Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Easy pickling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

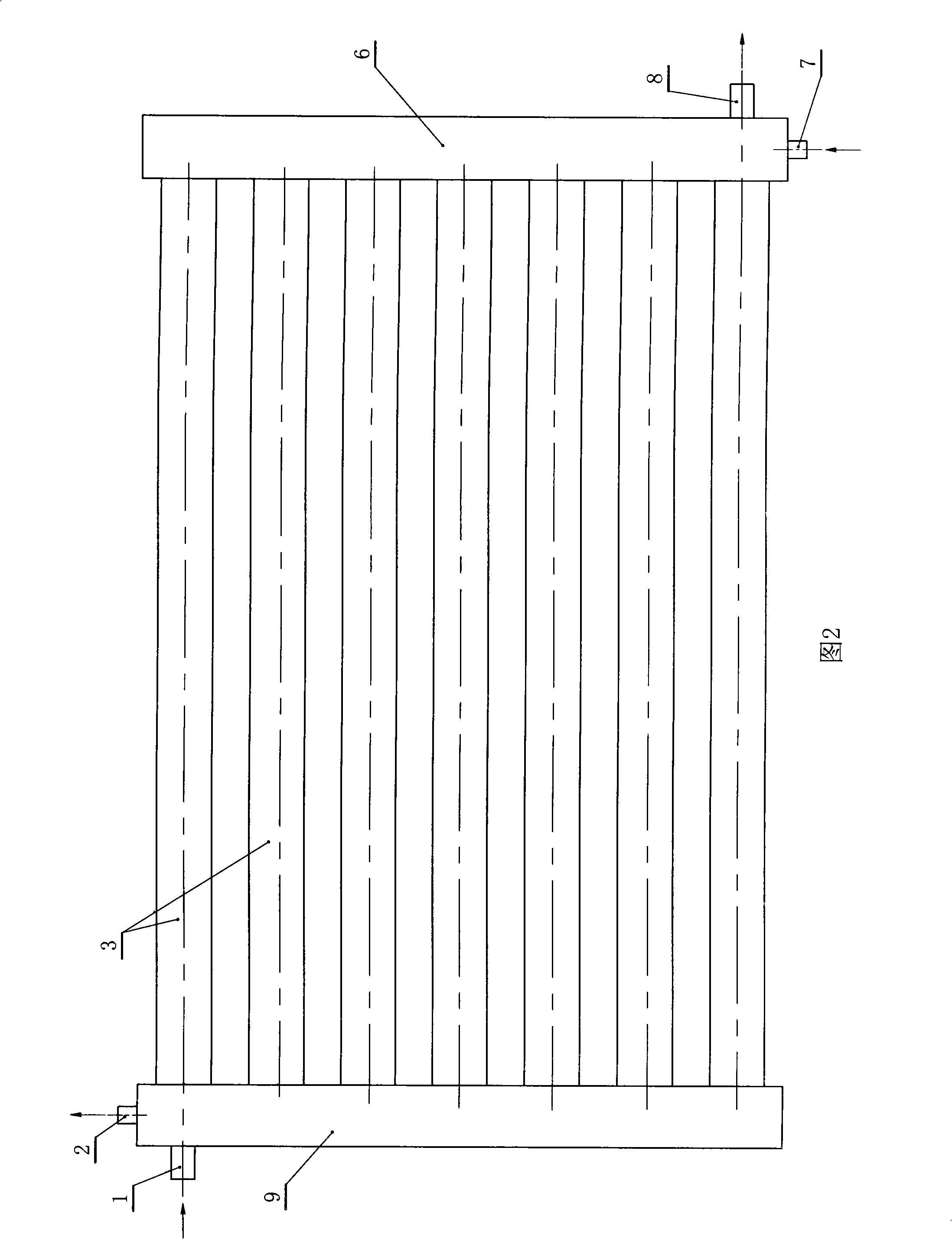

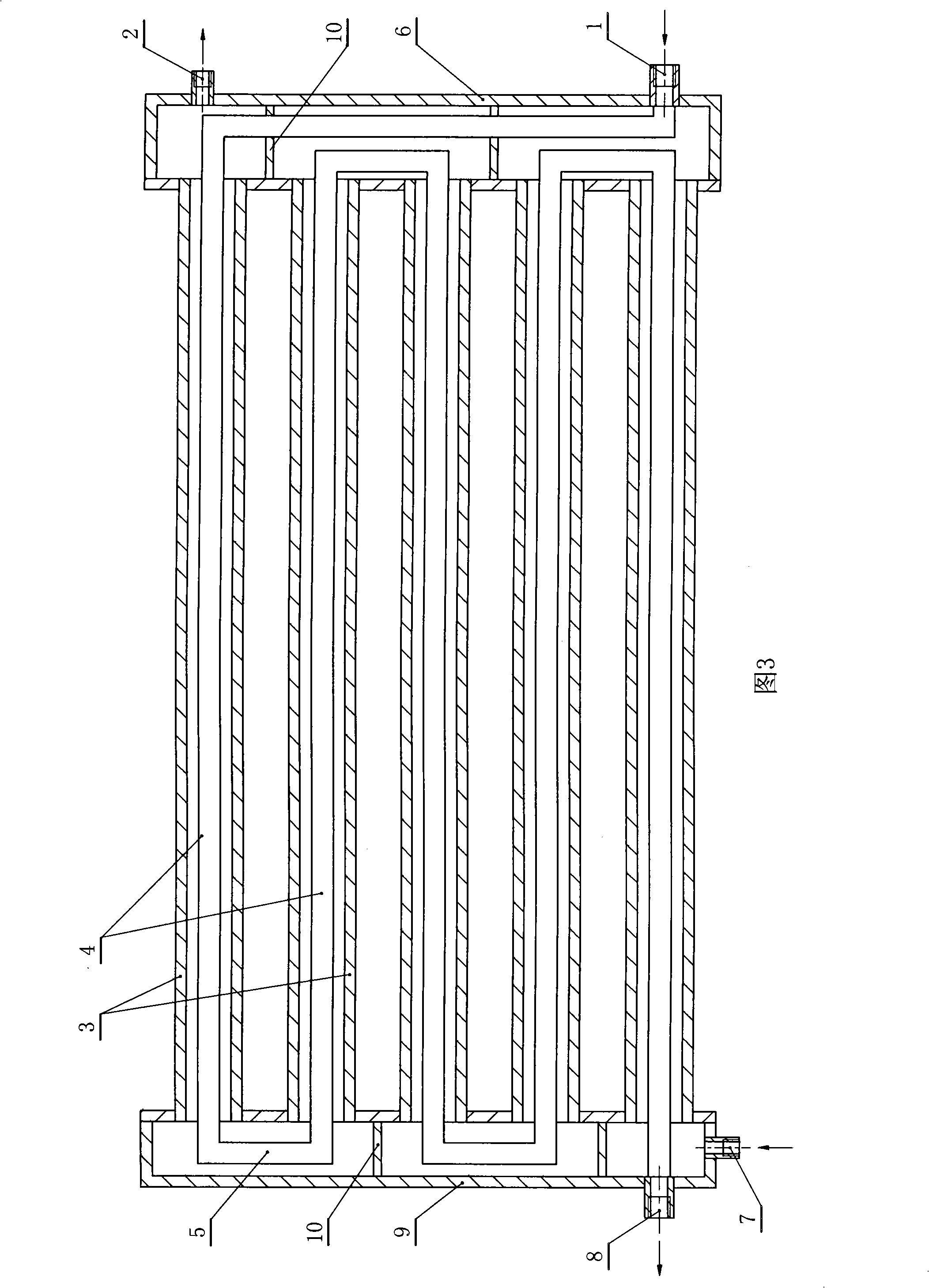

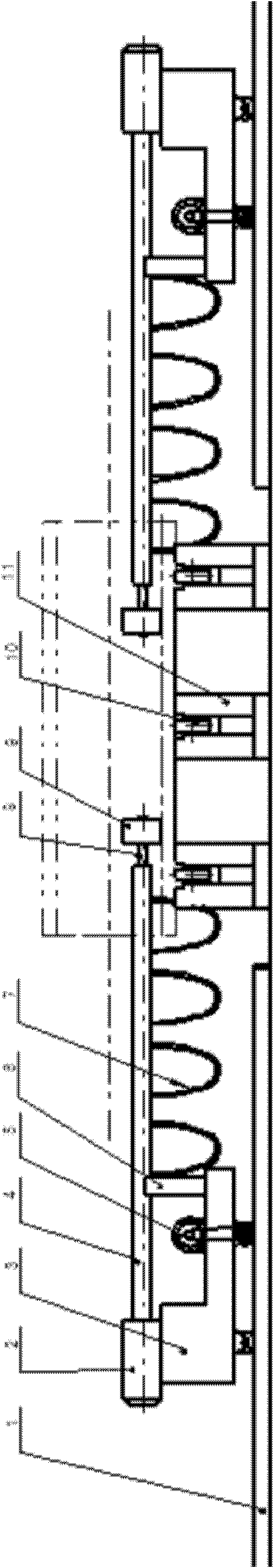

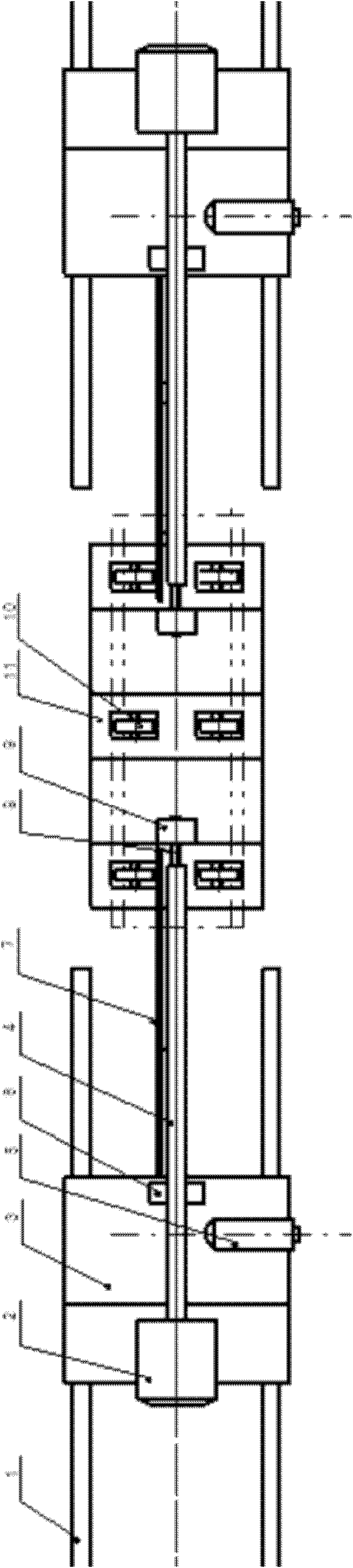

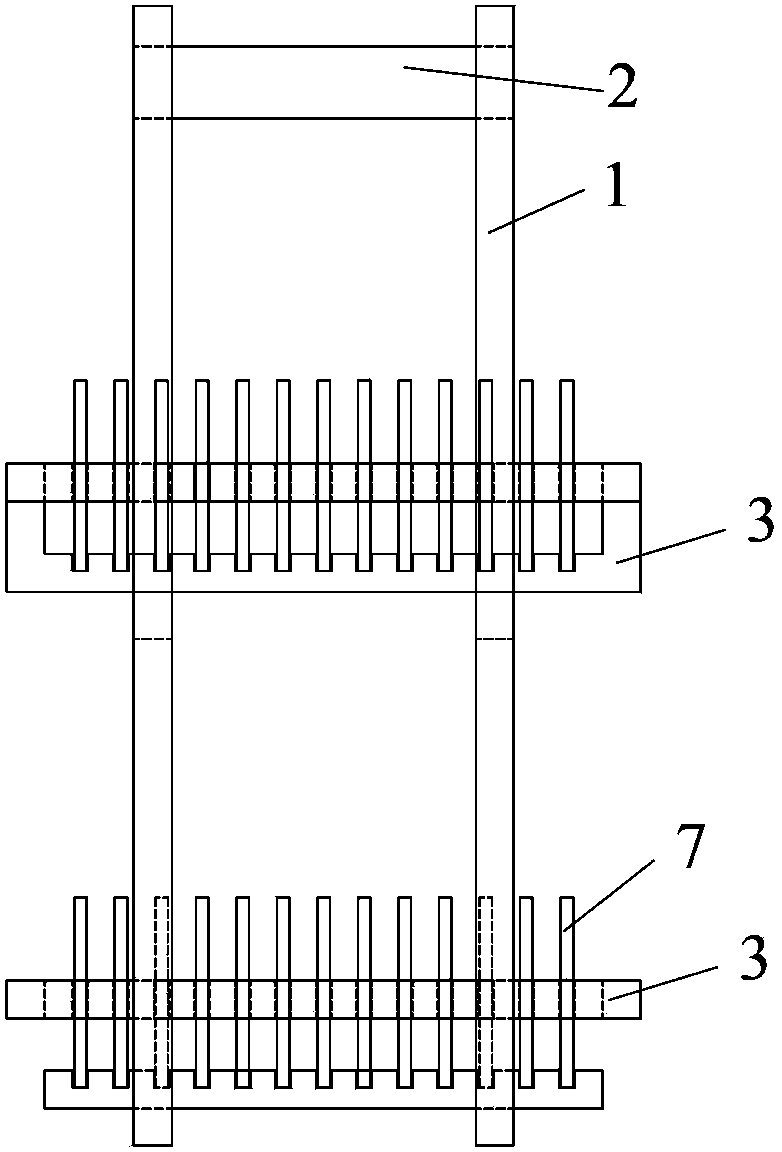

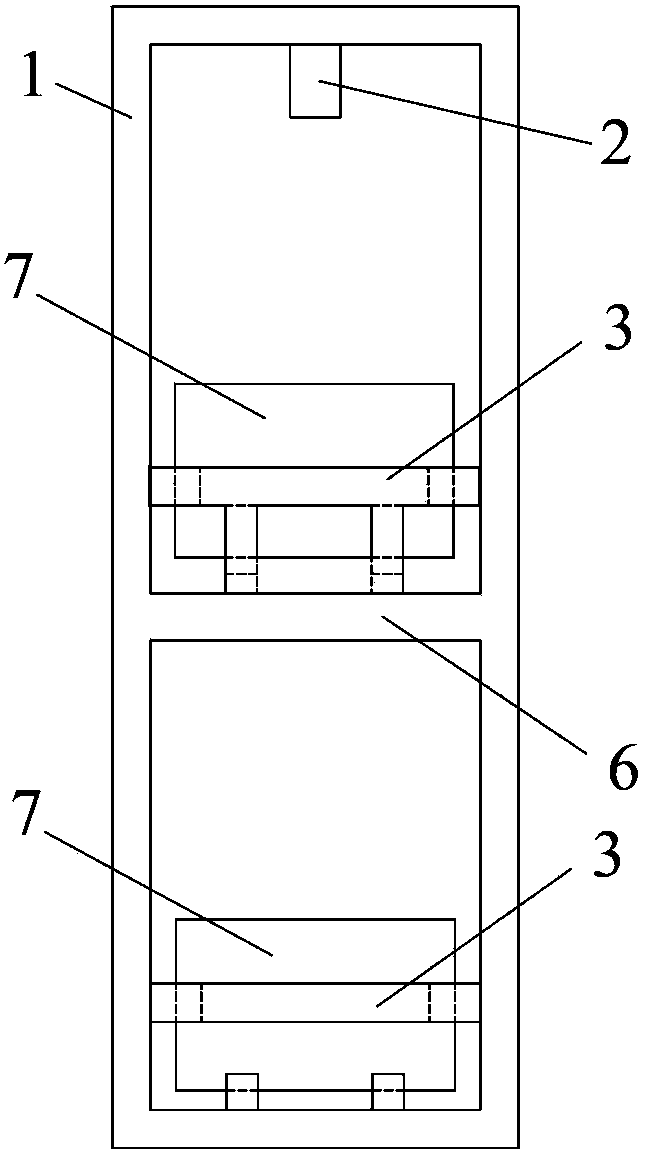

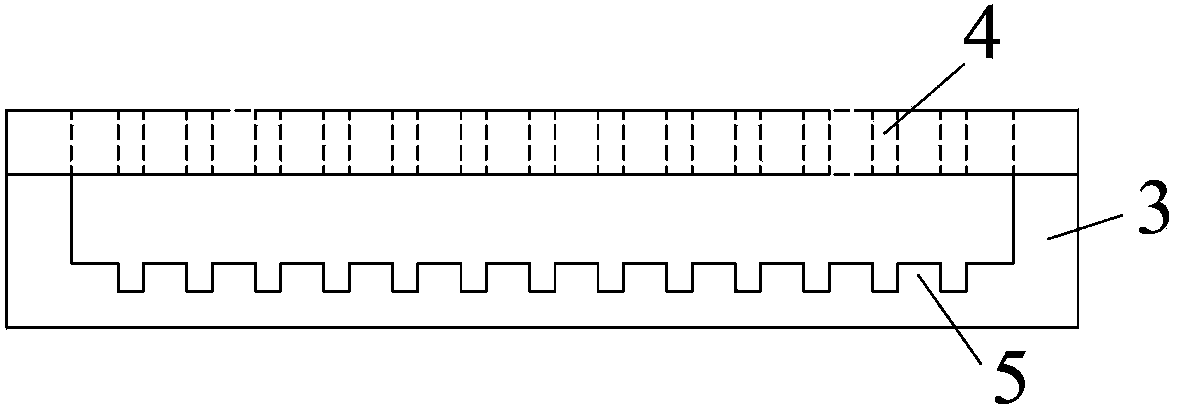

Header shunting heat storage adverse current type heat exchanger

InactiveCN101290196ANot easy to formLarge cavityStationary tubular conduit assembliesCounter flowEngineering

The invention discloses a header tank divided-flow heat-storage counter flow heat exchanger, which comprises a left header tank and a right header tank which are connected with a warm air water inlet, a warm air water outlet, a tap water inlet and a tap water outlet, wherein, a plurality of tap water heat-absorbing pipes are connected with the left and right header tanks; warm air heat supply pipes are connected through tap water heat-absorbing pipes; the warm air heat supply pipes are serially communicated with each other by heat supply communicating pipes; one end of each warm air heat supply pipe is connected with the warm air water inlet, while the other end is connected with the warm air water outlet; and a plurality of water insulation boards is alternatively connected the inside of the left and the right header tanks in order to separate the left and right header tanks to obtain the oriented flow channel. The counter flow heat exchanger of the invention has the advantages that: firstly the heat exchange efficiency is high and the temperature of the outlet water is high; secondly the joints of the heat supply pipes are arranged on the same level of axis line, which is suitably installed in household-measured users of the new heat supply pipe network unit, in particular to the needs of the three northeast provinces; thirdly the users can take a shower in the heat supply region of low temperature, and the heat-absorbing pipes at heat supply region of high temperature is free from scale formation; finally the counter flow heat exchanger is totally made of stainless steel, thereby saving brass pipe, reducing the cost and producing the clean water by exchange.

Owner:张伟

Superhigh-strength cold rolling band steel with anti-tensile strength above 880Mpa and its production

ActiveCN1940108AReduce the temperatureHigh strengthFurnace typesHeat treatment process controlAcid washingStrip steel

High strength cold-strip steel whose tensile strength is over 880Mpa , its component is ( weight percentage): C:0.14-0.24%;Si:0.2-1.2%;Mn:1.5-2.5%;P:<0.02%; S:<0.02%;N:<=0.005%;Ti:0.03-0.1%;Nb:0-0.04%;B:0.002- 0.006%;Al:0.02-0.08%;the other is composed of Fe and other inevitable impurity. Its method is as following: Steel billet-> hot-rolling-> acid-washing-> cold rolling-> continuous annealing; its main manufacture technological parameter is as following: The anneal temperature is between750DEG C-850DEG C, heat preservation time is controlled to between 40s-150s; Air cooling speed is 30-60DEG C / s, cooling down to350-500DEG C; The hydrocooling temperature is below 200DEG C; The drawing-back temperature is 150-300DEG C, drawing-back time is 100-300s; the unknit rate is 0-0.8%.

