Stainless steel pickling and passivation solution as well as preparation method and use method thereof

A pickling passivation, stainless steel technology, applied in the direction of metal material coating process, etc., can solve the cleaning time up to 2-10 hours, affect the health of operators, weld bead is easy to white and other problems, to achieve pickling and Good passivation effect, low cost, good brightness and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

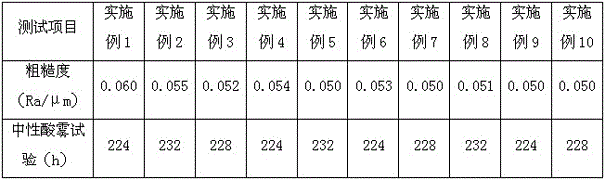

Examples

Embodiment 1

[0050] A kind of stainless steel pickling passivation solution, described stainless steel pickling passivation solution comprises the raw material of following weight percentage:

[0051] Nitric acid 14%

[0052] Hydrofluoric acid 3%

[0053] Non-ionic surfactant 0.6%

[0054] Corrosion inhibitor 0.41%

[0055] Oxidizing agent 0.05%

[0056] Ionic surfactant 0.03%

[0057] water balance.

[0058] The nonionic surfactant is alkylphenol polyoxyethylene ether.

[0059] The corrosion inhibitor consists of 0.11% thiourea and 0.3% glycerol.

[0060] The oxidizing agent is sodium iodate.

[0061] The ionic surfactant is octadecyl dimethyl ammonium chloride.

[0062] The invention discloses a method for preparing a stainless steel pickling passivation solution. The raw materials are weighed and mixed uniformly by weight percentage to prepare a stainless steel pickling passivation solution.

[0063]A method for using the stainless steel pickling passivation solution. The stain...

Embodiment 2

[0065] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0066] A kind of stainless steel pickling passivation solution, described stainless steel pickling passivation solution comprises the raw material of following weight percentage:

[0067] Nitric acid 16%

[0068] Hydrofluoric acid 4%

[0069] Nonionic surfactant 0.7%

[0070] Corrosion inhibitor 0.47%

[0071] Oxidizing agent 0.08%

[0072] Ionic surfactant 0.04%

[0073] water balance.

[0074] The nonionic surfactant is an alkyl polyoxyethylene ether.

[0075] The corrosion inhibitor consists of 0.12% thiourea and 0.35% glycerol.

[0076] A method for using the stainless steel pickling passivation solution. The stainless steel product to be treated is soaked in the stainless steel pickling passivation solution for 12 minutes and then rinsed with water.

Embodiment 3

[0078] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0079] A kind of stainless steel pickling passivation solution, described stainless steel pickling passivation solution comprises the raw material of following weight percentage:

[0080] Nitric acid 18%

[0081] Hydrofluoric acid 5%

[0082] Nonionic surfactant 0.8%

[0083] Corrosion inhibitor 0.53%

[0084] Oxidizing agent 0.1%

[0085] Ionic surfactant 0.05%

[0086] water balance.

[0087] The nonionic surfactant is a mixture of alkylphenol polyoxyethylene ether and alkyl polyoxyethylene ether in a weight ratio of 1:0.8.

[0088] The corrosion inhibitor consists of 0.13% thiourea and 0.4% glycerol.

[0089] A method for using the stainless steel pickling passivation solution. The stainless steel product to be treated is soaked in the stainless steel pickling passivation solution for 15 minutes and then rinsed with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com