Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate and preparation method thereof

An aluminum alloy sheet and aluminum alloy technology, applied in the field of light metal material preparation and processing, can solve the problems of low production efficiency, long time consumption, complex alloy production process, etc., and achieve the effects of improving production efficiency, avoiding long time consumption, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

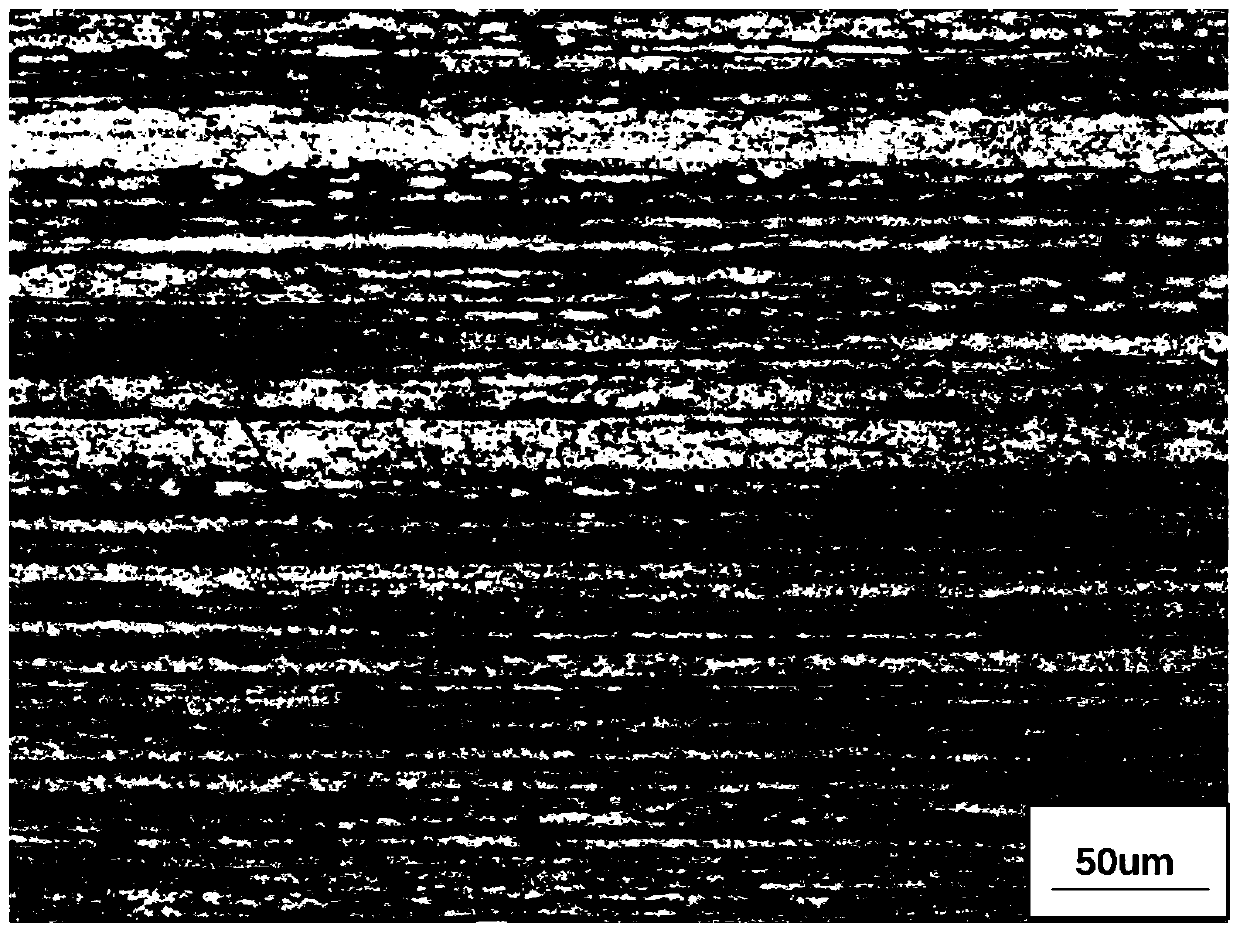

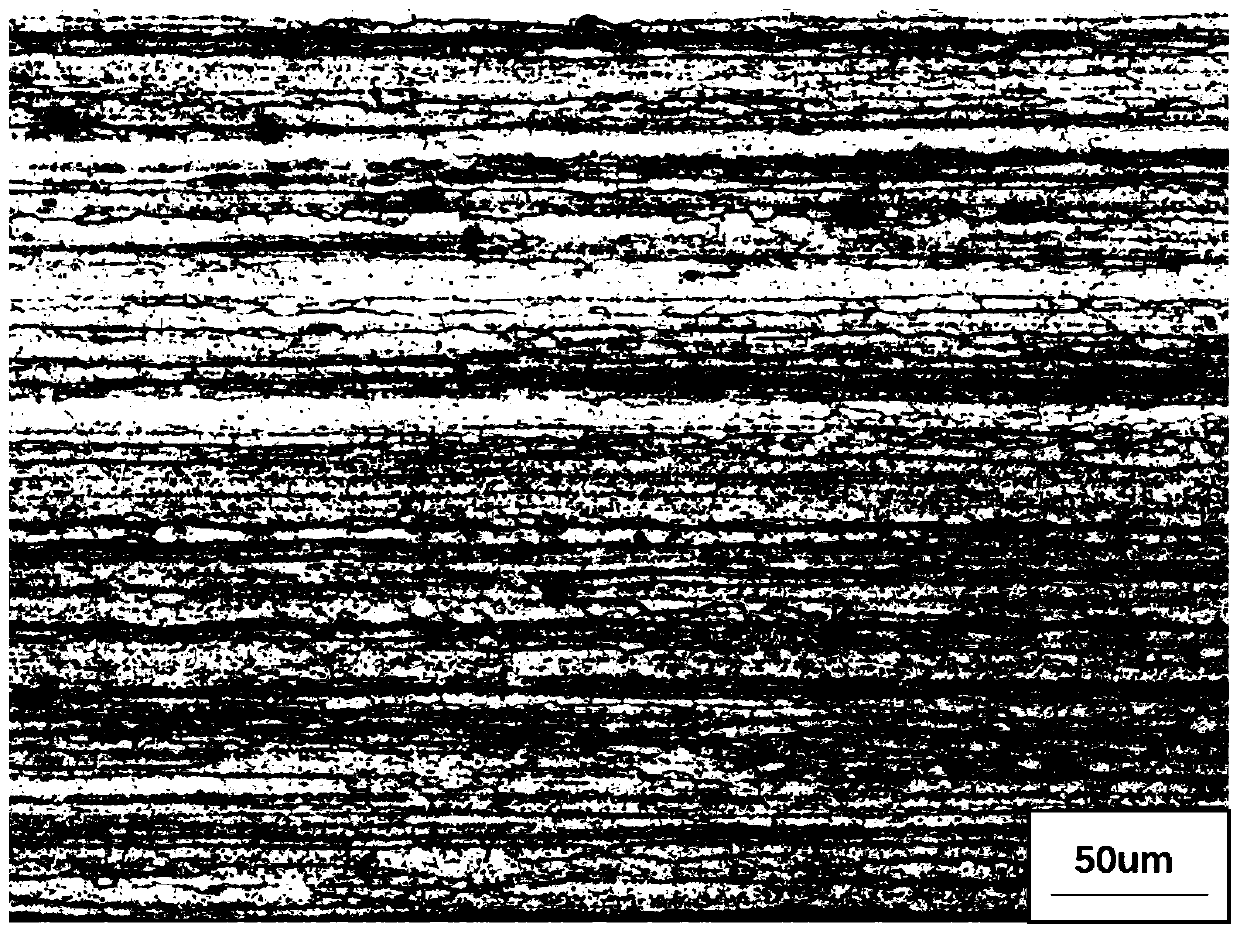

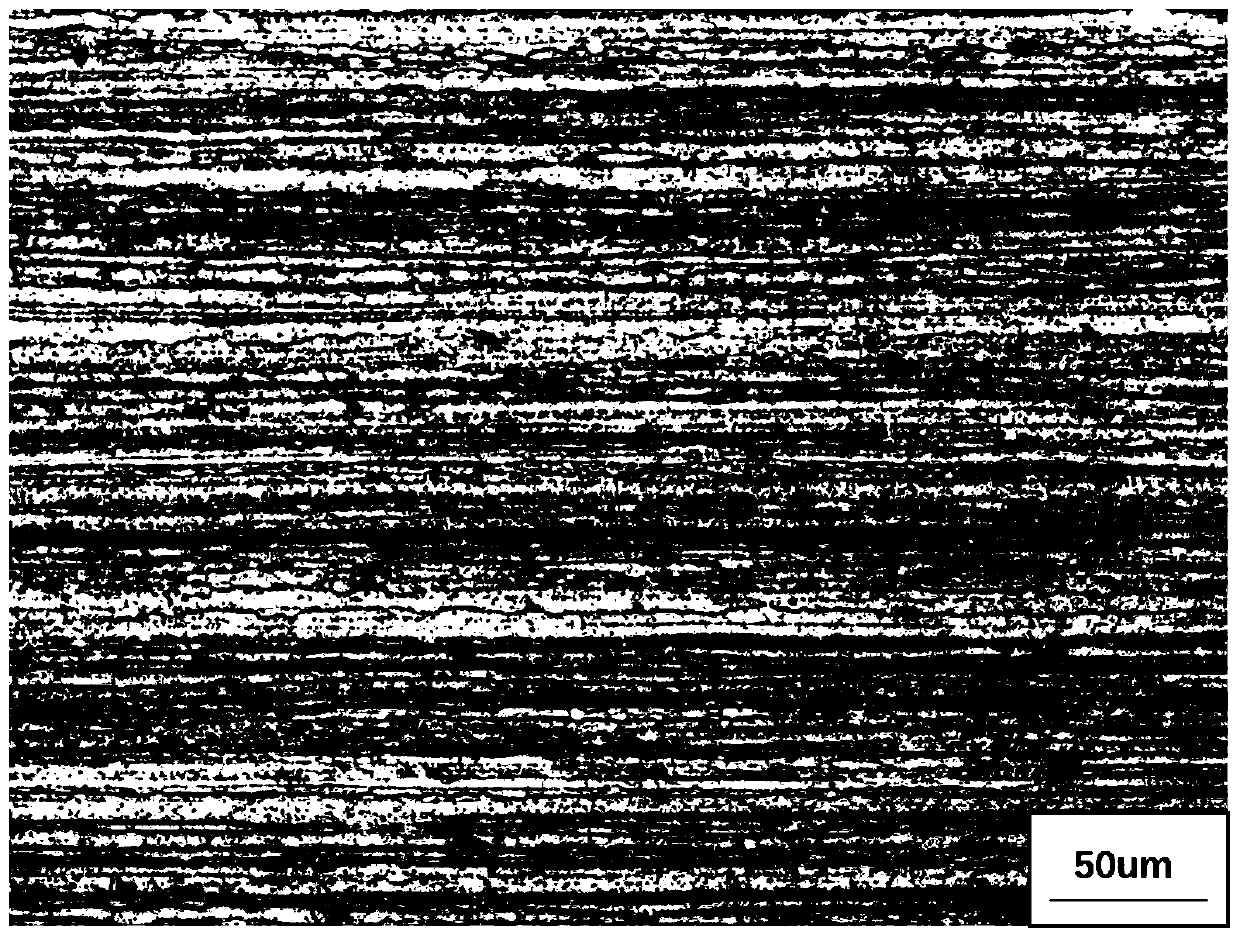

Image

Examples

preparation example Construction

[0034] The preparation method of the Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate provided by the embodiment of the present invention includes the following steps: batching, melting and casting, stress relief annealing, machining, heating, extrusion, Quenching, stretching straightening, aging.

[0035] Melt pure aluminum and all intermediate alloys together, the melting temperature is 760℃~790℃, add covering agent during melting, the covering agent is prepared by sodium chloride and potassium chloride according to the ratio of 1:1, after complete melting, refining