Owner:BAOSHAN IRON & STEEL CO LTD

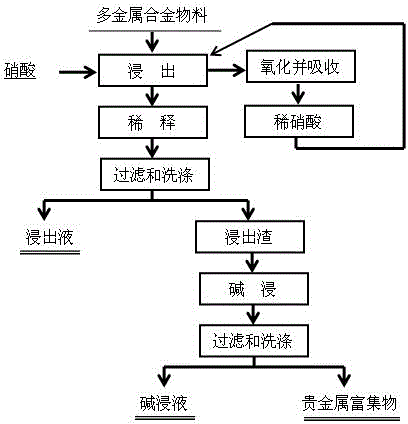

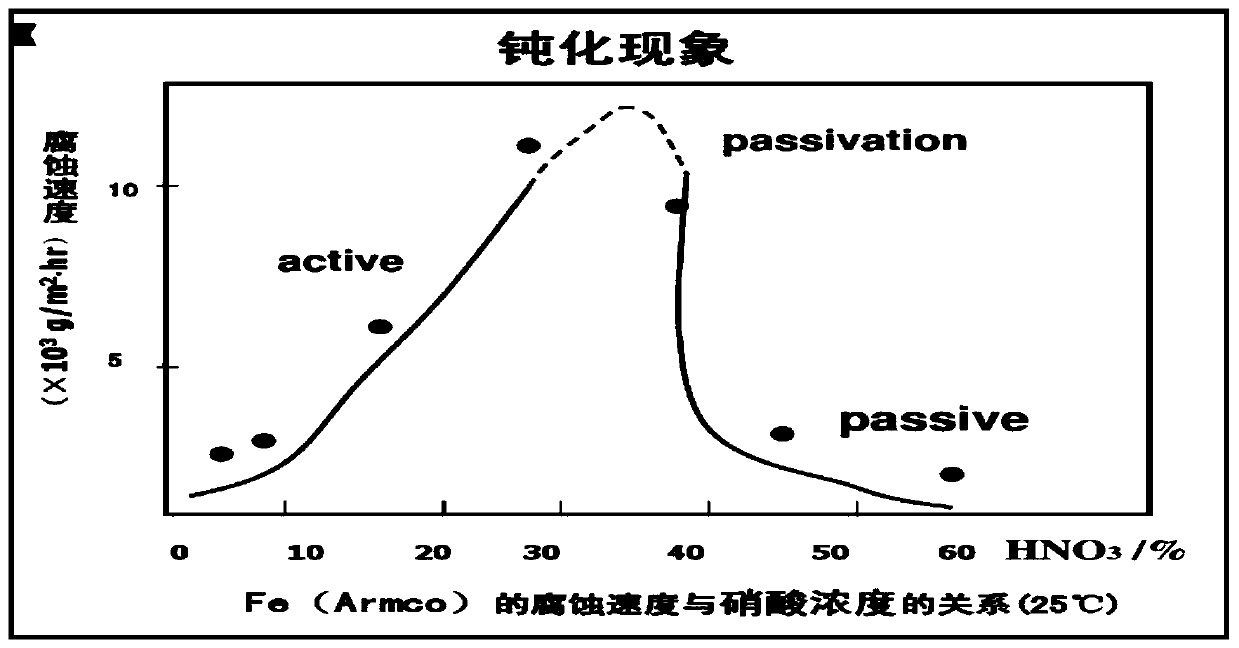

Method for enriching precious metal by dissolving multi-metal alloy material through nitric acid

ActiveCN105886769AEasy to operateMature production equipmentProcess efficiency improvementEnvironmentally friendlyBismuth

Owner:KUNMING BOREN PRECIOUS METALS

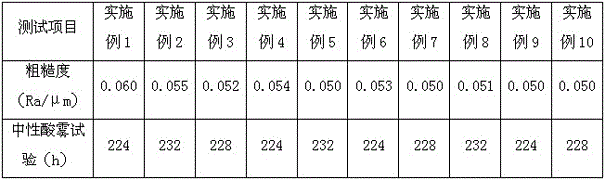

Stainless steel pickling and passivation solution as well as preparation method and use method thereof

ActiveCN106086848AStrong oxidation abilityHighly corrosiveMetallic material coating processesHydrofluoric acidSURFACTANT BLEND

The invention relates to the technical field of metal passivation, and specifically relates to a stainless steel pickling and passivation solution as well as a preparation method and a use method thereof. The stainless steel pickling and passivation solution comprises the following raw materials in percentage by weight: 14-22% of nitric acid, 3-7% of hydrofluoric acid, 0.6-1.0% of nonionic surfactant, 0.41-0.65% of corrosion inhibitor, 0.05-0.15% of oxidant, 0.03-0.07% of ionic surfactant and the balance water. The stainless steel pickling and passivation solution disclosed by the invention is capable of carrying out pickling and passivation on a stainless steel product under a normal-temperature condition, safe and environment-friendly, high in stability, good in pickling and passivation effects, and low in cost.

Owner:Dongguan Kaimeng Chemical Co Ltd

Hot-rolled stainless steel annealing process under protection of full hydrogen gas

The present invention relates to a hot-rolled stainlesss steel annealing process under the condition of full hydrogen protection, in particular, it is applicable for annealing ferritic and martensitic hot-rolled stainless steel roll, and includes the following steps: a). in the course of heating adopting hydrogen gas whose hydrogen gas content is above 99.99% oxygen content is below 10 to the minus fifth and dew-point is -60 deg.C--30 deg.C as protection gas to make sweeping, and controlling the dew-point of atmosphere in the furnace at -30 deg.C--50 deg.C; b). adopting heating and heat-insulating temp. of 830-870 deg.C, after the centre of bottom of steel roll is reached to heat-insulating temp. for 1-3 hr., stopping heating; and c). using heating cover to slowly cool for 3-5 hr., using cooling cover to quickly cool to control temp. of bottom of steel roll to 200-300 deg.C, tapping and naturally cooling.

Owner:NINGBO BAOXIN STAINLESS STEEL

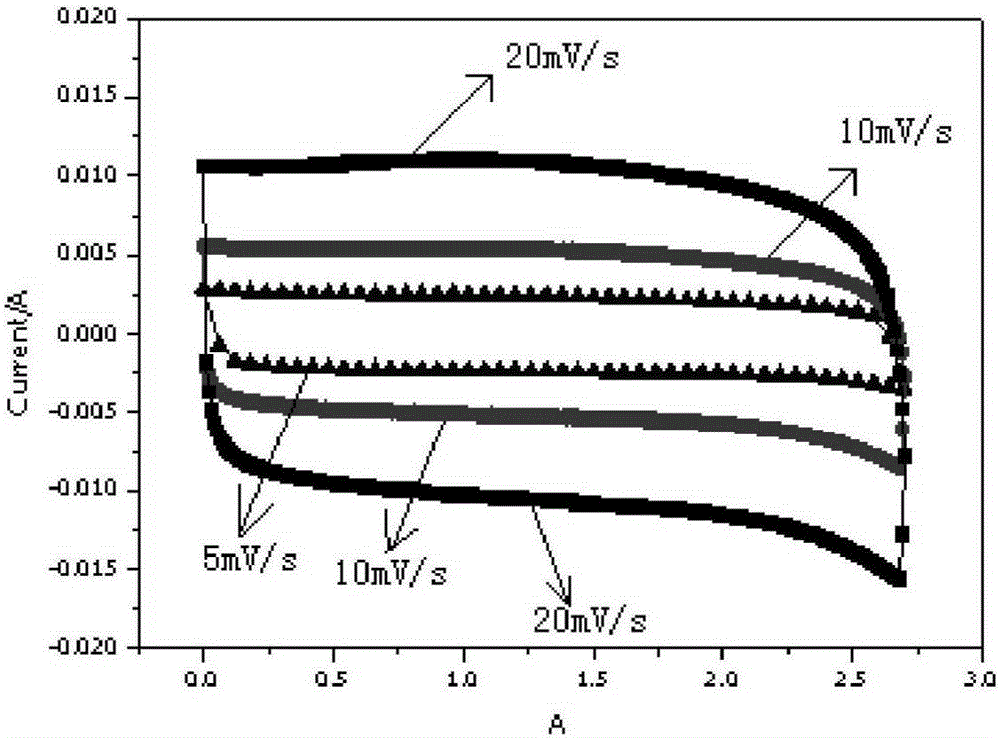

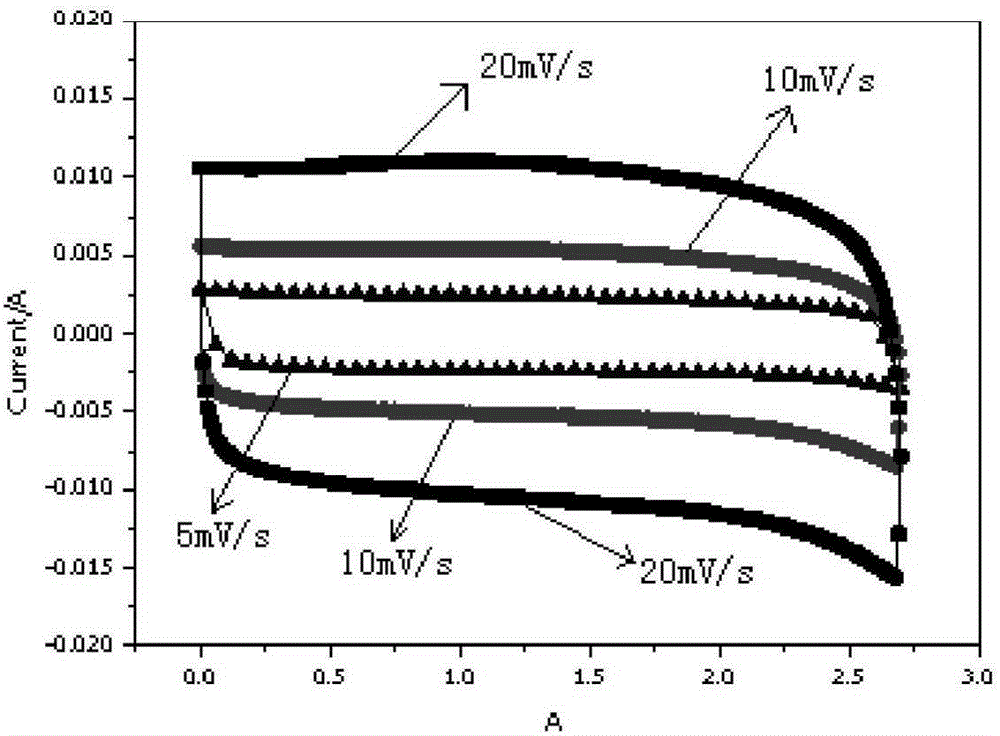

Method for preparing electrode materials with hollow carbon fibers coated with manganese dioxide

ActiveCN105513822AMild preparation conditionsMultiple load areasHybrid capacitor electrodesHybrid/EDL manufactureFiberCarbon fibers

The invention discloses a method for preparing electrode materials with hollow carbon fibers coated with manganese dioxide, and relates to the technical field of preparation of electrode materials. The method includes the steps that metal-oxide nanorods inside carbon fibers are washed away through acid, and the hollow carbon fibers are obtained; the surfaces of the carbon fibers are loaded with MnO2 with the hydrothermal method; polytetrafluoroethylene serves as a binding agent, acetylene black serves as an electric conduction assistant agent, foamed nickel serves as a current collector, and the HCNF@MnO2 electrode materials are prepared. According to the preparing process, the condition is mild, and the environment is friendly; economically, as cheap metal oxide is used, technology cost is reduced; the method is suitable for mass production.

Owner:YANGZHOU UNIV

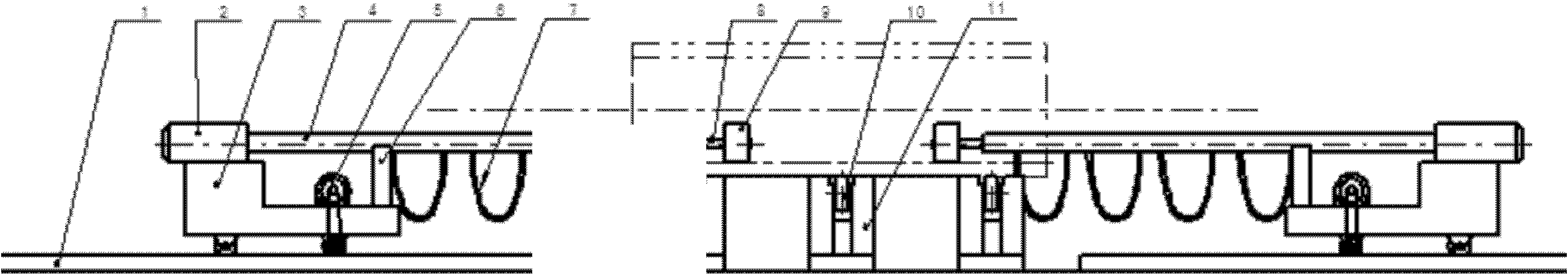

Inner wall washer of steel tube

InactiveCN101884991AImprove removal efficiencyIncrease intensityHollow article cleaningElectric machineryAcid washing

The invention relates to an inner wall washer of a steel tube. The washer comprises a track, a rail car, an iron-brush motor, a trolley motor, a steel tube bracket and an iron brush, wherein the rail car runs on the track, the trolley motor is fixed on the rail car, the wheels of the rail car are driven to rotate by the rail car, the iron-brush motor is fixed at the rear part of the rail car, the end part of the output shaft of the iron-brush motor is coaxially provided with the iron brush, a water spraying pipe is mounted at the side of the output shaft and the opening of the water spraying pipe faces to the diametric plane of the iron brush. The invention has the advantages of simple overall structure, scientific and reasonable design, high washing efficiency and perfect washing effect, and can be used for effectively cleaning the graphite adhered to the surface of the inner wall of the steel tube after the process of thermal diffusion so as to reduce the adherence of graphite, which is beneficial to acid washing of steel tube, thereby improving the subsequent processing quality of steel tube.

Owner:天津润德中天钢管有限公司

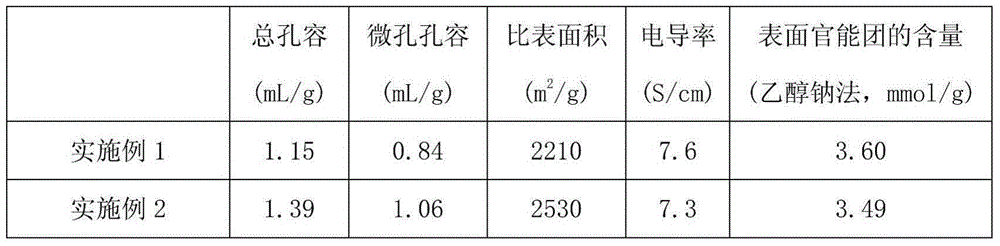

Low-alkali activated preparation method and application of pitch-based activated carbon

ActiveCN105174260AReduced service lifeExtended service lifeHybrid capacitor electrodesActivated carbonAlkali activated

The invention provides a low-alkali activated preparation method and application of pitch-based activated carbon. The method comprises the steps that pitch is taken as the raw materials and sequentially processed through coking, mixing with solid alkali, pre-activating, activating, cleaning and the like, and the pitch-based activated carbon is prepared. According to the preparation method, green coke and the alkali are mixed evenly through pre-activating treatment, and on one hand, contact of the green coke and the alkali is enlarged, so that the preparation method has the advantages that at least three eighths of the alkali using amount is saved compared with the prior art, the service life of an activating oven is prolonged, the discharge quantity and treatment difficulty of cleaning effluent are reduced, and the advantages of energy conservation and environment protection are achieved; on the other hand, the quality homogeneity of the activated carbon can be improved, and property difference among the products of different batches can be avoided; in addition, activating treatment is performed on pre-activating products by quickly increasing the temperature, corrosion of the strong alkali on equipment at high temperature for a long time is reduced, the number of functional groups on the surface of the activated carbon can be reasonable, and improvement of the electric conductivity of the products is facilitated.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

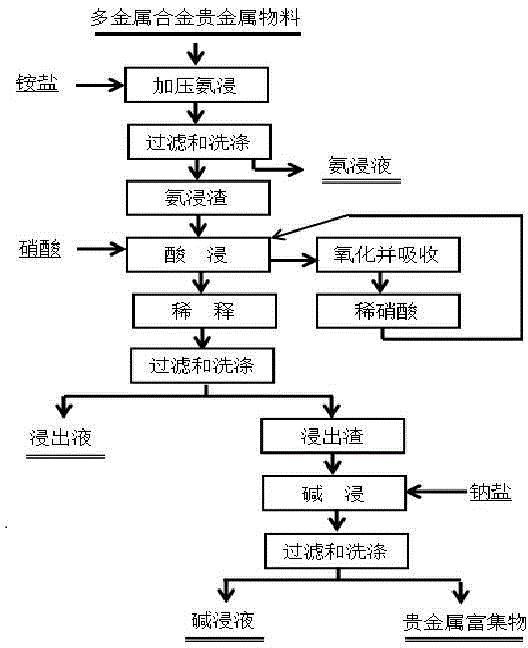

Method for collecting noble metal from polymetallic alloy material

ActiveCN105861836AHigh enrichment ratioEasy to operateProcess efficiency improvementPrecious metalAntimony

The present invention discloses a method for collecting noble metal from polymetallic alloy material. The method is as below: mixing a polymetallic alloy material with ammonium salt, placing the mixture in an autoclave for pressure leaching of primary metals copper and nickel, filtering and washing after leaching, respectively acquiring a leaching solution and ammonia leaching residue, and using the leaching solution as copper and nickel recycling raw material; adding nitric acid into ammonia leaching residue, leaching in a closed titanium reactor for some time, and heating to concentrate and evaporate residual nitrate; when the reaction products reach a viscous state, stopping heating, while adding water for dilution, filtering and washing to respectively obtain a leaching solution and acid leaching residue containing antimony, gold, platinum and palladium; using the leaching solution containing lead as a raw material for recycling lead; removing antimony by pressure alkali leaching, filtering and washing to obtain alkaline leaching solution and alkaline leaching slag; and immersing precious metals into the slag, so as to effectively enrich precious metals. The method has the advantages of simple operation procedure, mature equipment, environment-friendliness, low production cost, high precious metal enrichment ratio, and good prospects for industrial application.

Owner:KUNMING BOREN PRECIOUS METALS

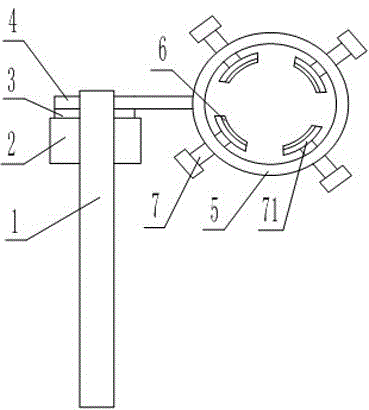

Method for removing rust on outer wall of petroleum drill rod

InactiveCN105598057AEasy to removeEasy picklingCleaning using toolsCleaning using liquidsMotor drivePetroleum

The invention discloses a method for removing rust on the outer wall of a petroleum drill rod. The method comprises the following steps: 1, scraping away dirt on the outer wall of the drill rod with a cleaning device; 2, spraying a diluted hydrochloric acid solution to the outer wall of the drill rod with the dirt scraped away; 3, conducting washing on the outer wall of the drill rod which is treated through the diluted hydrochloric acid solution; 4, wiping the outer wall of the drill rod with cleaning cloth. By means of the rust removal method, manual operation is not needed after the dirt-scraping step is completed, friction between a cleaning plate and the outer wall of the drill rod is achieved under motor drive, and furthermore the dirt on the outer wall of the drill rod can be removed, so that the dirt and the rust on the outer wall of the drill rod are loosened, subsequent pickling and washing are facilitated, operation is simple and convenient, efficiency of cleaning the outer wall of the drill rod is greatly improved, the rust and other alkaline dirt are dissolved through the diluted hydrochloric acid solution, finally, the dirt is removed through washing, operation is convenient, and the dirt is cleared away thoroughly.

