Strip steel pickling system with spraying system

A technology of spraying system and steel acid, which is applied in the field of coil and strip steel production, can solve the problems of poor pickling effect, residual iron scale, unsatisfactory and other problems, and achieve the guarantee of pickling quality, high control precision and convenient control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

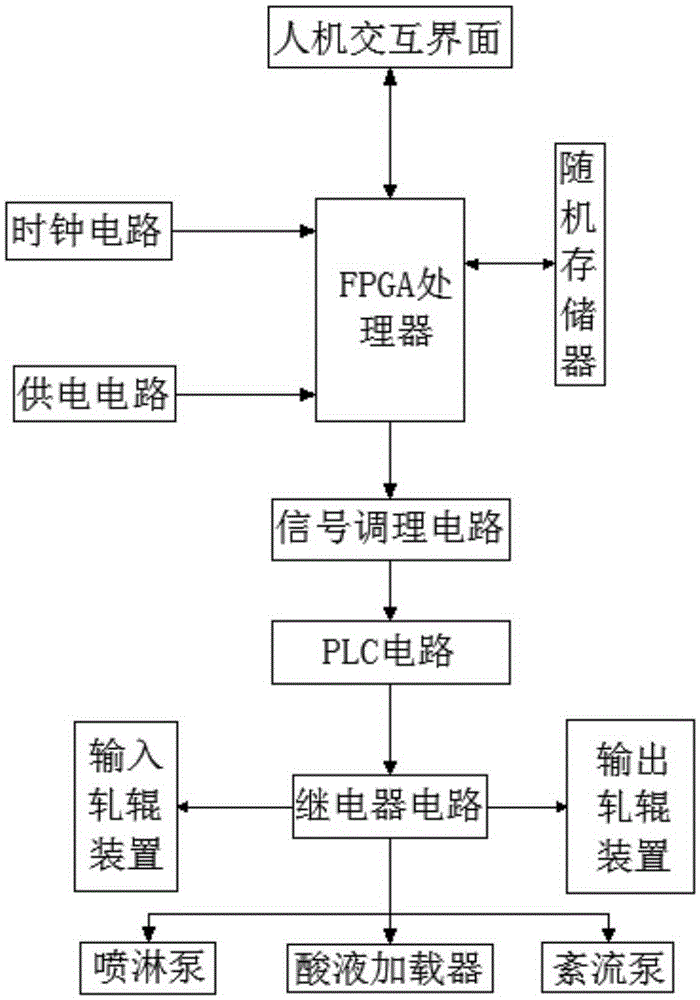

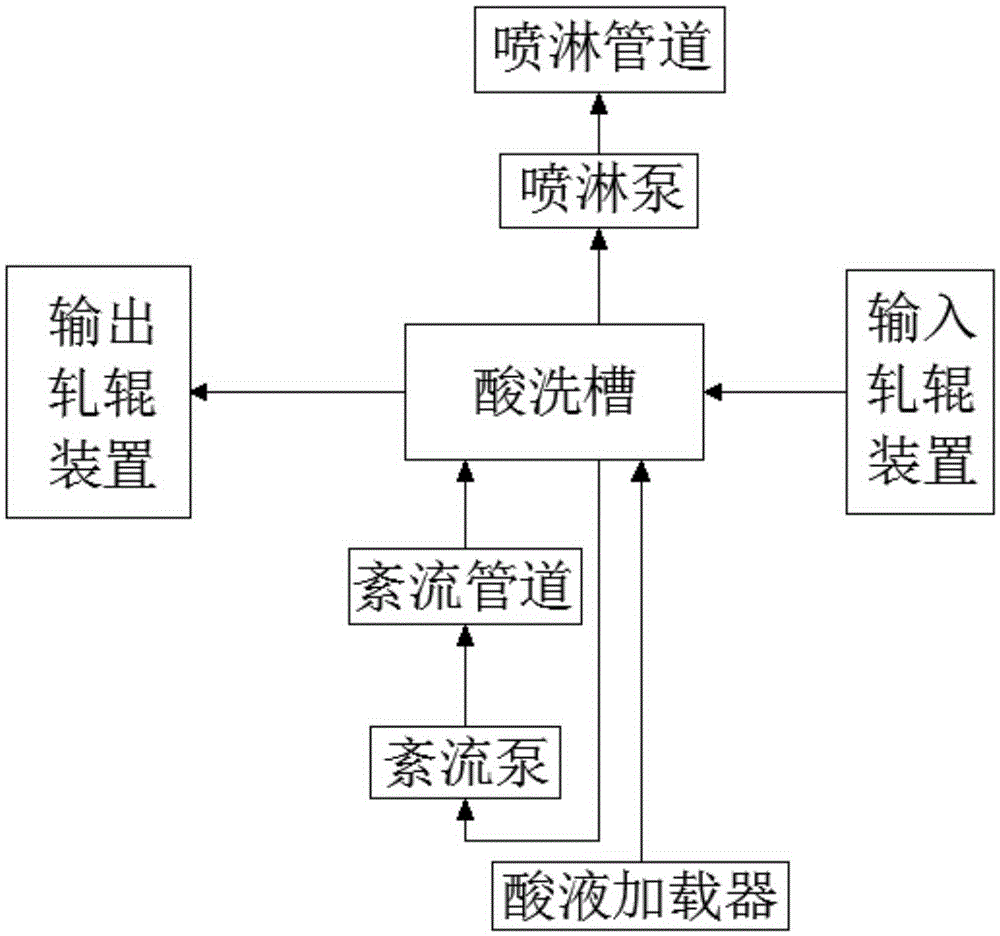

[0022] A strip steel pickling system with a spray system, which uses a combination of spray system and turbulent flow system to pickle the strip steel, which can improve the surface state of the steel plate surface in the acid tank, so that the iron scale on the steel plate surface can be obtained Fully pickling, the surface of the steel plate after pickling has no iron scale, the surface of the plate is bright, and the quality is stable, and an intelligent control system is used to control the pickling process and the fluidity of the acid in the pickling tank. The operation of the steel is managed synchronously to achieve the optimal pickling of the strip, such as figure 1 , figure 2 As shown, the following structure is particularly arranged: comprising a strip steel pickling device and a control system connected with the strip steel pickling device, the control system is provided with an FPGA processor, a power supply circuit, a storage circuit, and a signal processing circ...

Embodiment 2