and degassing, wait for When the temperature drops below 730°C, add pure zinc and pure magnesium. The pure magnesium is calculated according to the burning loss of 3-5%, and cast into an aluminum alloy cylindrical ingot of 300mm-500mm.

[0036] Aluminum alloy cylindrical ingots need to be annealed for stress relief in the range of 220-300 °C.

[0037] Homogenization annealing is not r...

Embodiment example 2

[0046] According to the ingredients and weight percentages of 3.0% Zn, 1.5% Mg, 0.4% Mn, 0.3% Cr, 0.2% Zr, 0.2% Er, 0.3Si and the rest are Al, Al-Mn, Al-Zr, Al-Er and Al-Cr master alloys, pure magnesium according to the proportion of burning loss of about 5%, pure aluminum (99.85%) and master alloys are melted at a temperature of 780°C at the same time, and covering agents are added during melting. Prepare sodium chloride and potassium chloride at a ratio of 1:1. After the alloy is completely melted, refining and degassing, slag removal, static cooling to 720°C, adding pure zinc (99.9%) and pure magnesium (99.9%) in turn, after the pure magnesium is completely melted, stirring, slag removal, at 710°C It is poured into an aluminum alloy cylindrical ingot with a diameter of 500mm at a certain temperature. The aluminum alloy cylindrical ingot according to After stress relieving annealing, after the saw head cuts the outer circle, it is slowly heated to 440°C, kept for 3 hours,...

Embodiment example 3

[0049] According to the composition and weight percentage of 2.8% Zn, 1.7% Mg, 0.3% Mn, 0.15% Cr, 0.2% Zr, 0.2% Er, 0.2Si, the rest is Al, and Al-Mn, Al-Zr, Al-Er and Al-Cr master alloys, pure magnesium according to the proportion of burning loss of about 5%, pure aluminum (99.85%) and master alloys are melted at a temperature of 780°C at the same time, and covering agents are added during melting. Prepare sodium chloride and potassium chloride at a ratio of 1:1. After the alloy is completely melted, refining and degassing, slag removal, static cooling to 720°C, adding pure zinc (99.9%) and pure magnesium (99.9%) in turn, after the pure magnesium is completely melted, stirring, slag removal, at 710°C It is poured into an aluminum alloy cylindrical ingot with a diameter of 300mm at a certain temperature. The aluminum alloy cylindrical ingot according to After stress relieving annealing, after the saw head cuts the outer circle, it is slowly heated to 440°C, kept for 3 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com