Method for assisting brazing by carbon nanotube reinforced type three-dimensional middle layer

A carbon nanotube, three-dimensional structure technology, applied in the field of brazing ceramics and metals, can solve the problems of insufficient high temperature performance and large residual stress, and achieve the effects of improving high temperature performance, relieving residual stress and relieving residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

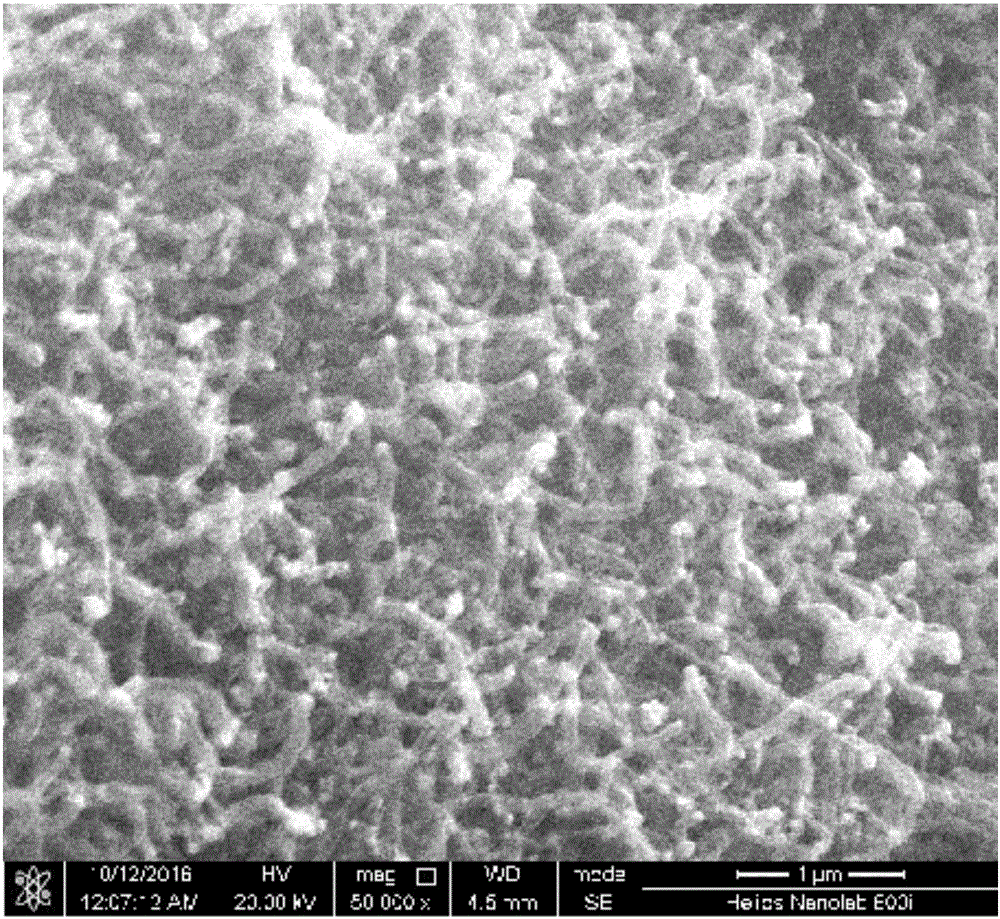

Image

Examples

specific Embodiment approach 1

[0022] Embodiment 1: A method for assisting brazing of a carbon nanotube-reinforced three-dimensional structure intermediate layer described in this embodiment is carried out in accordance with the following steps:

[0023] 1. Wash the metal foam with hydrochloric acid, acetone, absolute ethanol and deionized water with a concentration of 1mol / L-3mol / L for 10 minutes, and then dry it naturally to obtain the pretreated metal foam. Add the catalyst to the In water ethanol, obtain the dehydrated ethanol solution of the catalyst with the concentration of 0.001mol / L~1mol / L, impregnate the foam metal after pretreatment in the dehydrated ethanol solution of the catalyst with the concentration of 0.001mol / L~1mol / L , let stand for 1h, and then dry naturally to obtain the foamed metal after soaking;

[0024] 2. Place the soaked metal foam in a plasma-enhanced chemical vapor deposition vacuum device, evacuate until the pressure is below 20Pa~100Pa, pass in hydrogen gas, adjust the flow r...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment is different from Embodiment 1 in that the metal foam described in step 1 is copper foam or nickel foam. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the catalyst described in step 1 is nickel nitrate hexahydrate, iron nitrate, cobalt nitrate, nickel sulfate, iron sulfate or cobalt sulfate. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com