High-toughness rare earth heat-resistant magnesium alloy and preparation method thereof

A magnesium alloy and rare earth technology, which is used in the deformation processing of non-ferrous metal materials and the field of metal materials, can solve the problems of weak plastic deformation resistance, poor overall toughness and ductility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

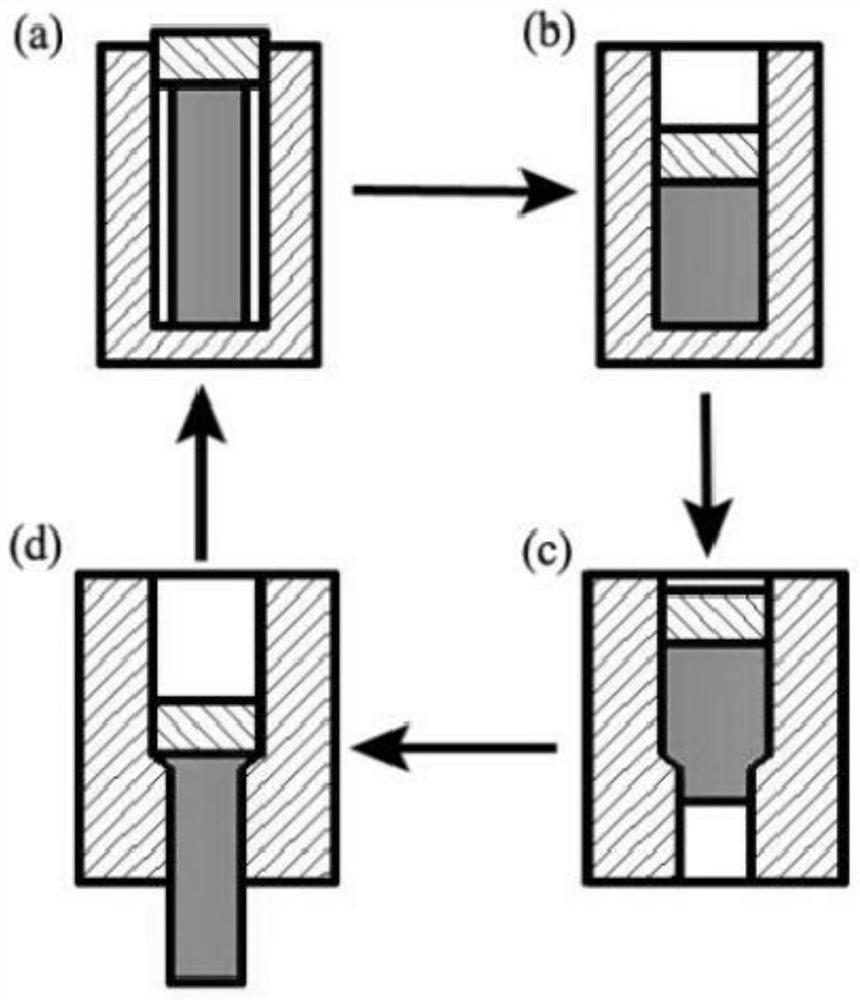

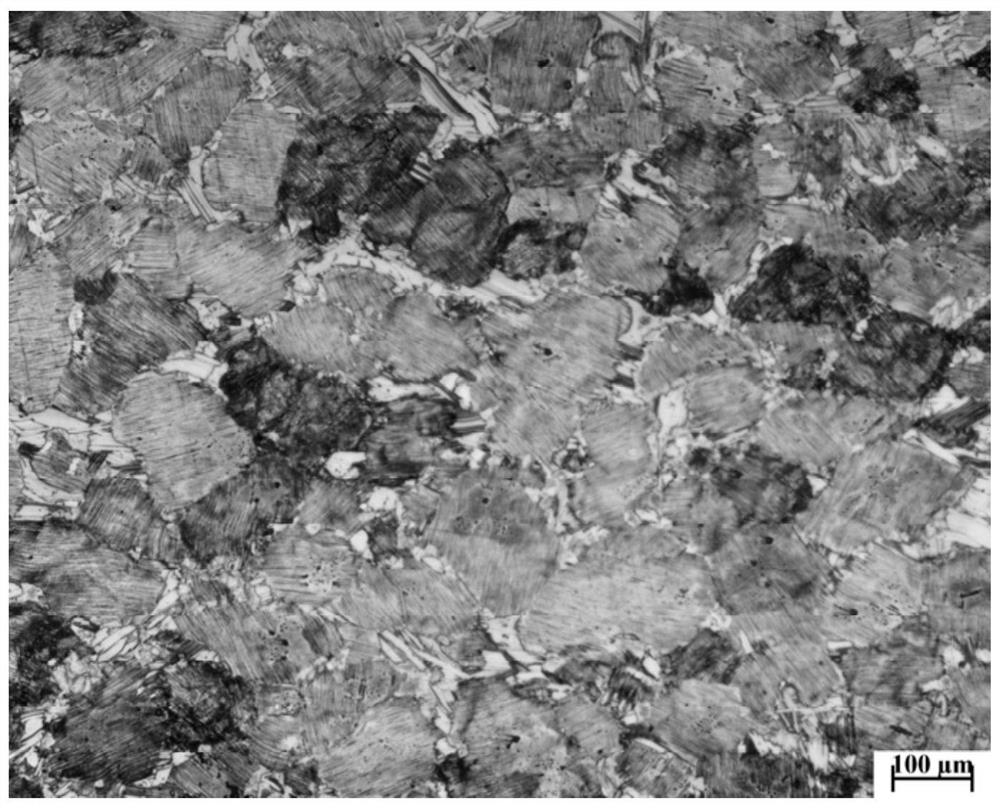

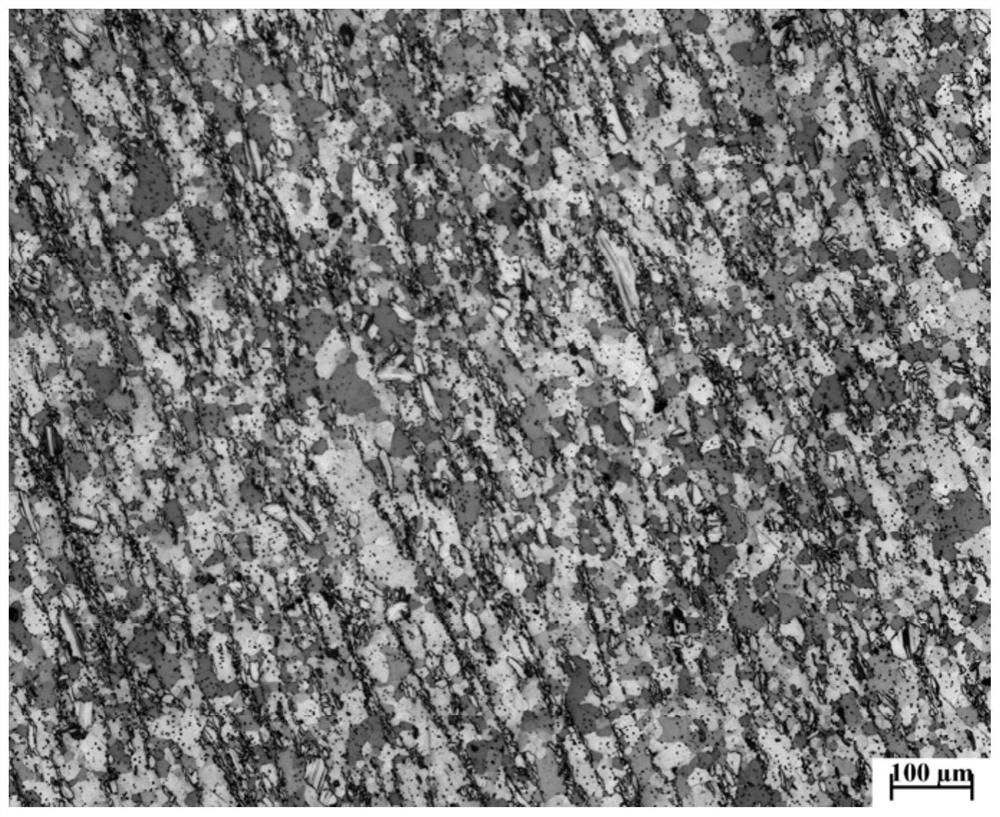

Method used

Image

Examples

Embodiment 1

[0043] The high-strength rare earth heat-resistant magnesium alloy is formulated according to the following mass percentages: 10.0% Gd, 3.6% Y, 2% Zn, 0.5% Zr, and the balance is magnesium and unavoidable impurity elements, and is prepared into a magnesium alloy bar. The tensile strength and elongation of the obtained magnesium alloy rods were tested, and the specific test results are shown in Table 1.

[0044] The mechanical property data obtained in the magnesium alloy rod test prepared in the embodiment one of table 1

[0045] Tensile strength (Rm) / MPa Yield strength (R p0.2 ) / MPa

Elongation (A) / % first heat 315 226 22 second heat 323 231 20 third heat 325 223 20 Fourth heat 313 219 22

[0046] The concrete preparation method of this alloy comprises the following steps:

[0047] (1) Preparation of magnesium alloy cast rod: first design the alloy element proportioning material according to the above mass percentage, a...

Embodiment 2

