A Cu-containing high-entropy alloy coating with liquid phase separation structure and preparation method thereof

A high-entropy alloy and liquid-phase separation technology, applied in metal material coating process, coating and other directions, can solve the problem of rare high-entropy alloy composition, and achieve the effects of high hardness, cost reduction and coating toughness improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

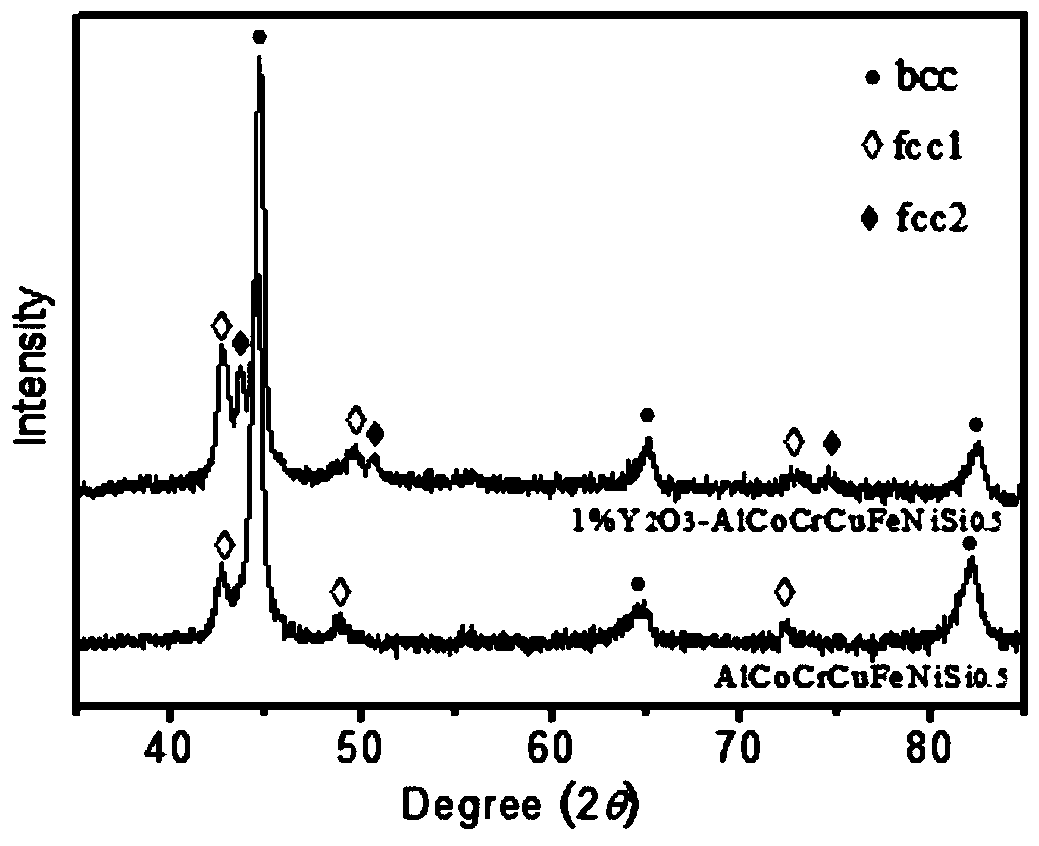

[0031] A Cu-containing high-entropy alloy coating with a liquid phase separation structure, which is obtained by alloying five or more metal or non-metal elements in an equiatomic ratio or close to an equiatomic ratio, in addition to adding different amounts of Nano Y 2 o 3 , nano Y 2 o 3 The particle size distribution is between 20 and 100nm. In this embodiment, four kinds of high-entropy alloy powders are prefabricated, which are respectively recorded as 0.5% Y 2 o 3 -AlCoCrCuFeNiSi 0.5 , 1%Y 2 o 3 -CoCrCu 2FeNi, 2% Y 2 o 3 - AlCoCrCuFeNi and 3% Y 2 o 3 - CoCrCuFeNi, where, 0.5% Y 2 o 3 -AlCoCrCuFeNiSi 0.5 Y in high entropy alloys 2 o 3 The mass fraction is 0.5%, and the molar ratio of other metal elements is: Al:Co:Cr:Cu:Fe:Ni:Si=1:1:1:1:1:1:0.5; 1%Y 2 o 3 -CoCrCu 2 Y in FeNi high entropy alloy 2 o 3 The mass fraction is 1%, and the molar ratio of other metal elements is: Co:Cr:Cu:Fe:Ni=1:1:2:1:1; 2%Y 2 o 3 -Y in AlCoCrCuFeNi high entropy alloy 2 o ...

Embodiment 2

[0036] A Cu-containing high-entropy alloy coating with a liquid phase separation structure, which is obtained by alloying five or more metal or non-metal elements in an equiatomic ratio or close to an equiatomic ratio, in addition to adding different amounts of Nano Y 2 o 3 , nano Y 2 o 3 The particle size distribution is between 20 and 100nm. In this embodiment, two kinds of high-entropy alloy powders are prefabricated, respectively denoted as 0.5% Y 2 o 3 -CuCo 0.5 Ni 1.2 CrAl 1.5 Fe 1.5 and 2.5% Y 2 o 3 -CuCrCoMoAl 1.5 Ti, of which, 0.5% Y 2 o 3 -CuCo 0.5 Ni 1.2 CrAl 1.5 Fe 1.5 Y in high entropy alloys 2 o 3 The mass fraction is 0.5%, and the molar ratio of other metal elements is: Cu:Co:Ni:Cr:Al:Fe=1:0.5:1.2:1:1.5:1.5; 2.5%Y 2 o 3 -CuCrCoMoAl 1.5 Y in Ti high entropy alloy 2 o 3 The mass fraction is 2.5%, and the molar ratio of other metal elements is: Cu:Cr:Co:Mo:Al:Ti=1:1:1:1:1.5:1; the purity of various metal powders in this embodiment is all ≥ ...

Embodiment 3

[0041] A Cu-containing high-entropy alloy coating with a liquid phase separation structure, which is obtained by alloying five or more metal or non-metal elements in an equiatomic ratio or close to an equiatomic ratio, in addition to adding different amounts of Nano Y 2 o 3 , nano Y 2 o 3 The particle size distribution is between 20 and 100nm. In this embodiment, two kinds of high-entropy alloy powders are prefabricated, respectively denoted as 0.8% Y 2 o 3 -CoCrCuFeNiAl 1.2 Ti 0.5 and 1.5% Y 2 o 3 -Al 1.2 CuNi 0.8 CrFe, of which, 0.8% Y 2 o 3 -CoCrCuFeNiAl 1.2 Ti 0.5 Y in high entropy alloys 2 o 3The mass fraction is 0.8%, and the molar ratio of other metal elements is: Co:Cr:Cu:Fe:Ni:Al:Ti=1:1:1:1:1:1.2:0.5; 1.5%Y 2 o 3 -Al 1.2 CuNi 0.8 Y in CrFe high entropy alloy 2 o 3 The mass fraction of the metal elements is 1.5%, and the molar ratio of other metal elements is: Al:Cu:Ni:Cr:Fe=1.2:1:0.8:1:1; the purity of various metal powders in this embodiment is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com