Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Does not affect toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

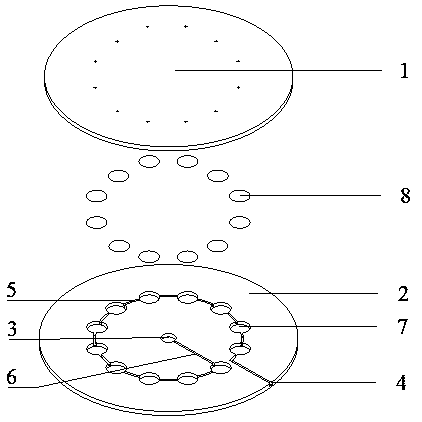

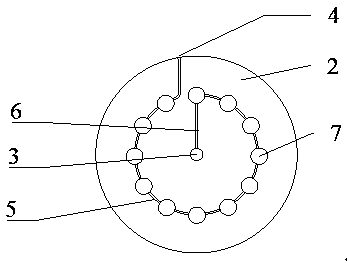

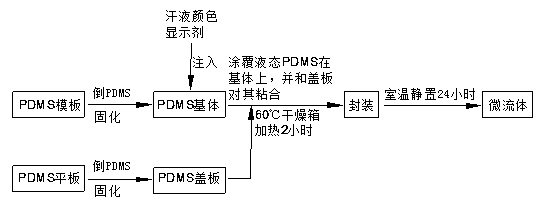

Flexible microfluid equipment for collecting human body sweat and sweat collecting and detecting method thereof

InactiveCN107802293ALow priceChangeable shapeSurgeryVaccination/ovulation diagnosticsHuman bodyHigh volume manufacturing

The invention discloses a set of flexible microfluid equipment for collecting human body sweat and a sweat collecting and detecting method thereof. The flexible microfluid equipment comprises a base body and a cover plate, wherein the base body is used for providing a module of a passage and a cavity for transmitting and accommodating the sweat, and the cover plate is the semitransparent cover plate used for sealing the base body. The base body comprises a sweat inlet, a sweat outlet and a microfluid passage. The microfluid passage comprises a capillary tube and a microfluid cavity, wherein the capillary tube is used for controlling fluids flowing through the passage in the microfluid equipment, and the microfluid cavity is used for storing the sweat and is provided with a displaying agentinside. The equipment is fixed on the human body, after the sweat enters into the microfluid passage, a + mark on the cover plate is positioned by a mobile software, colors in the microfluid cavity at different positions are scanned, so as to obtain the sweat content at some time; meanwhile, after the sweat collecting is finished, the sweat is extracted from the sweat outlet by an injector, and the sweat is used for storing and conducting medical detection. The equipment is easy in usage, low in raw material and processing cost, capable of being massively produced, and wide in applicability.

Owner:XIANGTAN UNIV

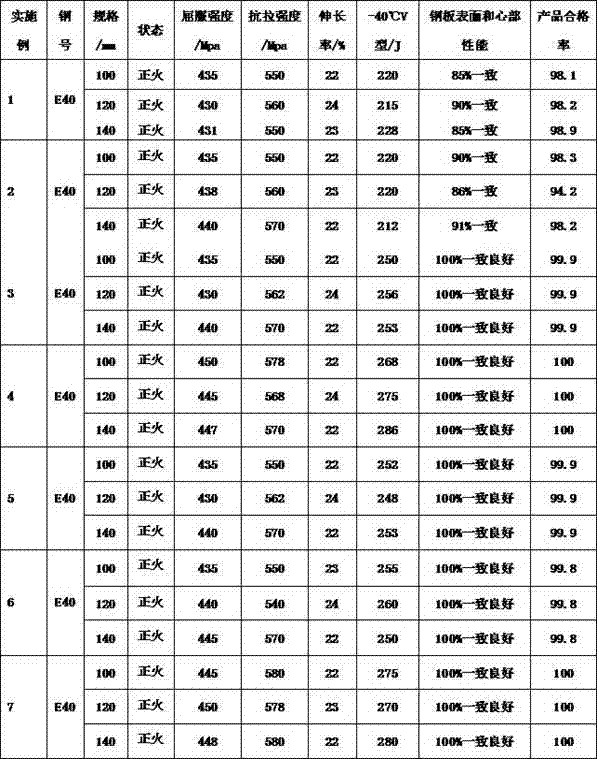

E40 high-strength ship plate steel and method for manufacturing same

The invention discloses E40 high-strength ship plate steel. The E40 high-strength ship plate steel comprises, by mass, from 0.13% to 0.16% of C, from 0.2% to 0.4% of Si, from 1.5% to 1.6% of Mn, lower than or equal to 0.03% of P, lower than or equal to 0.005% of S, from 0.30% to 0.35% of Ni, from 0.055% to 0.065% of V, from 0.035% to 0.045% of Nb, from 0.010% to 0.020% of Ti, from 0.015% to 0.035% of Als and the balance Fe. A method for manufacturing the E40 high-strength ship plate steel includes a pretreatment process for melted iron, a smelting process implemented by the aid of a converter, an argon blowing treatment process, an LF (ladle furnace) refining process, a VD (vacuum degasser) refining process, a continuous casting process, a heating process, a controlled rolling and controlled cooling process, a stack cooling process and a heat treatment process. The E40 high-strength ship plate steel and the method have the advantages that the E40 high-strength steel is successfully developed, the yield strength of the E40 high-strength ship plate steel ranges from 430MPa to 450MPa, the tensile strength of the E40 high-strength ship plate steel ranges from 550MPa to 580MPa, the elongation of the E40 high-strength ship plate steel ranges from 22% to 24%, V-type impact power of the E40 high-strength ship plate steel ranges from 210J to 280J at the temperature of minus 40 DEG C, and performance indexes of a steel plate made of the E40 high-strength ship plate steel completely meet standards and requirements of clients.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

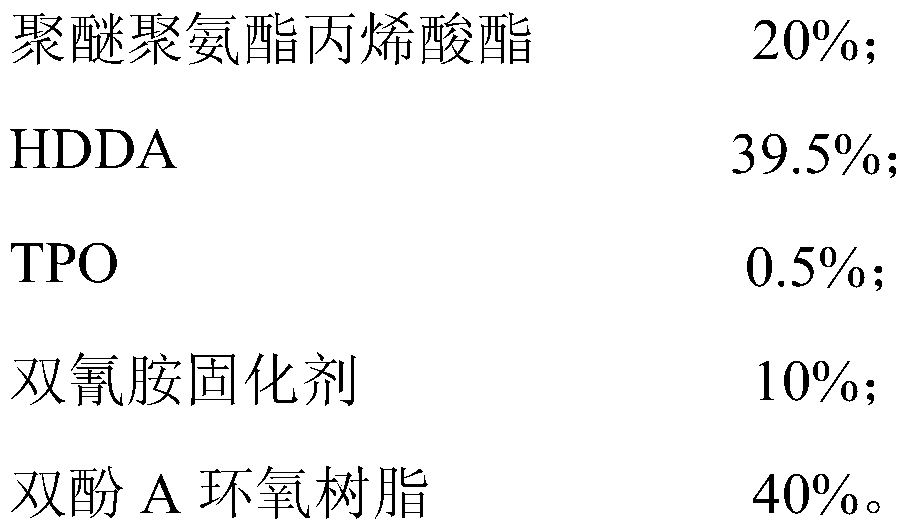

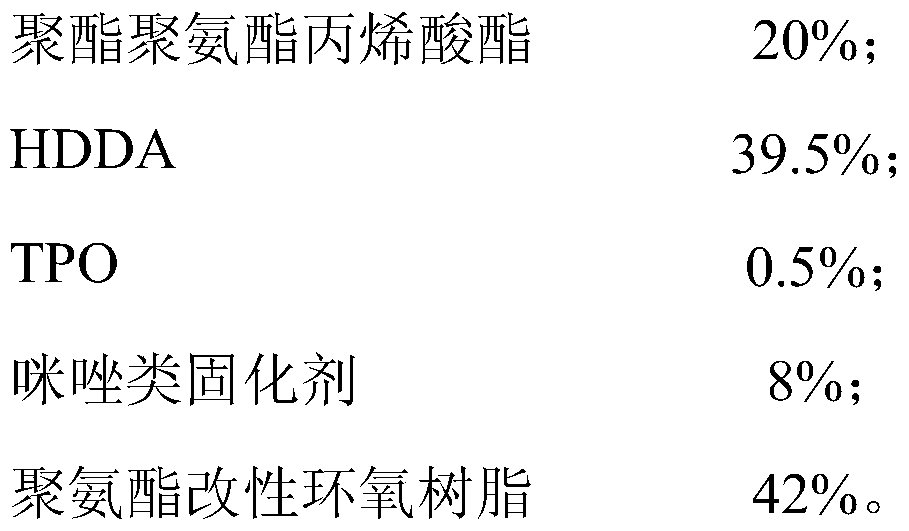

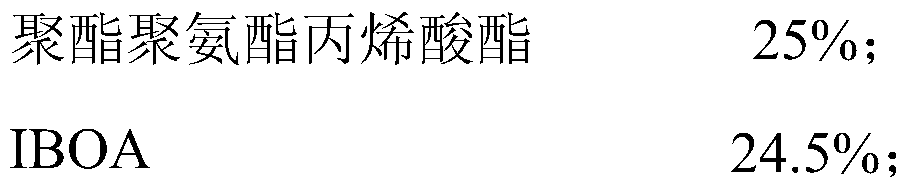

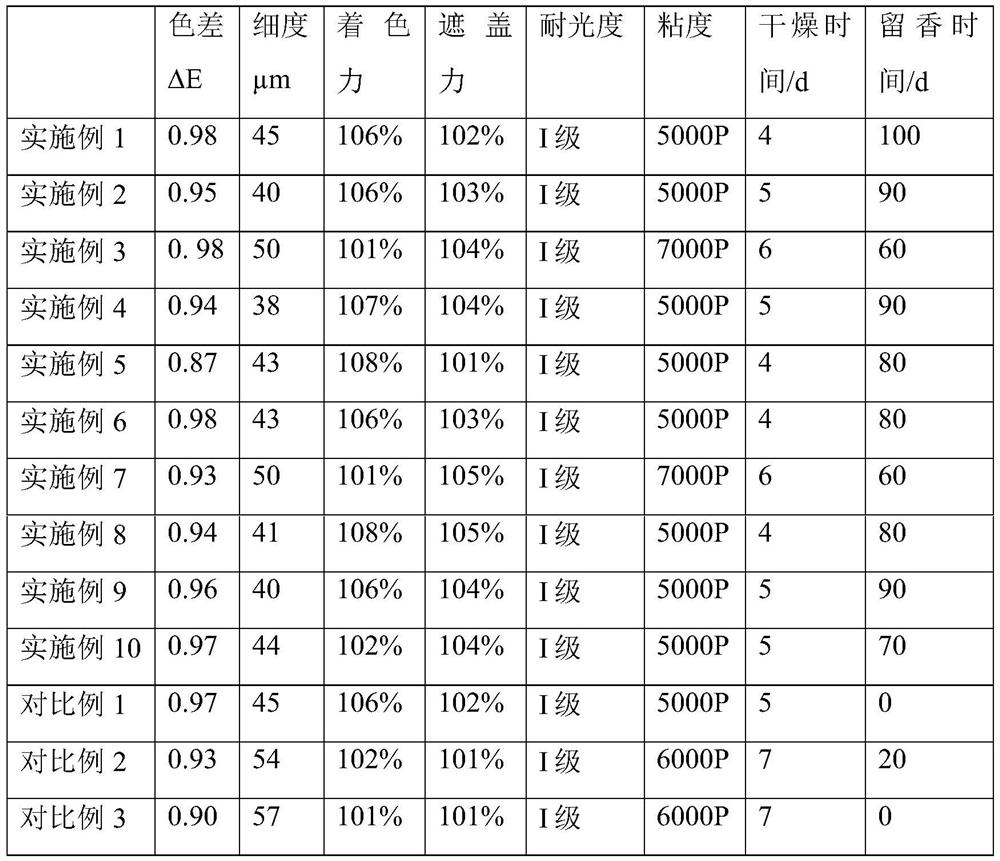

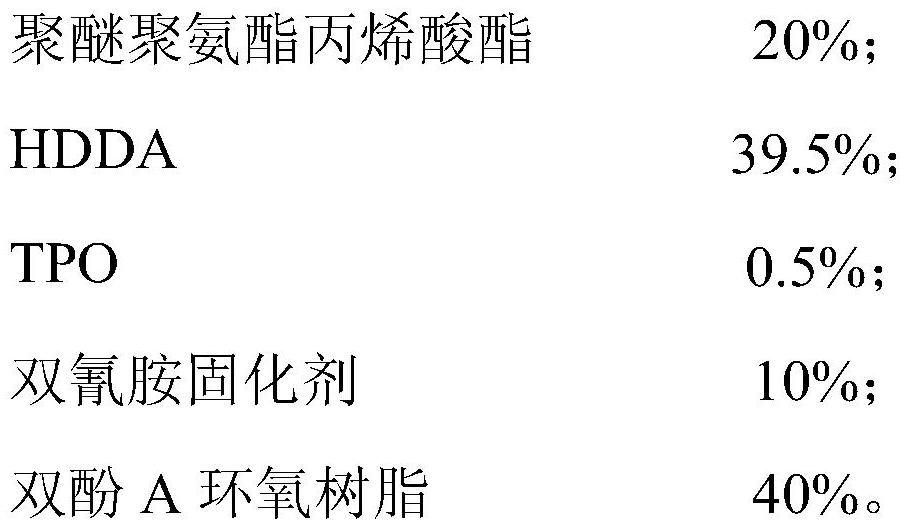

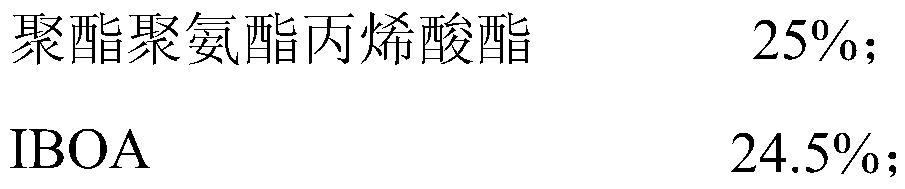

Photo-thermal double curing 3D printing method and product thereof

ActiveCN110128773AImprove toughnessStrong application valueAdditive manufacturing apparatusPolyesterEpoxy

The invention discloses a photo-thermal double curing 3D printing method and a product thereof, and the photo-thermal double curing 3D printing method comprises the following steps: mixing raw materials, carrying out photocuring 3D printing, and heating and curing to obtain a 3D printed product. The raw materials include polyurethane acrylate, a diluent, an initiator, epoxy resin and a thermotropic curing agent. The polyurethane acrylate is obtained by reacting isocyanate with polyol and then capping with hydroxyl-containing acrylate, and the polyol is polyester polyol or polyether polyol withthe molecular weight not less than 1000. The method avoids the phenomenon that polymerization products become brittle due to thermal curing of epoxy resin, realizes the basic toughness of epoxy resindual curing products, and meets the application in industrial manufacturing.