[0065] In this embodiment, the high-strength rare earth heat-resistant magnesium alloy is proportioned according to the following mass percentages: 8.4% Gd, 3.4% Y, 2% Zn, 0.4% Zr, and the balance is magnesium and unavoidable impurity elements, The alloy is prepared by the same preparation method as in Example 1. Specifically, a magnesium alloy cast rod of φ400×4200 mm is prepared by semi-continuous casting according to (1.1) to (1.5) of step (1) in Example 1; Then heat up the magnesium alloy cast rod to 300°C, hold it for 4 hours, and then homogenize it at 525°C for 8 hours; carry out upsetting and extrusion composite deformation of the cast rod after homogenization treatment: first heat the cast rod to 300°C, and hold it for 2 hours. First-level heating, then heating the cast rod to 480°C, holding it for 6 hours for second-level heating, and performing upsetting and extrusion compound deformation on the heated rod. The heating temperature of the mold is 430°C, and the extrusi...

Embodiment 3

[0067] In this embodiment, the high-strength rare earth heat-resistant magnesium alloy is proportioned according to the following mass percentages: 9.2% Gd, 3.1% Y, 1.8% Zn, 0.5% Zr, and the balance is magnesium and unavoidable impurity elements, The alloy is prepared by the same preparation method as in Example 1. Specifically, a magnesium alloy cast rod of φ400×4200 mm is prepared by semi-continuous casting according to (1.1) to (1.5) of step (1) in Example 1; Then heat up the magnesium alloy cast rod to 300°C, hold it for 4 hours, and then homogenize it at 525°C for 8 hours; carry out upsetting and extrusion composite deformation of the cast rod after homogenization treatment: first heat the cast rod to 300°C, and hold it for 2 hours. First-level heating, then heating the cast rod to 480°C, holding it for 6 hours for second-level heating, and performing upsetting and extrusion compound deformation on the heated rod. The heating temperature of the mold is 440°C, and the extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com