Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Meet special use requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water high light wearable intaglio ink and preparing method thereof

The invention relates to a water-base printing ink and its producing method, especially water-base high light friction resistance gravure oil and the producing method thereof. The oil is suitable for packing print in the soft packing field such as food, drink, medicine, health products, chemicals and etc. The water-base high light friction resistance gravure oil is composed of acrylic resin, acrylic emulsion, dye, ethanol, built-up agent, dispersant, deionized water, water-base emulsifying wax, antifoamer, leveling agent. The inventive product completely meets the requirement of the gravure oil, has a reliable quality and can replace the solvent gravure oil, which can be dilute by the tap water of ethanol. The printing device can be washed directly by the tap water. The product has a high concentration, a low viscosity, a good printing adaptability has no harm to the environment and human body. The presswork has a clear pattern, a bright color, a powerful attached fastness, a good water resistance and friction resistance, has no harmful residue after drying and is not easy to fade and shed.

Owner:浙江永在油墨有限公司

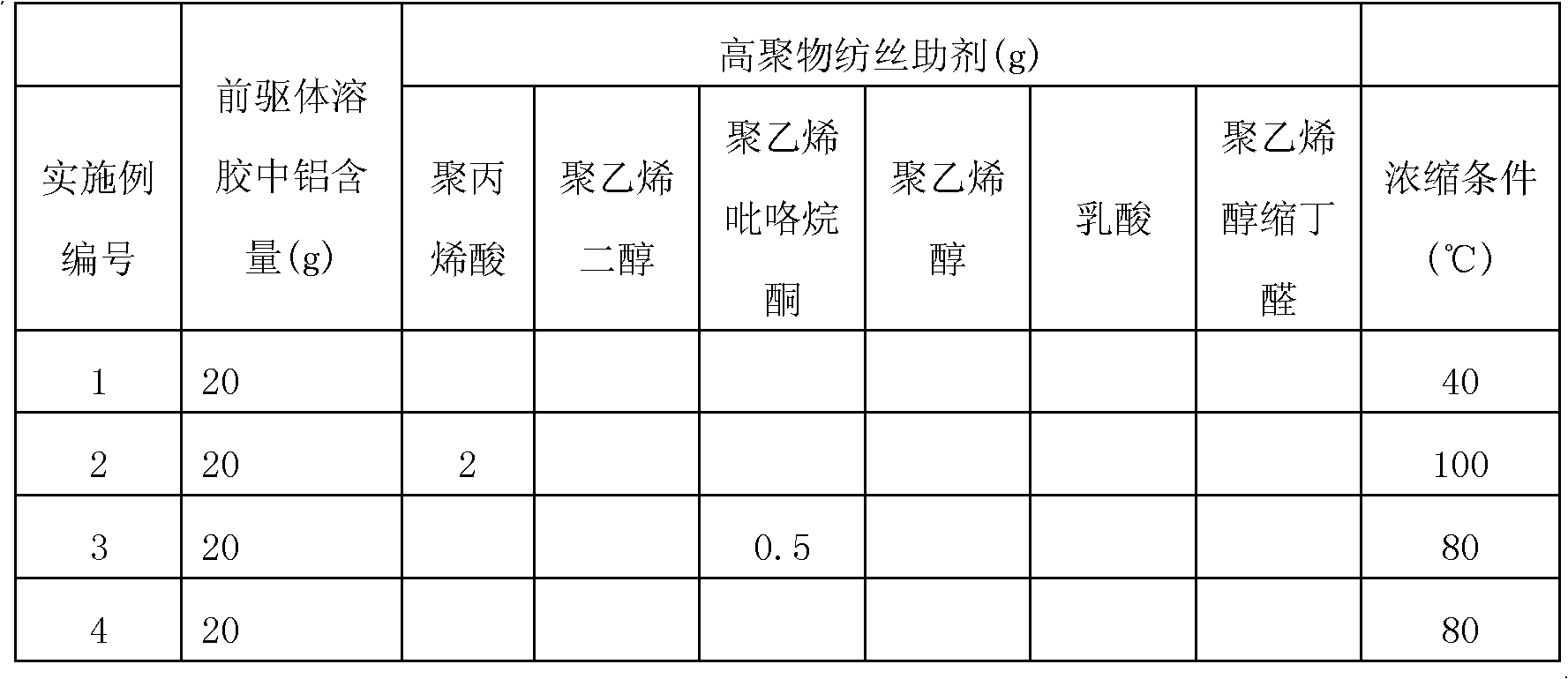

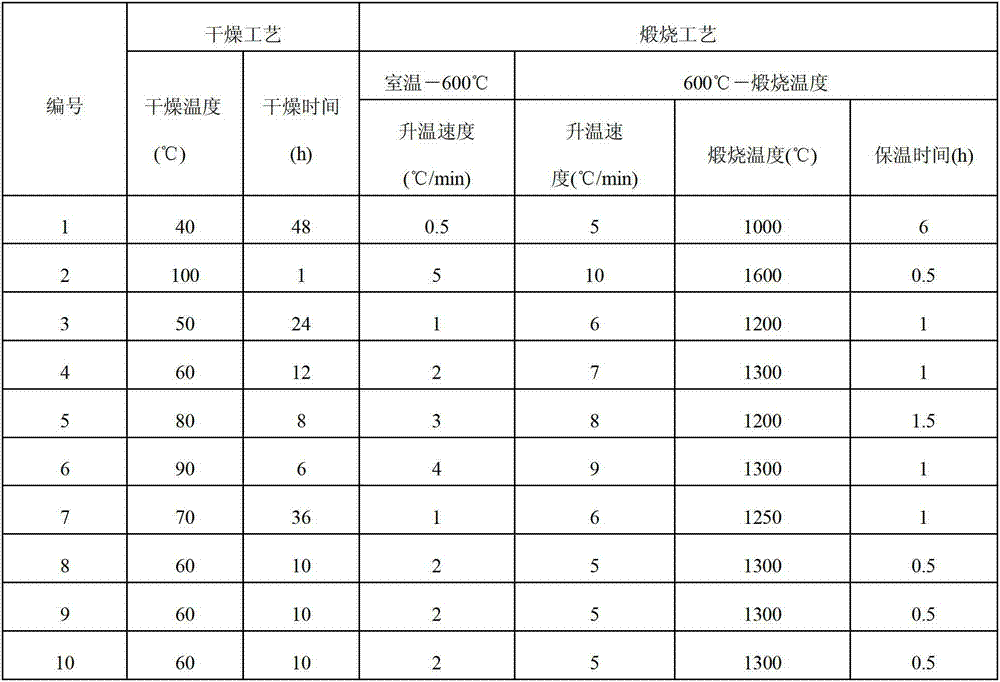

Process for preparing alumina-based continuous fiber with sol-gel method

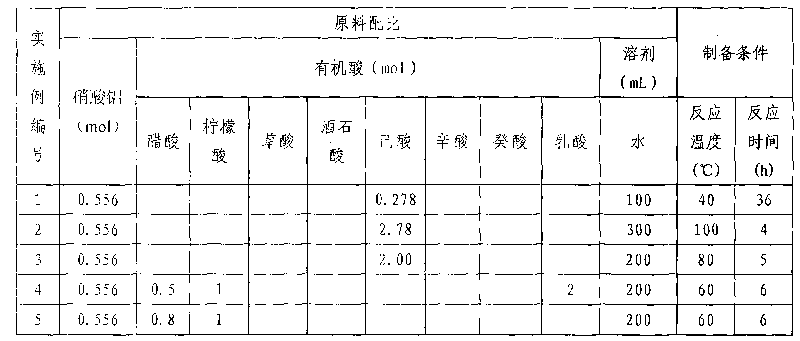

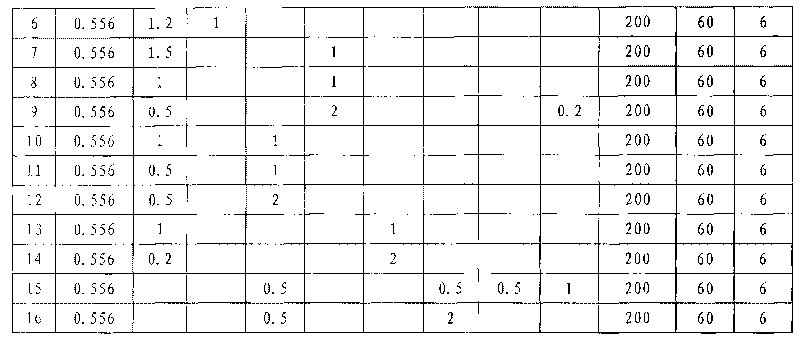

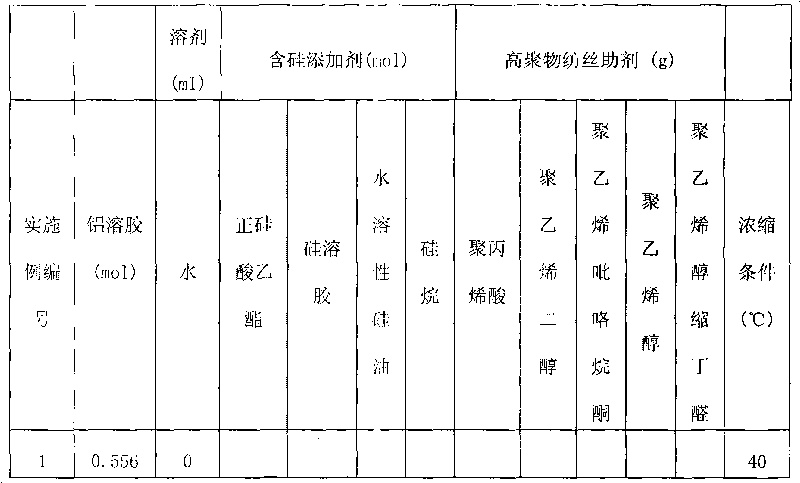

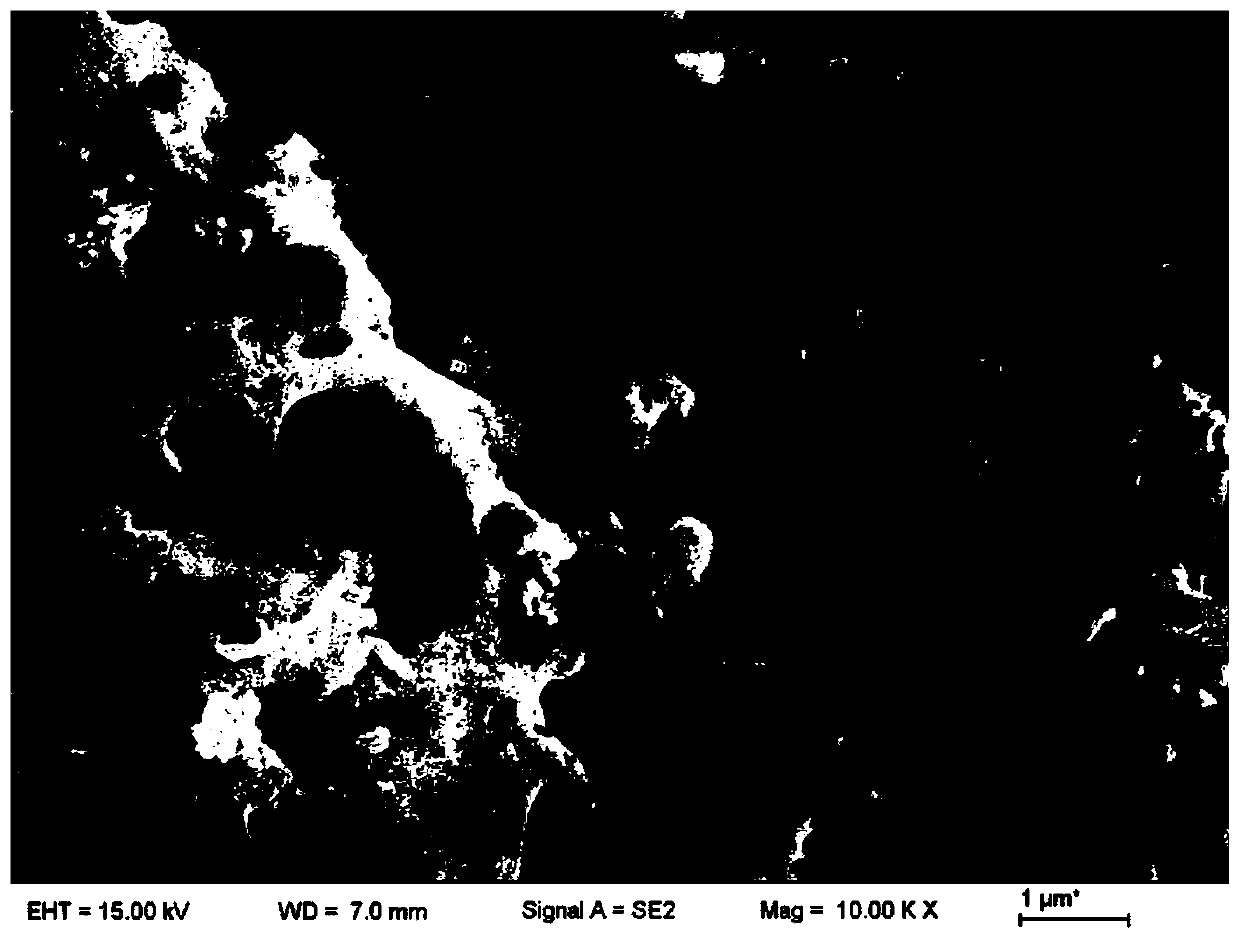

The invention discloses a process for preparing alumina-based continuous fiber with a sol-gel method. The process comprises the following steps of: adding aluminium nitrate and one or a plurality of kinds of carboxylic acids with the carbon number of 2 to 24 to distilled water; ensuring the mixture to react in the condition of continuous stirring under a certain temperature to obtain transparent carboxylate aluminium gel; adding a certain amount of solvent to the carboxylate aluminium gel, and adding a certain amount of silicon-contained additives and superpolymer spinning additives to obtain an alumina-based fiber