Owner:SICHUAN XILIN OIL SUPPLIES EQUIP

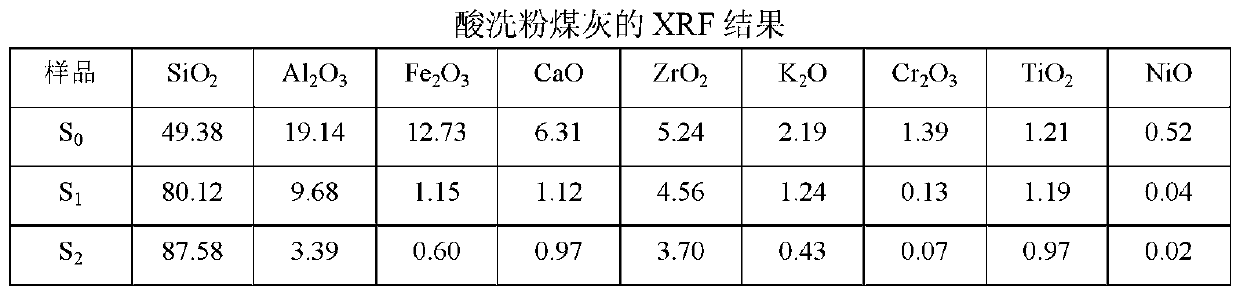

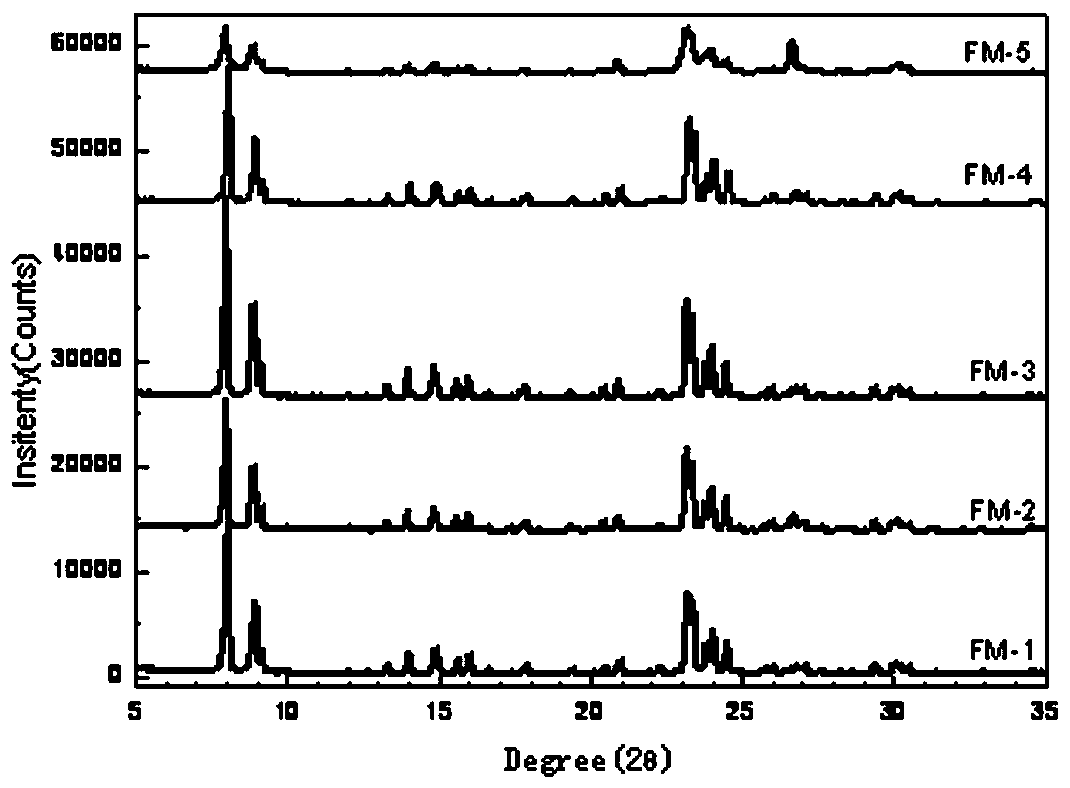

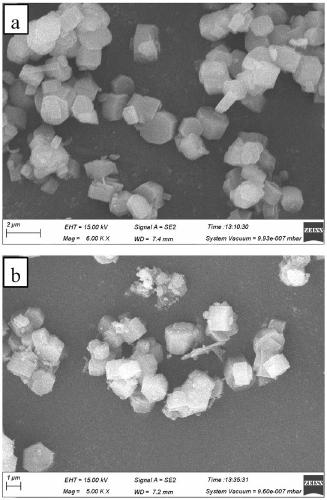

Preparation method of sodium-free fly ash-based ZSM-5 molecular sieve

InactiveCN110156044ASmall particle sizeWide variety of sourcesPentasil aluminosilicate zeoliteWaste treatmentBall mill

The invention discloses a preparation method of a sodium-free fly ash-based ZSM-5 molecular sieve. The preparation method is characterized by comprising the following steps: a, carrying out ball milling on a certain amount of coal ash by using a ball mill, then fully carrying out calcining and activating by using a muffle furnace to obtain calcined fly ash without organic matter; b, adding a certain amount of distilled water and hydrochloric acid into the calcined fly ash, putting the mixture in a reaction kettle, carrying out a hydrothermal reaction, carrying out washing to neutrality, and carrying out drying to obtain acid-washed fly ash; and c, adding a silicon source into a certain amount of the acid-washed fly ash to adjust the silicon-aluminum ratio of the material, adding water anda template agent, and then carrying out a hydrothermal reaction to directly obtain the fly ash-based ZSM-5 molecular sieve which is free of strong alkali such as sodium hydroxide and the like by a one-step hydrothermal method. The fly ash with large reserves and wide sources is used for replacing expensive chemical reagents as raw materials to synthesize the ZSM-5 molecular sieve with high added value, so that difficulty of solid waste treatment is reduced, and meanwhile, a new idea is provided for synthesis of the ZSM-5 molecular sieve.