Owner:HANGZHOU NORMAL UNIVERSITY

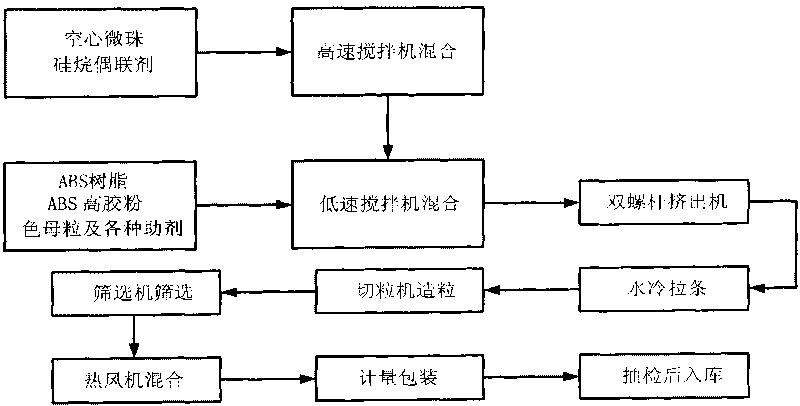

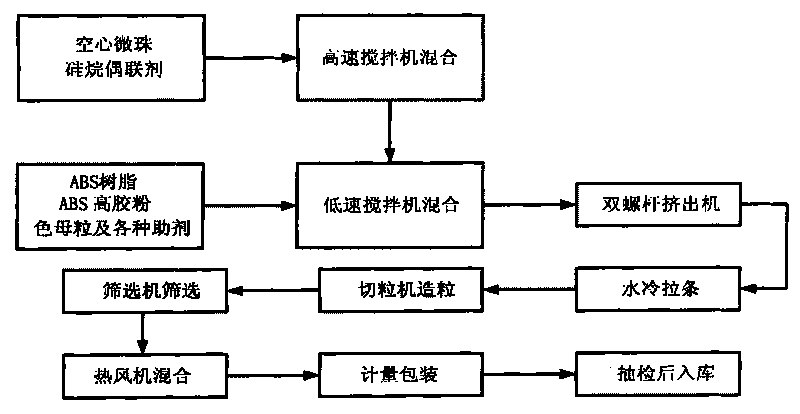

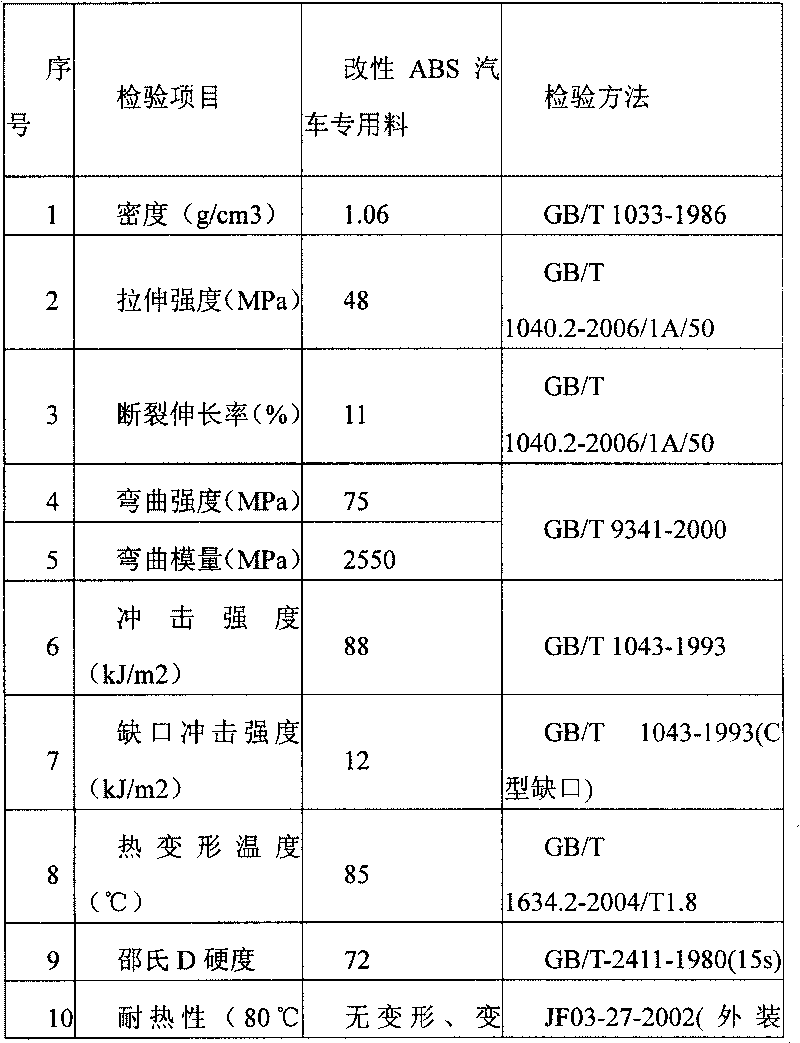

Modified ABS automobile special material and production method thereof

The invention provides a modified ABS automobile special material comprising the following components in the formula in parts by weight: 100 parts of resin matrix ABS, 5-15 parts of active filler hollow microsphere, 4-8 parts of high rubber powder ABS, 0.5-0.8 part of age resister and 2-4 parts of master batch. In the above formula composition, the matrix resin ABS is granular substance; the active filler hollow microsphere is processed by silane coupling agent KH 550; the age resister mainly comprises master antioxidant, slave antioxidant and uvioresistant agent which are all powdery substance; the color of the master batch is determined according to product requirements, and the master batch is granular substance. The invention utilizes the principle that solubility parameters are similar; other polymers and various auxiliary agents, such as age resister, flexibilizer, fillers and the like are added into the ABS material and carry out molten mechanical mixing at certain temperature so as to obtain a new material applied on lorry parts.

Owner:CHINA FIRST AUTOMOBILE

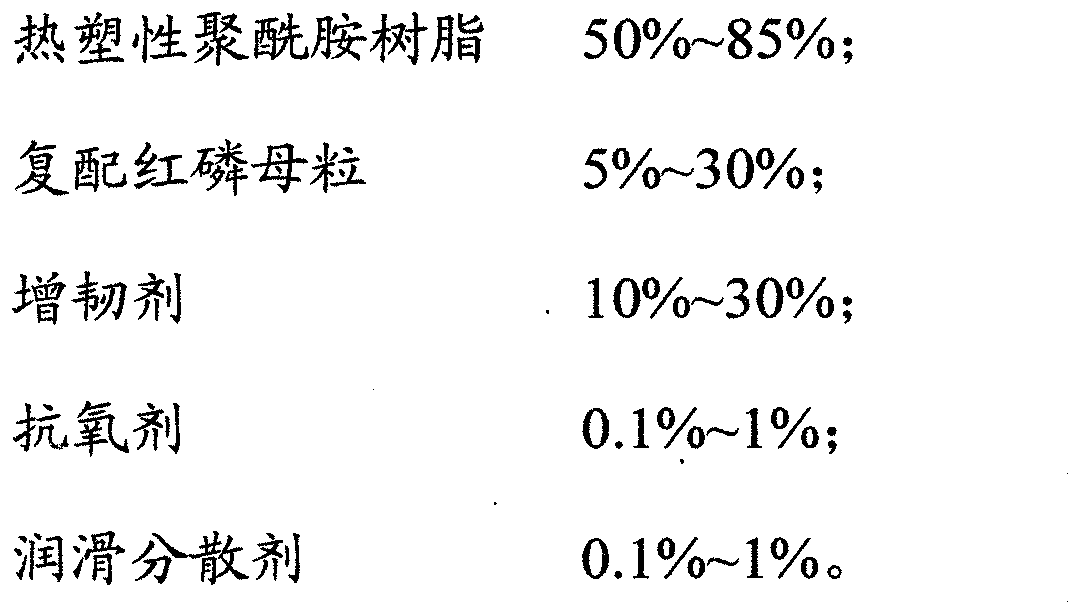

Halogen-free red phosphorus flame retardant nylon with high toughness and preparation method of nylon

The invention relates to halogen-free red phosphorus flame retardant nylon with high toughness for manufacturing explosion-proof equipment and a preparation method of the nylon. The nylon comprises 50-85% of thermoplastic polyamide resin, 5-30% of compound red phosphorus masterbatch, 10-30% of a flexibilizer, 0.1-1% of an antioxidant and 0.1-1% of a lubricating dispersant. The preparation method comprises the following steps: firstly, putting the components in parts by weight in a high mixer to be mixed for 2-5 minutes; then, putting the mixed materials from a main feed inlet of a twin-screw extruder to the extruder; carrying melt extrusion and prilling; and then preparing the red phosphorus flame retardant nylon with high toughness, wherein the temperatures of the regions of the twin-screw extruder are controlled in a range of 220-280 DEG C and the screw speed is controlled at 300-400RPM. By replacing common red phosphorus masterbatch with the compound red phosphorus masterbatch and adding the flexibilizer, the nylon material prepared satisfies the demand of high flame retardance, high toughness, no halogen and environment friendliness, and is more suitable for manufacturing explosion-proof equipment.

Owner:温州科力塑业有限公司

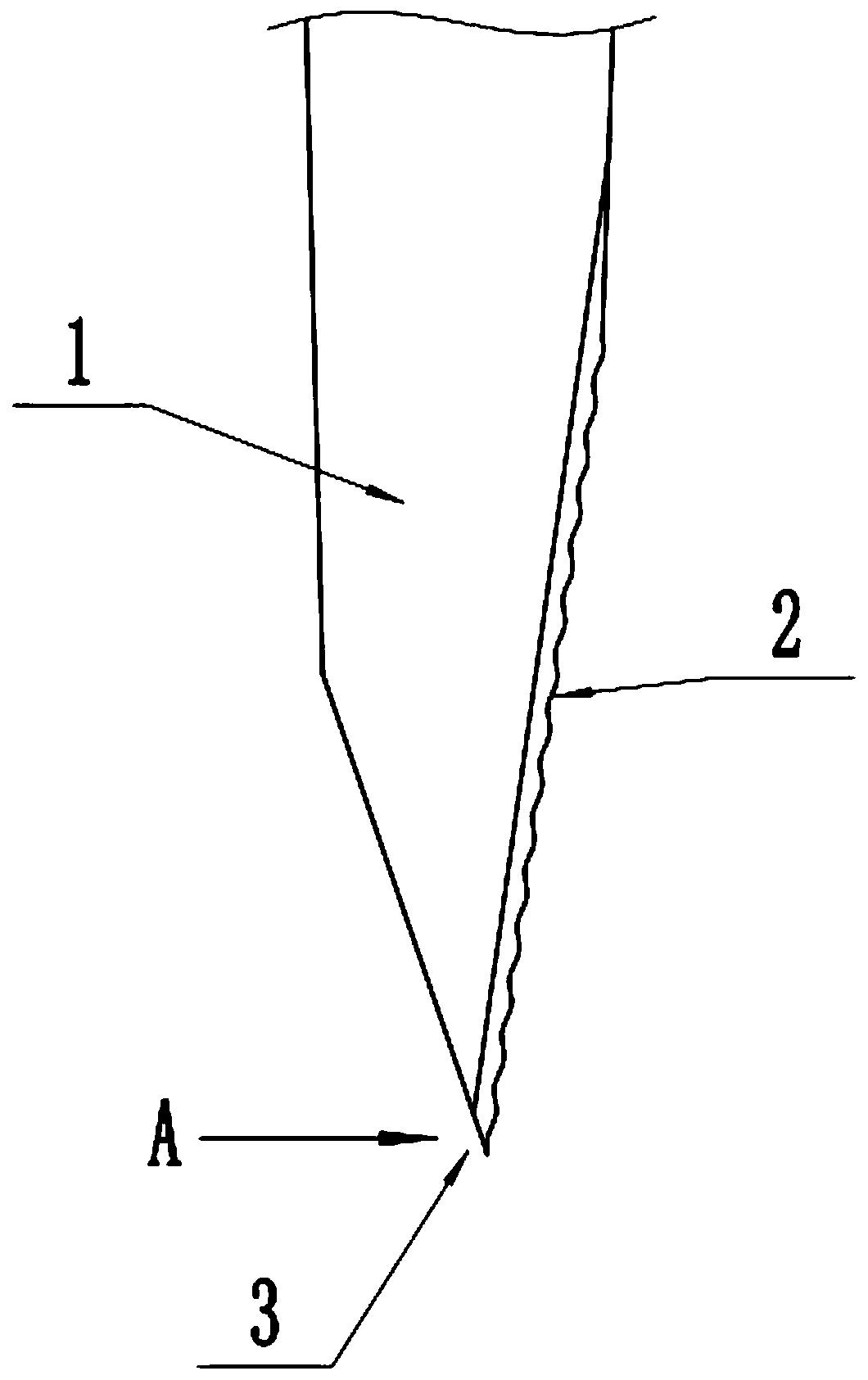

Shield cutter for complex geology

InactiveCN104353827ALow failure rateDoes not affect toughnessTurbinesOther manufacturing equipments/toolsCarbideAlloy

The invention discloses a shield cutter for complex geology. The shield cutter comprises the following components in percentage by weight: 14.5 to 15 percent of Co powder with the purity of 99.9 percent, 0.1 to 0.5 percent of Re, 11 to 15 percent of WC (Wolfram Carbide) powder with the granularity of 3 to 5 microns, 20 to 22 percent of WC powder with the granularity of 8 to 13 microns, and the balance of WC powder with the granularity of 5 to 8 microns. The complex geological shield cutter has the advantages that a high-toughness and high-wear resistance alloy produced by mixing medium particle primary WC with large proportion, crude particles with medium proportion and relatively thin medium particle primary WC with small proportion can well adapt to ultra-complex geological conditions in China, the fail rate of the shield cutter is reduced, the shield efficiency is improved, the bending resistance is greater than 3,000N / mm<2>, and the hardness is HRA85.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

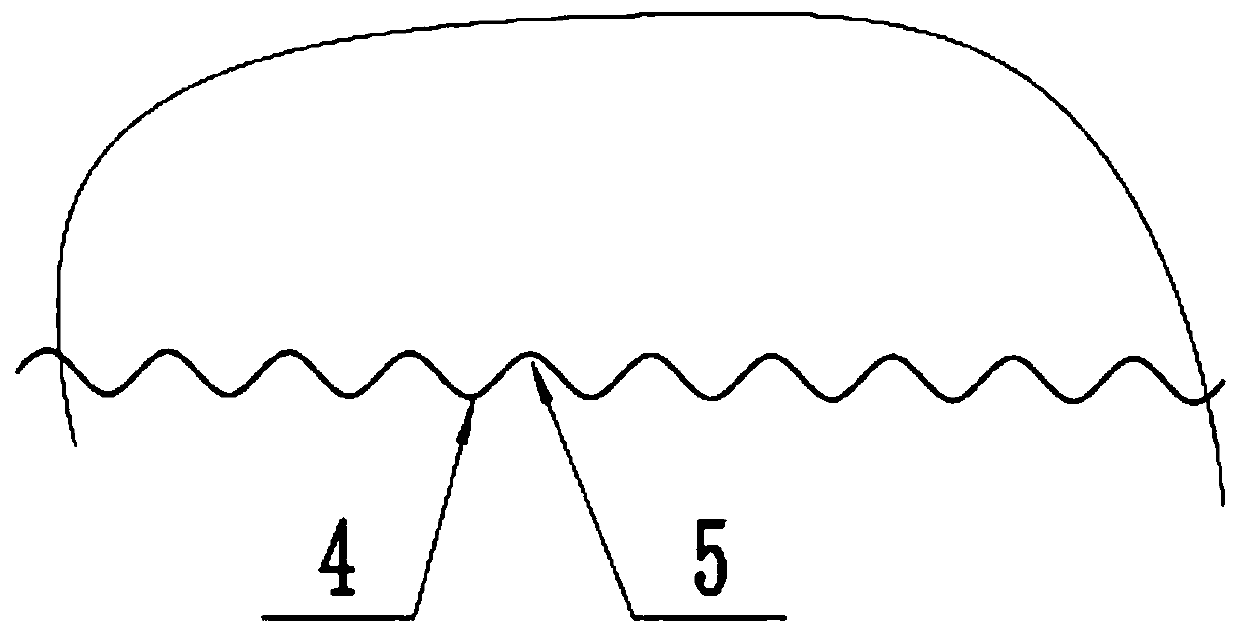

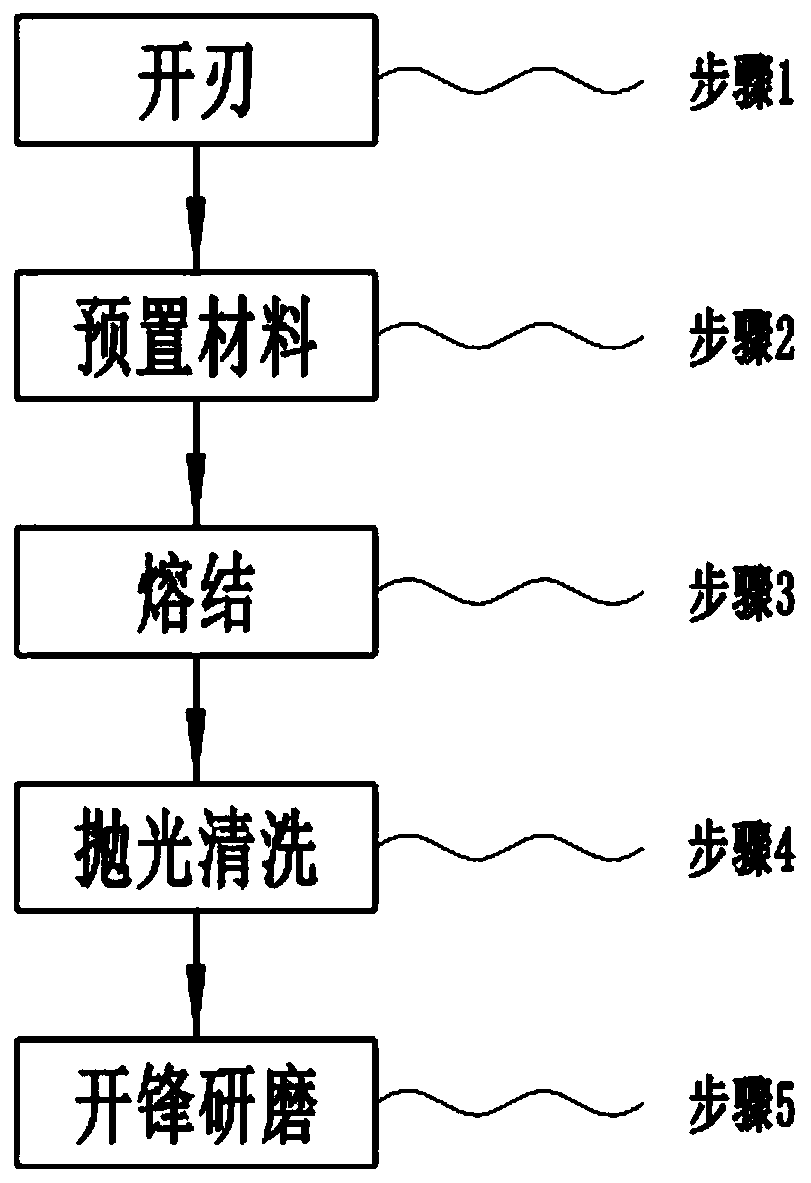

Cutting edge structure, manufacturing method of cutting edge and kitchen knife

InactiveCN111055308AImprove wear resistanceHigh hardnessMetallic material coating processesMetal working apparatusStructural engineeringHigh wear resistance

Relating to the technical field of cutters, the embodiment of the invention discloses a cutting edge structure, a manufacturing method of the cutting edge structure and a kitchen knife. The cutting edge structure comprises a cutter body and a composite material layer, the composite material layer is arranged on one side face of the cutter body, the composite material layer and the cutter body forman integral structure through three times of high-temperature sintering, the surface of the composite material layer is in an uneven concave-convex shape, and the thickness of the composite materiallayer is 20-30 micrometers. The cutting edge structure provided by the embodiment of the invention integrally has the advantages of high wear resistance, high cutting performance, high toughness and high hardness.

