Method for collecting noble metal from polymetallic alloy material

A multi-metal and precious metal technology, applied in the direction of improving process efficiency, etc., to achieve the effects of low production cost, simple process operation, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

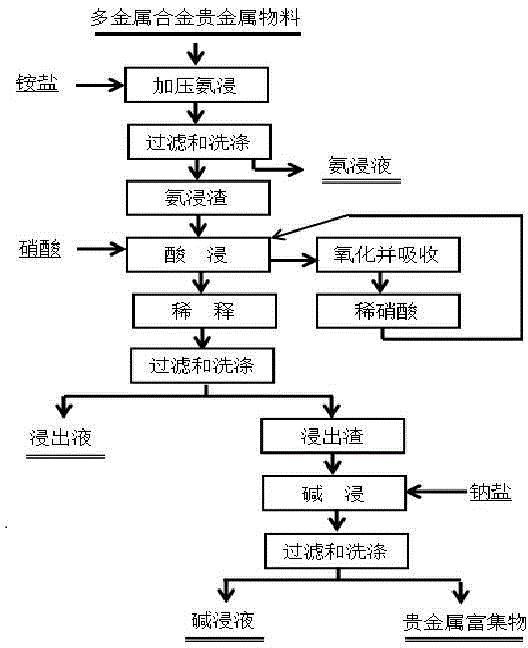

[0026] See attached figure 1 , conditions: 1000 grams of multi-metal alloy materials, the amount of ammonium carbonate is 1 times the weight ratio of the raw materials, the amount of ammonia water is 2 times the weight ratio of the raw materials, the leaching temperature is 100 ° C, the pressure is 0.8 MPa, the time is 6 hours, and the stirring speed is 250 rpm. After the pressure leaching is completed, filter and wash to obtain ammonia leaching liquid and ammonia leaching residue respectively; use nitric acid to selectively leach lead, and the amount of nitric acid is 0.8 times the weight of the material. Add water to dilute, and the amount of water added is twice the weight ratio of the material. After stirring evenly, filtering and washing, the acid leaching solution and acid leaching residue are obtained respectively. The leaching solution mainly contains lead, etc., and the acid leaching residue contains antimony, gold, platinum, palladium, etc. Metals; acid leaching slag...

Embodiment 2

[0028] See attached figure 1 , conditions: 5000 grams of multi-metal alloy materials, the amount of ammonium bicarbonate is 1.5 times the weight ratio of raw materials, the amount of ammonia water added is 1 times the weight ratio of raw materials, the leaching temperature is 120 ° C, the pressure is 1.0 MPa, the time is 4 hours, and the stirring speed is 250 rpm. After the pressure leaching is completed, filter and wash to obtain ammonia leaching liquid and ammonia leaching residue respectively; use nitric acid to selectively leaching lead, the amount of nitric acid is 0.9 times the weight of the material, when the sample is analyzed and the lead leaching is complete, continue heating and concentrating until viscous , add low-concentration sodium hydroxide to dilute, and the dosage is 2 times of the weight ratio of the material. After stirring evenly, filtering and washing, acid leaching solution and acid leaching residue are obtained respectively. The leaching solution mainly...

Embodiment 3

[0030] See attached figure 1 , Conditions: see attached picture, conditions: 10,000 grams of multi-metal alloy materials, the amount of ammonium bicarbonate is 1.0 times the weight ratio of the raw materials, the amount of ammonia water is 1.5 times the weight ratio of the raw materials, the leaching temperature is 160°C, the pressure is 1.6MPa, and the time is 4h , the stirring speed is 250rpm, after the pressurized leaching is finished, filter and wash to obtain the ammonia leaching solution and the ammonia leaching residue respectively; use nitric acid to selectively leaching lead, the amount of nitric acid is 1.0 times of the material weight, when the sampling analysis is complete, continue Heat and concentrate until viscous, add low-concentration sodium carbonate to dilute, the dosage is 1 times the weight ratio of the material, stir evenly, filter and wash, and obtain acid leaching liquid and acid leaching residue respectively. The leaching liquid mainly contains lead, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com