Owner:HENAN POLYTECHNIC UNIV

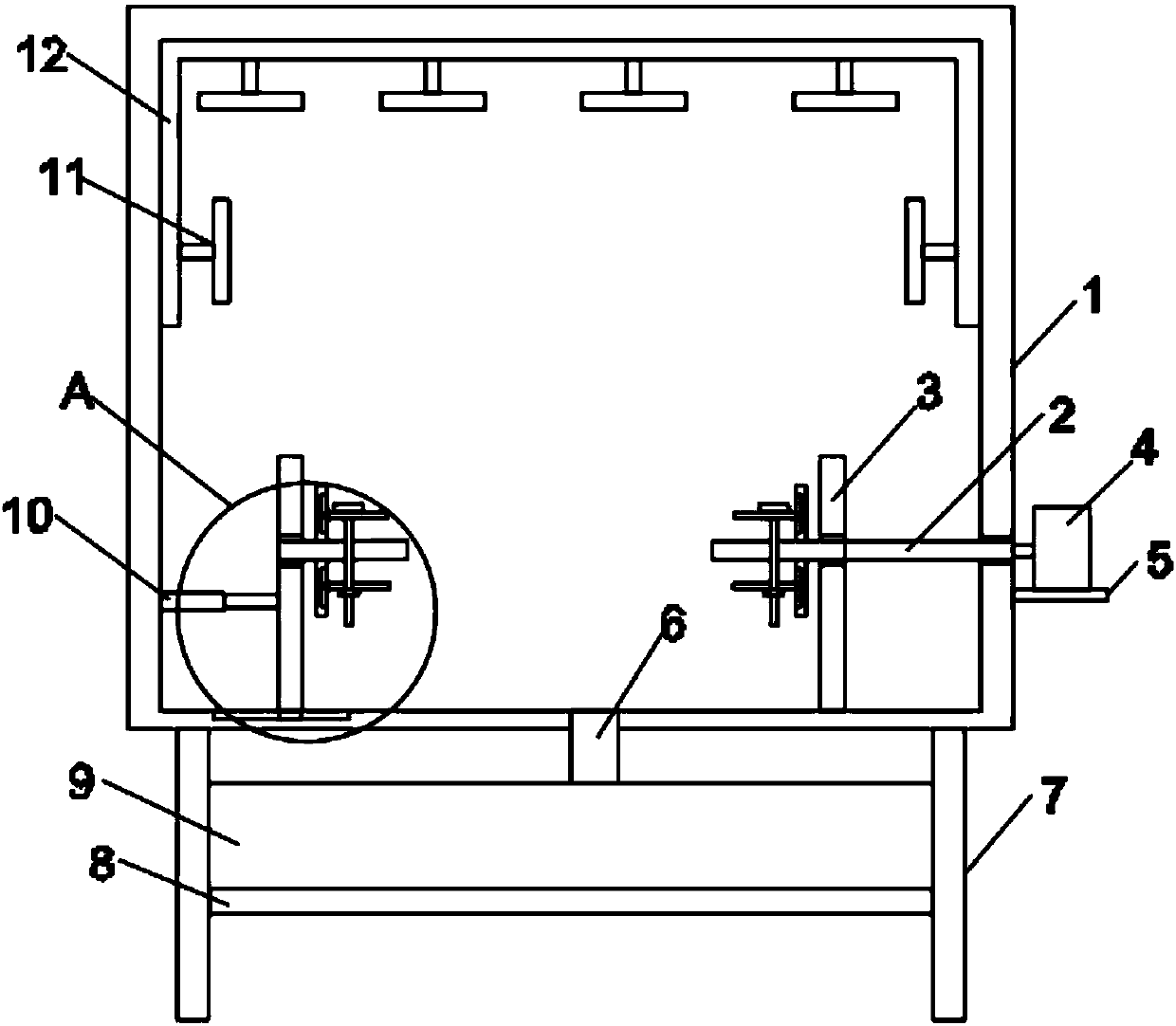

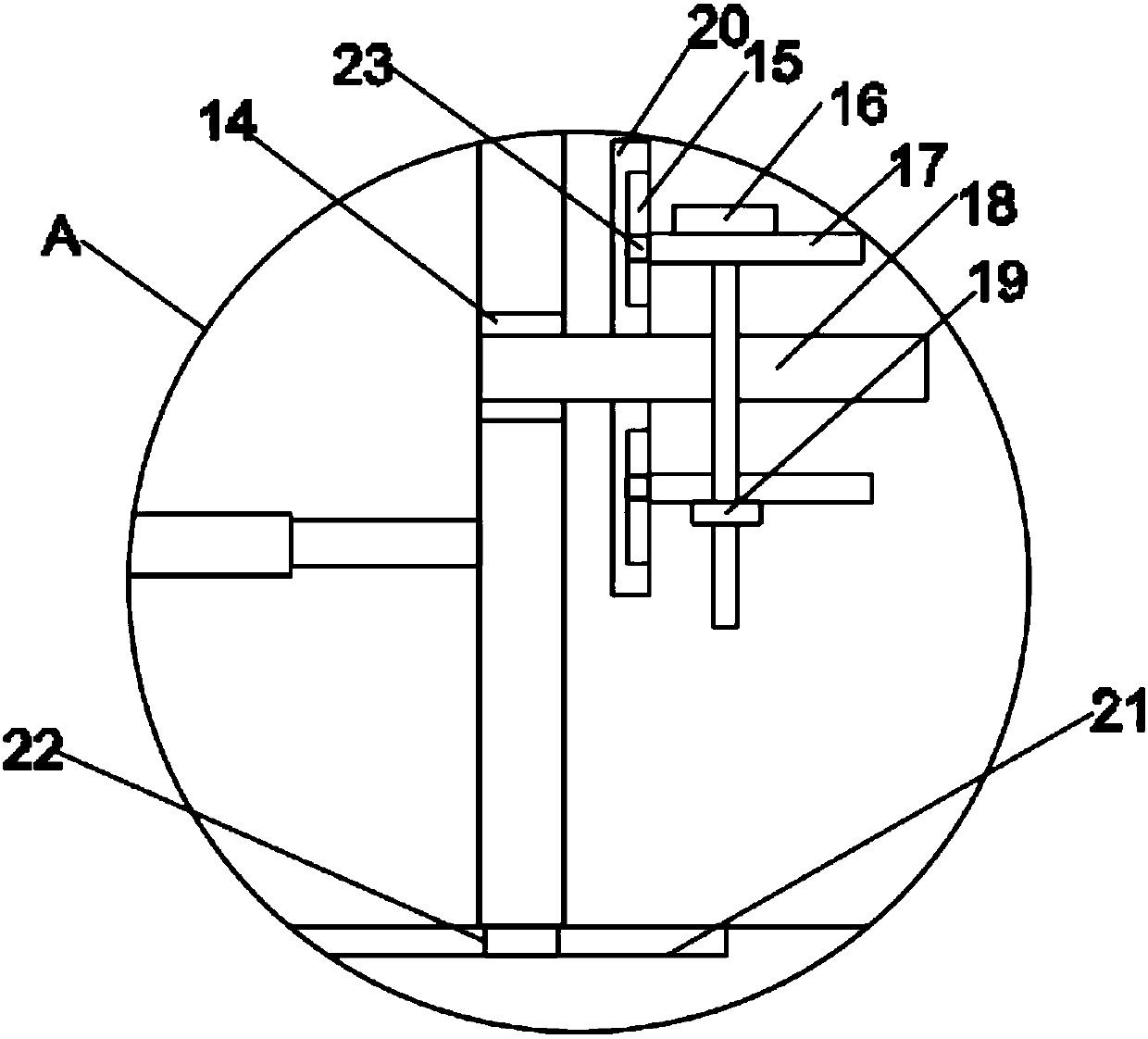

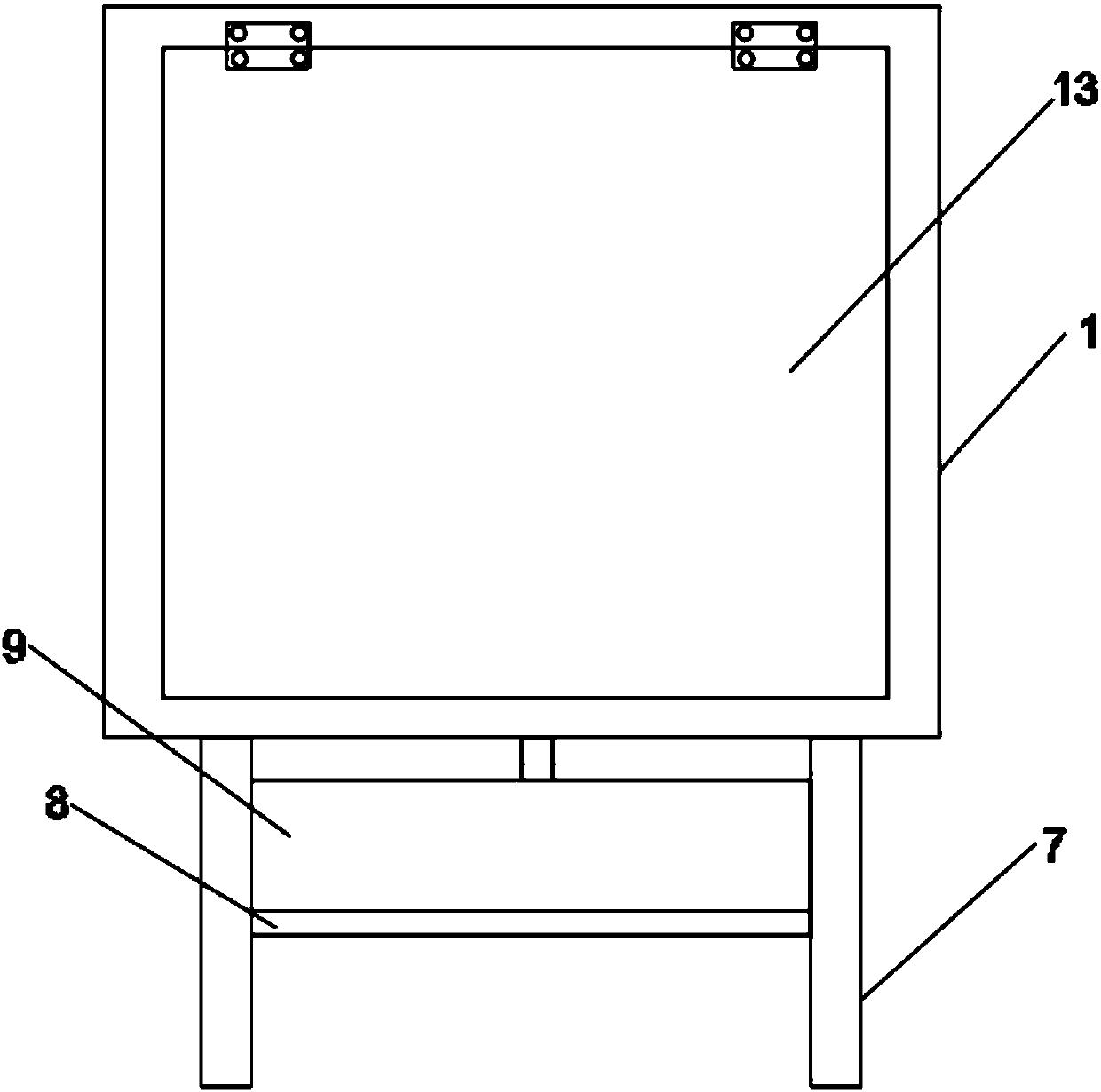

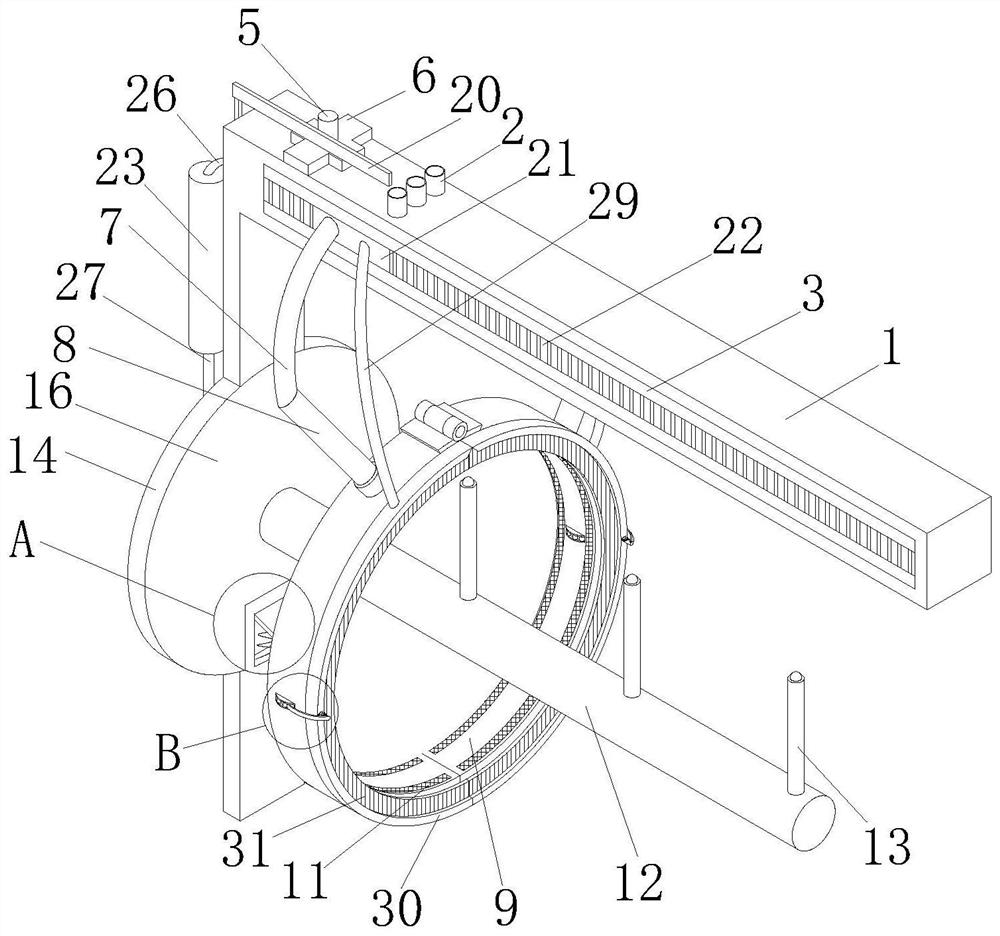

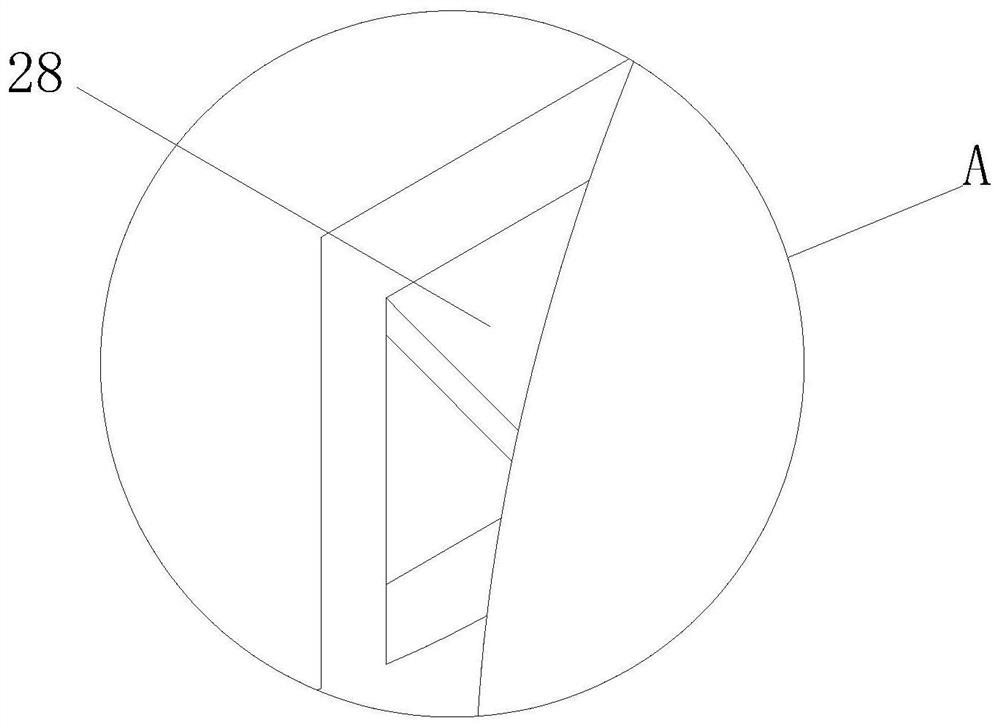

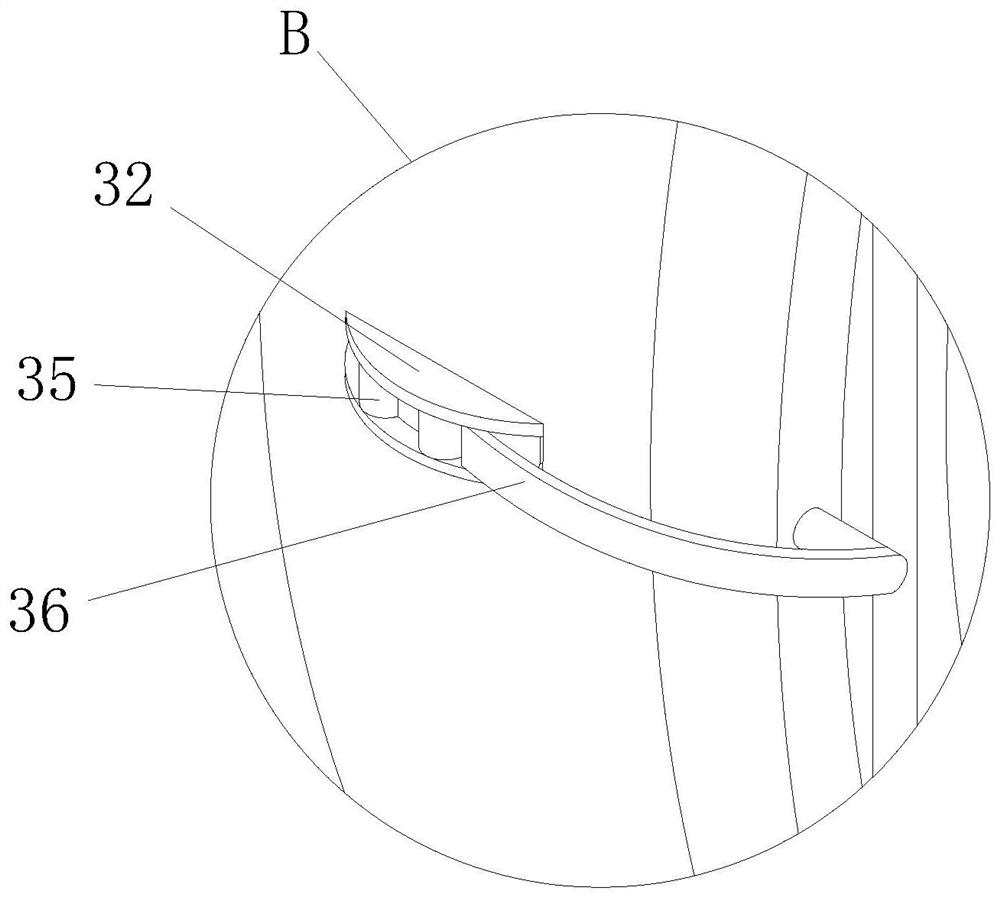

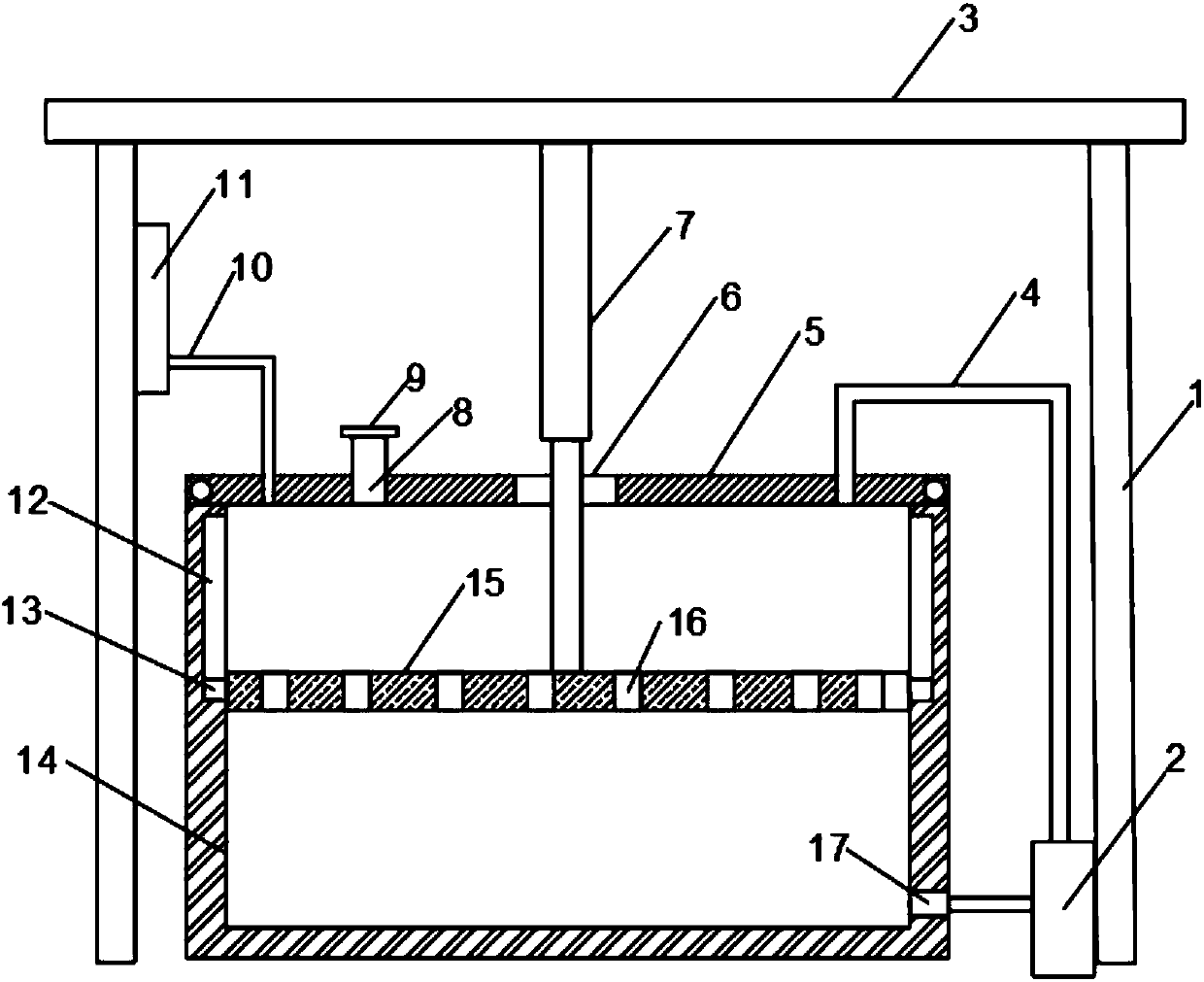

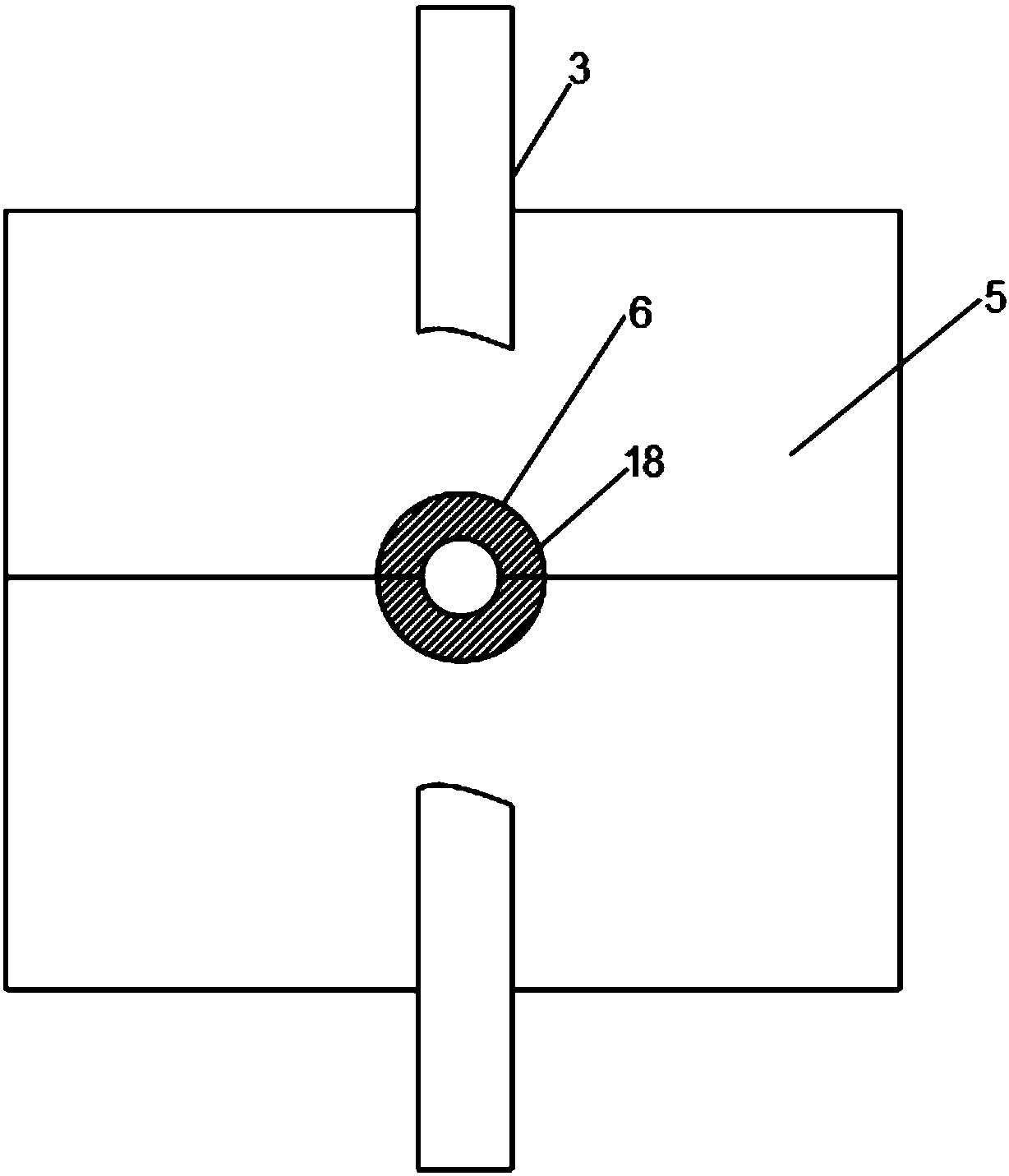

Novel steel pipe pickling derusting device

The invention relates to the technical field of pickling and derusting devices, in particular to a novel steel pipe pickling and derusting device, which includes a casing, a conduit is provided on the top wall of the casing, a nozzle is provided on the conduit, and a nozzle is provided on the casing. Clamping mechanisms are provided on both sides of the bottom wall, the clamping mechanism includes a support frame, a bearing seat is vertically arranged on the support frame, a second rotating shaft is rollingly connected in the bearing seat, and the second rotating shaft is connected to There is a fixed plate, the two ends of the fixed plate are provided with splints, the splint is provided with bolts, the bolts pass through the splint and the second rotating shaft, the lower end of the housing is provided with a motor support plate, and the motor supports A motor is arranged on the board, the output shaft of the motor is fixedly connected with a first rotating shaft, the first rotating shaft is fixedly connected with the second rotating shaft, transparent glass is hinged on the housing, and an outlet is provided at the lower end of the housing. The acid port is provided with supporting legs on both sides of the lower end of the shell. The invention has the characteristics of thorough rust removal.

Owner:湖北加恒实业有限公司

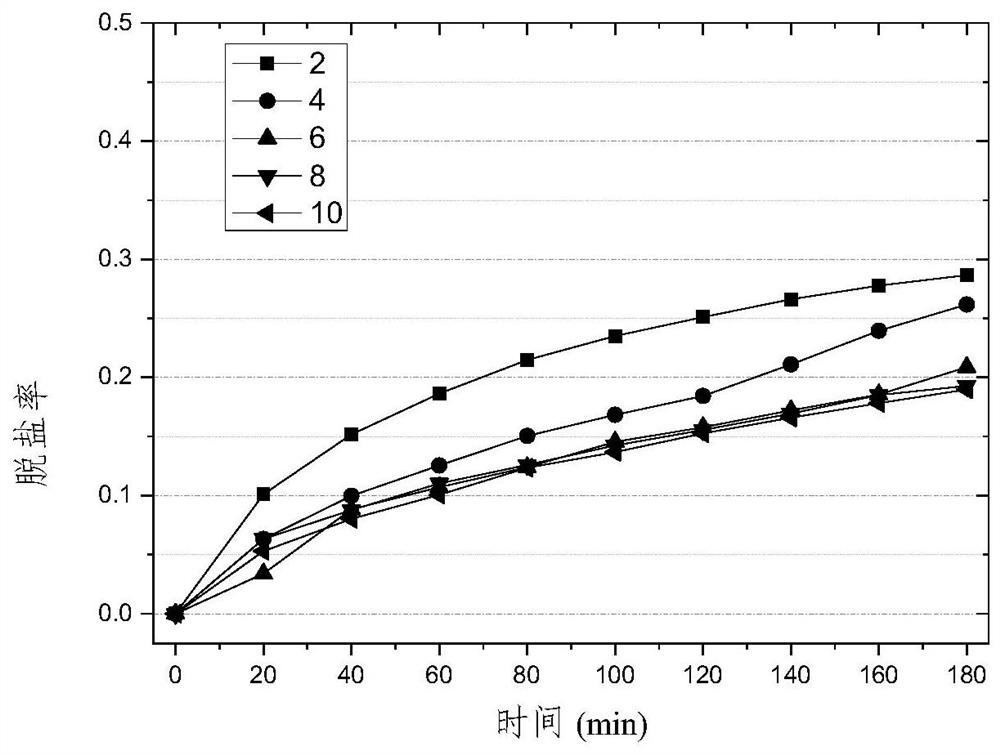

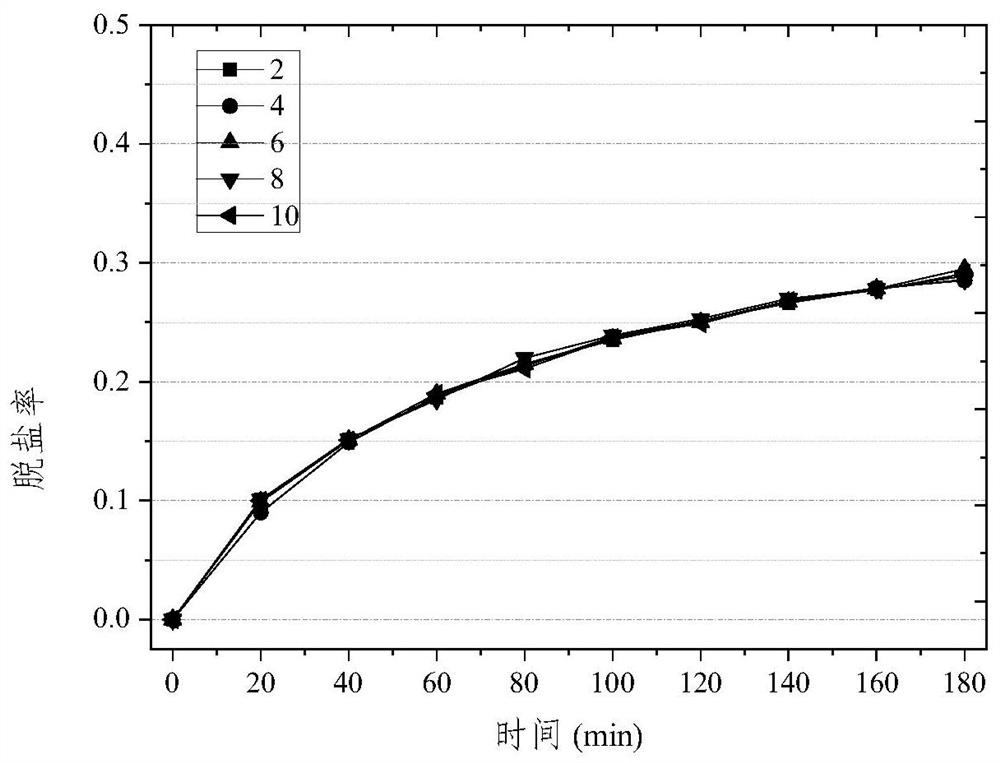

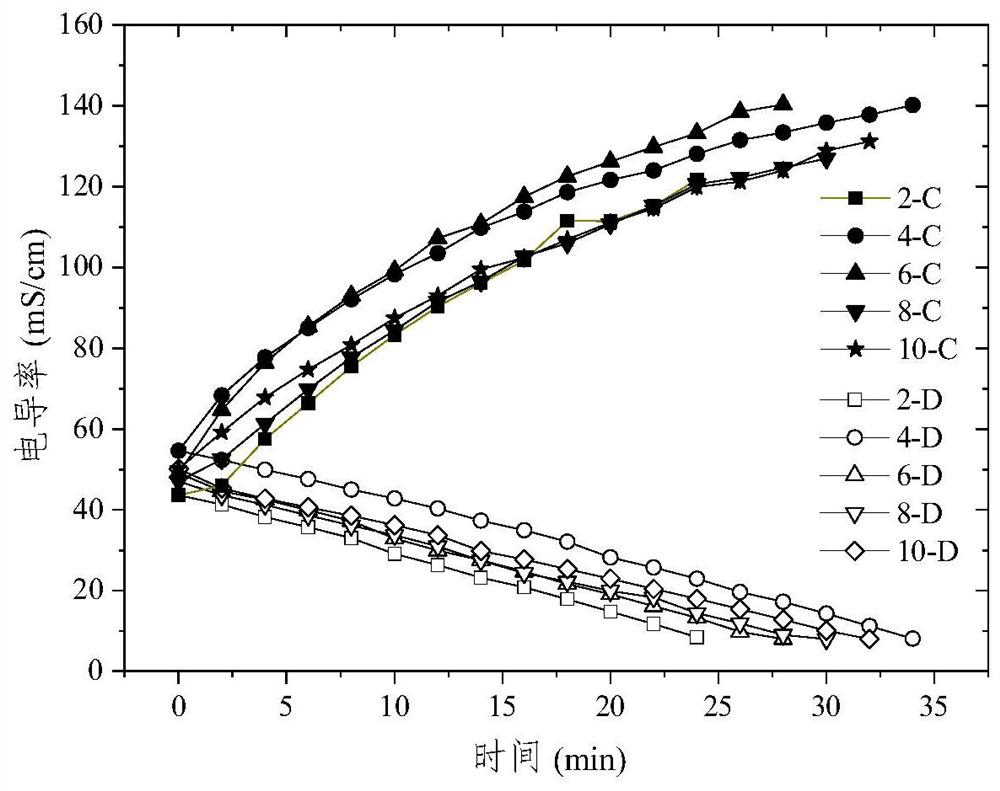

Method for cleaning membrane pollution in process of electrodialysis treatment on paper-making reconstituted tobacco extract liquor