Owner:黄发强

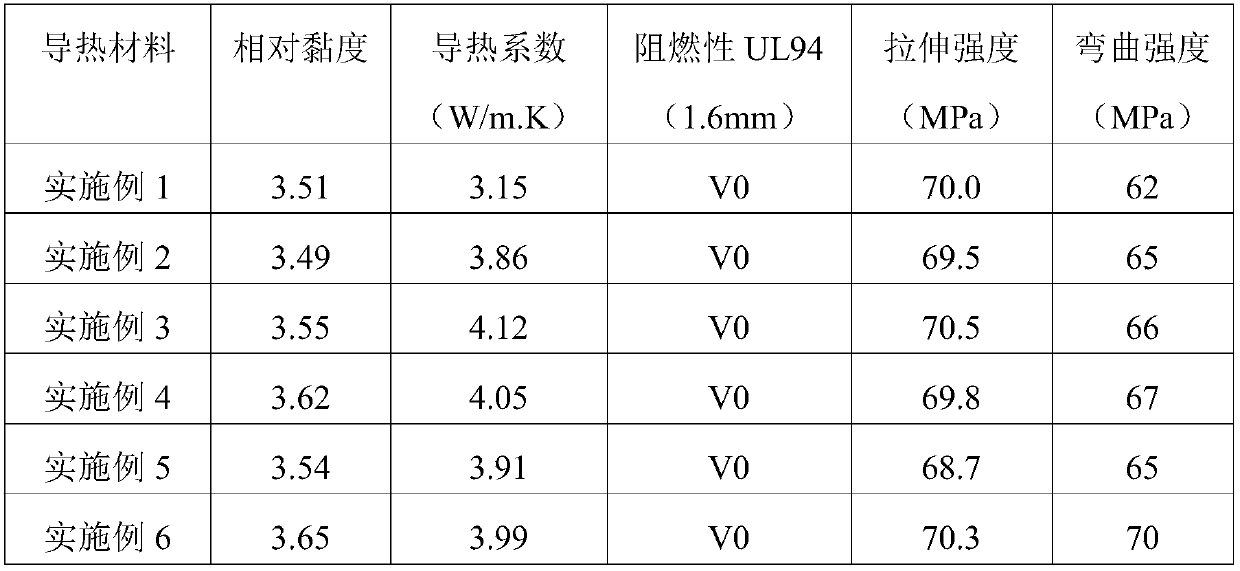

High-flowability nylon composite material and preparation method thereof

InactiveCN107722621AImprove liquidityLiquidity will not affectHeat-exchange elementsGlass fiberWear resistant

The invention discloses a high-flowability nylon composite material, which is prepared from nylon, a heat conduction wear-resistant filling material, a first flowability enhancing agent and a second flowability enhancing agent, wherein the first flowability enhancing agent is nanometer ultrafine talcum powder; the heat conduction wear-resistant filling material is prepared from aluminum hydroxide,nanometer particulate alpha-Al2O3 and magnesium hydroxide. The invention discloses a preparation method of the high-flowability nylon composite material. The method comprises the following steps of proportioning and mixing the nylon, the heat conduction wear-resisting filling material, the first flowability enhancing agent, the second flowability enhancing agent, a coupling agent, an antioxidantand a lubricating agent to obtain a mixed material; adding the mixed materials into a double-screw extruder for fusion plasticization; then, adding glass fiber into a mold head of the double-screw extruder for extrusion; performing cooling, palletization and drying to obtain the high-flowability nylon composite material. The high-flowability nylon composite material provided by the invention has good flowability; in addition, the mechanical strength is unchanged; the high heat conduction, flame-retardant and wear-resistant performance is realized; the preparation method is simple; the cost islow.

Owner:广州维邦新材料科技有限公司

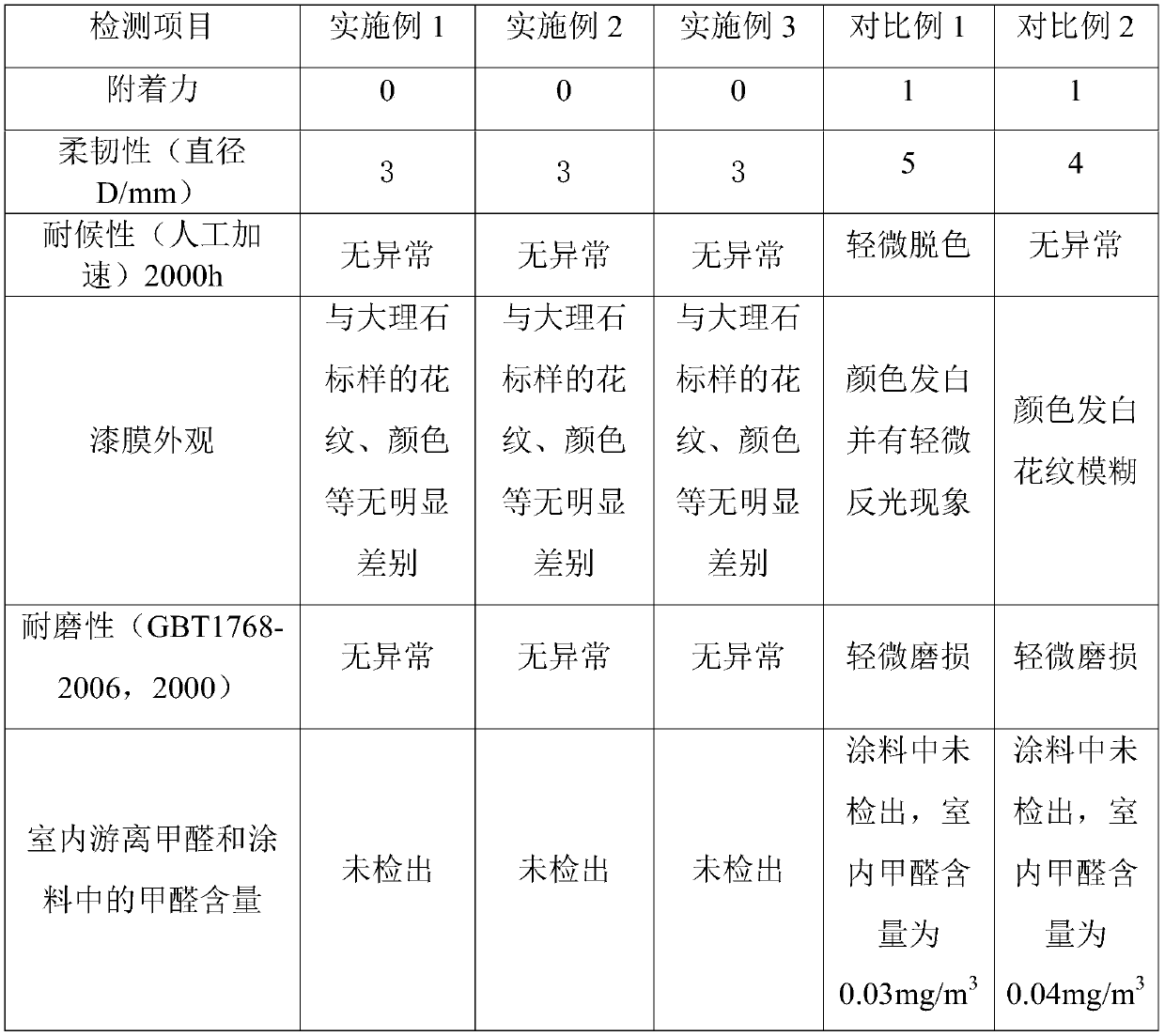

Sand-in-water coating and preparation method thereof

The invention relates to the technical field of coatings, and particularly discloses a sand-in-water coating and a preparation method thereof. The sand-in-water coating comprises, by weight, 20-30 parts of a protective glue, 50-60 parts of a toning base paint and 15-25 parts of a continuous phase. The sand-in-water coating has the advantages of strong adhesive force, high toughness, good wear resistance and good weather resistance, and a film formed by the coating can achieve the natural effect and beauty of marble textures.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

