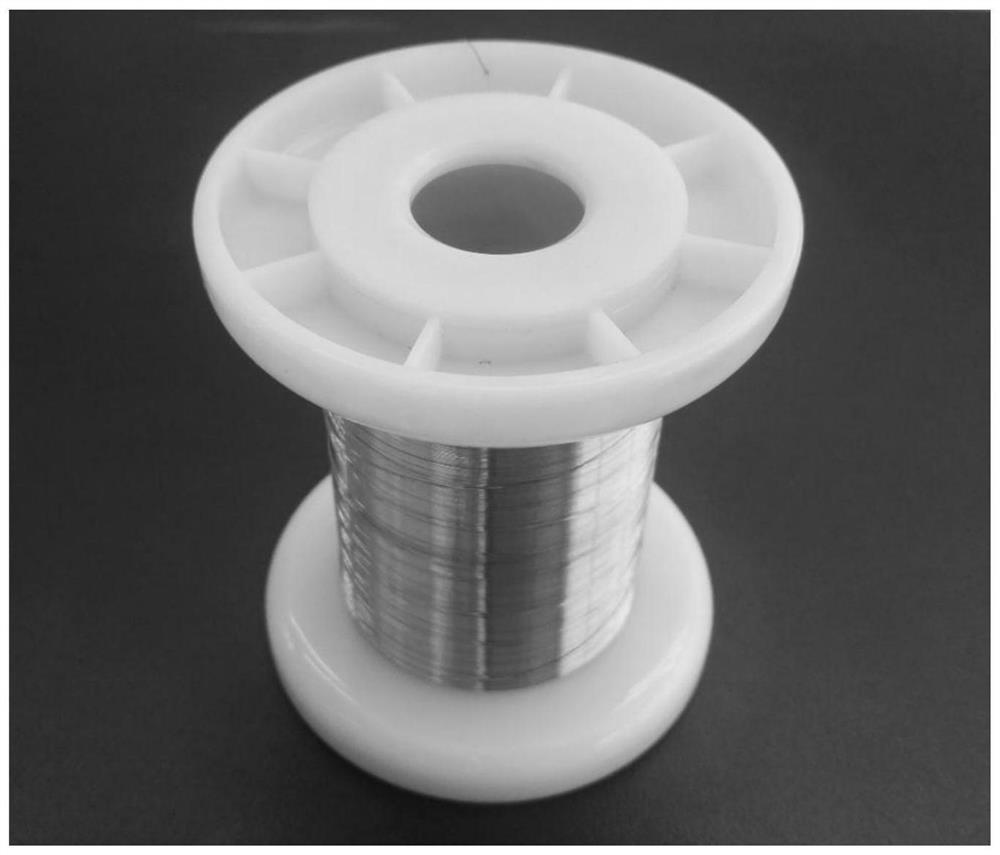

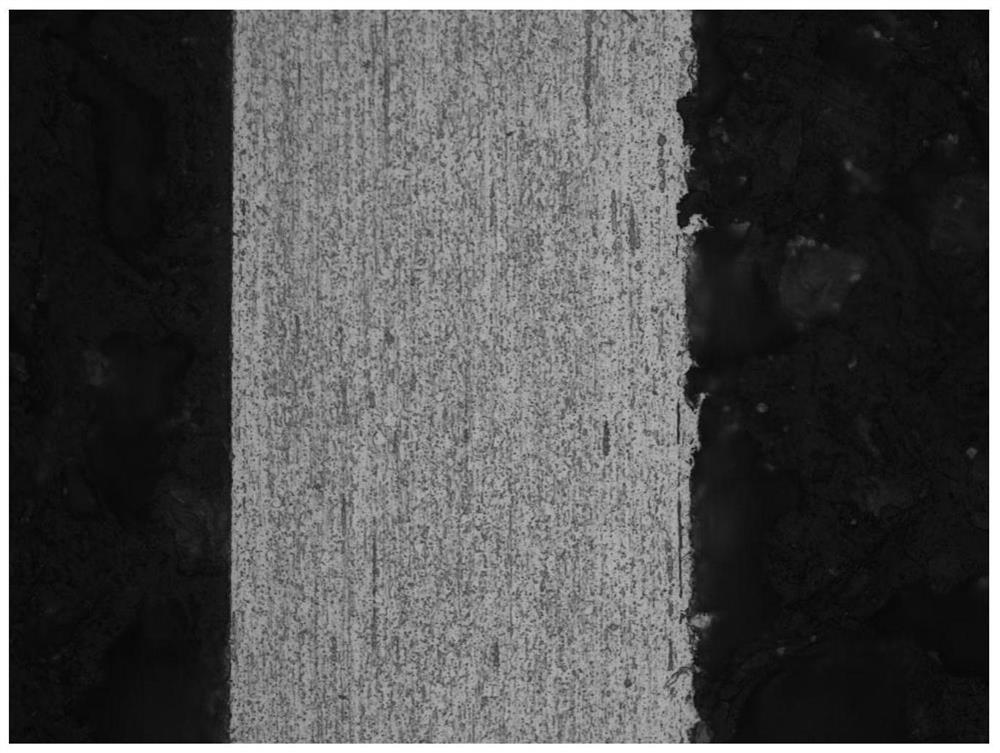

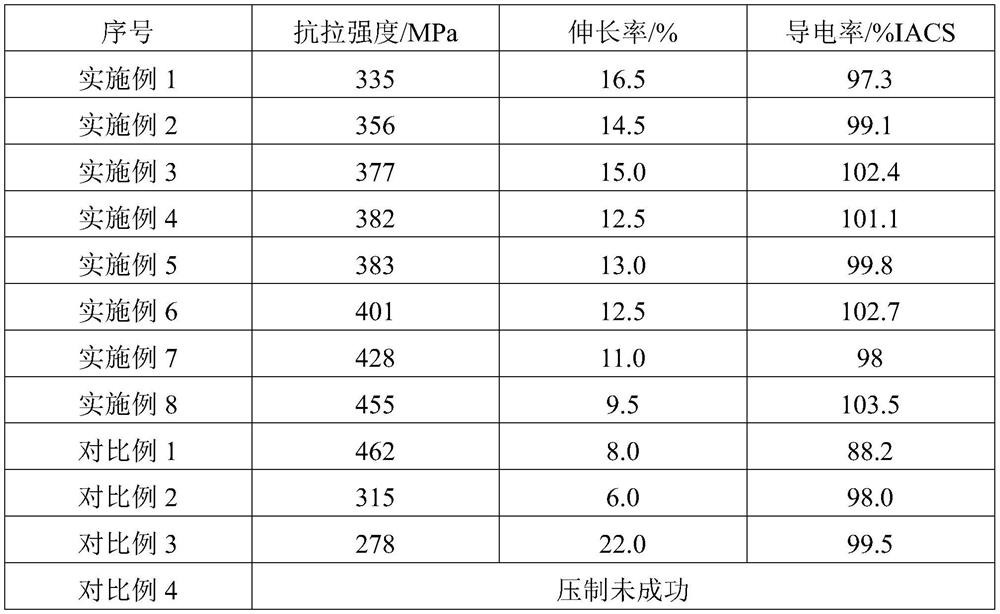

A kind of high-strength and high-conductivity graphene-copper composite wire and preparation method thereof

ActiveCN112359244BHigh strengthImprove conductivityFurnace typesHeat treatment furnacesWire rodGraphite

The invention discloses a high-strength and high-conductivity graphene-copper composite wire and a preparation method thereof, which belong to the technical field of composite material processing and heat treatment. In the graphene-copper composite wire, the graphene content is 0.05-0.8wt.%, the total content of impurity elements is ≤0.1wt.%, and the balance is copper. The high-strength and high-conductivity graphene-copper composite wire prepared by the present invention has uniform graphene Dispersed and oriented distributed in the copper matrix, its tensile strength reaches 330-480MPa, elongation 6%-20%, electrical conductivity 95-105% IACS, and has excellent comprehensive performance.

Owner:GRIMAT ENG INST CO LTD

Aluminum alloy material for high-strength and high-toughness glasses frame and preparation method of aluminum alloy material

PendingCN113061788AFine grain structureSegregation tendency is smallNon-optical partsEyewearLanthanide

The invention discloses an aluminum alloy material for a high-strength and high-toughness glasses frame. The aluminum alloy material comprises the following chemical components: Si, Fe, Cu, Mn, Mg, Cr, Zn, Zr, RE, Ti and the balance Al. A preparation method comprises the following steps of: heating and melting the prepared high-strength and high-toughness aluminum alloy raw material, performing purification treatment, and casting the melt into a cast ingot for subsequent processing. The aluminum alloy material disclosed by the invention is an Al-Zn-Mg-Cu alloy, the alloy strength and toughness are maximized by optimizing the alloy component design, the produced cast ingot is uniform in component at each position and small in internal stress, stress relief annealing is not needed, and due to the addition of transition group elements Zr and lanthanide elements (La and Ce), the microscopic grain structure is refined, and the strength and toughness of the alloy are improved.

Owner:深圳市金悦志丰眼镜有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com