InactiveCN111672326AImprove the effect of alkaline cleaning processRestore fluxTobacco preparationTobacco treatmentMembrane foulingProcess engineering

The invention discloses a method for cleaning membrane pollution in the process of electrodialysis treatment on paper-making reconstituted tobacco extract liquor, which is used for cleaning an electrodialysis system generating membrane pollution through the cleaning processes of primary water washing, reversed-pole alkaline washing, secondary water washing, reversed-pole acid washing and tertiarywater washing in sequence. According to the cleaning method, membrane pollution in the electrodialysis process can be effectively solved, the desalination rate of an electrodialysis system is remarkably recovered, and reliable operation guarantee is provided for the process of treating the paper-making process reconstituted tobacco extracting solution through electrodialysis.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Making method of flavored stewed duck in soy sauce

InactiveCN105661350AEnsure adequate intakeEasy picklingClimate change adaptationFood scienceMaterials preparationSoya sauce

The invention provides a making method of flavored stewed duck in soy sauce and belongs to the field of processing of meat products.The making method comprises the following steps: (1), preparing materials, (2), pickling, (3), tumbling, (4), soaking, (5), cooking, and (6), air drying; wherein the preparation of materials includes: material preparation, marinade preparation, and pickling juice preparation.Burdening of the marinade and pickling juice is simplified and ratio of the ingredients is optimized so that salt level is moderate, the process is simple and applicable and meat is delicate and tasty.

Owner:XIAOXIAN XULAOSAN FOOD CO LTD

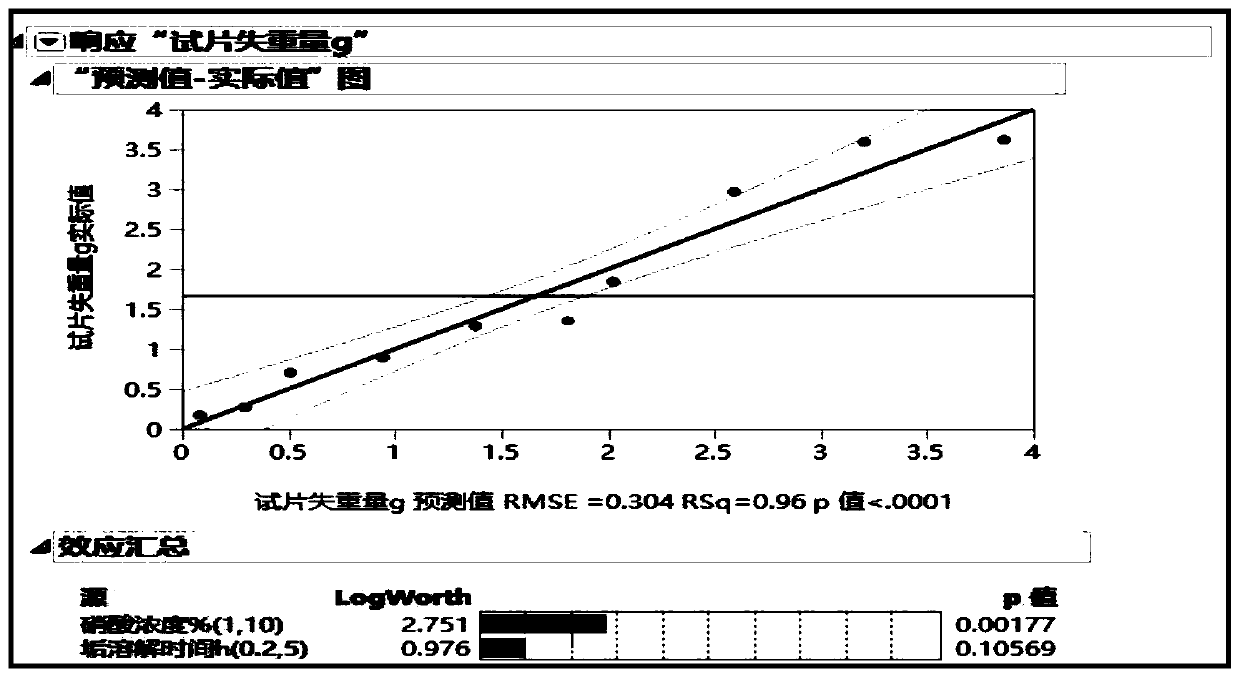

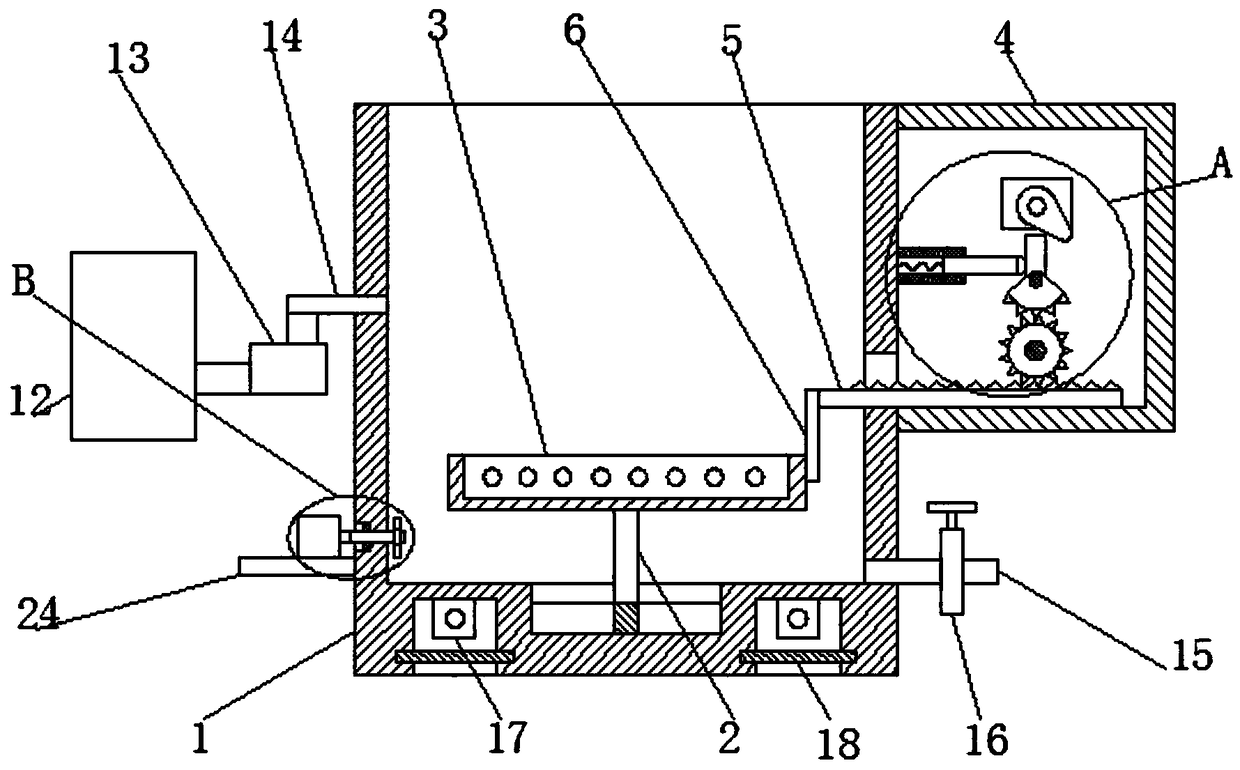

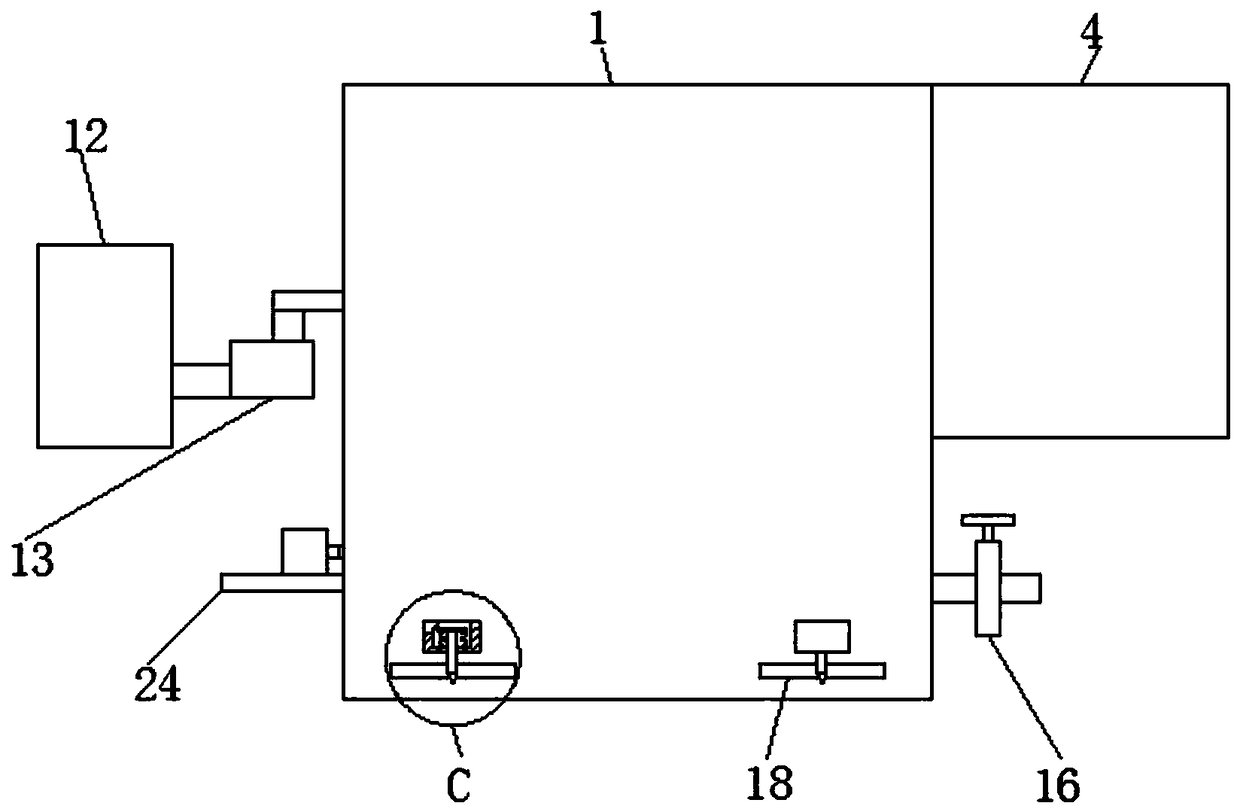

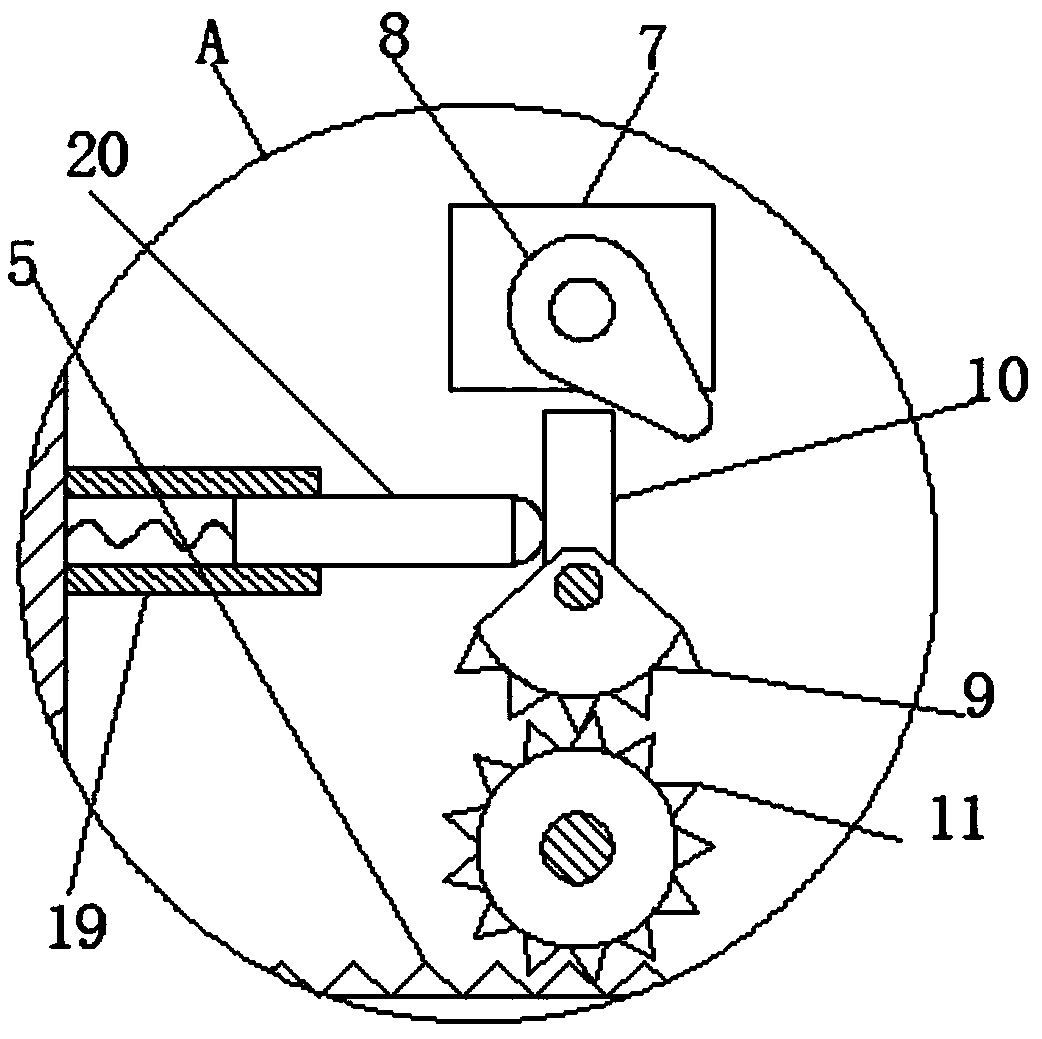

Optimization method of heat exchanger pickling process

ActiveCN111322904AEasy picklingSmall amount of corrosionFlush cleaningProcess engineeringIndustrial engineering

The invention belongs to the technical field of heat exchanger cleaning, and particularly relates to an optimization method of a heat exchanger pickling process. Firstly, according to scale layer components of a heat exchanger, comprehensive screening is conducted through a superposition graph of data statistical analysis software, and proper cleaning acid is found; under the effective concentration of the corrosion inhibitor, the screened standard test pieces with the cleaning acid and the heat exchanger shell made of the same material are used for carrying out a corrosion experiment, two sets of comparison data are obtained, the corrosion weight loss of the standard test pieces in acid with different concentrations is measured without adding the corrosion inhibitor in one set, and the weight loss of the standard test pieces is measured after the corrosion inhibitor is added in the other set; establishing a predicted value-actual value model of the corrosion weight reduction of the test piece, and finding out the optimal cleaning acid concentration by using a prediction descriptor of data software, and in the pickling process, the corrosion amount of the heat exchanger shell is minimum, and optimization of the heat exchanger pickling process is achieved. By the method, the problem of serious corrosion of the shell during pickling of the heat exchanger can be solved, and heat exchange efficiency of the heat exchanger is improved after pickling.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

Acid pickling device for cotton knitted fabric

ActiveCN109023782APickling uniformEasy picklingTextile treatment containersTextile treatment machine arrangementsEngineering

The invention relates to the technical field of acid pickling devices, and discloses an acid pickling device for a cotton knitted fabric. The device includes an acid pickling box, the top of the acidpickling box opens, the bottom in the acid pickling box is provided with a T-shaped slide groove, the inside of the sliding groove is slidably connected with a slider matched with the sliding groove,the top of the slider extends to the outside of the sliding groove and is fixedly connected with a material bearing box, the outer side wall of the acid pickling box is fixedly connected with a transmission box, one end of the transmission box opens, the outer side wall of the acid pickling box is provided with a square hole communicated with the transmission box, the inside of the square hole isslidably connected with a rack, the bottom in the square hole is flushed with the bottom in the transmission box, one end of the rack extends to the inside of the acid pickling box and is fixedly connected with a push block, the bottom of the push block is fixedly connected with the outer side wall of the material bearing box, the other end of the rack extends to the inside of the transmission box, and the inner side wall of the transmission box is fixedly connected with a first motor. The acid pickling device for the cotton knitted fabric can make the cotton knitted fabric uniformly pickled and make acid pickling liquid uniformly heated.