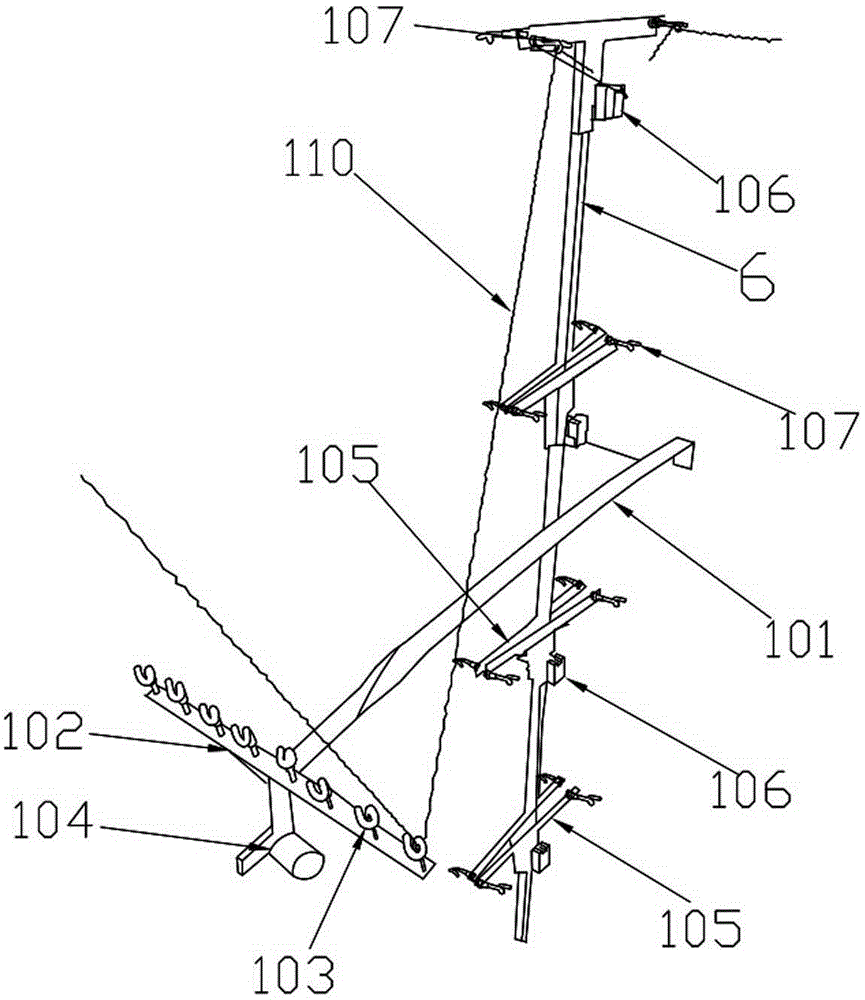

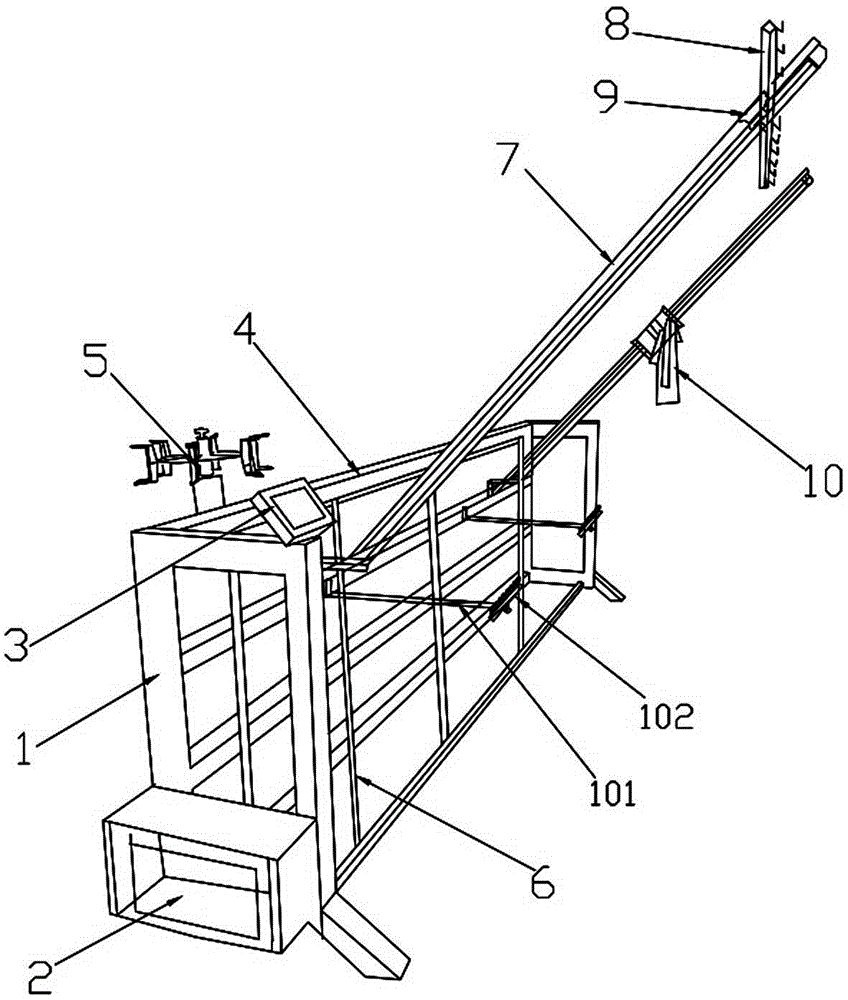

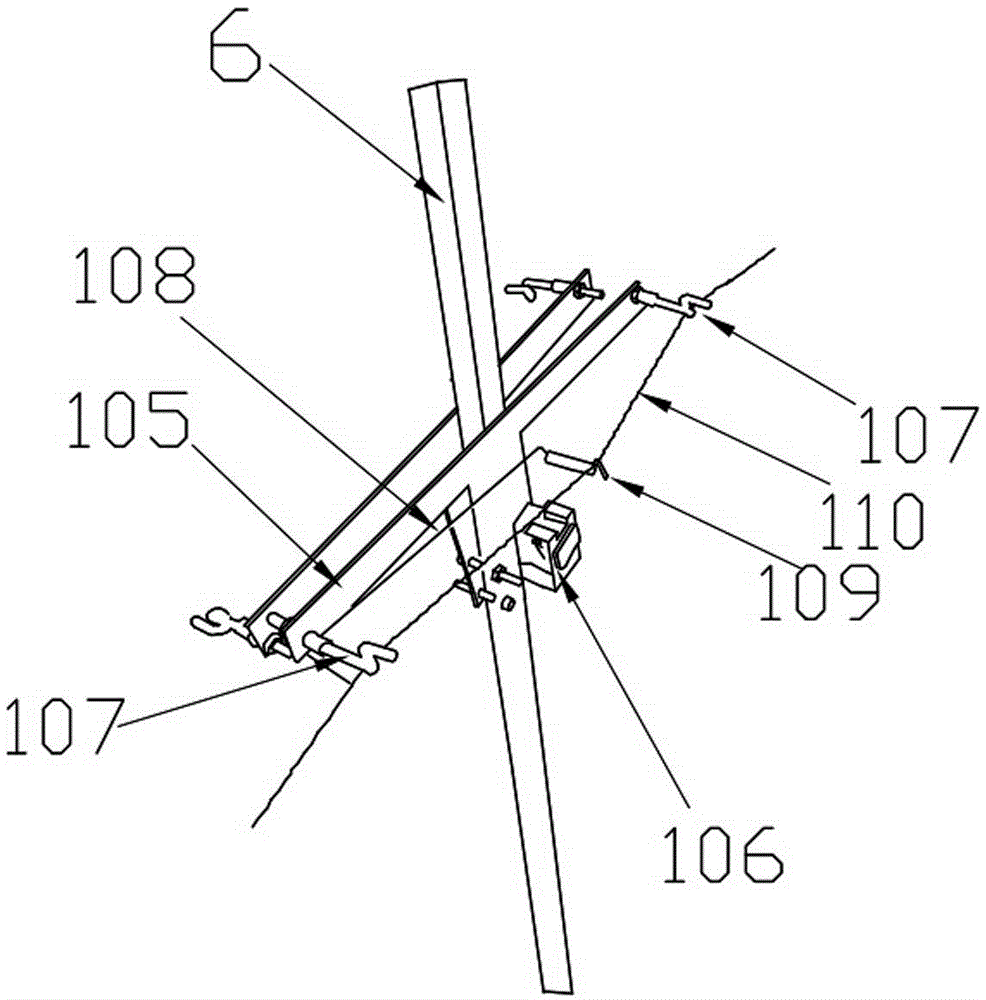

Semi-automatic sheet disassembling machine

ActiveCN105297274AGuaranteed sustainable workAvoid cable jamsTextile disintegration and recoveryFibre disintegrationYarnSemi automatic

The invention discloses a semi-automatic sheet disassembling machine in the field of wool weaving equipment. The semi-automatic sheet disassembling machine comprises a metal rack and thread winding devices arranged on the metal rack. The metal rack comprises two or more cross beams which are arranged in parallel, the thread winding devices are arranged on the cross beams, two or more thread winding devices are evenly arranged on each cross beam, and each thread winding device is used for winding a combined yarn. Each thread winding device is further connected with a control panel. Each control panel comprises a main control module, a signal input module and a signal output module. Hung sheet lifting devices, yarn shaking devices and thread distributing frames which are vertically mounted are arranged at the front end of the metal rack. Semi-automatic thread removing can be achieved by the entire machine, a plurality of sheets (wool weaving sheets) only need to be hung through manual work, the wool weaving sheets are hung on a sheet hanging rack, yarn shaking and thread winding can be conducted through the yarn shaking devices and the thread winding devices after sheet hanging is completed and then threads are connected, both the yarn shaking process and the thread winding process are automatic, and fatigue caused by long-time operation by operators is avoided; besides, the working efficiency is four times or more times of working efficiency of a traditional electric sheet disassembling machine.

Owner:曾勇军

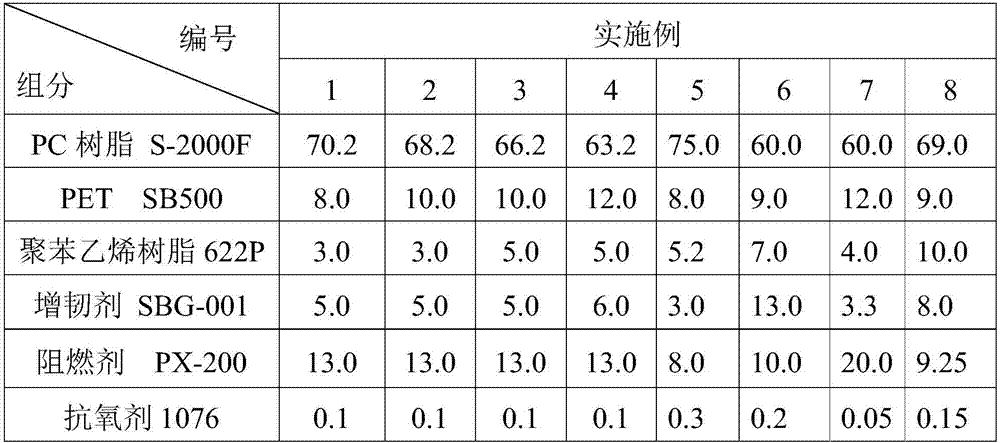

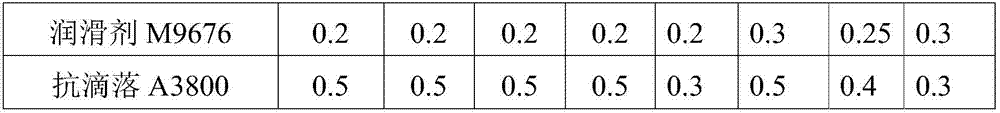

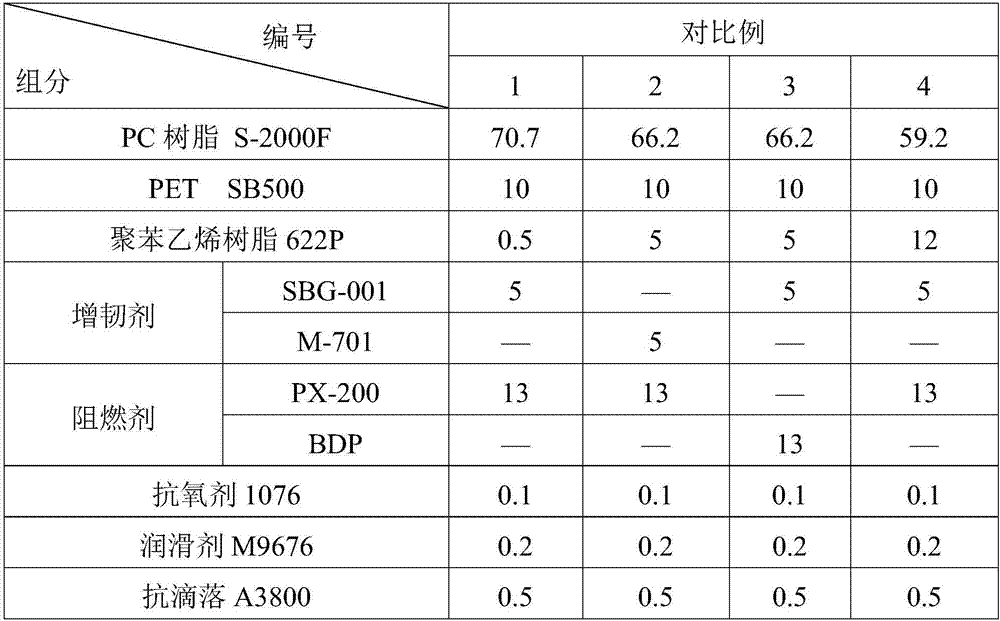

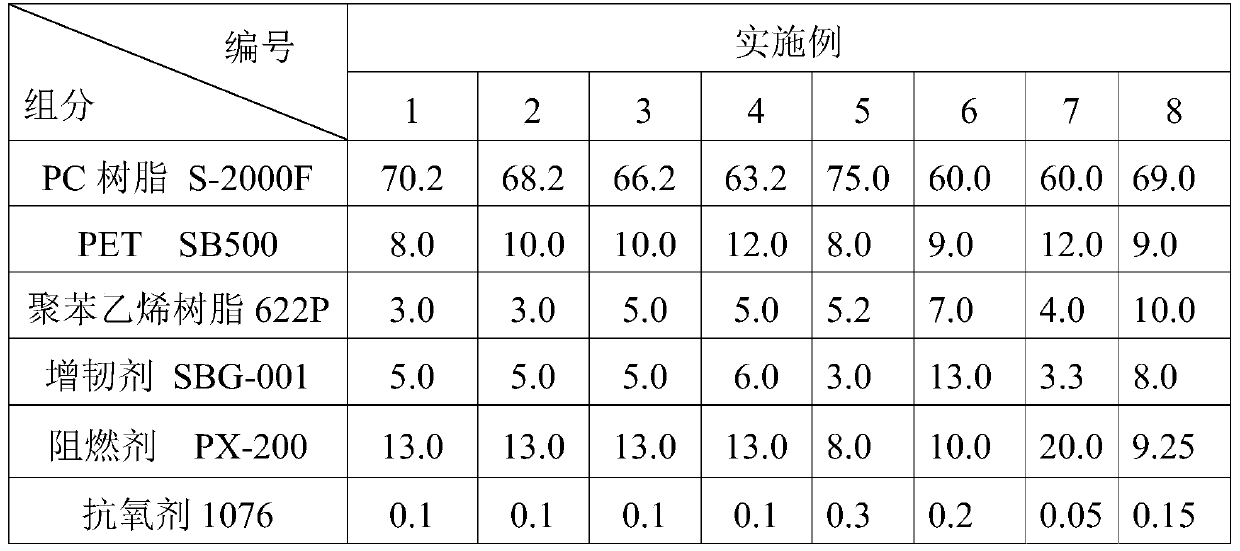

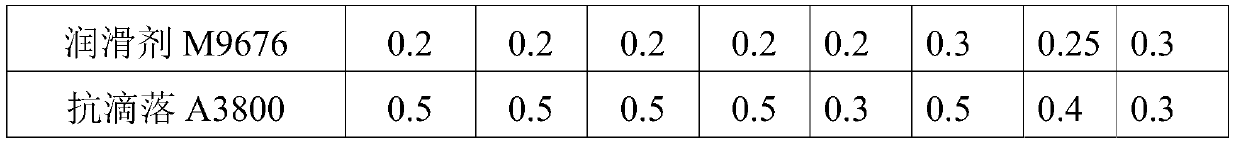

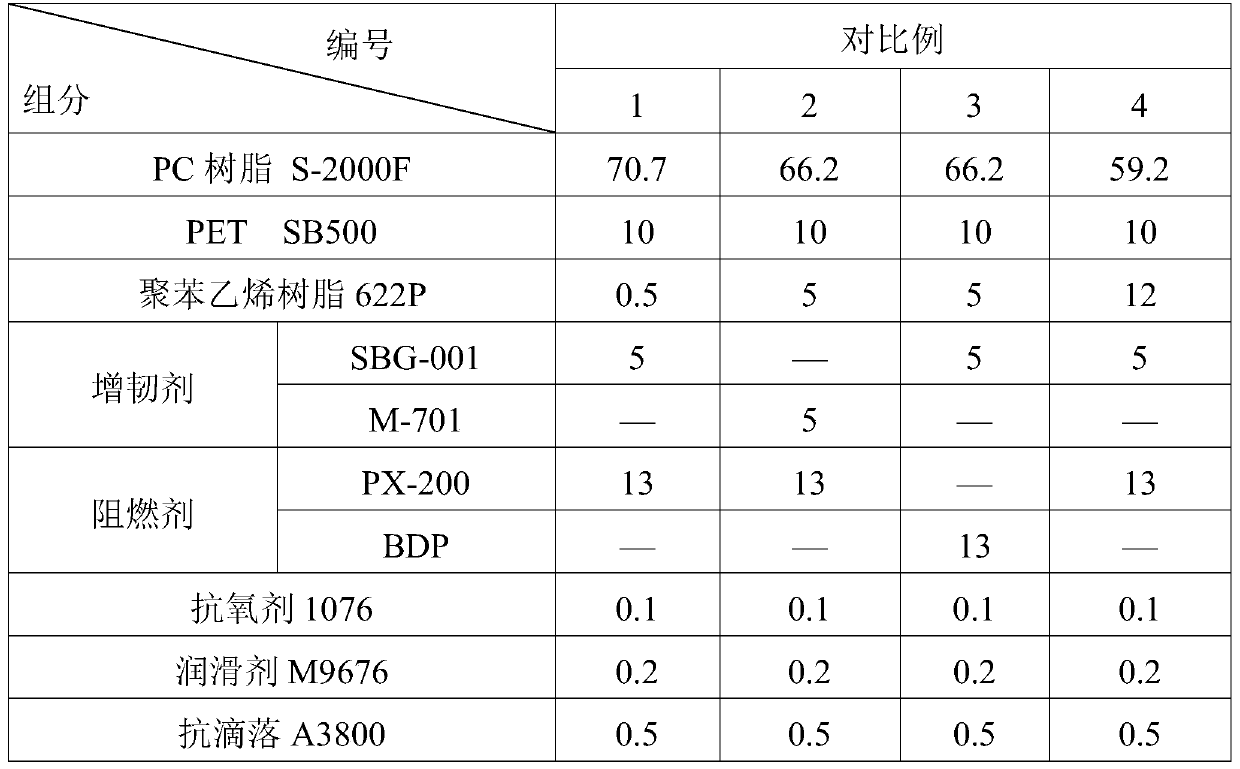

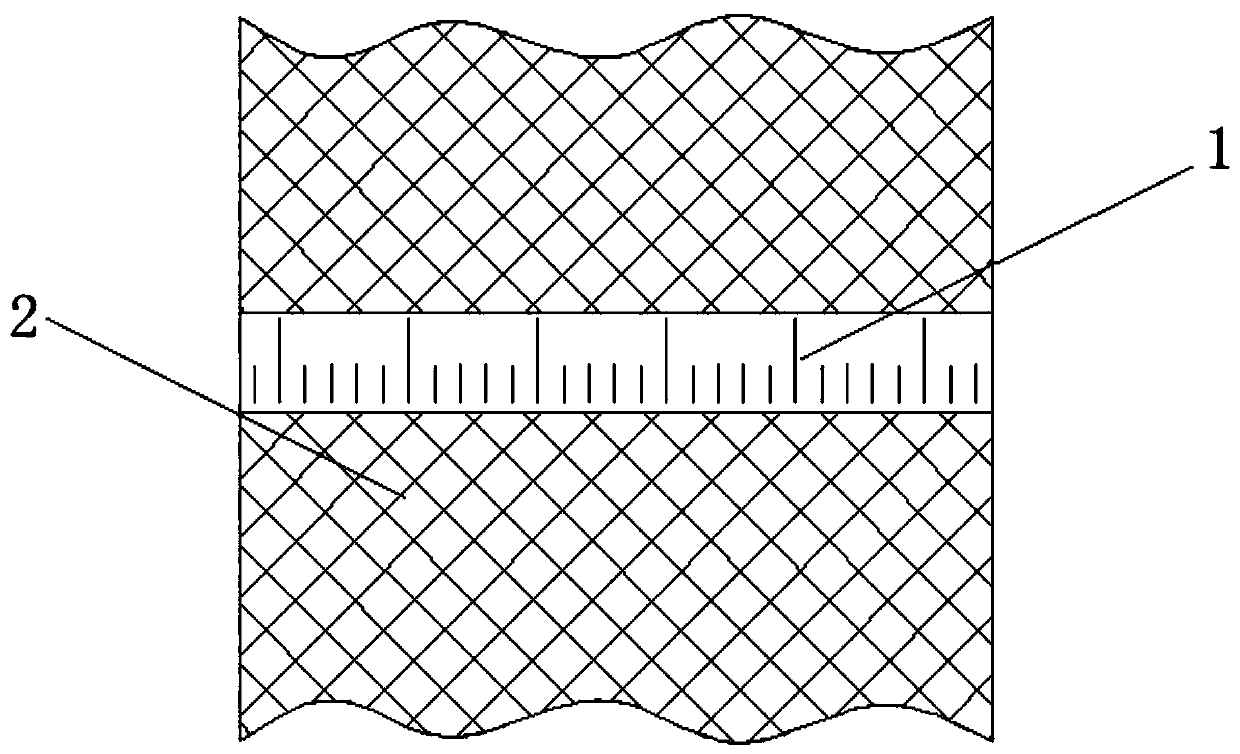

Halogen-free flame retardant PC/PET composite material with good appearance and preparation method thereof

The invention discloses a halogen-free flame retardant PC / PET composite material with a good appearance, which comprises 60-75 parts of PC resin, 8-12 parts of PET resin, 3-10 parts of polystyrene resin, 3.0-13.0 parts of a flexibilizer, 8-20 parts of a halogen-free flame retardant, 0.05-0.3 part of an antioxidant and 0.5-0.8 part of other additives, wherein the halogen-free flame retardant is a solid poly-condensed type halogen-free phosphate flame retardant. The PC / PET composite material prepared according to the preparation method disclosed by the invention selects high impact polystyrene, so that the liquidity of the composite material is greatly promoted, the appearance of the welded wire is improved while the toughness of the composite material is not influenced, the acquired composite material is higher in liquidity, fire resistance and mechanical property and the composite material is suitable for a thin-wall part and especially is suitable for the occasion with higher requirement for use environment.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

3D printing material with diamond light sensation and preparation method thereof

ActiveCN112300551AGuaranteed mirror effectNot easily oxidizedAdditive manufacturing apparatusIncreasing energy efficiencyPlastic materialsMirror plane

The invention discloses a 3D printing material with diamond light sensation and a preparation method of the 3D printing material. The 3D printing material comprises the following components in parts by mass: 75-99 parts of a plastic raw material, 10-20 parts of glass-coated silver powder, 2-10 parts of a toughening agent, 2-5 parts of a compatilizer and 0.1-2 parts of diffusion oil. According to the invention, the glass-coated silver powder is added into the components, the gloss of the silver powder is close to that of diamond and is not easy to oxidize, and meanwhile, the glass is used as abase material, so that distortion and shearing of the glass in the subsequent process can be avoided, and the complete mirror surface effect of the surface of the 3D printing material in the preparation process is ensured, meanwhile, the preparation process of the glass silver-coated powder is optimized, and the gloss and the mechanical property of the material are remarkably improved, so that theprepared 3D printing material suitable for FDM desktop level has diamond light sensation, is not easy to oxidize and blacken, and is excellent in mechanical property, smooth in printing process, freeof warping, free of fracture and free of wiredrawing.

