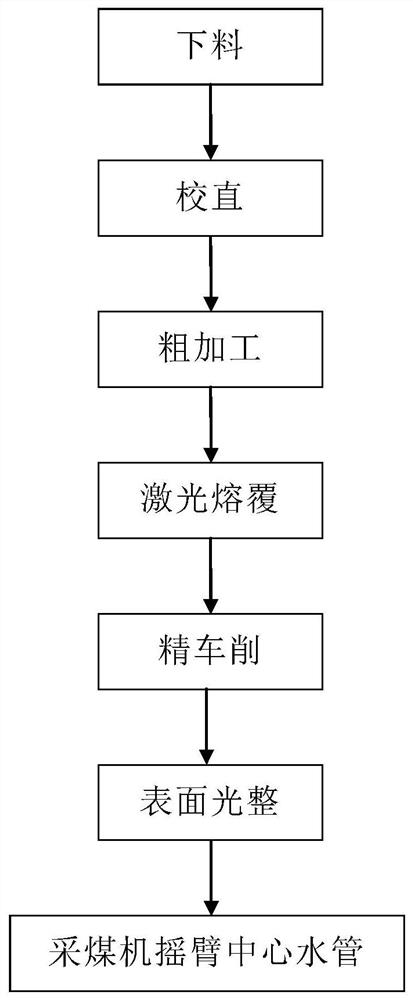

A manufacturing process of a wear-resistant and corrosion-resistant central water pipe for the rocker arm of a coal mining machine

A central water pipe and manufacturing process technology, applied in metal material coating process, coating and other directions, can solve the problems of unstable quality, long production cycle of chrome plating, etc., to achieve the control of deformation, good anti-oxidation atmosphere, stable sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment includes the following steps:

[0051] Step 1, blanking: sawing the pipe material to obtain the central water pipe wool; the outer diameter of the central water pipe wool is D, and the inner diameter is d; wherein D is 40mm, and d is 24mm;

[0052] Step 2, straightening: straightening the central water pipe wool material obtained in step 1 to obtain the straightened central water pipe wool material; the straightened central water pipe wool material has a non-straightness of 0.4mm;

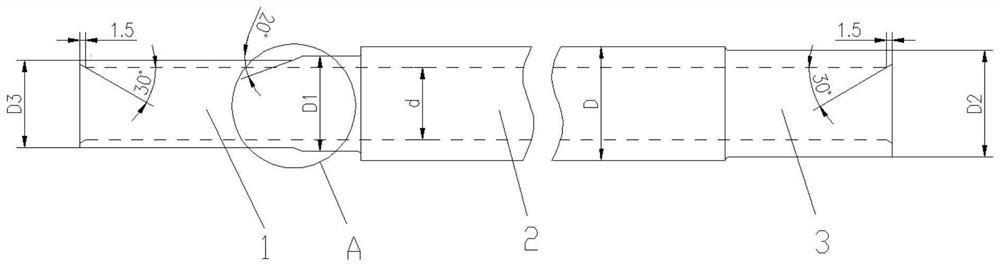

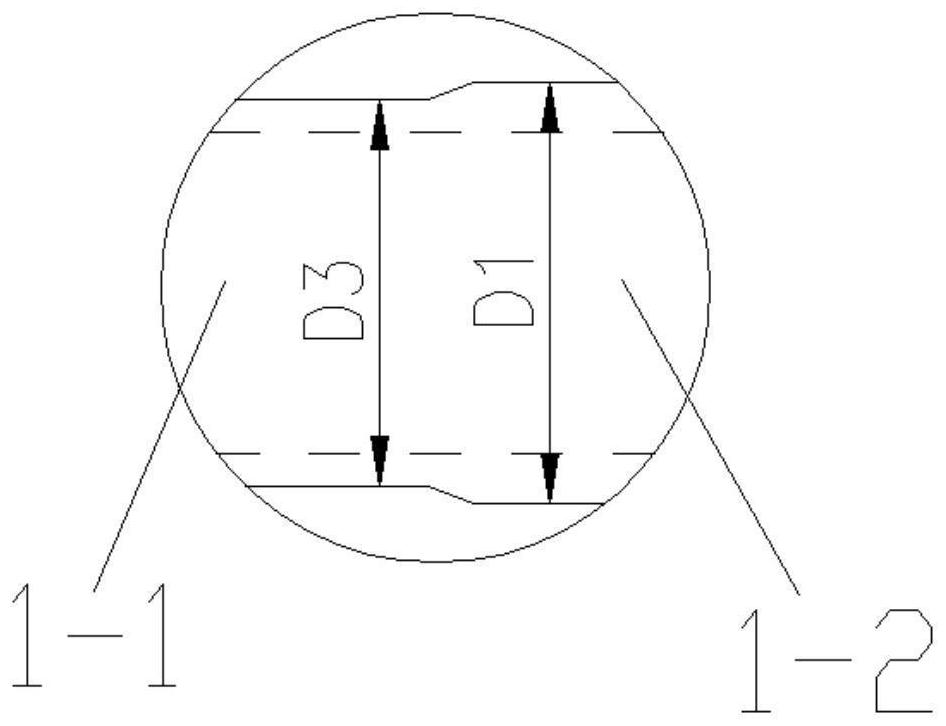

[0053] Step 3. Rough machining: turning the straightened central water pipe material obtained in step 2 to obtain a central water pipe blank; The outer diameter of the main body section is D, the inner diameter is d, and the outer diameter of the dynamic sealing section is D 1 , the inner diameter is d, and the outer diameter of the static sealing section is D 2 , the inner diameter is d, the dynamic sealing section is composed of a laser cladding section and a non-laser cl...

Embodiment 2

[0060] This embodiment includes the following steps:

[0061] Step 1, blanking: sawing the pipe material to obtain the central water pipe wool; the outer diameter of the central water pipe wool is D, and the inner diameter is d; wherein D is 30mm, and d is 19mm;

[0062] Step 2, straightening: straightening the central water pipe wool material obtained in step 1 to obtain the straightened central water pipe wool material; the straightened central water pipe wool material has a non-straightness of 0.3mm;

[0063] Step 3. Rough machining: turning the straightened central water pipe material obtained in step 2 to obtain a central water pipe blank; The outer diameter of the main body section is D, the inner diameter is d, and the outer diameter of the dynamic sealing section is D 1 , the inner diameter is d, and the outer diameter of the static sealing section is D 2 , the inner diameter is d, the dynamic sealing section is composed of a laser cladding section and a non-laser cl...

Embodiment 3

[0069] This embodiment includes the following steps:

[0070] Step 1, blanking: sawing the pipe material to obtain the central water pipe wool; the outer diameter of the central water pipe wool is D, and the inner diameter is d; wherein D is 35mm, and d is 19mm;

[0071] Step 2, straightening: straightening the central water pipe wool material obtained in step 1 to obtain the straightened central water pipe wool material; the straightened central water pipe wool material has a non-straightness of 0.4 mm;

[0072] Step 3. Rough machining: turning the straightened central water pipe material obtained in step 2 to obtain a central water pipe blank; The outer diameter of the main body section is D, the inner diameter is d, and the outer diameter of the dynamic sealing section is D 1 , the inner diameter is d, and the outer diameter of the static sealing section is D 2 , the inner diameter is d, the dynamic sealing section is composed of a laser cladding section and a non-laser c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com