3D printing material with diamond light sensation and preparation method thereof

A 3D printing, light-sensing technology, applied in the field of 3D printing consumables, can solve the problems of aggravating surface metal oxidation, yellowing, loss of metallic luster, etc., to achieve the effect of not easy to oxidize, increase gloss and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

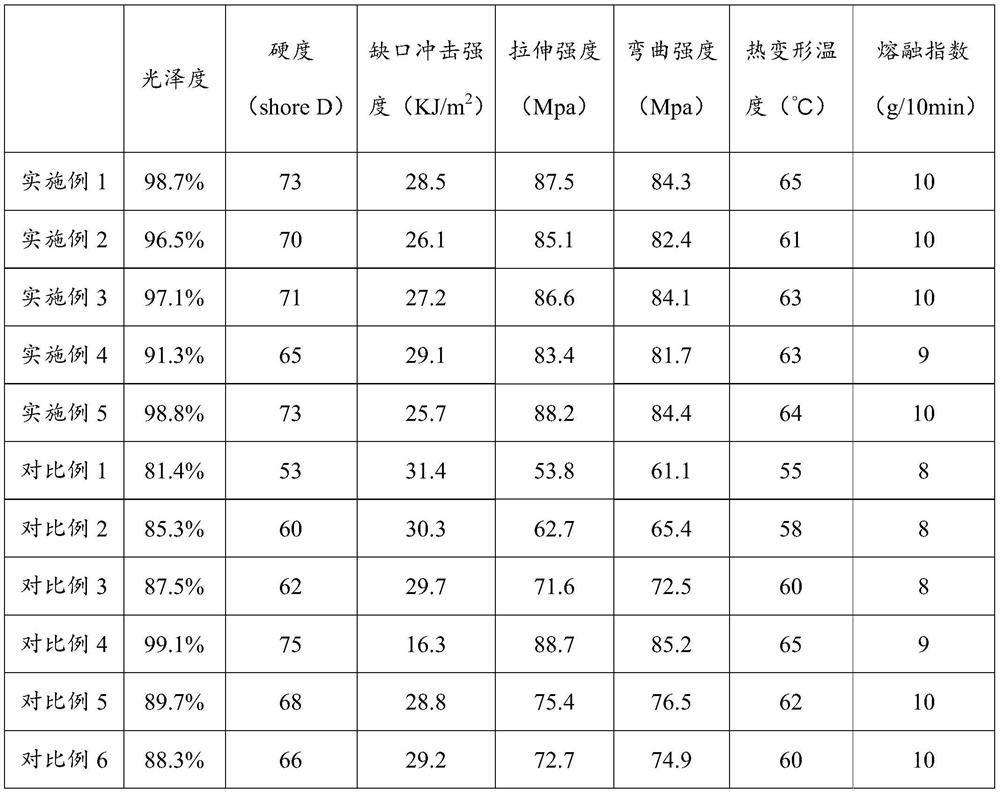

Examples

Embodiment 1

[0027] This embodiment provides a 3D printing material with diamond light sensitivity, including the following components by mass: plastic raw materials: 50 parts of PLA (polylactic acid) and 30 parts of PBS (polybutylene succinate); 15 parts of glass-coated silver powder: toughening agent: 5 parts of polyadipate / butylene terephthalate; nucleating agent: 3 parts of montmorillonite; compatibilizer: maleic anhydride grafted compatibilizer PE-g - 3 parts ST, 1 part Diffuser Oil.

[0028] This embodiment also provides the preparation method of the 3D printing material, specifically:

[0029](1) Preparation of glass-coated silver powder: take 800g of glass particles with an average particle size of 10-200μm as the base material, put them into 2L of industrial deionized water and stir, heat up to 70-80°C, and then add 50mL of 1mol silver powder within 10 minutes / L tin tetrachloride solution to modify the glass surface to facilitate subsequent silver coating; after filtering, add t...

Embodiment 2

[0033] The difference between this example and Example 1 is that the 3D printing material components in this example do not contain nucleating agent: montmorillonite.

Embodiment 3

[0035] The difference between this embodiment and Example 1 is that the 3D printing material of this embodiment includes the following components in parts by mass: plastic raw material: PETG (polyethylene terephthalate-1,4-cyclohexyl 60 parts of alkanedimethanol ester) and 15 parts of TPU (thermoplastic polyurethane elastomer); 10 parts of glass-coated silver powder: toughening agent: 2 parts of polysuccinic acid / butylene terephthalate; nucleating agent: talcum powder 2 parts; compatibilizer: 2 parts of silane coupling agent KH-5500, 0.1 part of diffusing oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com