Owner:深圳市华海天贸科技有限公司

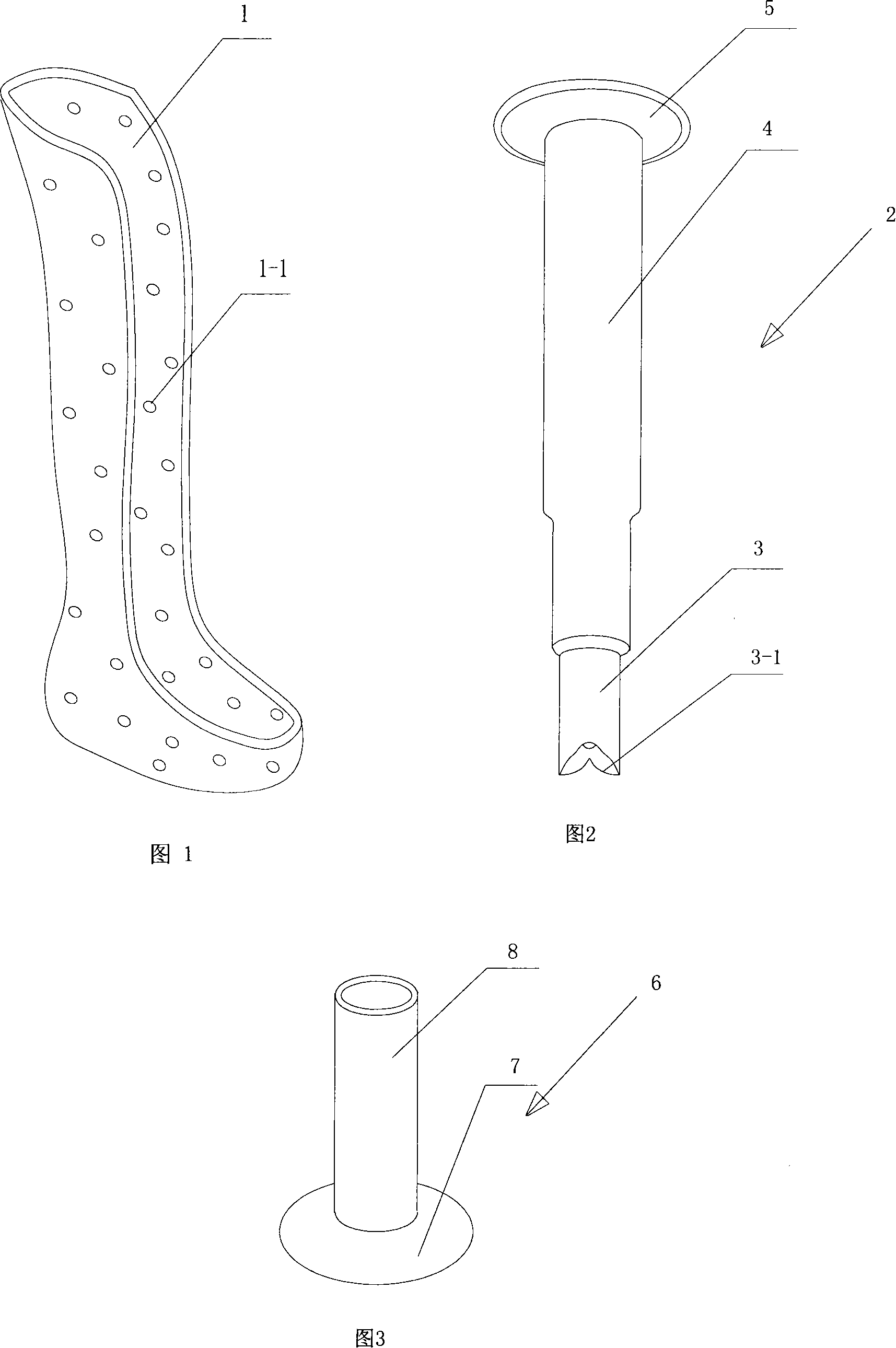

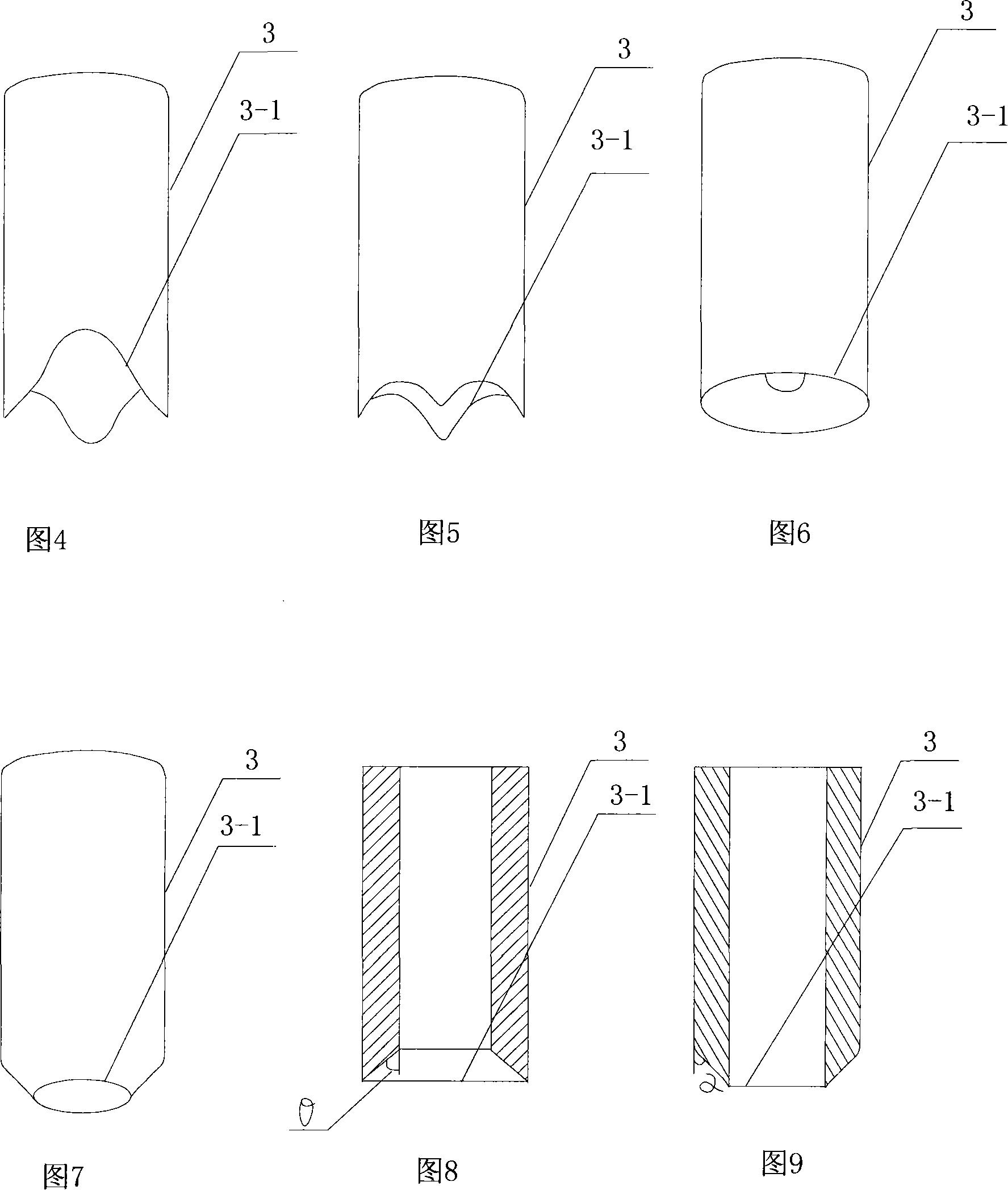

Ventilating type plaster bandage for medical purpose and perforator

InactiveCN101108152AEnsure ventilation and drynessEliminate or reduce humidityPlaster of paris bandagesPlaster CastsMechanical engineering

The invention relates to a permeable medical plaster cast and hole puncher. The permeable medical plaster comprises a plaster cast which has a plurality of breather holes. The specialized hole puncher is composed of a hole-punching peg and a hole-punching prick; wherein, the prick peg comprises a base and a pillar canal; the hole-punching prick is composed of a prick rod and a prick head. The prick head has blade mouth. The invention resolves the difficulty of imporosity of the existing medical gesso; the gesso hole-puncher can punching a plurality of hole freely on the premises of not impacting the fixing intensity, tenacity and fixing effect of the gesso without breaking off the gesso powder. The invention has the advantages of rational design, convenient operation, safety and reliability, scientific ness, beauty and durability.

Owner:孙进和

Threaded steel and preparation method thereof

The invention relates to the field of iron and steel smelting, and provides threaded steel and a preparation method thereof. The preparation method is used for improving the intensity of the threadedsteel. The preparation method of the threaded steel provided by the invention sequentially comprises the working procedures of electric furnace smelting, external refining, continuous casting, hot rolling, cooling, cutting and end flattening, wherein in the electric furnace smelting working procedure, cast iron, copper ingots and vanadium ingots are subjected to eutectic melting stirring; in the process from electric furnace smelting to external refining, silicon iron and ferromanganese iron alloy are added; ferro phosphorus is added into the working procedure of external refining; the cast iron accounts for 900 to 1000 mass parts; the copper ingots account for 2 to 4 mass parts; the vanadium ingots account for 0.4 to 0.8 mass parts; the silicon iron accounts for 2.5 to 5 mass parts; the ferromanganese iron alloy accounts for 35 to 45 mass parts; the ferro phosphorus accounts for 10 to 25 mass parts. C, Mn, V, Cu and Fe are compounded to be prepared into alloy; the intensity of the threaded streel can be effectively improved; meanwhile, the toughness of the threaded steel cannot be influenced.

Owner:广州广钢新材料股份有限公司

Cobalt-chromium alloy biological material and preparation method thereof

ActiveCN111996415AExtend surface preparation timeReduce processing efficiencyPharmaceutical delivery mechanismProsthesisManufactured materialBiological materials

The invention discloses a cobalt-chromium alloy biological material and a preparation method thereof. The cobalt-chromium alloy biological material comprises the following components according to theweight percent and the balance is Co. The preparation method of the material comprises the following steps that the raw materials are weighed in proportion, Co, Mo, Cr, Si, Fe, C and N are mixed and smelted, homogenizing is conducted, and then casting and molding are conducted according to biological requirements; and ZrO2 is sprayed on the surface of a cast and uncooled product, and then the cobalt-chromium alloy biological material is obtained through natural cooling. According to the scheme, the composition of the alloy material is improved, the mechanical property and biocompatibility of the material are effectively improved, the surface of the alloy material is modified through spraying, phase change is generated on the surface of the alloy material, the strength of the alloy surfaceis improved, meanwhile, the internal toughness of the alloy is maintained, the surface of the material is more resistant to abrasion, and then it is ensured that the material has long service life.

