Pipe inner surface acid pickling device and method

A surface acid and pipe material technology, which is applied in the field of pipe inner surface pickling equipment, can solve the problems of high technical level requirements for operators, unfavorable mass production, and difficult control of product quality stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

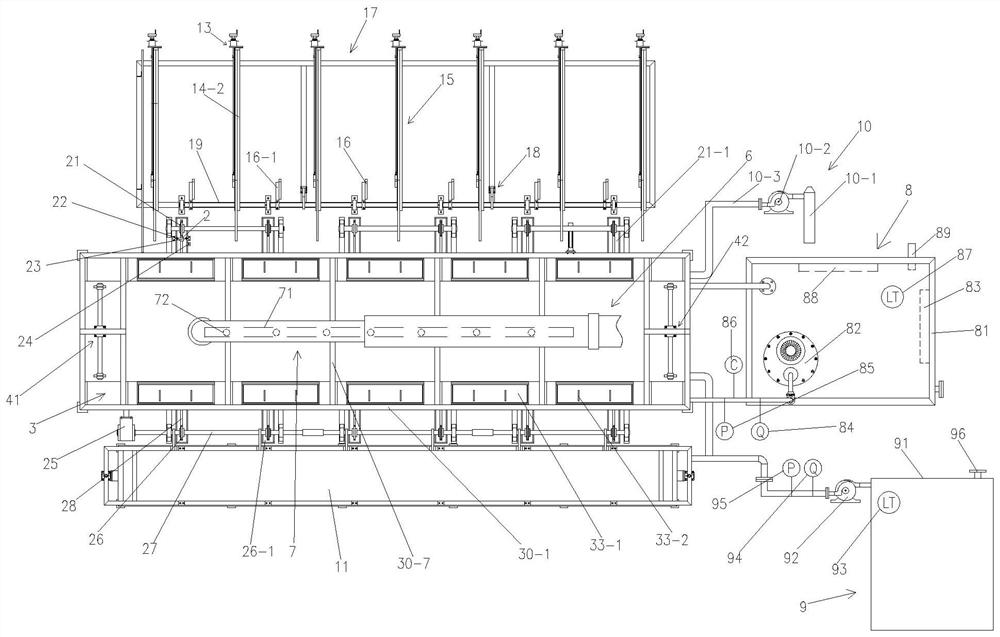

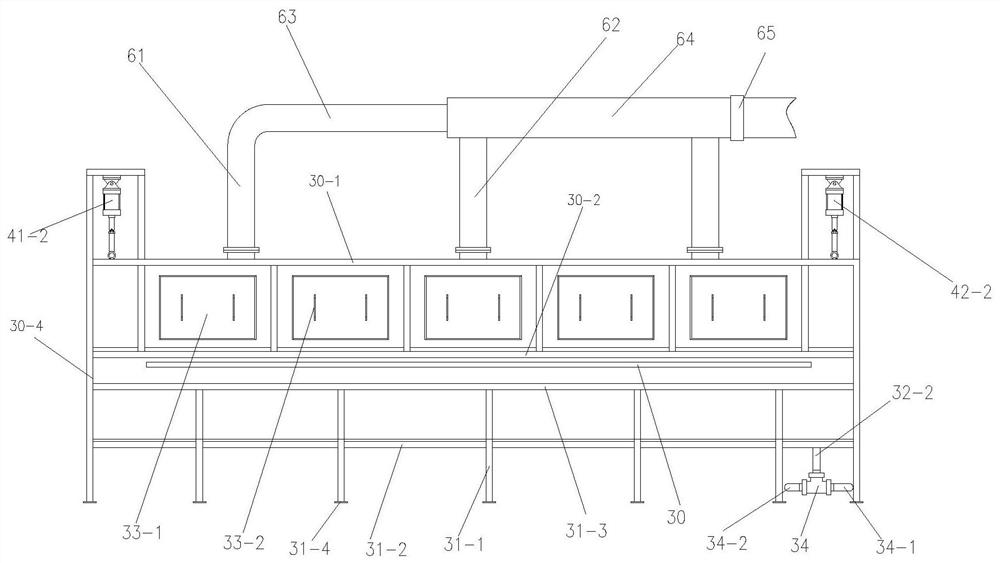

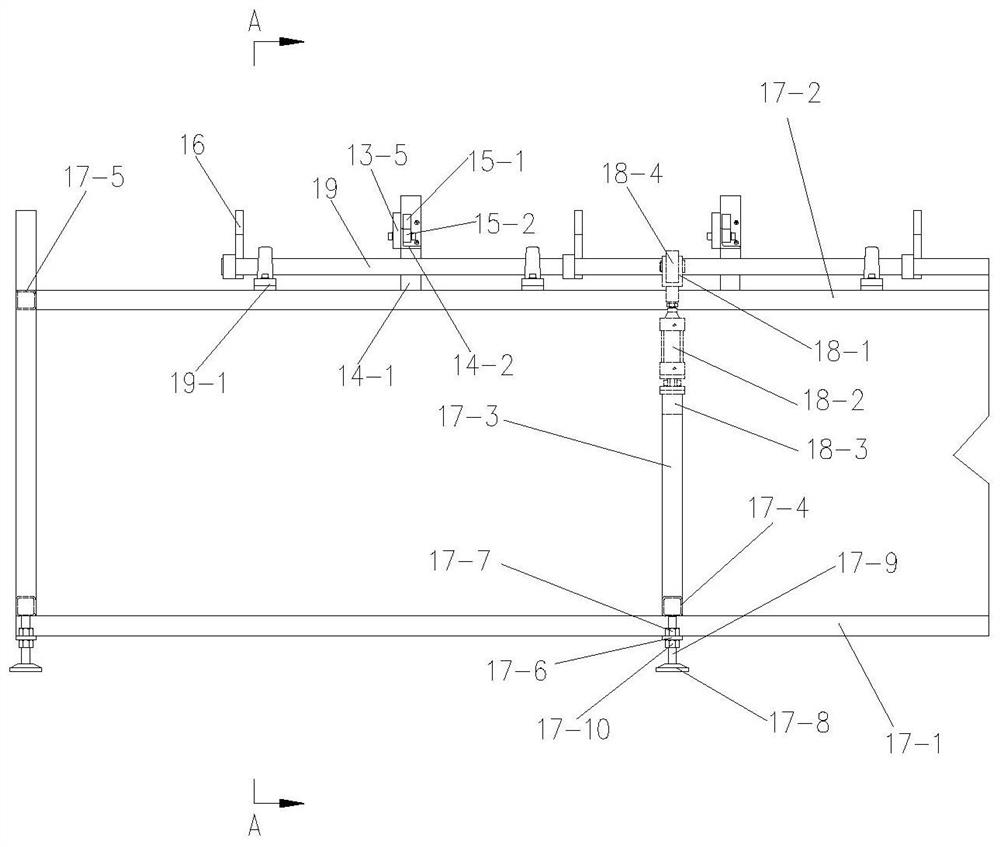

[0147] Such as figure 1 , figure 2 and Figure 16 The shown pickling device for the inner surface of pipes includes a pipe feeding platform, a feeding mechanism, a pickling mechanism for pickling the inner surface of pipes, and a soaking tank arranged at the outlet 30 of the pickling mechanism 11 and a monitoring module that monitors the feeding mechanism and the pickling mechanism, the feeding mechanism includes a feeding mechanism that is arranged on the pipe feeding platform and that pulls the pipe material and passes through the pickling chamber 3. A pipe conveying mechanism for conveying pipes. The pipe feeding platform includes a frame body 17 and a holding mechanism arranged on the frame body 17 for placing pipe materials. The material shifting mechanism is located on the frame body 17 on;

[0148] The pickling mechanism includes a pickling rack body, a pickling chamber 3 arranged on the pickling rack body, a lifting mechanism arranged in the pickling chamber 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com