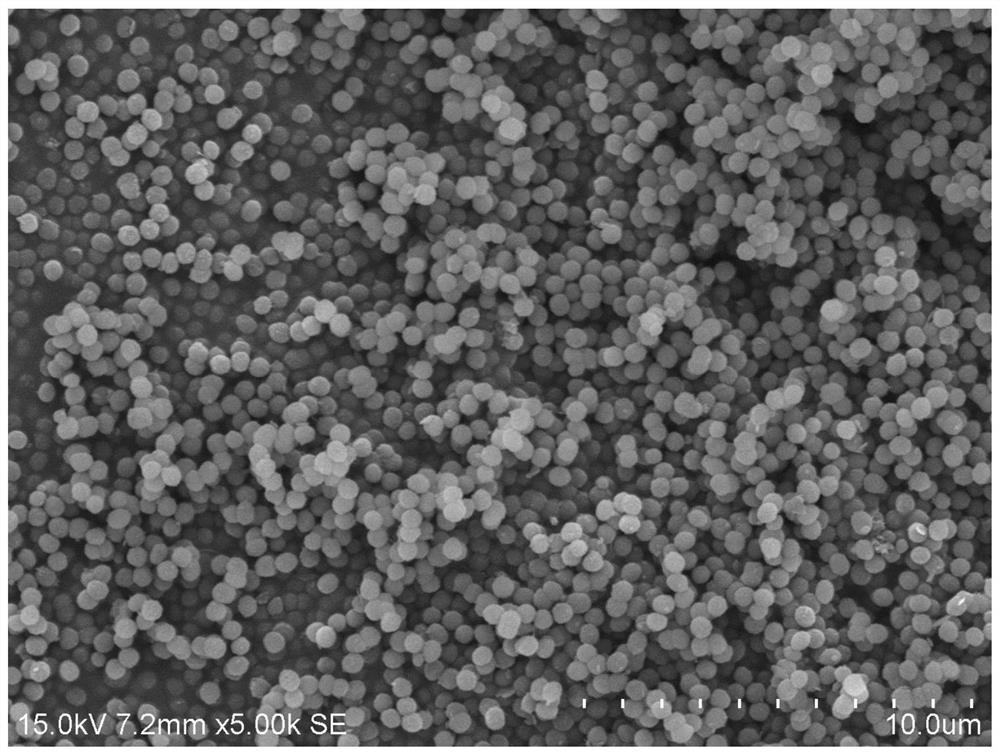

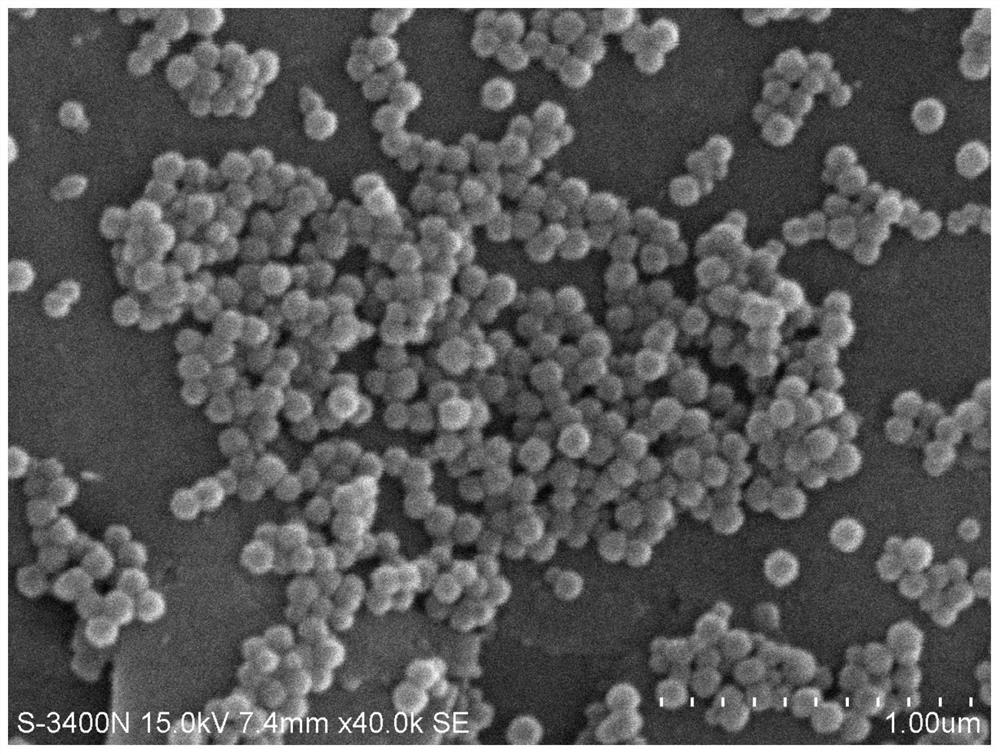

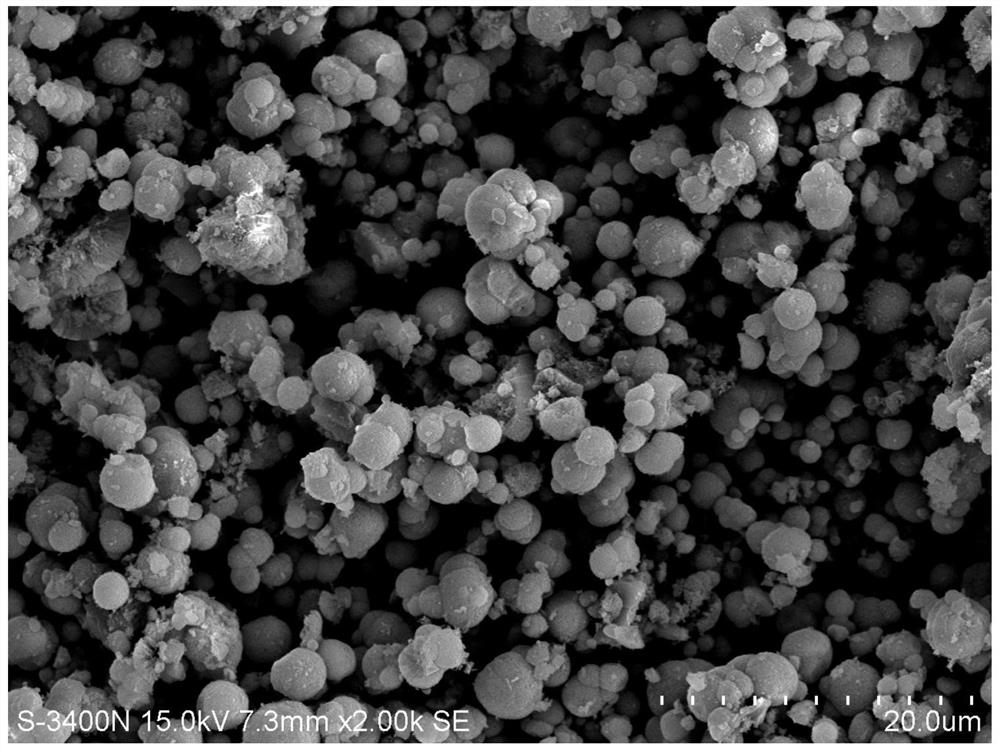

Preparation process for preparing regular spherical calcium carbonate through calcium chloride and ammonia water solution carbonization method

An ammonia solution and a preparation process technology, applied in the field of calcium carbonate, can solve the problem that spherical calcium carbonate particle morphology and particle size are difficult to control, it is difficult to prepare spherical calcium carbonate with uniform particle size, and large-scale industrial production cannot be realized. problem, to achieve the effect of good pickling to remove the template, uniform and stable quality, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation technology of calcium chloride, ammonia solution carbonization regulation whole spherical calcium carbonate, comprises the following steps:

[0034] (1) Preparation of calcium chloride and ammonia solution: calcium hydroxide and water at room temperature are fully stirred and dissolved according to the mass ratio of 1:4, and the molar ratio of calcium hydroxide and ammonium chloride is 1:2.05 Add ammonium chloride and fully stir to dissolve the reaction, that is, there is a slight excess of ammonium chloride. After sufficient reaction, filter the obtained calcium chloride and ammonia solution to remove insoluble matter and impurities to obtain a clear liquid. Add methanol to adjust the concentration of calcium chloride to 10%. The addition amount is 40% of the prepared calcium chloride and ammonia solution quality;

[0035] (2) Addition of the crystal morphology control agent: pump the calcium chloride and ammonia solution that have adjusted the co...

Embodiment 2

[0039]A kind of preparation technology of calcium chloride, ammonia solution carbonization regulation whole spherical calcium carbonate, comprises the following steps:

[0040] (1) Preparation of calcium chloride and ammonia solution: calcium hydroxide and water at room temperature are fully stirred and dissolved according to the mass ratio of 1:5, and the molar ratio of calcium hydroxide and ammonium chloride is 1:2.2 Add ammonium chloride and fully stir to dissolve the reaction, that is, there is a slight excess of ammonium chloride. After sufficient reaction, filter the obtained calcium chloride and ammonia solution to remove insoluble matter and impurities to obtain a clear liquid. Add ethanol to adjust the concentration of calcium chloride to 8%, ethanol The addition amount is 50% of the prepared calcium chloride and ammonia solution quality;

[0041] (2) Addition of crystal morphology control agent: pump the calcium chloride and ammonia solution with adjusted concentrati...

Embodiment 3

[0045] A kind of preparation technology of calcium chloride, ammonia solution carbonization regulation whole spherical calcium carbonate, comprises the following steps:

[0046] (1) Preparation of calcium chloride and ammonia solution: calcium hydroxide and water at room temperature are fully stirred and dissolved according to the mass ratio of 1:4, and the molar ratio of calcium hydroxide and ammonium chloride is 1:2.05 Add ammonium chloride and fully stir to dissolve the reaction, i.e. ammonium chloride is slightly excessive. After sufficient reaction, filter the obtained calcium chloride and ammonia solution to remove insoluble matter and impurities to obtain a clear liquid. Add water to adjust the concentration of calcium chloride to 10%. Add organic solvent as carbon dioxide dissolving agent and calcium carbonate crystal form stabilizer;

[0047] (2) Crystal morphology control agent is added: no crystal morphology control agent is added;

[0048] (3) Carbonization: adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com