Owner:中怡(深圳)医疗科技集团有限公司

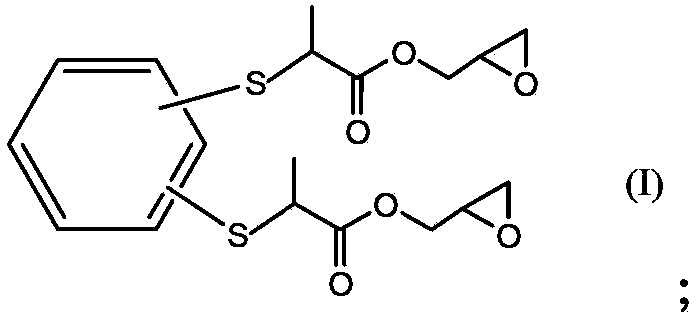

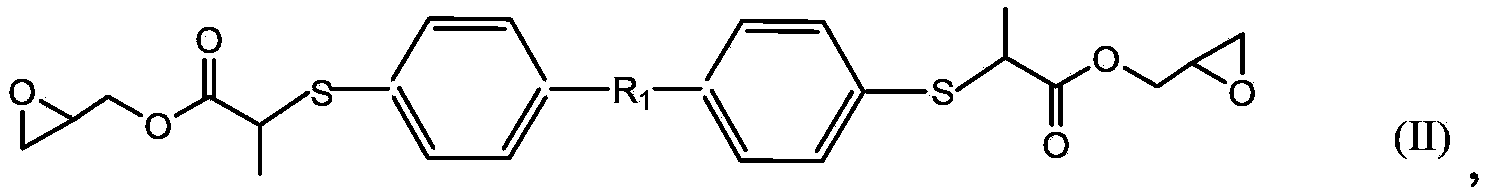

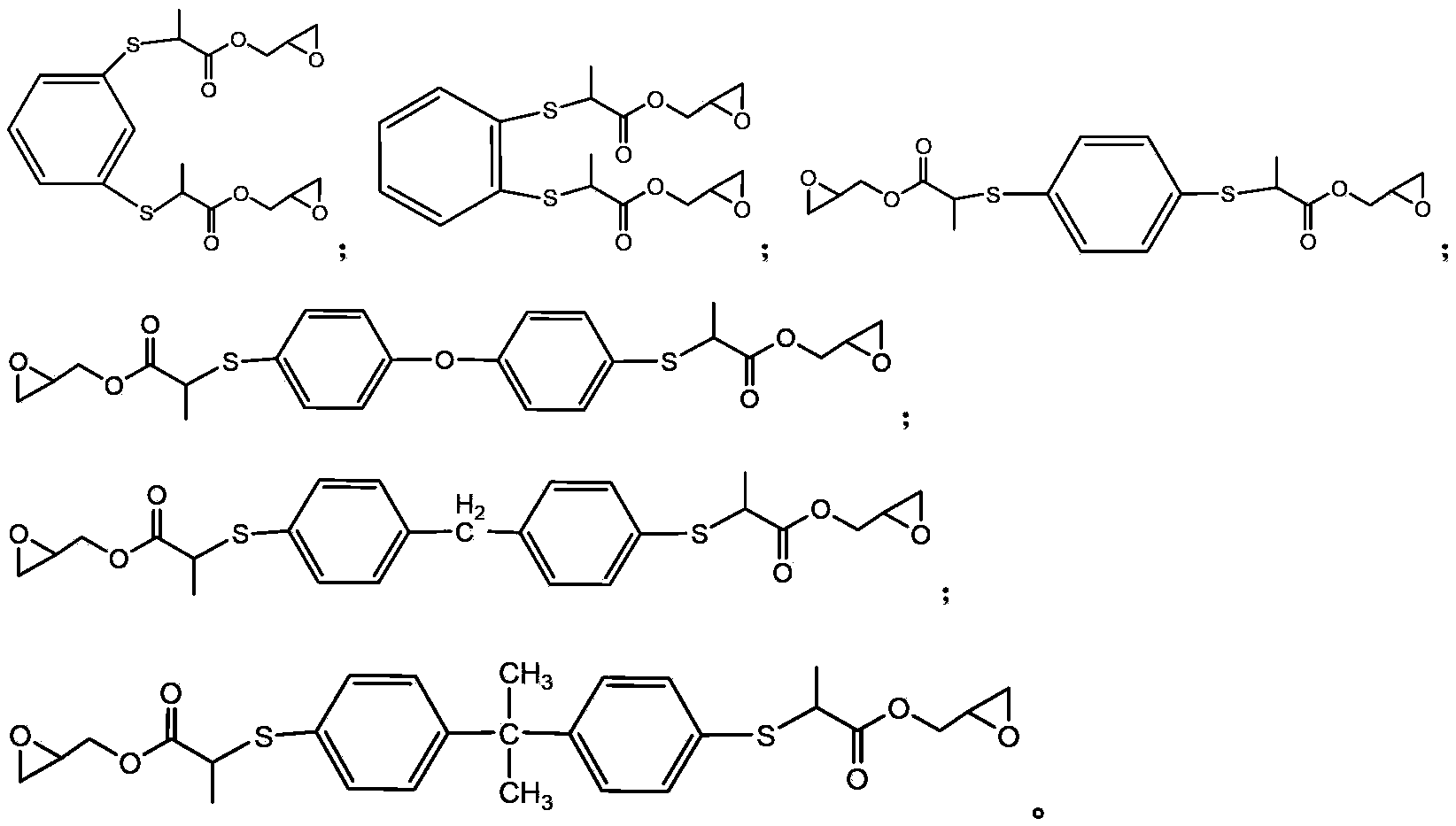

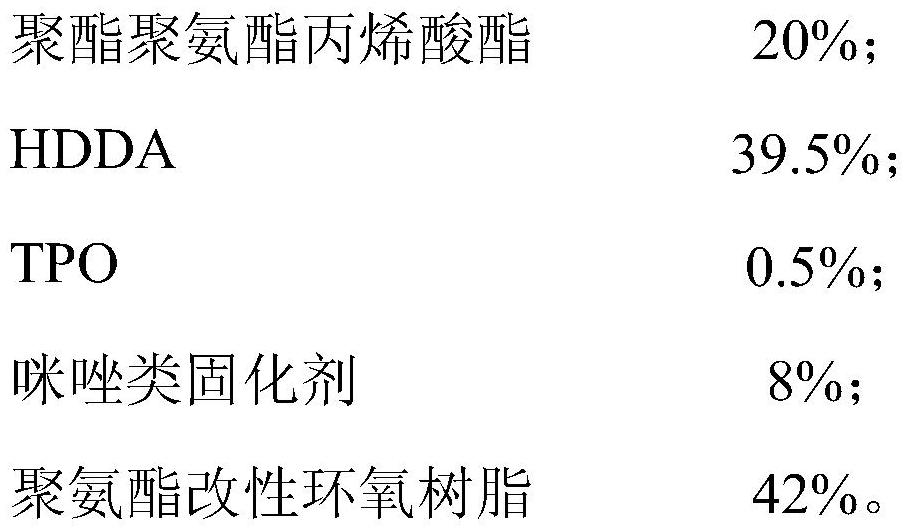

Sulfur-containing epoxide resin and preparation method thereof

ActiveCN103145646BLow viscosityGood storage stabilityOrganic chemistryEpoxy resin coatingsGlycidyl methacrylateSolvent free

The invention relates to a sulfur-containing epoxide resin and a preparation method thereof. The sulfur-containing epoxide resin is obtained by reacting a dithiol compound and glycidyl methacrylate in a stirring way at -5-20 DEG C for 4-10 hours. Compared with the traditional sulfur-containing epoxide resin, the sulfur-containing epoxide resin prepared through the method disclosed by the invention is lower in viscosity and higher in storage stability, can be applied to the fields of environment-friendly low-volatilization paint, low-volatilization resin, solvent-free epoxide resin insulating paint, and the like and can be directly applied without being added with an organic solvent or an active diluent; and compared with bisphenol A epoxide resin, the sulfur-containing epoxide resin disclosed by the invention is much lower in viscosity, shortened in gelation time by about 20% during solidification, enhanced in tensile strength and bend strength by about 10% and obviously increased in glass transition temperature and hardly influences the toughness. Besides, the preparation method disclosed by the invention has the advantages of simpleness, low pollution and low cost.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD +1

A kind of oil paint with lasting fragrance and preparation method thereof

The invention discloses an oil paint with long-lasting fragrance, which is made of the following components in mass percentage: 40-80% of pigment powder, 15-58% of linseed oil, 1-5% of essence, and 1% of fragrance-retaining agent ~5%. The oil paint with long-lasting fragrance provided by the invention has excellent oil painting effect and long-lasting and pleasant fragrance, and can provide good experience in addition to vision and smell when painting.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of photo-thermal dual curing 3D printing method and its product

ActiveCN110128773BImprove toughnessStrong application valueAdditive manufacturing apparatus3d printPolyester

Owner:HANGZHOU NORMAL UNIVERSITY

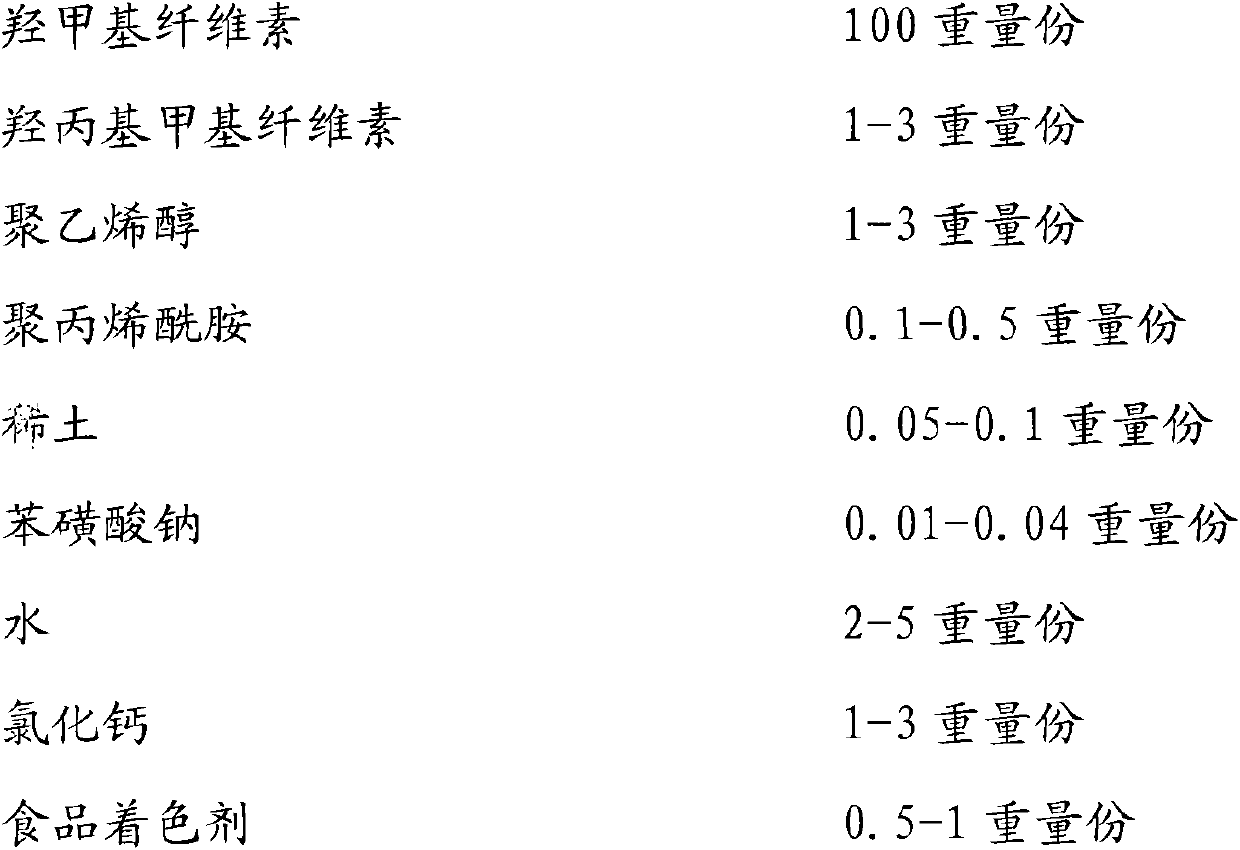

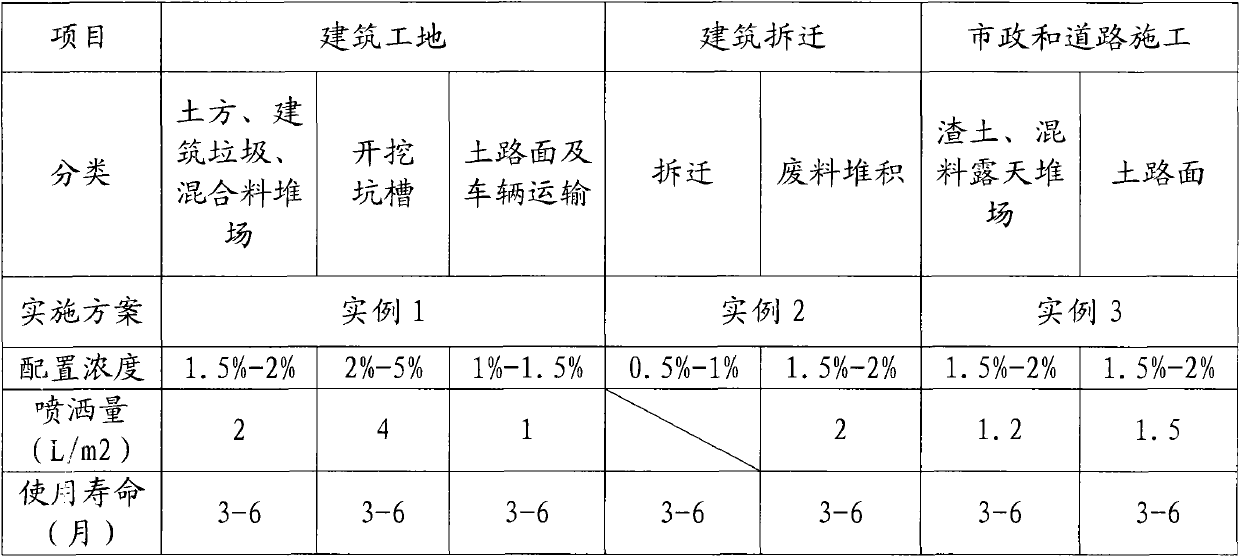

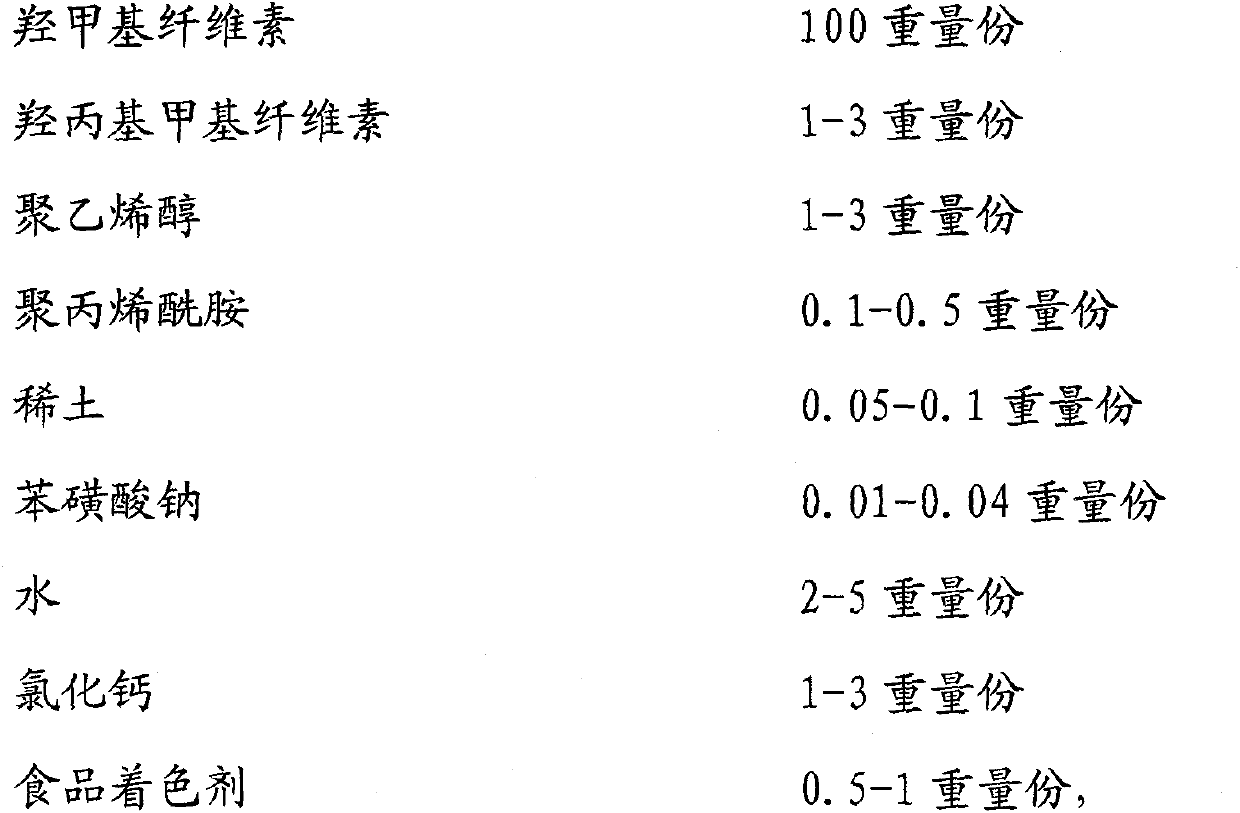

Dust suppressant for constructional engineering and preparation method thereof

The invention relates to a dust suppressant for constructional engineering and a preparation method thereof. The dust suppressant for constructional engineering consists of carboxymethyl cellulose, hydroxypropyl methyl cellulose, polyvinyl alcohol, polyacrylamide, rare earth, benzene sulfonic acid sodium salt, a food coloring agent and water. The dust suppressant for constructional engineering is mainly applied to construction site construction, building removing, municipal administration path construction and the like. The dust suppressant does not contain heavy metals and toxic and side effects, is low in cost and convenient to spray; the dust suppressant can improve soil quality, and regulate soil viscosity and water content; the dust suppressant is easily and biochemically degraded, does not harm the soil and vegetation and cannot cause secondary pollution.

Owner:BEIJING JINKE COMPOSITE MATERIAL

A kind of cobalt-chromium alloy biological material and preparation method thereof

ActiveCN111996415BExtend surface preparation timeReduce processing efficiencyPharmaceutical delivery mechanismProsthesisManufactured materialBiocompatibility

The invention discloses a cobalt-chromium alloy biological material and a preparation method thereof, which comprises the following components in terms of weight percentage: the balance is Co. The preparation method of the material is to weigh the raw materials in proportion, mix and smelt Co, Mo, Cr, Si, Fe, C, N, homogenize and cast according to biological requirements; spray ZrO on the surface of the cast and uncooled product. 2 , and then cooled naturally to obtain a cobalt-chromium alloy biomaterial; this scheme improves the composition of the alloy material, effectively improves the mechanical properties and biocompatibility of the material, and modifies the surface of the alloy material by spraying, causing a phase change on the surface to enhance The strength of the alloy surface while maintaining the toughness inside the alloy makes the surface of the material more wear-resistant, thereby ensuring its high service life.