Owner:嘉善中帛针纺有限公司

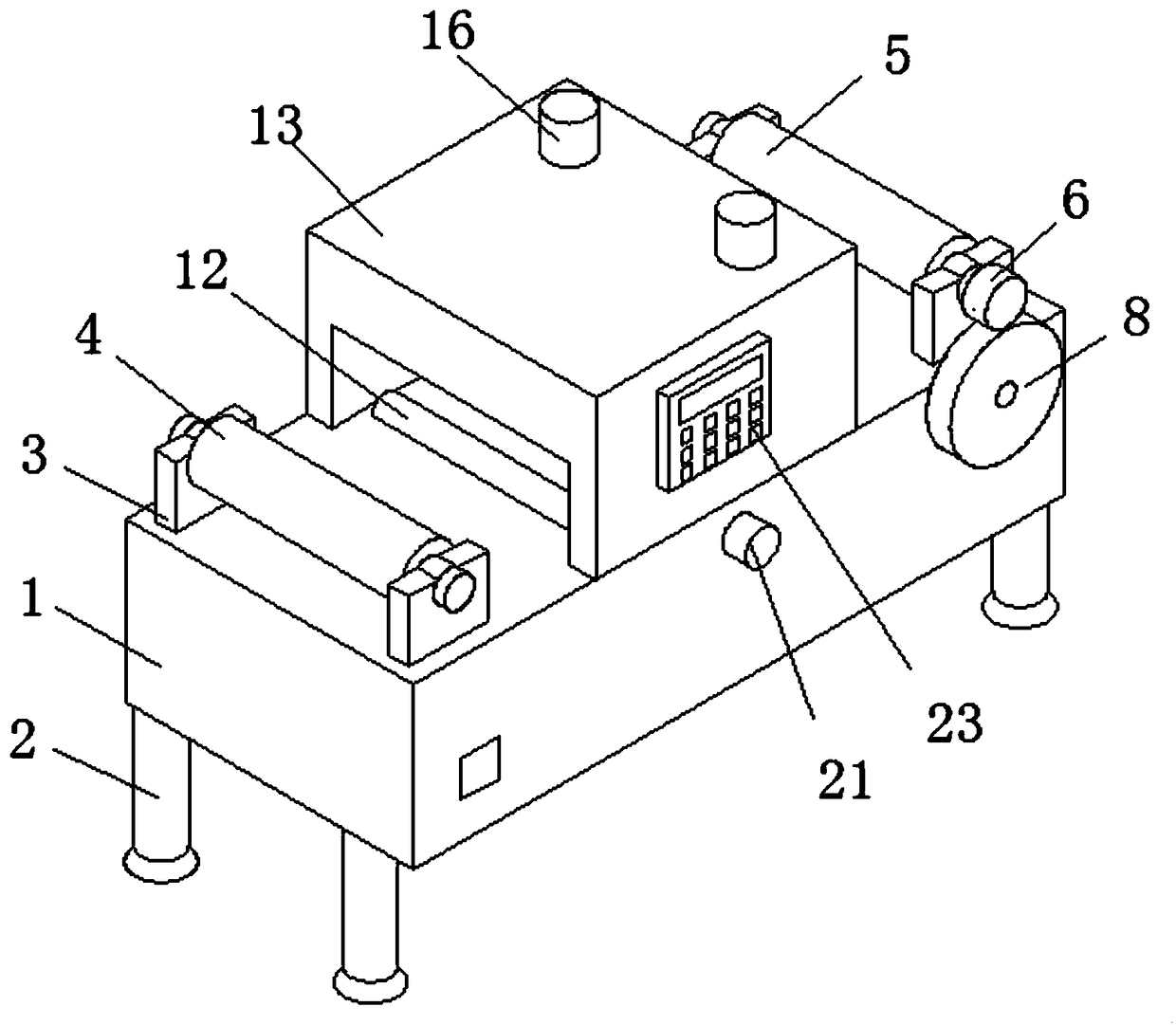

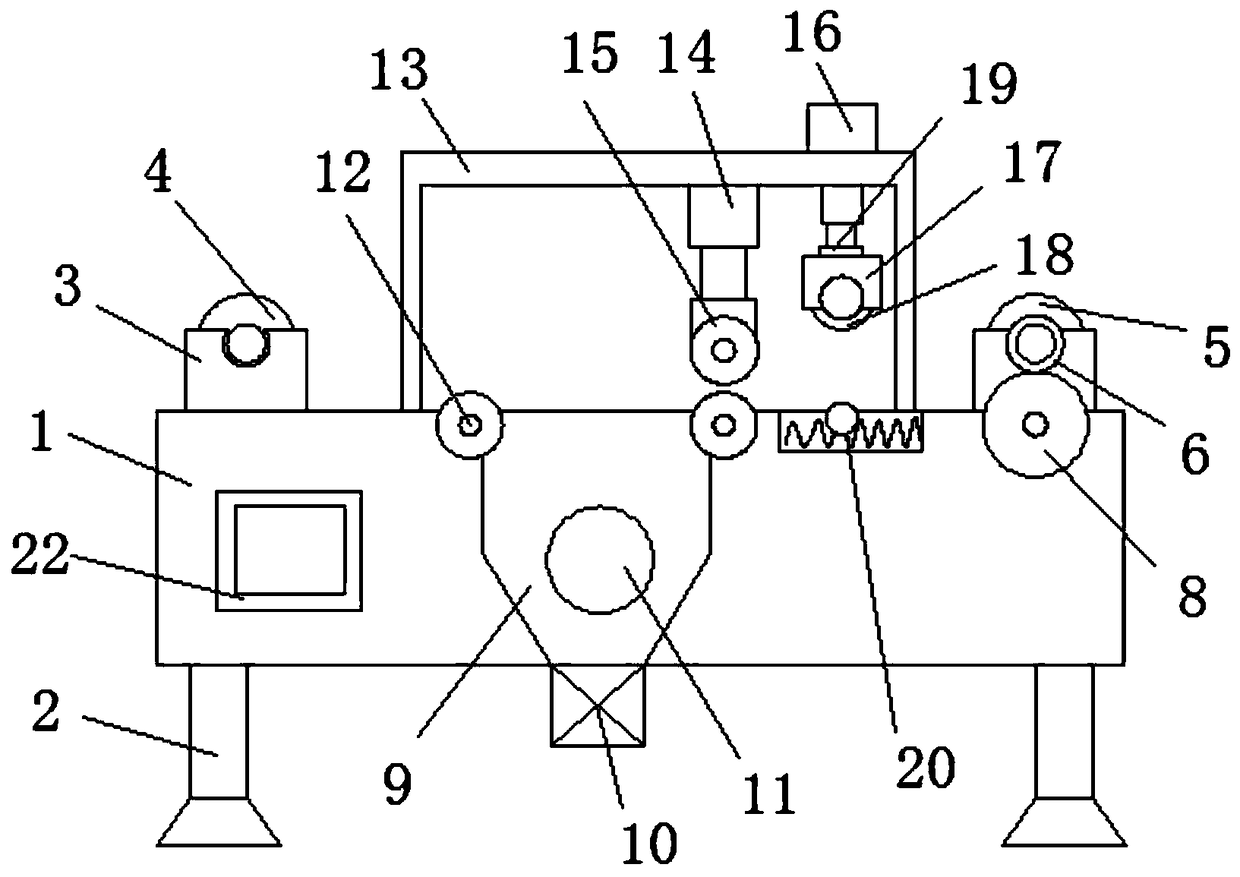

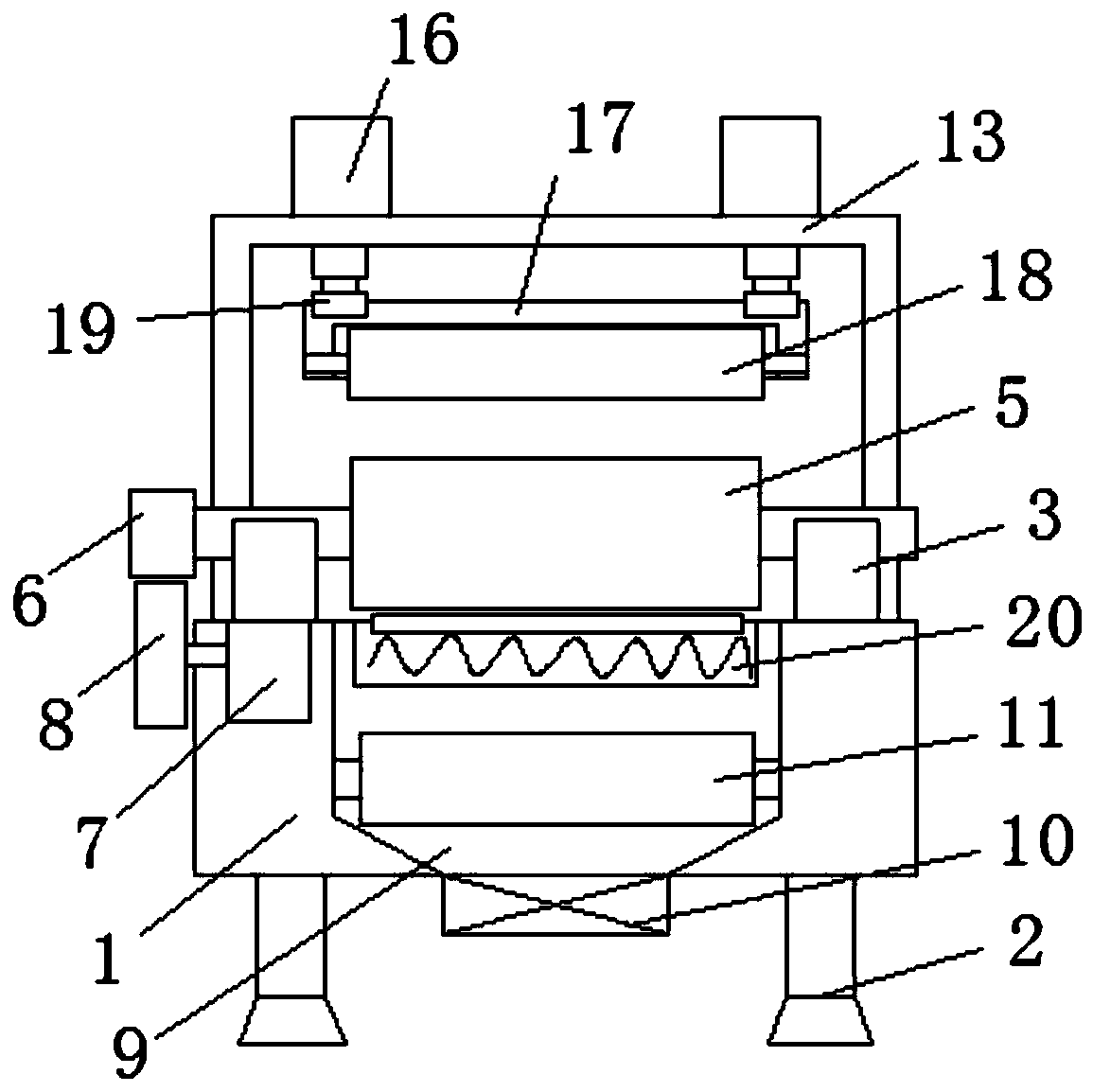

Steel strip acid pickling printing device for metal machining

InactiveCN108823586AEasy picklingSimple structural designEmbossing decorationsMetal machiningEngineering

The invention discloses a steel strip acid pickling printing device for metal machining. The steel strip acid pickling printing device comprises a base, a discharging roller and a receiving roller aremovably installed between the two sides of the base and a supporting base correspondingly, an acid pickling groove is formed in the middle portion of the top of the base, a bottom roller is fixedly installed at the bottom end of the interior of the acid pickling groove through a bearing, guide rollers are inlaid at the two ends of the top of the acid pickling groove, a shell is welded to the position, located on the outer side of the acid pickling groove, of the top of the base, electric cylinder bodies are fixedly installed at the front and back ends of the one side of the top of the shell,output shafts of the electric cylinder bodies penetrate the shell to be fixedly connected with a portal frame, the bottom end of the interior of the portal frame is fixedly provided with a compressionroller used for printing through a rolling bearing, and an electric heating plate is inlaid in the position, located at the positive lower end of compression roller, of the top of the base. The steelstrip acid pickling printing device is simple and reasonable in structural design, convenient to operate, small in occupied land area, safe, stable, wide in application scope and favorable for popularization and generalization, saves time and labor, improves the working efficiency and reduces the machining cost.

Owner:新昌县明拓机械有限公司

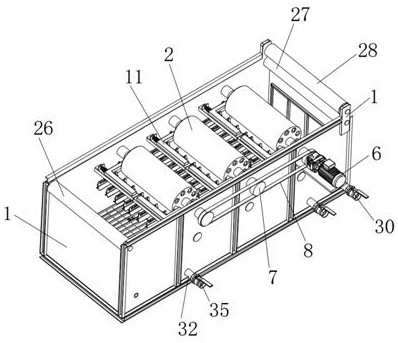

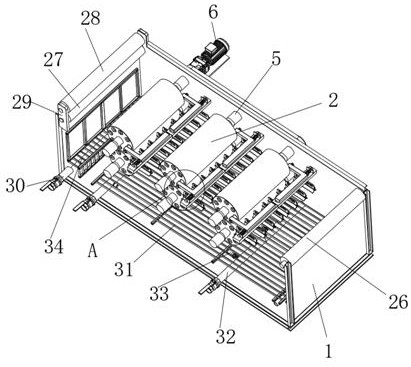

Pipe inner surface acid pickling device and method

PendingCN112111748ASimple structureReasonable designConveyor partsMicrocontrollerStructural engineering

The invention discloses a pipe inner surface acid pickling device and method. The pipe inner surface acid pickling device comprises a pipe feeding rack, a feeding mechanism, an acid pickling mechanism, a soaking tank and a monitoring module. The pipe feeding rack comprises a rack body, a containing mechanism and a pipe conveying mechanism. A shifting mechanism is located on the rack body. The acidpickling mechanism comprises an acid pickling chamber, a lifting mechanism and a nozzle mechanism. The nozzle mechanism is connected with an acid supply mechanism, a water supply mechanism and an airsupply mechanism. A conveying groove for placing a pipe is formed in the pipe conveying mechanism. The monitoring module comprises a monitoring box and a microcontroller. A limiting sensor and a counting sensor are arranged in the pipe conveying mechanism. The method comprises the following steps that 1, feeding a pipe; 2, conveying the pipe; 3, lifting and pressing the pipe; 4, pickling, washingand drying the pipe; and 5, soaking the pipe. Feeding, acid pickling, flushing, drying and soaking of the pipe are achieved, manual participation is reduced, and the production efficiency is high.

