Multi-element composite reinforced molybdenum alloy and preparation method thereof

A multi-component composite and molybdenum alloy technology, applied in the field of powder metallurgy, can solve the problems of insufficient comprehensive performance and single performance of molybdenum alloy, and achieve the effects of improving high-temperature comprehensive performance, improving plasticity and processability, and low high-temperature creep rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

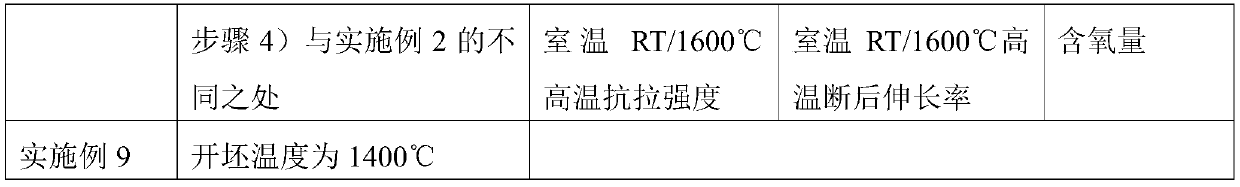

Examples

Embodiment 1

[0035] (1) Firstly weigh the raw materials according to the weight percentage of Mo-0.50Ti-0.10Zr-0.12C-1.0Hf-0.50Re, and then carry out the mixing treatment, wherein, the Fischer particle size of Mo and Re powders is 3.0 μm, TiH 2 , ZrH 2 , HfC, Mo 2 The particle size of powder C is -300 mesh; the raw materials are mixed in a three-dimensional vacuum mixer for 4 hours, and mixed evenly to obtain molybdenum alloy powder for later use.

[0036] (2) Put the molybdenum alloy powder prepared in the step (1) into the cavity of the mould, press and form it under the conditions of 150MPa and holding pressure for 5s, and obtain a formed billet.

[0037] (3) Place the formed blank obtained in step (2) in a high-temperature vacuum sintering furnace for sintering. The high-temperature sintering temperature is 2250° C., the holding time is 4 hours, and the vacuum degree throughout the sintering process is better than 5×10 -2 Pa, where the vacuum degree in the furnace before 1500°C is be...

Embodiment 2

[0042] (1) First, weigh the raw materials according to the weight percentage of Mo-0.45Ti-0.08Zr-0.10C-1.2Hf-1.0Re, and carry out the mixing treatment, wherein, the Fischer particle size of Mo and Re powder is 3.5 μm, and TiH 2 , ZrH 2 , HfC, Mo 2 The particle size of powder C is -200 mesh; the raw materials are mixed in a three-dimensional vacuum mixer for 6 hours, and mixed evenly to obtain molybdenum alloy powder for later use.

[0043] (2) Put the molybdenum alloy powder prepared in step (1) into the cavity of the mold, press and form under the conditions of 200MPa and holding pressure for 10s, and obtain a formed blank.

[0044] (3) Place the formed billet obtained in step (2) into a high-temperature vacuum sintering furnace for sintering. The high-temperature sintering temperature is 2200° C., the holding time is 5 hours, and the vacuum degree throughout the sintering process is better than 5×10 -2 Pa, where the vacuum degree in the furnace before 1500°C is better than...

Embodiment 3

[0050] (1) First, weigh the raw materials according to the weight percentage of Mo-0.40Ti-0.07Zr-0.08C-1.0Hf-1.0Re, wherein Re is added in the form of ammonium rhenate, the molybdenum powder Fisherman’s particle size is 4.0 μm, TiH 2 , ZrH 2 , HfC, Mo 2 C. The particle size of ammonium rhenate powder is -150 mesh; then, the mixed powder of molybdenum powder and ammonium rhenate is subjected to hydrogen reduction treatment, wherein the temperature of the first hydrogen reduction treatment is 450 ° C, and the time is 30 minutes. The temperature of the hydrogen reduction treatment is 900°C and the time is 30 minutes to obtain the molybdenum-rhenium alloy powder that meets the ratio requirements; finally, the molybdenum-rhenium alloy powder and other raw material powders are mixed in a double-motion vacuum mixer for 4 hours, and the molybdenum-rhenium alloy powder is mixed evenly to obtain molybdenum Alloy powder spare.

[0051] (2) Put the molybdenum alloy powder prepared in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com