Owner:中怡(深圳)医疗科技集团有限公司

Antiquing bamboo preparing method

InactiveCN108748519AWith artistic effectDoes not affect toughnessGrinding machine componentsWood treatment detailsPermeationDye molecule

The invention belongs to the technical field of bamboo old making, and particularly relates to an antiquing bamboo preparing method. Ten days ago before bamboo cutting, a sunshade net with the sunshade rate being 75%-85% is arranged above the bamboo, brush application of an infection bacteria solution is conducted on the surface of the bamboo at random, cutting is conducted, and the original bamboo is polished after being sterilized and cleaned; two-time coloring is sequentially conducted on the surface of the bamboo after polishing, color wiping and color homogenizing treatment is conducted after completion, and after completion, the antiquing bamboo is obtained through drying; and the infection bacteria solution is a stereostratum cor-ticioides infection bacteria solution. Compared withthe prior art, the antiquing bamboo preparing method has the following beneficial effects that the stereostratum cor-ticioides infection bacteria solution is used for treating the to-be-cut bamboo under the shading condition, irregular damage can be formed on the surface of the bamboo while the tenacity of the bamboo cannot be influenced, meanwhile, the defect that dye molecules are not prone to permeation can be overcome, the bamboo old making antiquing effect is natural and attractive in cooperation with two-time coloring and later treatment, and the color fixing effect is good; and the artistic effect is achieved, and usage and popularization can be achieved.

Owner:FUNAN NATURE ARTS & CRAFTS

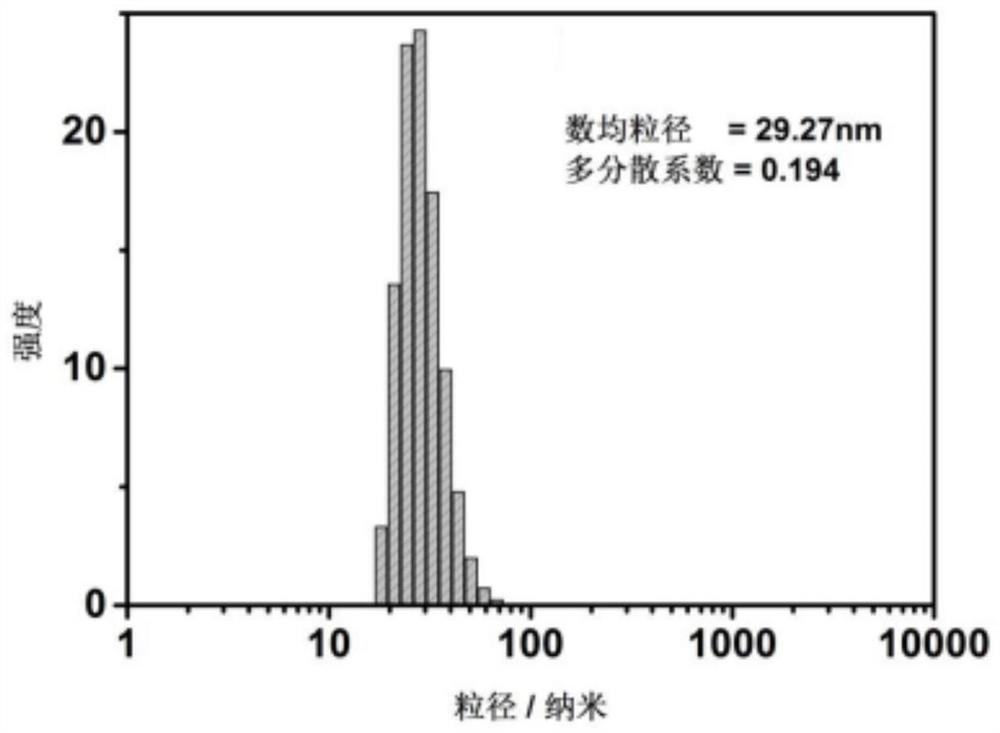

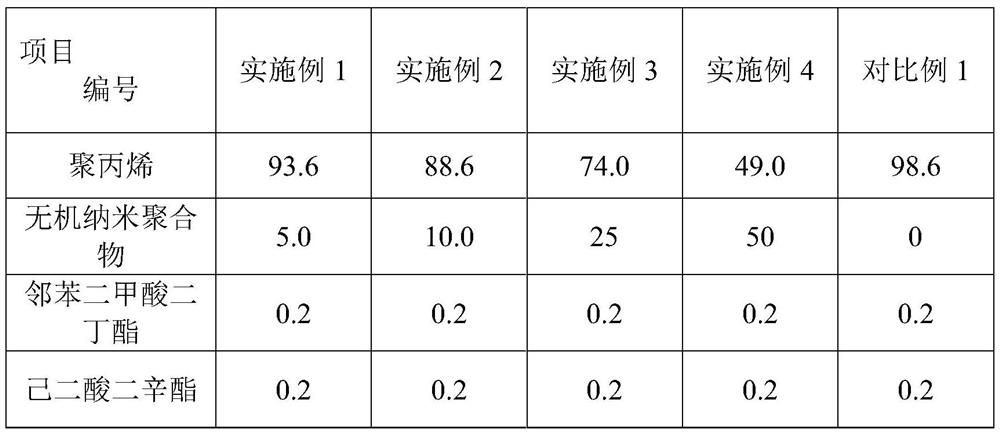

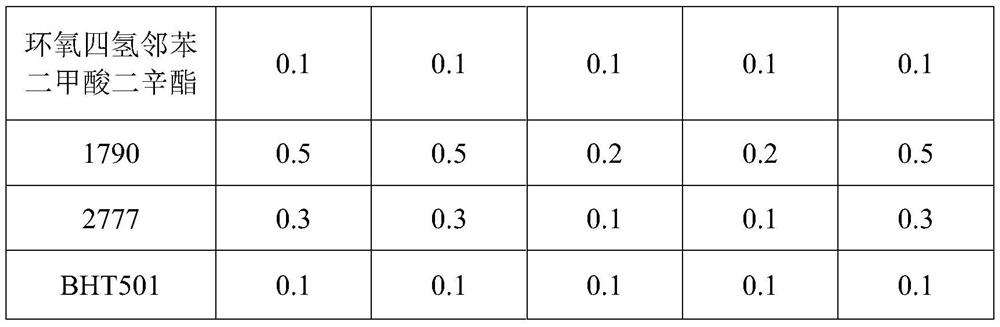

Inorganic nano polymer modified high-strength plastic and preparation method thereof

PendingCN111825918AIncrease forceProne to agglomerationMaterial nanotechnologyPolymer sciencePolymer modified

The invention provides an inorganic nano polymer modified high-strength plastic and a preparation method thereof. The inorganic nano polymer modified high-strength plastic comprises the following components by mass: 50-100 parts of a polymer matrix material, 0-50 parts of an inorganic nano polymer, 0.1-0.5 part of a plasticizer and 0.1-2 parts of an antioxidant; the inorganic nano polymer comprises the following components by mass: 20%-70% of nano silica sol, 10%-70% of alkoxysilane, 0.01%-5% of an acid catalyst, 0.1%-10% of an anion modifier, 0.05%-0.2% of a polymerization inhibitor and 2%-20% of a water-soluble solvent, the preparation process comprises the following steps of: melting the polymer matrix material, the inorganic nano polymer, the plasticizer and the oxidant at high temperature, then performing blending, extruding and granulating to obtain the inorganic nano polymer modified high-strength plastic. The mechanical property and wear resistance of the high-strength plasticprepared by the method are remarkably improved, the surface of the inorganic nano polymer contains active groups and has excellent compatibility with the polymer matrix material, and the prepared composite material has no particle migration or agglomeration phenomena and no stress defect in the long-term use process.

Owner:湖南翰墨新材料有限公司

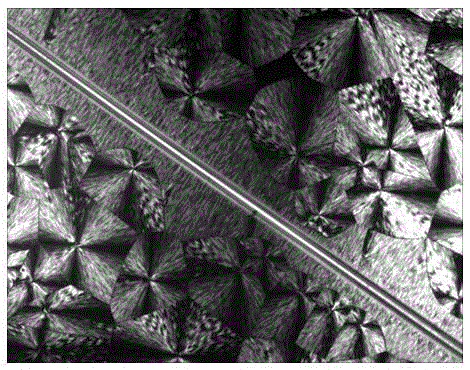

Levorotatory polylactic acid traversing column crystals and preparation method therefor

The invention relates to levorotatory polylactic acid traversing column crystals. The levorotatory polylactic acid traversing column crystals comprise the following ingredients: 85-95% of levorotatory polylactic acid and 5-15% of levorotatory polylactic acid fibers. The preparation method comprises the following steps: firstly, levorotatory polylactic acid fibers are subjected to vacuum drying for 5-8h at a temperature of 130-150 DEG C, and levorotatory polylactic acid is subjected to vacuum drying for3-7h at a temperature of 130-150 DEG C; secondly, the polylactic acid processed in the first step is heated to 180-200 DEG C, and the state is kept for 10min; thirdly, the polylactic acid fibers processed in the first step are introduced to the polylactic acid body with an initial concentration of 0.01-0.02g / ml processed in the second step at a temperature of 130-150 DEG C; fourthly, the products in the third steps are annealed to 110-130 DEG C rapidly, the state is kept for 30-180min, and thus the products are crystallized fully; fifthly, the products after full crystallization in the fourth step are taken out and cooled to the room temperature. The preparation method is simple and easily available, the cost is low, industrial production is hopeful, and the levorotatory polylactic acid traversing column crystals have great potential economic benefits.

Owner:SHAANXI UNIV OF SCI & TECH

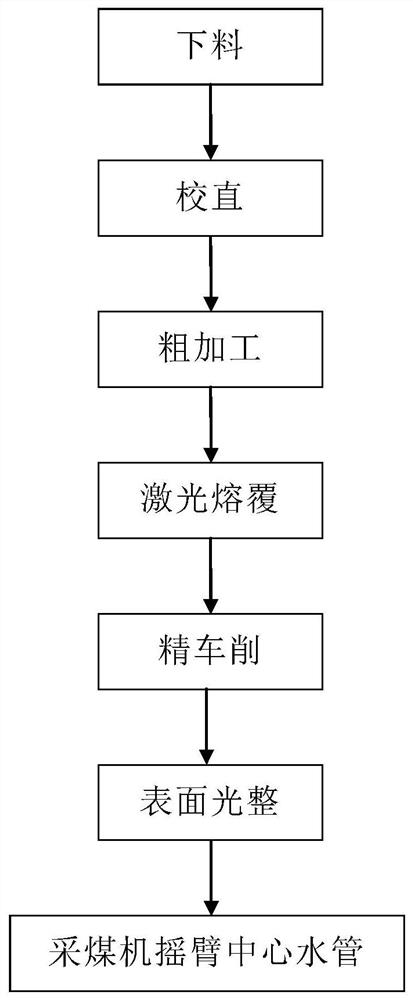

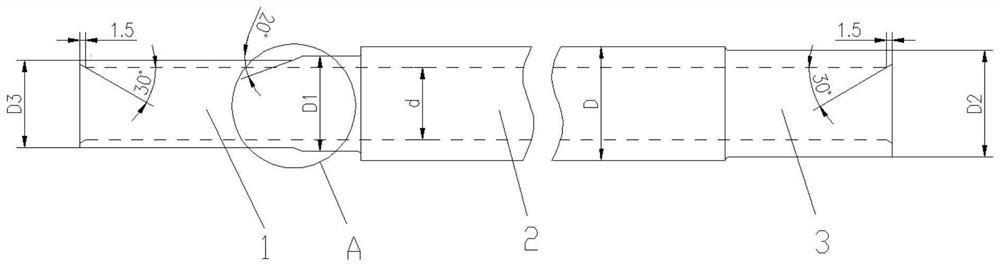

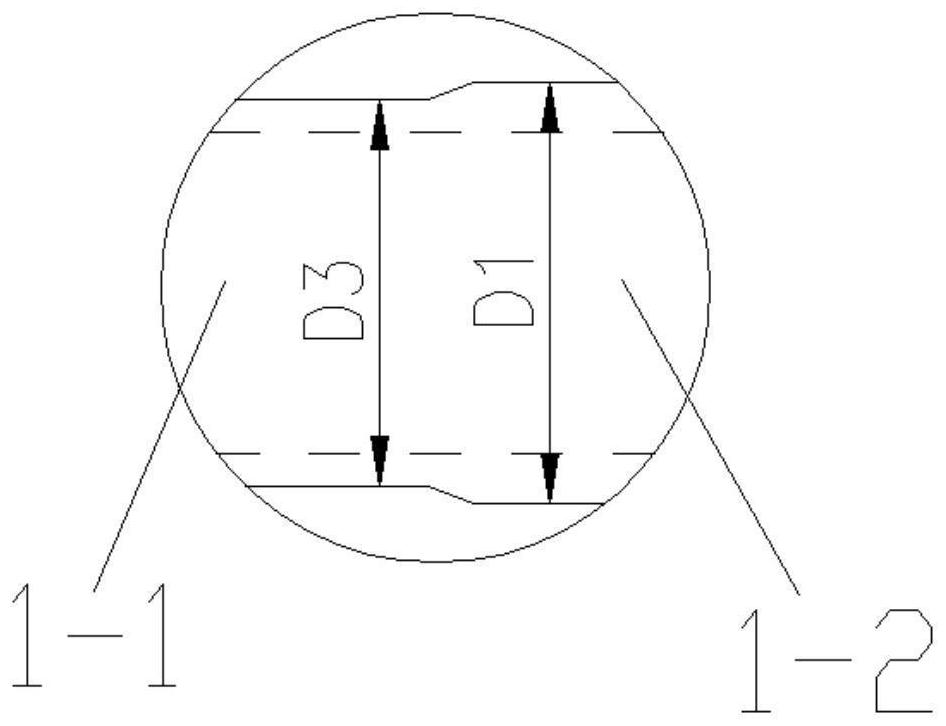

A manufacturing process of a wear-resistant and corrosion-resistant central water pipe for the rocker arm of a coal mining machine

ActiveCN113199213BDoes not affect normal useImprove wear resistanceMetallic material coating processesRelative motionChrome plating

The invention discloses a manufacturing process for a wear-resistant and corrosion-resistant central water pipe of a rocker arm of a coal shearer, comprising the following steps: 1. blanking; 2. straightening; 3. rough machining; 4. laser cladding; ; Sixth, the surface is smooth, and the central water pipe of the rocker arm of the coal mining machine is obtained. In the present invention, a laser cladding section and a non-laser cladding section are processed on the dynamic sealing section, and a laser cladding layer is prepared by laser cladding on the laser cladding section. While reducing the laser cladding area, it does not It affects the use of the central water pipe. By controlling the parameters of laser cladding, the efficiency of laser cladding is improved, the surface of the cladding layer is smooth, the precision control is high, and the cladding layer is full. Laser cladding replaces the traditional chrome plating process. , improves the wear resistance and corrosion resistance of the dynamic sealing section, ensures that the dynamic sealing section can also play an excellent sealing role during relative movement, has a higher sealing effect, and can still seal stably when the central water pipe moves.