Owner:西安西部新锆科技股份有限公司

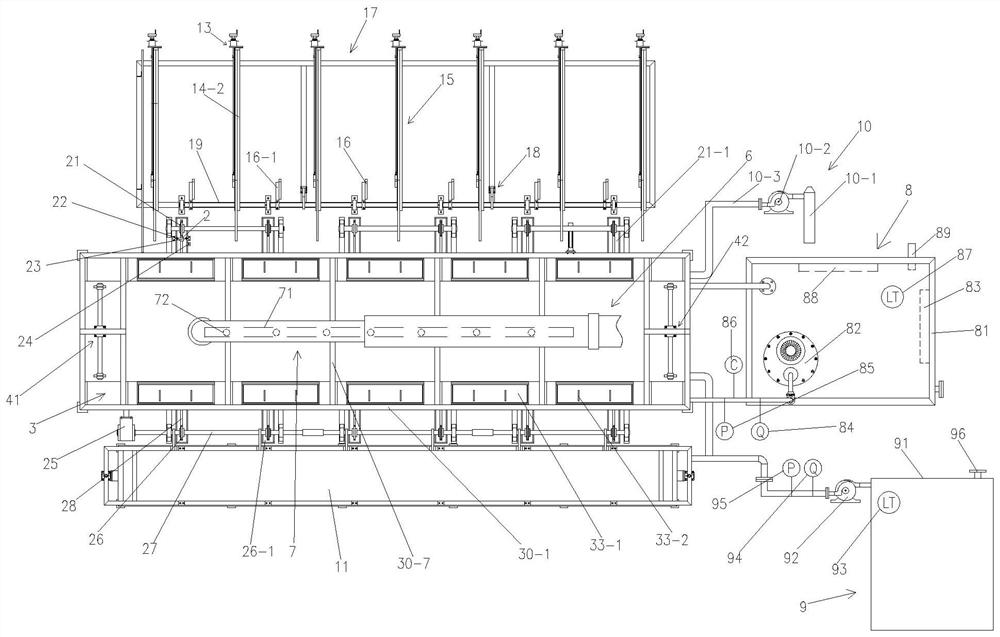

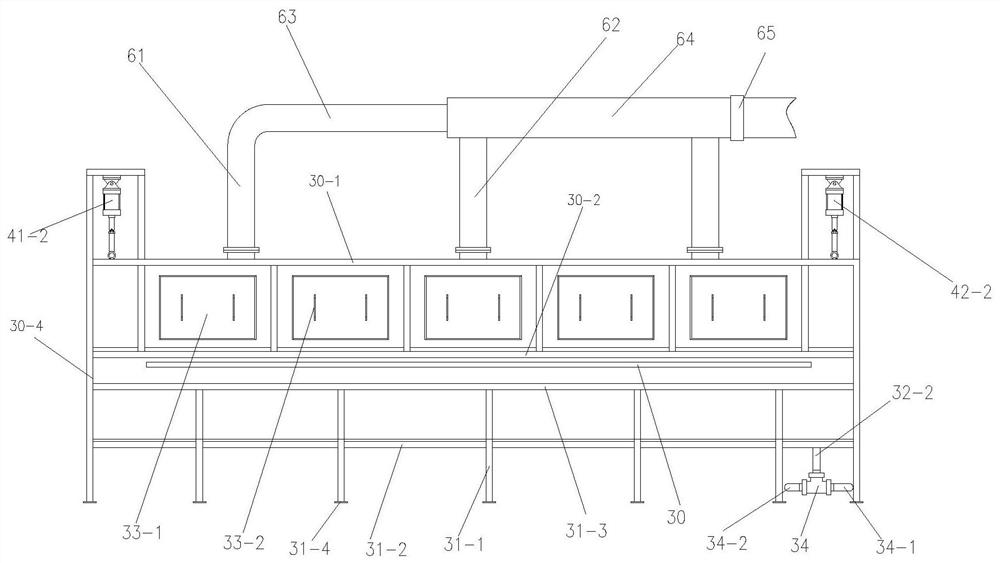

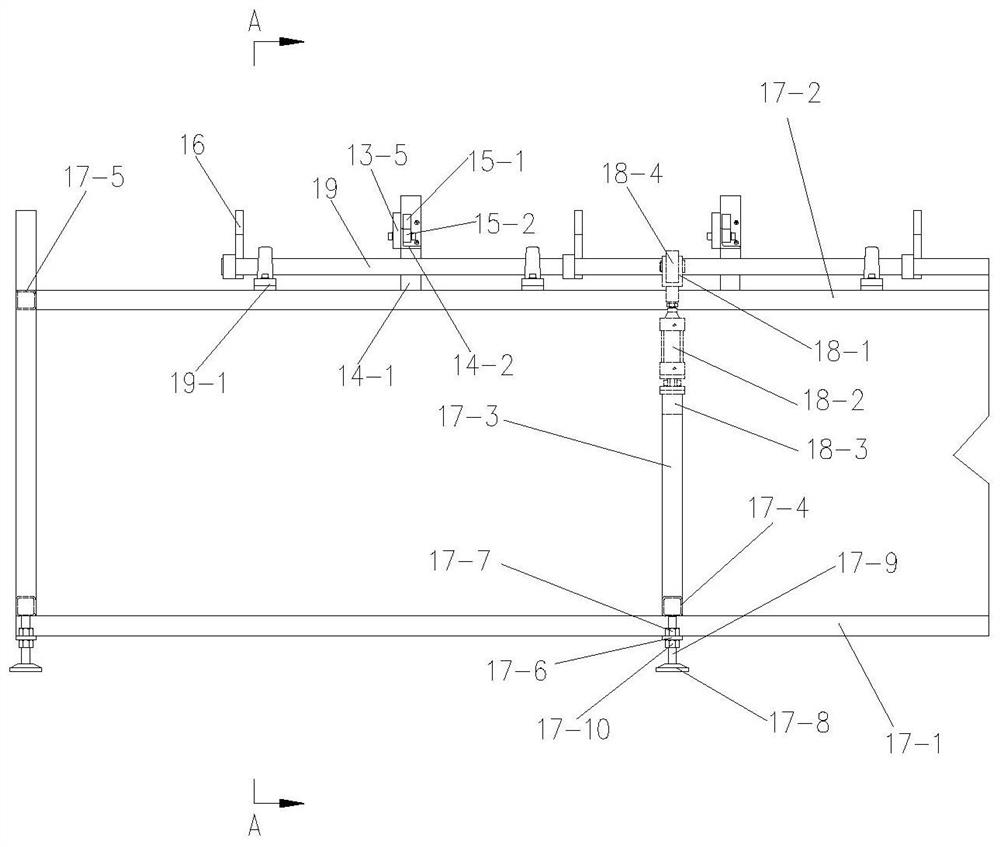

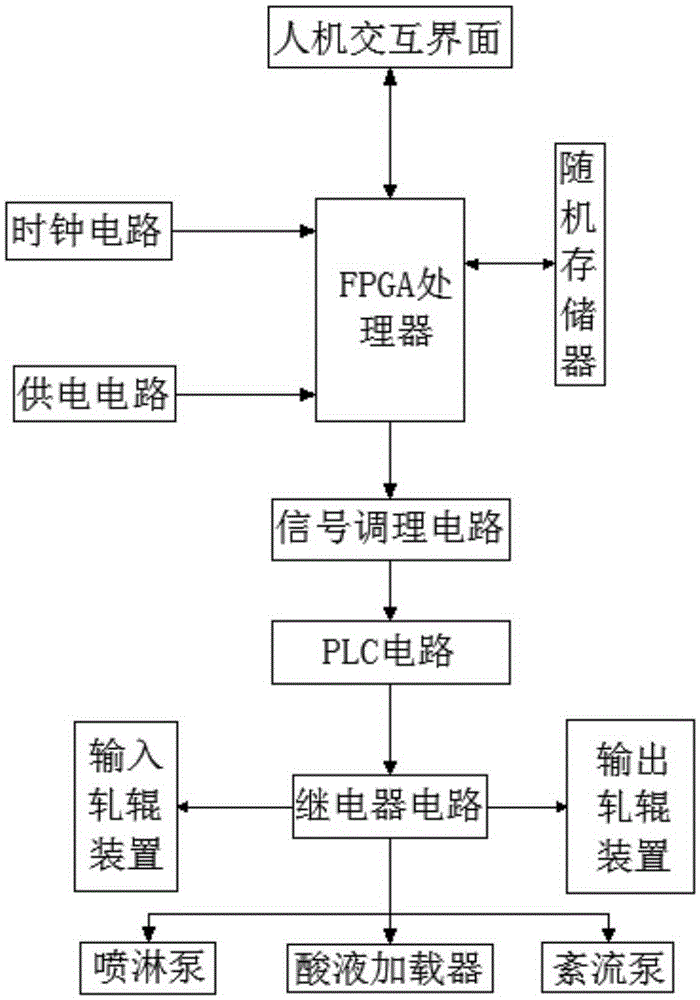

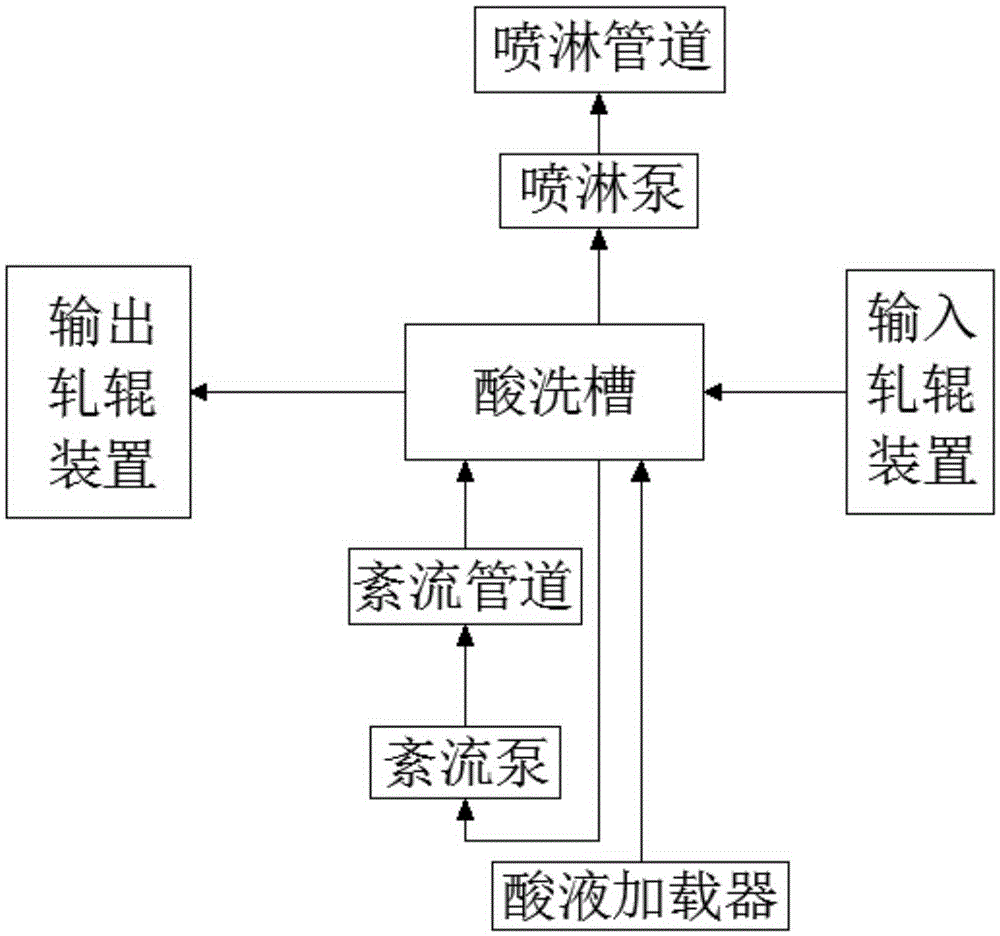

Strip steel pickling system with spraying system

The invention discloses a strip steel pickling system with a spraying system. The strip steel pickling system with the spraying system comprises a strip steel pickling device and a control system connected with the strip steel pickling device. A field programmable gate array (FPGA) processor, a power supply circuit, a storage circuit and a signal processing circuit are arranged in the control system. The FPGA processor is connected with the power supply circuit, the storage circuit and the signal processing circuit. The signal processing circuit is connected with the strip steel pickling device. Strip steel is pickled by combining the spraying system with a turbulent flow system so that the surface state of the surface, in an acid tank, of a steel plate can be improved, iron oxide skin on the surface of the steel plate can be fully pickled, no iron oxide skin exists on the surface of the pickled steel plate, the surface of the plate is bright, and the quality is stable; in addition, the intelligent control system is used for controlling the pickling process and the fluidity of acid liquor in the pickling tank, the pickling process and the operation of the strip steel are managed synchronously, and the strip steel is pickled optimally.

Owner:CHONGQING GUANGJI IND

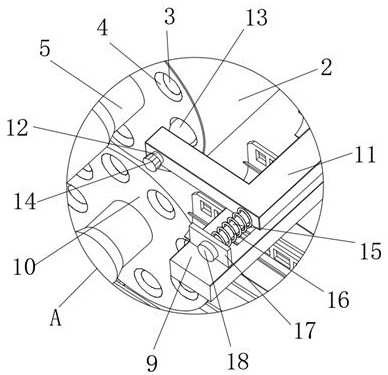

Stainless steel part pickling device

ActiveCN113403624AReduce the rate of disengagementIncrease pickling rangeCleaning using toolsCleaning using liquidsWater flowSlide plate

The invention relates to the technical field of stainless steel part machining, and discloses a stainless steel part pickling device, which comprises an injection cylinder; the inner walls of the left and right sides of the injection cylinder are sleeved with side frames; the front and rear inner walls of the side frames are fixedly connected with elastic telescopic pads; the corresponding ends of the front and rear corresponding elastic telescopic pads are fixedly connected with sliding plates; the top face of the injection cylinder is fixedly connected and communicated with three liquid conveying pipes; and the liquid conveying pipes on the left side and the right side correspond to two liquid conveying grooves correspondingly. Through arrangement of a lantern ring, the lantern ring can automatically deform into two states during acid pickling and cleaning, a stainless steel part is wrapped during acid pickling, the acid pickling range is widened, the speed that an acid solution is separated from the stainless steel part is reduced through the wrapping effect of the lantern ring, so that the advantage of saving resources is achieved, the lantern ring is unfolded on the stainless steel part during cleaning, the spraying effect is formed during cleaning, the effect and strength that water flow strikes the stainless steel part are improved through the height difference, and the cleaning effect is improved.

Owner:JIANGSU XIHU SPECIAL STEEL

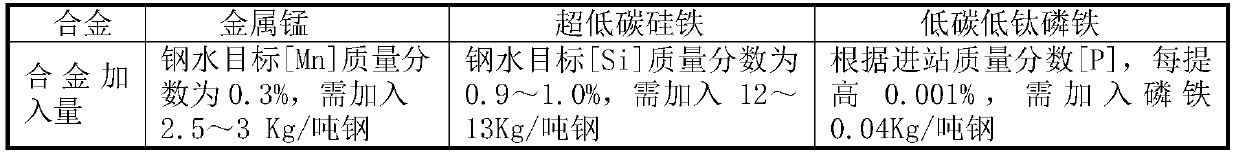

Non-oriented electrical steel and preparation method thereof

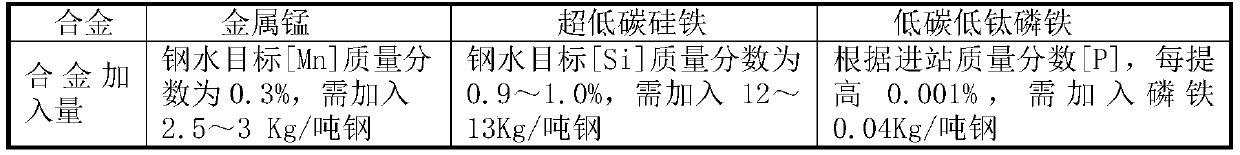

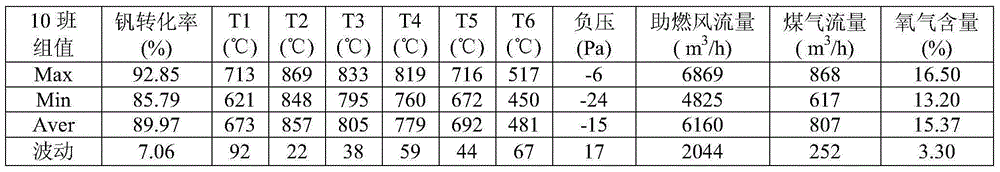

The invention relates to non-oriented electrical steel and a preparation method thereof. The non-oriented electrical steel comprises the following chemical components of, in percentage by mass, less than or equal to 0.0030% of C, 0.90-1.00% of Si, 0.2-0.40% of Mn, 0.015-0.40% of P, less than or equal to 0.004% of S, 0.025-0.035% of Als, less than or equal to 0.001% of Ti and the balance Fe and inevitable impurities. The preparation method comprises the following steps of converter control; ladle furnace refining, and specifically, the temperature of molten steel is increased to 1620 DEG C-1650DEG C, and then high-aluminum slag is added; and alloying, and specifically, the temperature of tundish molten steel in the continuous casting procedure is 1532 DEG C-1542 DEG C, wherein the time ofa continuous casting billet in a heating furnace is more than or equal to 120 minutes, the initial rolling temperature is 1060 DEG C-1100 DEG C, the finish rolling temperature is 980 DEG C-1020 DEG C,the final rolling temperature is 840 DEG C-880 DEG C, and the coiling temperature is 680 DEG C-720 DEG C. Through component and production process optimization, the non-oriented electrical steel withexcellent performance can be developed.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

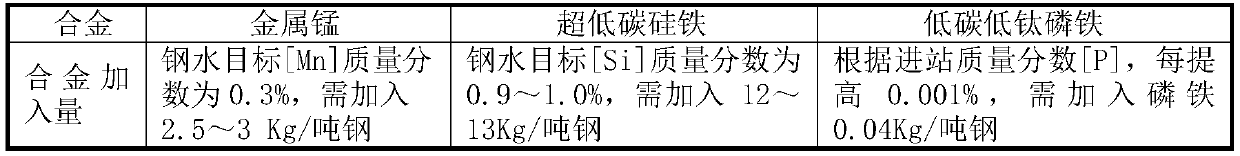

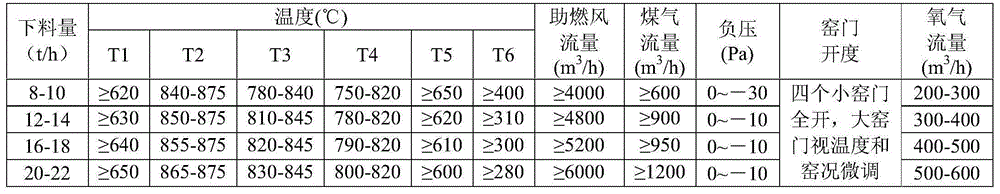

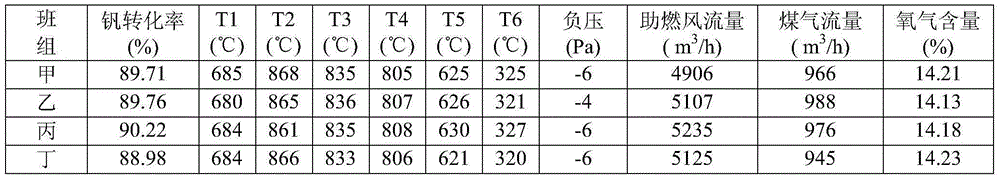

Method for controlling parameters of processes of calcifying and roasting vanadium slag during production of vanadium oxide

The invention relates to a method for controlling parameters of processes of calcifying and roasting vanadium slag by using a large rotary kiln during production of vanadium oxide, belongs to the field of metallurgy and provides a method for controlling parameters of processes of calcifying and roasting vanadium slag during production of vanadium oxide. According to the method, the large rotary kiln is used for calcifying and roasting the vanadium slag; the control method comprises the following steps: a, firstly adjusting various parameters of the large rotary kiln to reasonable ranges in sequence according to the following sequence of negative pressure, combustion-supporting air flow, oxygen flow, temperature of the rotary kiln and gas flow; and b, finely adjusting the rotary kiln door to control the stability of various parameters in the step a in sequence according to the following sequence of the gas flow, the temperature of the rotary kiln, the combustion-supporting air flow, the oxygen flow and the negative pressure. The method is capable of ensuring the stability of various process parameters; meanwhile, the method can be used for producing black, loose and high-quality roasted clinker with few particles; the roasted clinker is liable to crush; the conversation rate of the acid-leached vanadium can reach up to 85-92%.

Owner:攀钢集团西昌钒制品科技有限公司

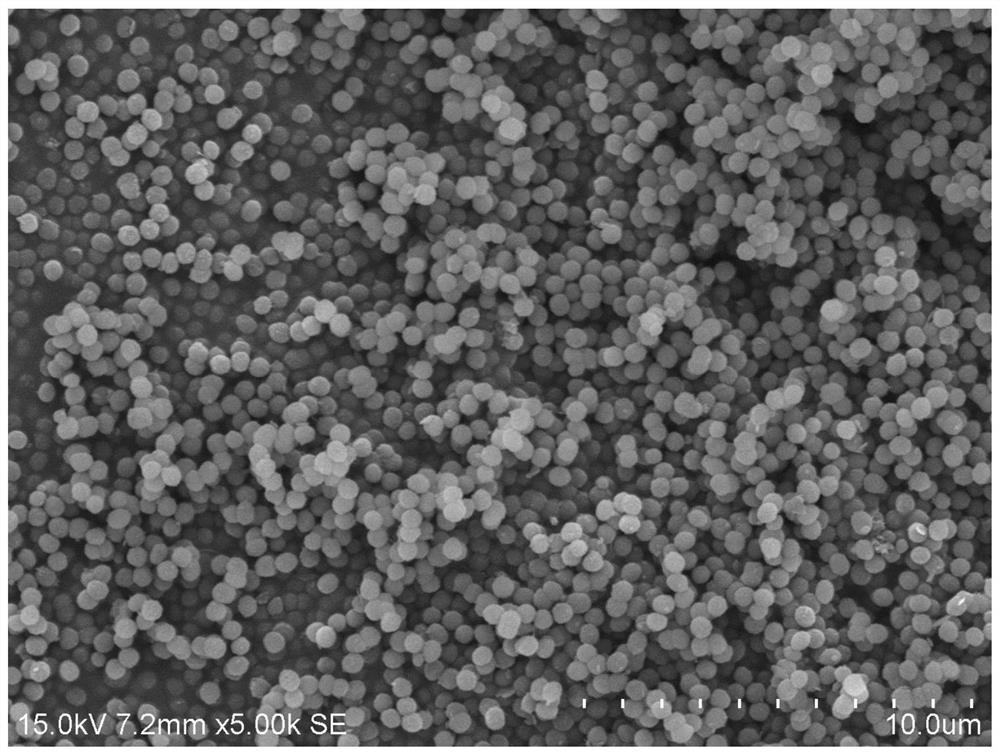

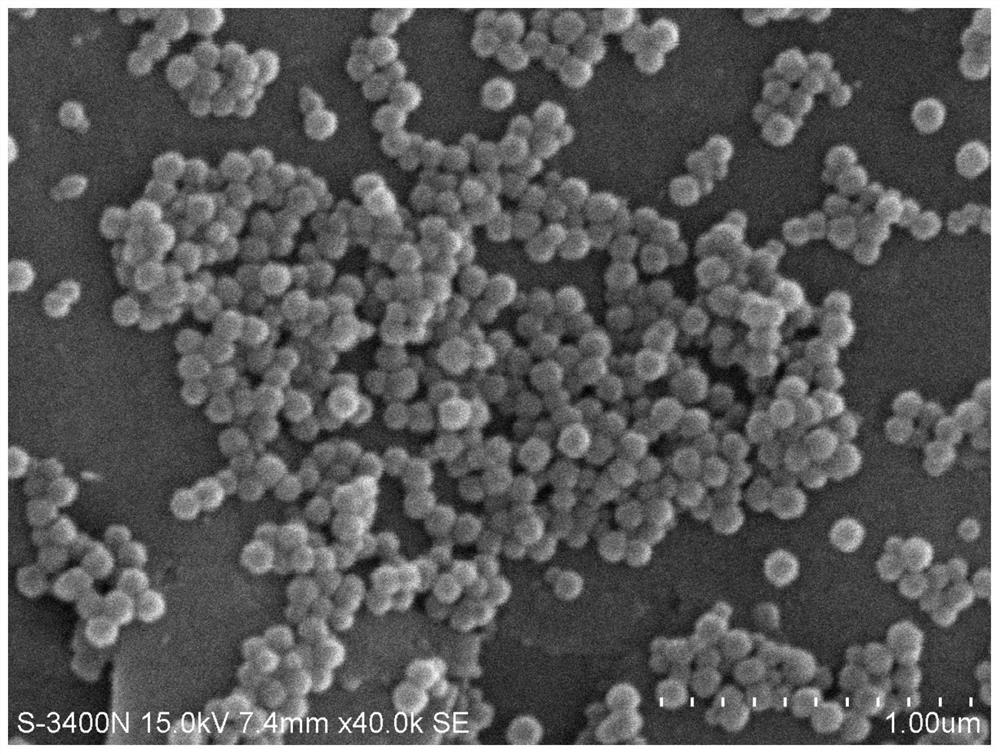

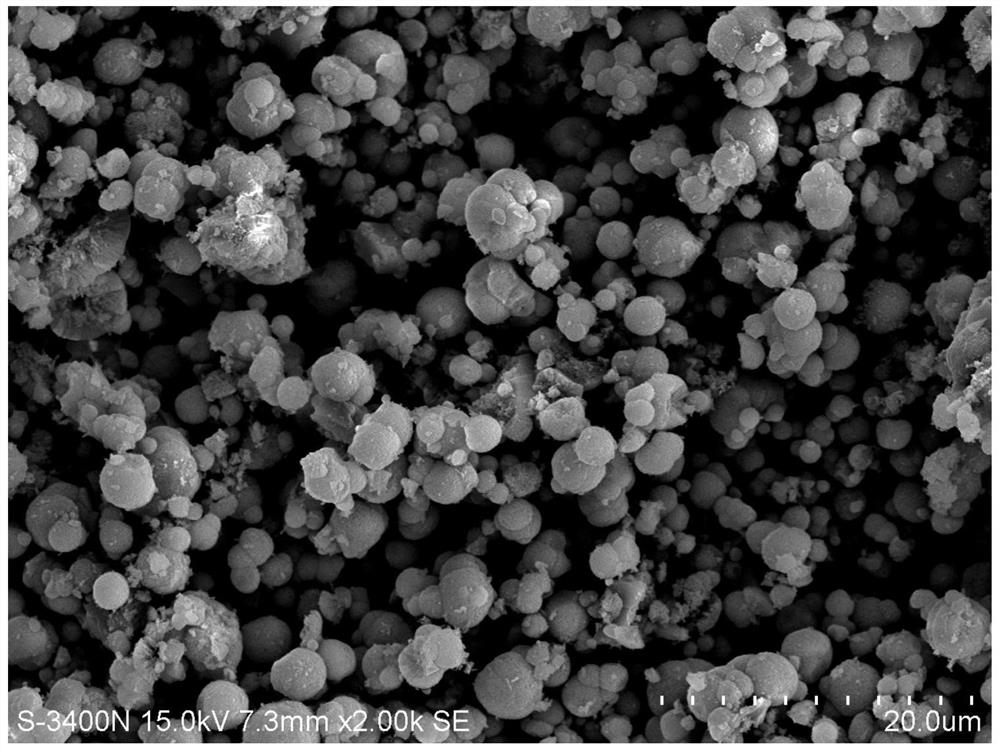

Preparation process for preparing regular spherical calcium carbonate through calcium chloride and ammonia water solution carbonization method

