Smelting process of low-carbon high-sulfur free-cutting steel

A free-cutting steel and high-sulfur technology, applied in the field of steel processing, can solve problems such as internal cracks in the billet, reduced production efficiency, and high production costs, and achieve the effects of enhancing strength, improving quality, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Smelting process of low-carbon high sulfur suspension steel, including the following steps:

[0033] (1) converter smelting treatment:

[0034] After the converter is out of the steel, stirring is carried out during this steel process, which is used to add aluminum blocks, silicon manganese, low carbon manganese iron, low carbon chrome iron, silicon alloy, thiron mine, lime;

[0035] (2) Refining:

[0036] Before the refining treatment, the steel water was first slag, and then sampled after energizing, according to the component content measured by the sampling, specifically silicon manganese, low carbon manganese, low carbon chromium, silicon Iron alloy, iron mine, phosphate, niobium titanium alloy, copper ingot;

[0037] (3) Connect casting:

[0038] In the continuous casting process, the whole process of protecting casting is used, and specialized special protective slag and special cover are used, and the overheating is controlled to 20 to 25 ° C, and electromagnetic st...

Embodiment 2

[0050] Smelting process of low-carbon high sulfur suspension steel, including the following steps:

[0051] (1) converter smelting treatment:

[0052] After the converter is out of the steel, stirring is carried out during this steel process, which is used to add aluminum blocks, silicon manganese, low carbon manganese iron, low carbon chrome iron, silicon alloy, thiron mine, lime;

[0053] (2) Refining:

[0054] Before the refining treatment, the steel water was first slag, and then sampled after energizing, according to the component content measured by the sampling, specifically silicon manganese, low carbon manganese, low carbon chromium, silicon Iron alloy, iron mine, phosphate, niobium titanium alloy, copper ingot;

[0055] (3) Connect casting:

[0056] In the continuous casting process, the whole process of protecting casting is used, and specialized special protective slag and special cover are used, and the overheating is controlled to 20 to 25 ° C, and electromagnetic st...

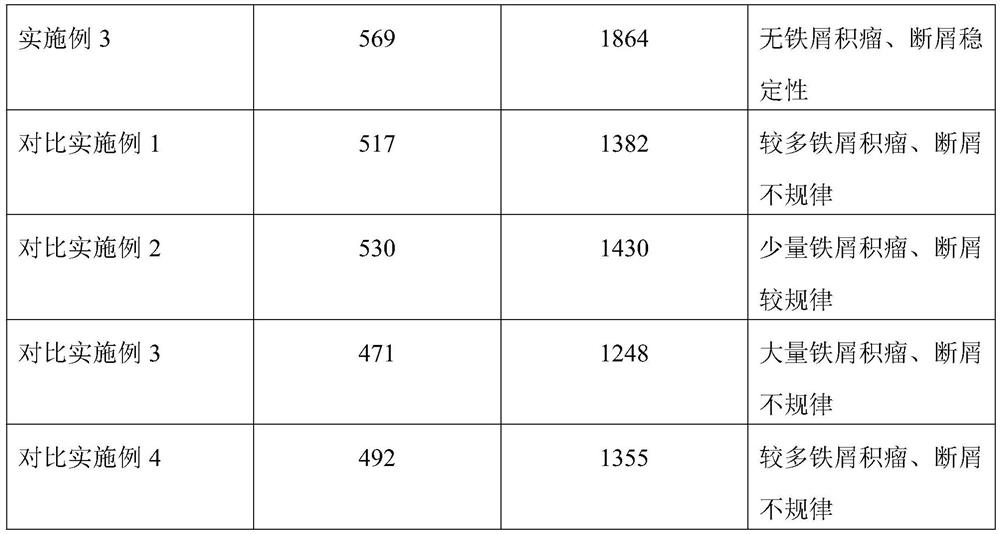

Embodiment 3

[0068] Smelting process of low-carbon high sulfur suspension steel, including the following steps:

[0069] (1) converter smelting treatment:

[0070] After the converter is out of the steel, stirring is carried out during this steel process, which is used to add aluminum blocks, silicon manganese, low carbon manganese iron, low carbon chrome iron, silicon alloy, thiron mine, lime;

[0071] (2) Refining:

[0072] Before the refining treatment, the steel water was first slag, and then sampled after energizing, according to the component content measured by the sampling, specifically silicon manganese, low carbon manganese, low carbon chromium, silicon Iron alloy, iron mine, phosphate, niobium titanium alloy, copper ingot;

[0073] (3) Connect casting:

[0074] In the continuous casting process, the whole process of protecting casting is used, and specialized special protective slag and special cover are used, and the overheating is controlled to 20 to 25 ° C, and electromagnetic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com