Owner:XIAN COAL MINING MACHINERY

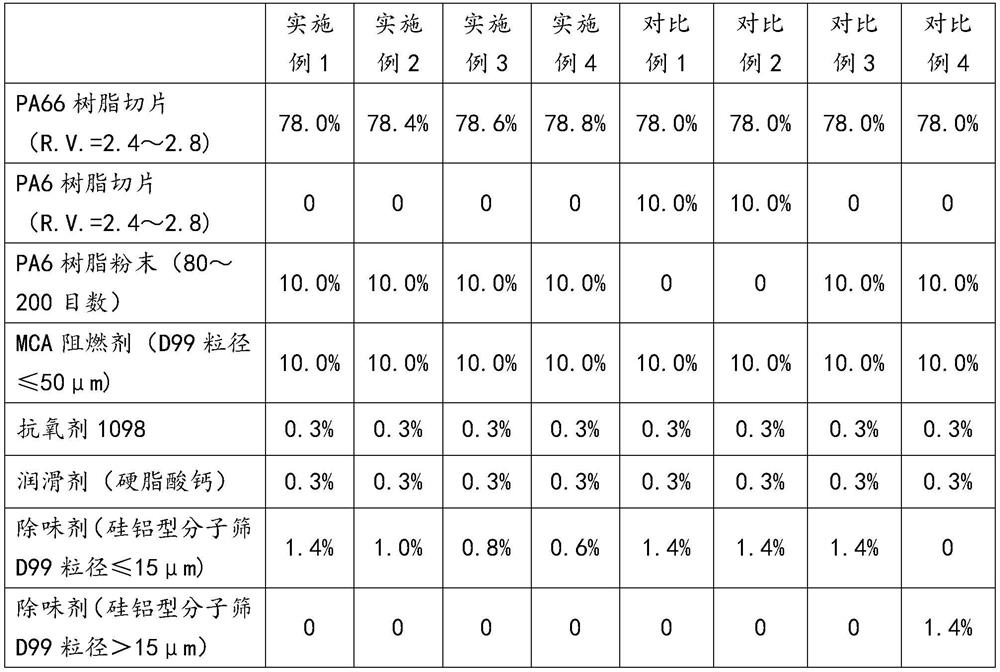

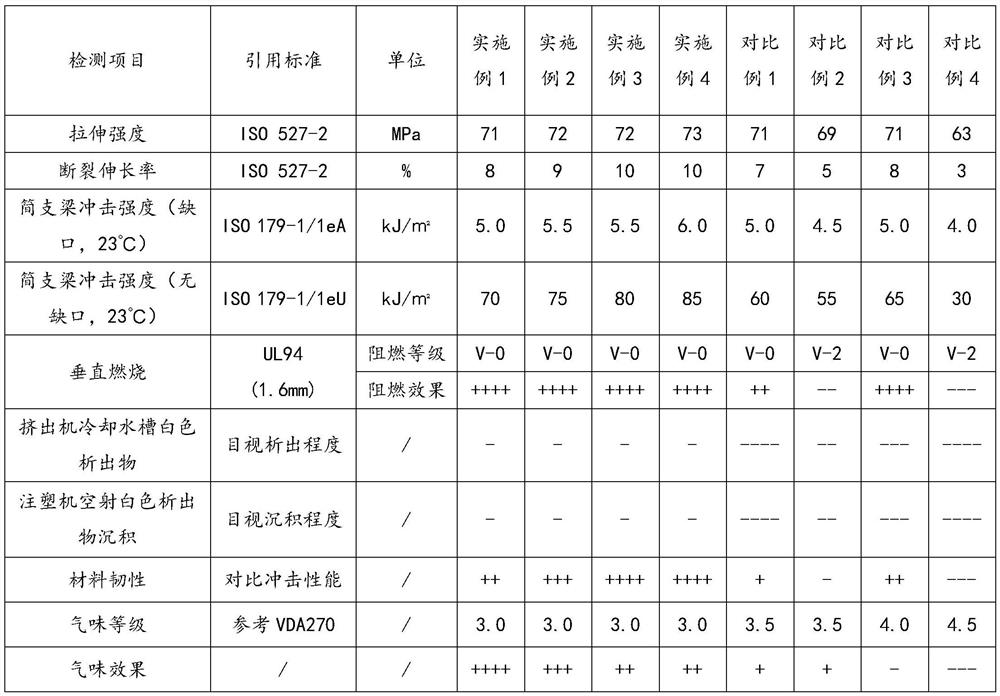

A low-odor and low-precipitation flame-retardant polyamide material, its preparation method and application

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Processing technology of epoxy glass fiber board

PendingCN114410068AImprove interface compatibilityIncreased interlaminar fracture strengthSynthetic resin layered productsGlass/slag layered productsGlass fiberPolymer science

The invention discloses a processing technology of an epoxy glass fiber board. The epoxy glass fiber board has the beneficial effects that epoxy resin formed by mixing petroleum-based epoxy resin and bio-based epoxy resin is used, and the curing capacity of the two resins at different curing temperatures is utilized, so that cohesion is generated between semi-curing and post-curing, a uniform cross-linked network is formed, and the tensile strength and interlayer fracture toughness of the epoxy glass fiber board are improved; the elongation at break and the tensile strength of the epoxy glass fiber board are improved by using the olive powder; diaminobenzene carborane and 5-chloro-m-phenylenediamine are mixed to form a curing agent; diaminobenzene carborane is used for optimizing the influence of complementary bio-based epoxy resin on the high-temperature adhesive; boron oxide formed by thermal oxidation degradation of nitrogen borane and silica sol are used for synergistically enhancing the flame retardance of the epoxy glass fiber board; 5-chloro-m-phenylenediamine has high thermal conductivity, and 5-chloro-m-phenylenediamine and silica sol cooperate to enhance the thermal conductivity of the epoxy glass fiber board and improve the heat dissipation performance.

Owner:广东纵胜新材料股份有限公司

Good appearance halogen-free flame retardant pc/pet composite material and preparation method thereof

The invention discloses a halogen-free flame retardant PC / PET composite material with a good appearance, which comprises 60-75 parts of PC resin, 8-12 parts of PET resin, 3-10 parts of polystyrene resin, 3.0-13.0 parts of a flexibilizer, 8-20 parts of a halogen-free flame retardant, 0.05-0.3 part of an antioxidant and 0.5-0.8 part of other additives, wherein the halogen-free flame retardant is a solid poly-condensed type halogen-free phosphate flame retardant. The PC / PET composite material prepared according to the preparation method disclosed by the invention selects high impact polystyrene, so that the liquidity of the composite material is greatly promoted, the appearance of the welded wire is improved while the toughness of the composite material is not influenced, the acquired composite material is higher in liquidity, fire resistance and mechanical property and the composite material is suitable for a thin-wall part and especially is suitable for the occasion with higher requirement for use environment.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

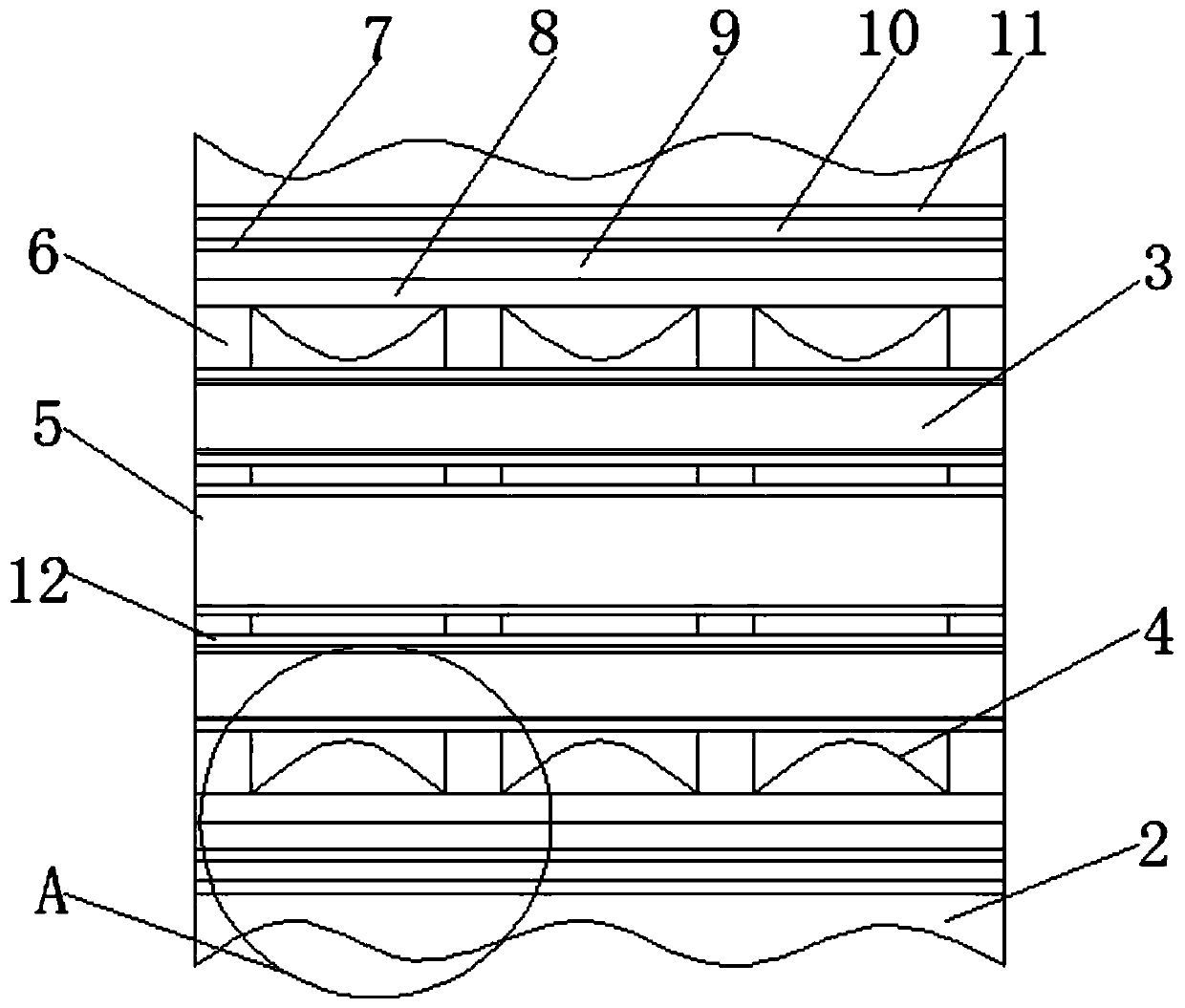

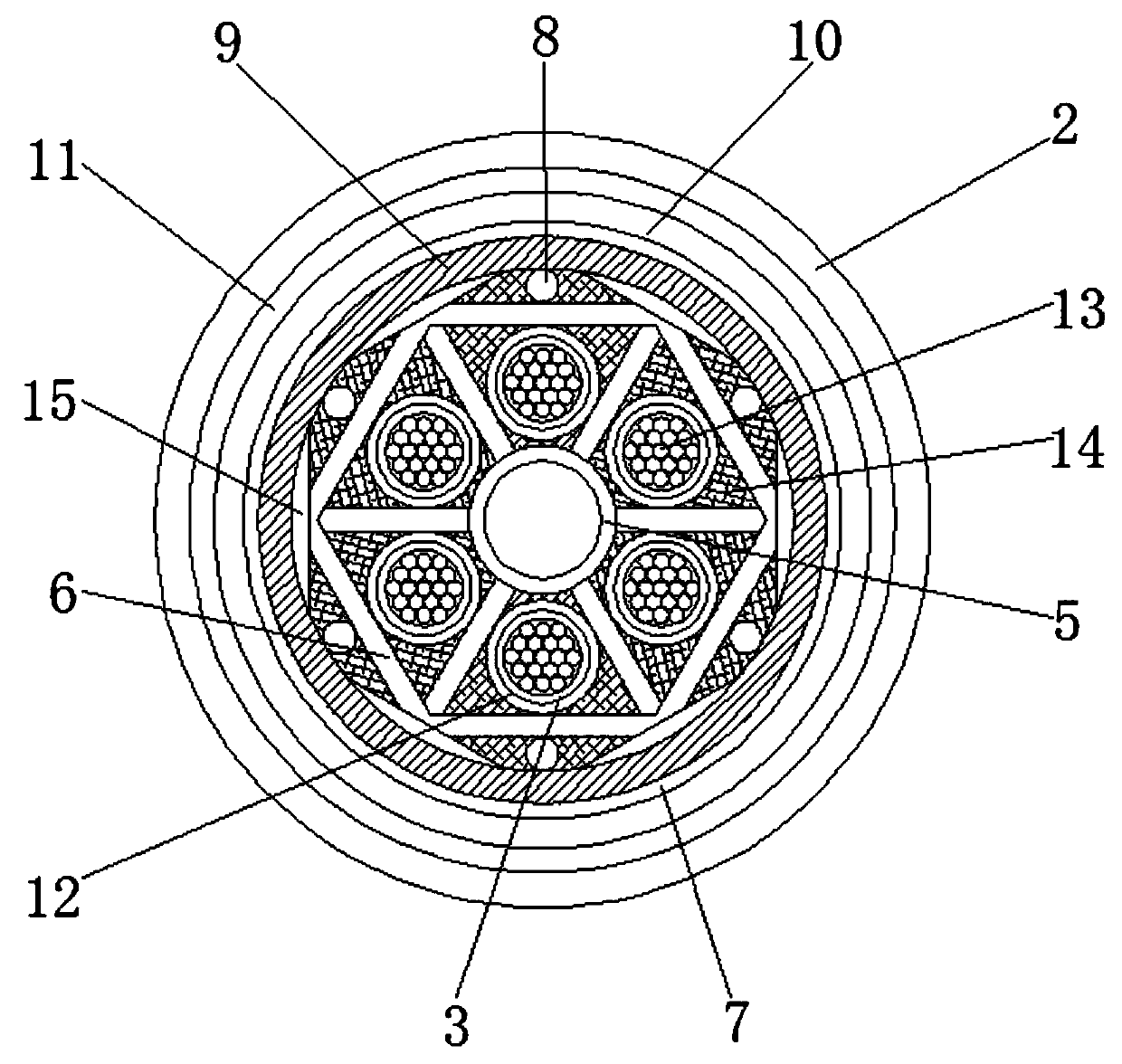

High-flexibility bending-resistant robot cable

InactiveCN110335706AProtection securityAvoid breakingFlexible cablesFlexible conductorsMetal stripsInsulation layer

The invention discloses a high-flexibility bending-resistant robot cable, which comprises a length scale line, a metal armor layer and an insulation layer. The inner side of a flame retardant layer isprovided with an elastic telescoping layer. The inner side of the elastic telescoping layer is uniformly equipped with a hexagonal frame. The inner corners of the hexagonal frame are uniformly equipped with connecting rods; and the ends, away from the hexagonal frame, of the connecting rods are equipped with a hollow pipe. An insulating layer is arranged between the adjacent connecting rods. Theinner portion of the insulating layer is provided with a cable core. The cable is provided with the elastic telescoping layer and the hexagonal frame, and through the elastic telescoping layer and thehexagonal frame, the cable can bend to each direction like a bendable straw, and is not easy to break; during the operation of a robot, the toughness of the cable is not affected by continuous bending and straightening; and the cable is internally provided with a memory metal strip, and after long-time bending and winding of the cable, the cable can restore to the original state freely.

Owner:大电机器人电缆(昆山)有限公司

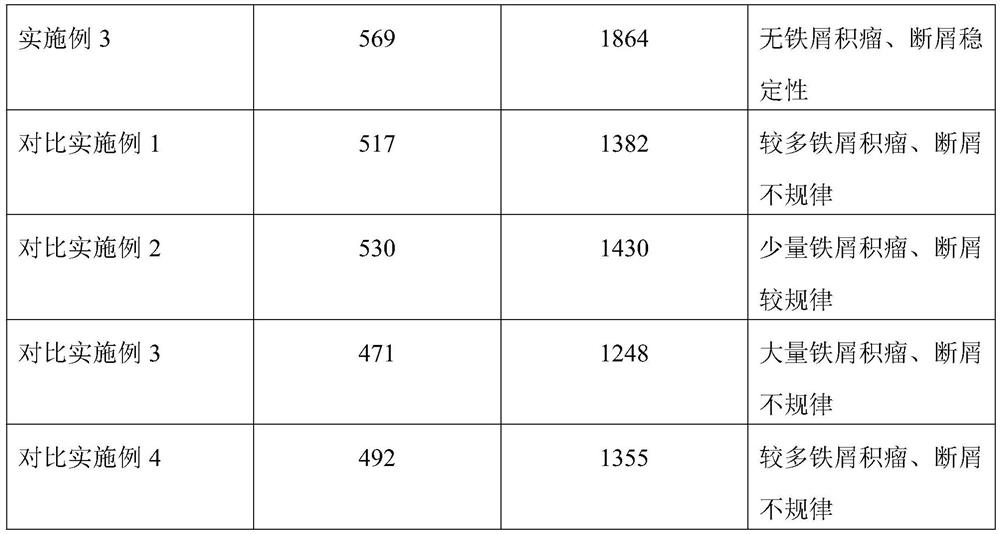

Smelting process of low-carbon high-sulfur free-cutting steel

InactiveCN112962017ADoes not affect plasticityDoes not affect toughnessManufacturing convertersSmelting processEconomic benefits

The invention discloses a smelting process of low-carbon high-sulfur free-cutting steel and relates to the technical field of steel processing. The smelting process comprises the following steps: (1) converter smelting treatment, (2) refining treatment, (3) continuous casting and (4) rolling cooling treatment. According to the smelting process, a method is simple, the steps are reasonably and normatively matched, industrial large-scale application and popularization are facilitated, and the prepared low-carbon high-sulfur free-cutting steel is high in comprehensive performance and has great market competitiveness and economic benefits.

Owner:长泰县兴宏驰工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com