Switch with trigger

A trigger and switch technology, which is applied in the field of switches with triggers, can solve the problems of trigger current and voltage distortion, affect the electrical performance of switches, and make it difficult to realize, so as to reduce the influence of stray parameters and make the electrical connection completely reliable , resistance to ablation and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

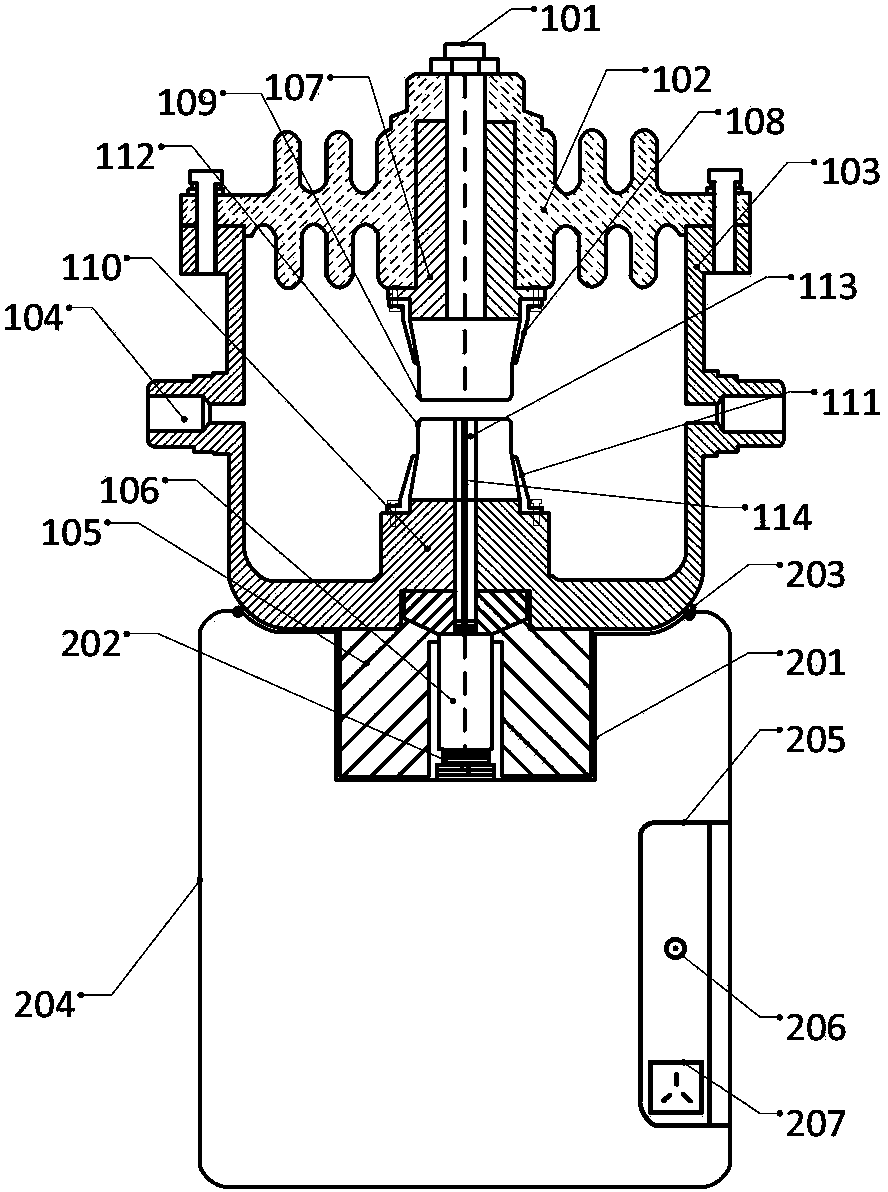

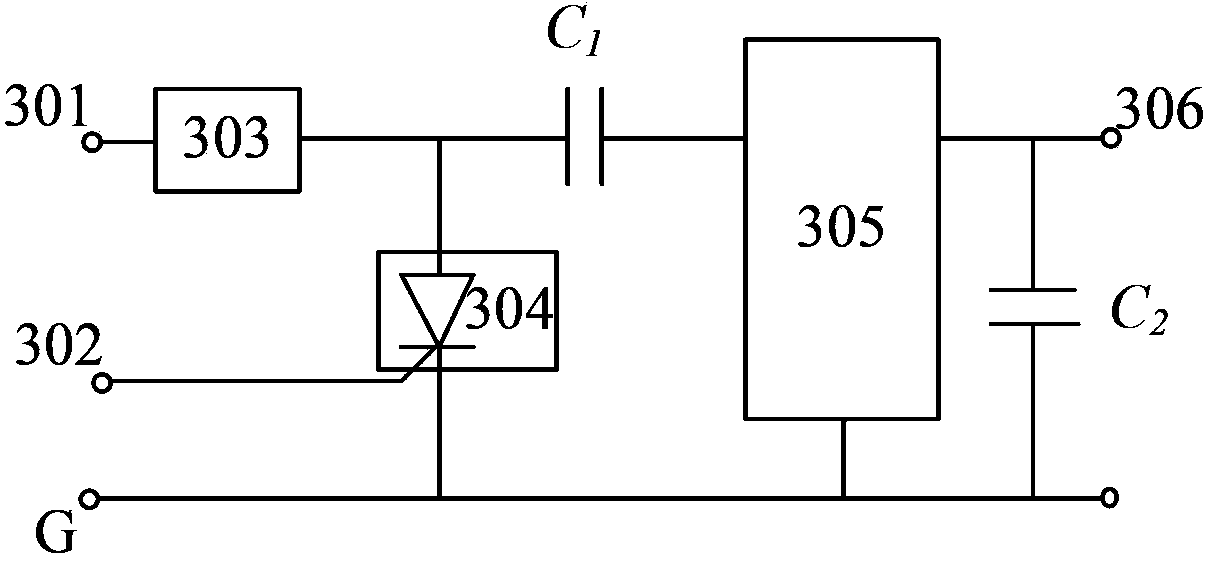

[0023] Such as figure 1 As shown, the switch with a trigger of the present invention includes a switch body 1 and a trigger 2 . The switch main body 1 includes a connection terminal 101, an insulating cover plate 102, a metal shell 103, a pair of gas nozzles 104, a cylindrical insulator 105, an extraction pole 106, an upper electrode base 107, an upper electrode sleeve 108, an upper graphite electrode 109, a lower An electrode base 110 , a lower electrode sleeve 111 , a lower graphite electrode 112 , a ceramic tube 113 , and a trigger pin 114 . The trigger 2 includes a trigger groove 201 , a trig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com