A low-odor and low-precipitation flame-retardant polyamide material, its preparation method and application

A flame-retardant polyamide, low-odor technology, applied in the field of MCA flame-retardant polyamide materials, can solve the problems of large ammonia odor, no further disclosure, and large odor, and achieve low odor, less injection mold deposition problems, and low odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

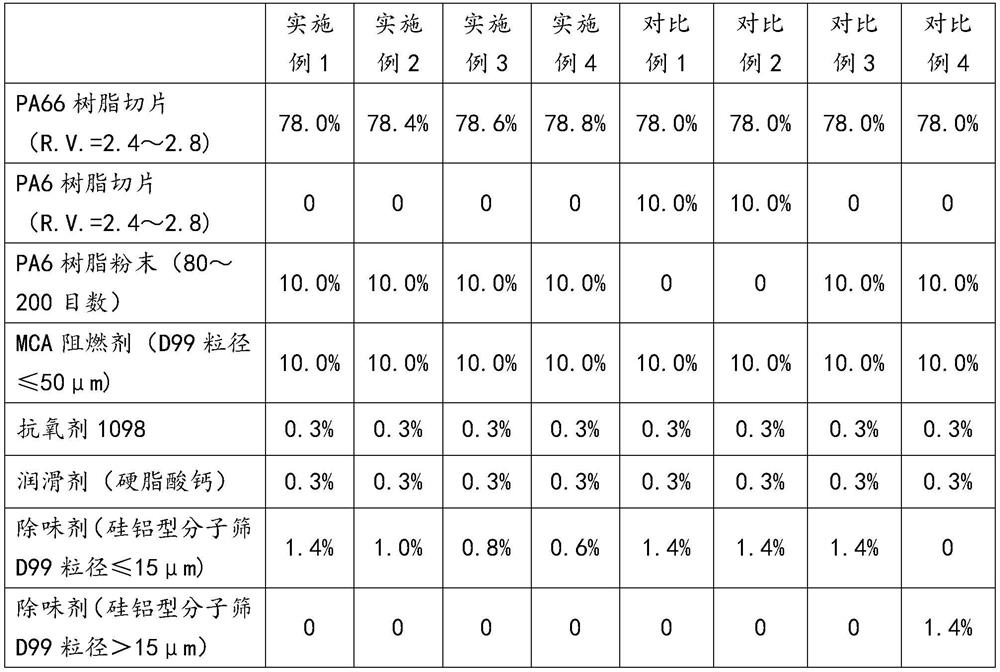

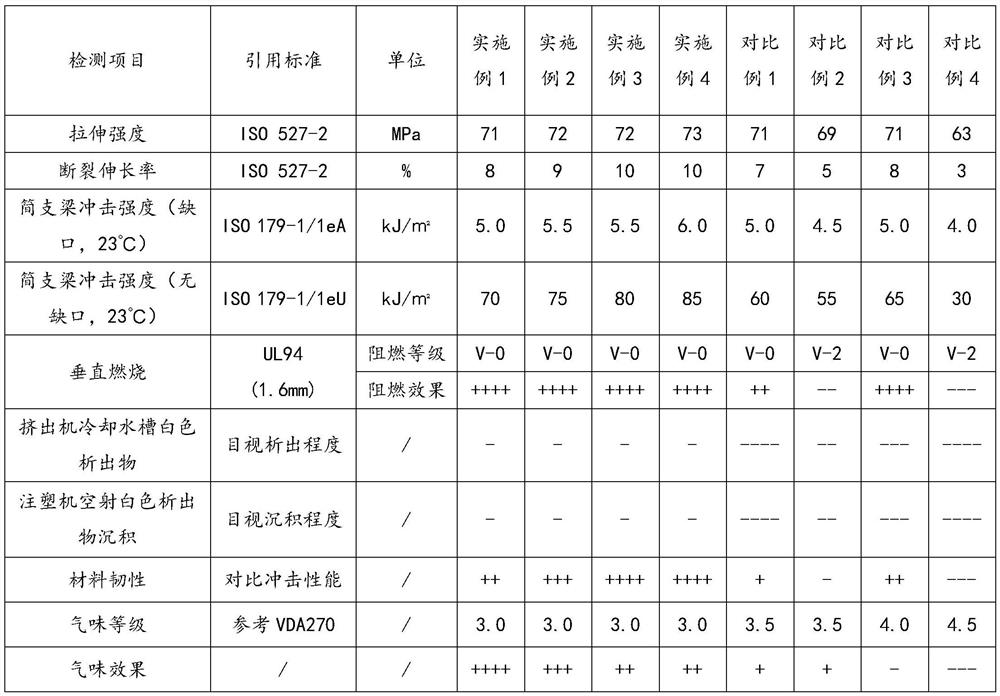

Embodiment 1-4

[0035] The preparation method of embodiment 1-4:

[0036] Step 1. Weigh PA6 resin powder and MCA flame retardant according to the ratio in Table 1, and put them into a high-speed mixer at a speed of 600r / min, mix for 2 minutes, mix well and evenly to form a flame retardant powder package, and set aside;

[0037] Step 2. Weigh the deodorant, calcium stearate and antioxidant 1098 according to the ratio in Table 1, and put them into a low-speed mixer at a speed of 100r / min, mix for 5min, mix well and form an additive package, and set aside ;

[0038] Step 3. Weigh the PA66 resin slices according to the ratio in Table 1, and feed the PA66 resin slices and the additive package obtained in step 2 from the main feeding port of the twin-screw extruder through weight loss weighing; The obtained flame retardant powder package is metered and fed from the side feeding port of the twin-screw extruder through a weight loss scale; the vacuum number of the twin-screw extruder is double vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com