PendingCN112142087AIncrease reaction rateImprove dissolution rateCalcium/strontium/barium carbonatesAqueous solutionCarbonization

The invention discloses a preparation process for preparing regular spherical calcium carbonate through acalcium chloride and ammonia water solution carbonization method. The preparation process comprises the following steps: adding an organic solvent into a calcium chloride and ammonia water solution to serve as a carbon dioxide dissolving agent and a calcium carbonate crystal form stabilizer, adding an inorganic morphology control agent into the calcium chloride and ammonia water solution, and fully mixing; and introducing carbon dioxide for carbonization until the pH value is lower than 8 to obtain calcium carbonate slurry, and dehydrating, washing and drying the calcium carbonate slurry to obtain the spherical calcium carbonate. The obtained spherical calcium carbonate does not need surface treatment, is regular in sphere, good in dispersity, simple in preparation process, short in carbonization time and low in production cost, and the particle size of the prepared spherical calcium carbonate can be adjusted and controlled within the range of 0.1-5 micron.

Owner:王权广

Pickling tank used for steel pipe acid pickling

The invention relates to the technical field of pickling pools, in particular to a pickling pool for pickling steel pipes, comprising a pool body, cover plates are hinged on both sides of the upper end of the pool body, and a placement plate is connected to the pool body through a sliding mechanism. And the cross-sectional area of the placing plate matches the cross-sectional area of the pool body, the placing plate is provided with a plurality of leakage holes, the both sides of the pool body are provided with support columns, and the space between the two support columns is The upper end is provided with a support plate, the lower end of the support plate is provided with a hydraulic rod, the middle of the two cover plates is provided with a semicircular hole, and the two semicircular holes form a circular hole, the output shaft of the hydraulic rod It is fixedly connected with the placement plate through a round hole. An acid outlet is provided on one side of the lower end of the pool body. One end of the acid outlet is connected to a water pump, and the other end of the water pump is connected to an acid guide hose. The other end passes through the cover plate and communicates with the pool body. The invention has the characteristics of thorough pickling and convenient putting in and taking out of steel pipes.

Owner:湖北加恒实业有限公司

Method for reducing porosity of surface coating of neodymium iron boron permanent magnet material

InactiveCN111020659AReduce porosityReduced magnetic flux lossPermanent magnet manufactureCapillary TubingPhysical chemistry

The invention discloses a method for reducing porosity of a surface coating of a neodymium iron boron permanent magnet material, belonging to the field of surface treatment of sintered neodymium ironboron permanent magnet materials. The method is characterized by comprising the steps of 1) deashing a neodymium iron boron permanent magnet material; 2) soaking the neodymium iron boron permanent magnet material in a sealant, and then carrying out water washing, wherein the sealant is an alcohol amine compound; 3) sequentially cleaning the wahsed neodymium iron boron permanent magnet material through an oil removal agent and an acid; and 4) activating the neodymium iron boron permanent magnet material, and then carrying out electroplating. According to the method for reducing the porosity ofthe surface coating of the neodymium iron boron permanent magnet material, hole sealing treatment is carried out before electroplating, water is sucked into gaps through capillary action, and oxide inthe gaps generates hydrated oxide through hydration, so that the volume of the oxide is increased, and the gaps are sealed; and furthermore, the porosity of the coating can be reduced, the coating isrelatively smooth and bright, and the magnetic flux loss of the magnet can be reduced.

Owner:ARCFL TECHNOLOGY LIMITED

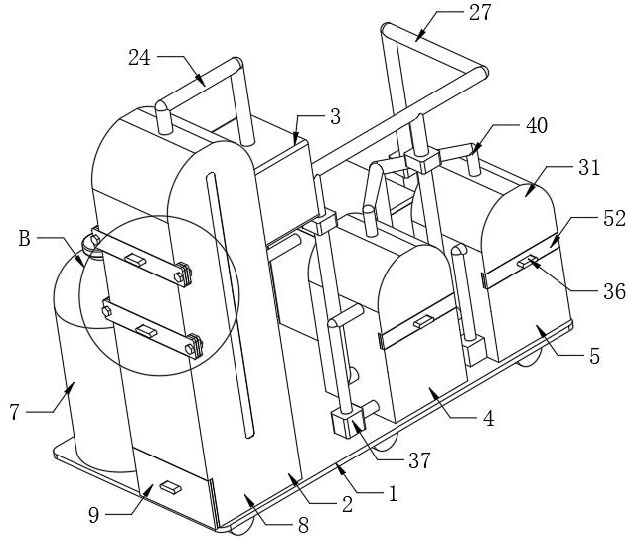

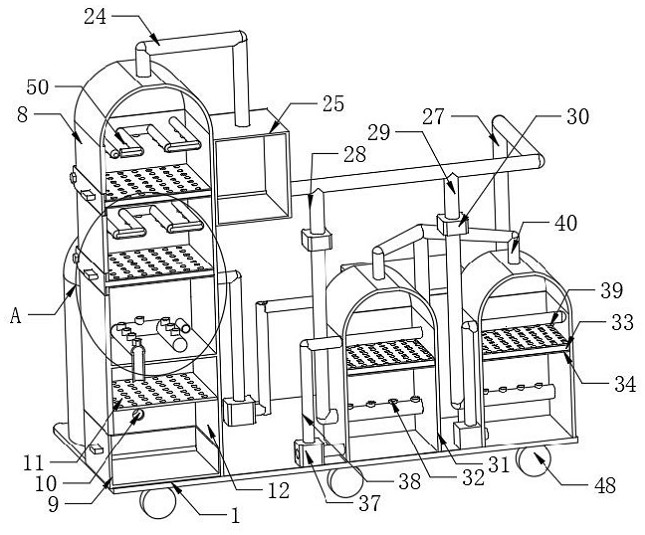

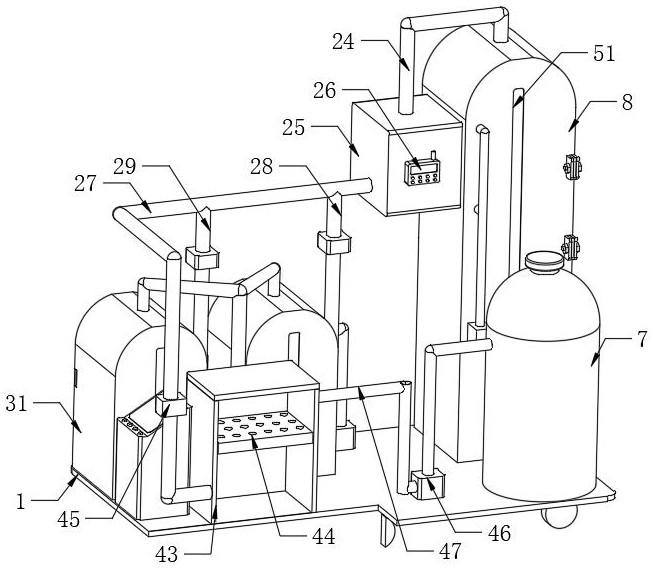

Electronic gas tail gas intelligent recovery device and method

ActiveCN112827272AImprove filtering effectEasy primary processingDispersed particle filtrationProcess engineeringMechanical engineering

The invention relates to the technical field of electronic gas tail gas recovery, and particularly relates to an intelligent electronic gas tail gas recovery device and method. The device comprises a base plate and a console, wherein the console is arranged at one end of the top of the base plate. The device further comprises a first processing mechanism, a detection mechanism, a second processing mechanism, a third processing mechanism, a gas dehumidification mechanism and an electronic gas collection tank, wherein the first processing mechanism is arranged at the other end of the top of the base plate, the second processing mechanism and the third processing mechanism are arranged at the top of the base plate and located on one side of the console, the gas dehumidification mechanism is arranged at the top of the base plate and located on the other side of the console, the electronic gas collection tank is installed at the top of the base plate and located on the side edge of the first processing mechanism, and the first processing mechanism comprises a first processing box. The device is compact in structure, continuous in operation, convenient to move, cost-saving and high in recovery efficiency.

Owner:铜陵安德科铭电子材料科技有限公司

Chip pickling device

InactiveCN111584401AAvoid distortionEasy picklingSemiconductor/solid-state device manufacturingProcess engineeringMechanical engineering

The invention discloses a chip pickling device. The device structurally comprises a top cover, a chip placing and rotating mechanism, a pickling machine body and a pickling solution discharge pipe. The top cover is hinged to the top of the pickling machine body; the pickling machine body is provided with the chip placing and rotating mechanism; and the bottom of one side of the pickling machine body is communicated with the pickling solution discharge pipe. Compared with the prior art, the device has the beneficial effects that: chips to be pickled can be placed, and the chips are independently placed one by one, so that area overlapping caused by chip stacking can be avoided, the contact area of the chips and the pickling solution is increased, and the acid washing efficiency and effect can be improved; in the pickling process, the chips can rotate with the rotating shaft as the axis, so that the chips and pickling water generate counterforce, so that pickling of the chips by the pickling water is more facilitated, and pickling of the chips is more sufficient; and after cleaning, stretching of the springs facilitates loosening of the pickled chips by the supporting blocks and pouring out of all the chips, and taking of the chips one by one is not needed.

Owner:郭志锋

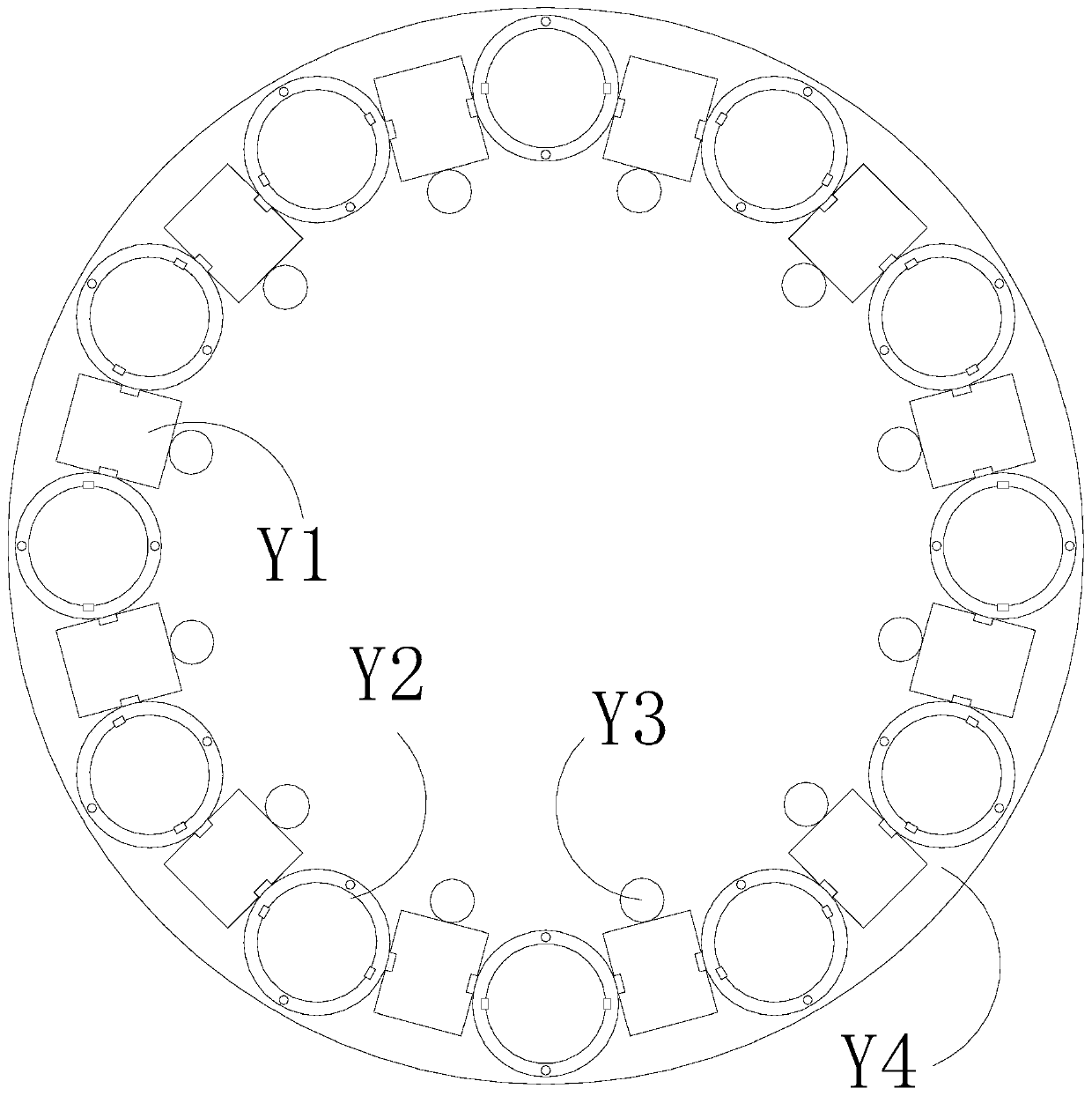

Cold-rolled sheet manufacturing device

The invention relates to the field of cold-rolled sheet manufacturing and pickling equipment, in particular to a cold-rolled sheet manufacturing device which comprises a device body. A plurality of extrusion pushing mechanisms are distributed on the inner side of the device body, and each extrusion pushing mechanism comprises an upper pressing roller and a lower pressing roller which are vertically, correspondingly and rotationally installed on the inner side of the device body. The inner side of the upper pressing roller and the inner side of the lower pressing roller are each provided with aplurality of flow guide channels distributed in an annular array mode, each flow guide channel is in a spiral shape with the screw pitch larger than that of the upper pressing roller, and the two ends of each flow guide channel penetrate through the outer surfaces of the two sides of the upper pressing roller or the lower pressing roller. Each extrusion pushing mechanism further comprises a fixing frame with the two ends fixedly connected to the inner walls of the two sides of the device body, the fixing frame is located in front of the upper pressing roller, and a sliding opening is formed in the upper end face of the fixing frame. The device is beneficial to flowing of the whole pickling solution in the pickling process, flowing of the pickling solution near the upper surface of the plate, cleaning of the surface of the plate and long-term use.

Owner:王东亮

Method for preparing baked duck eggs with lentinus edodes five-spice composite flavor

InactiveCN109007637AEasy to pickleReduce viscosityFood ingredient as flavour affecting agentFood ultrasonic treatmentCooking & bakingIllicium verum

The invention discloses a method for preparing baked duck eggs with lentinus edodes five-spice composite flavor. The method is as follows: firstly treating duck eggs with an acetic acid solution, andremoving the outer film on the surface of the duck egg shell so as to reduce the immersion resistance of water and salt and to make the duck eggs easier to pickle; adopting ultrasonic wave during thefirst pickling to promote salt Infiltration, to utilize the cavitation effect peculiar to ultrasonic oscillation, to reduce the mutual aggregation of egg white protein particles, to reduce the viscosity of egg white and to enhance the penetration of salt and flavor substances; then drying and powdering waste lentinus edodes pedicle, mixing the pedicle powder with spices such as chilies and star anise to obtain a spicy lentinus edodes compound pickling material, and pot-stewing the cooked duck eggs to obtain duck eggs with lentinus edodes five-spice composite flavor; and finally, conducting segmented baking to obtain the baked duck eggs which have a caramel color in appearance and are smooth and bright, slightly viscous, complete in shell and tough in structure. The baked duck eggs preparedby the method have fresh saltiness, pot-stewing fragrance and burnt fragrance all put into one, and are crispy outside and tender inside, rich in fragrance, rich in nutrients and convenient to carryat the same time.

Owner:HEFEI FULAIDUO FOOD

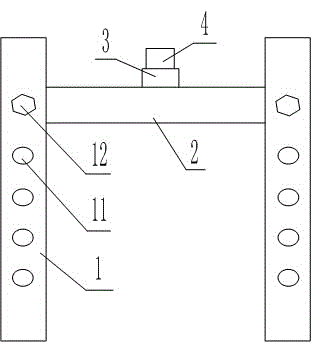

Rust-removing sample holder

InactiveCN103868843AEasy to insertRealize batch picklingWeather/light/corrosion resistanceRustPhysics

The invention relates to a sample holder, and particularly relates to a rust-removing sample holder. The rust-removing sample holder comprises two door-shaped frames and a cross beam which is arranged between top borders of the two door-shaped frames; sample baskets are arranged at the inner sides of the door-shaped frames; a plurality of upper blocking slots are arranged in two side borders of each sample basket in parallel, and lower blocking slots corresponding to the plurality of upper blocking slots one by one are arranged at the bottom of each sample basket, so that samples can be inserted into the corresponding upper blocking slots and the corresponding lower blocking slots. The rust-removing sample holder can be used for conveniently achieving processes of putting the samples into an acid slot and taking the samples out of the acid slot. Meanwhile, batch pickling of corroded samples can be realized, and the working efficiency is improved. In addition, the blocking slots are arranged in the sample baskets, so that the samples can be conveniently inserted into the blocking slots, and thus contact among the samples is avoided and quicker and better pickling is achieved.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com