[0024] This embodiment is further optimized on the basis of the above embodiments. Further, in order to better realize the present invention, the steel strip can be passed through the pickling tank, and the upper and lower surfaces of the steel strip can be controlled by the spray system and the turbulence system. The surface is cleaned, and at the same time, pickling liquid can be added to the pickling tank as needed, such as figure 1 , figure 2 As shown, the following structure is particularly provided: the strip pickling device is provided with a pickling tank, an input roll device, an output roll device, a spray system, a turbulent flow system and an acid loader, and the input roll device Connect the pickling tank, the pickling tank is connected to the output roll device, the pickling tank is respectively connected to the spray system and the turbulence system, and the signal processing circuit is respectively connected to the input roll device, the output roll device, th...

Embodiment 3

[0026] This embodiment is further optimized on the basis of the foregoing embodiments. Further, in order to better realize the present invention, the input roller device, the output roller device, the spray system, the acid loader and the turbulent flow can be automatically controlled through the relay circuit. system, such as figure 1 , figure 2 As shown, the following structure is particularly provided: the signal processing circuit is provided with a signal conditioning circuit, a PLC circuit and a relay circuit, and the FPGA processor is sequentially connected to the signal conditioning circuit, the PLC circuit and the relay circuit, and the relay circuits are respectively Connect the input roll device, output roll device, spray system, acid loader and turbulence system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com