precursor solution; concentrating the solution to obtain spinnable alumina-based fiber precursor sol; placing the concentrated sol to a liquid storage tank with a spray head, and spinning by adopting a dry method or a wet method to obtain alumina-based continuous fiber protofilament containing organic matters; and drying and sintering the protofilament to obtain the alumina-based continuous fiber. The alumina-based continuous fiber obtained by adopting the invention can be used for reinforcement of composite materials so as to further enhance the strength and toughness of the materials and improve the heat resistance of the materials, and is widely applied in the fields of aerospace, automobiles, and the like.

Owner:XI AN JIAOTONG UNIV

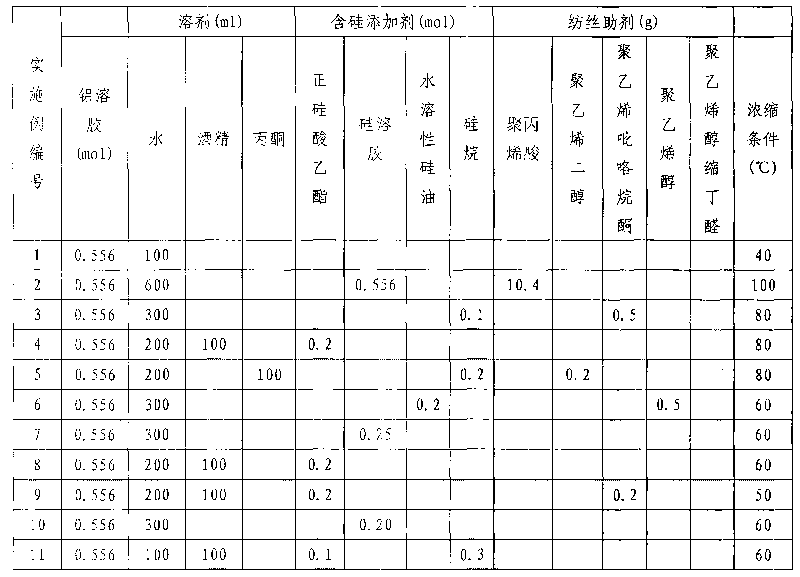

Process for preparing yttrium aluminum garnet-based continuous fibers through sol-gel method

InactiveCN102011215AAvoid growing upGrowth retardationArtificial filament washing/dryingFibre chemical featuresFiberYttrium

The invention discloses a process for preparing yttrium aluminum garnet-based continuous fibers through a sol-gel method. Yttrium aluminum garnet is taken as a main component, and a second component is added to serve as a grain inhibitor. The process comprises the following steps of: adding inorganic aluminum salt, yttrium oxide, the grain inhibitor, acetic acid and metal aluminum into distilled water, and reacting the mixture solution under the conditions of certain temperature, continuously stirring and condensing reflux so as to prepare grain inhibitor-containing yttrium aluminum garnet sol; adding a certain amount of spinning aid into the sol, and concentrating the solution so as to prepare spinnable fiber precursor sol; spinning to prepare precursors of organic matter-containing yttrium aluminum garnet-based continuous fibers by adopting a dry method or a wet method; and drying and sintering the precursors to prepare the yttrium aluminum garnet-based fibers. The prepared yttrium aluminum garnet-based continuous fibers can be used as reinforcement in a composite material to improve the strength, toughness and heat resistance of the material, and is widely applied in the fields of aerospace, automobiles and the like.

Owner:SHAANXI UNIV OF TECH

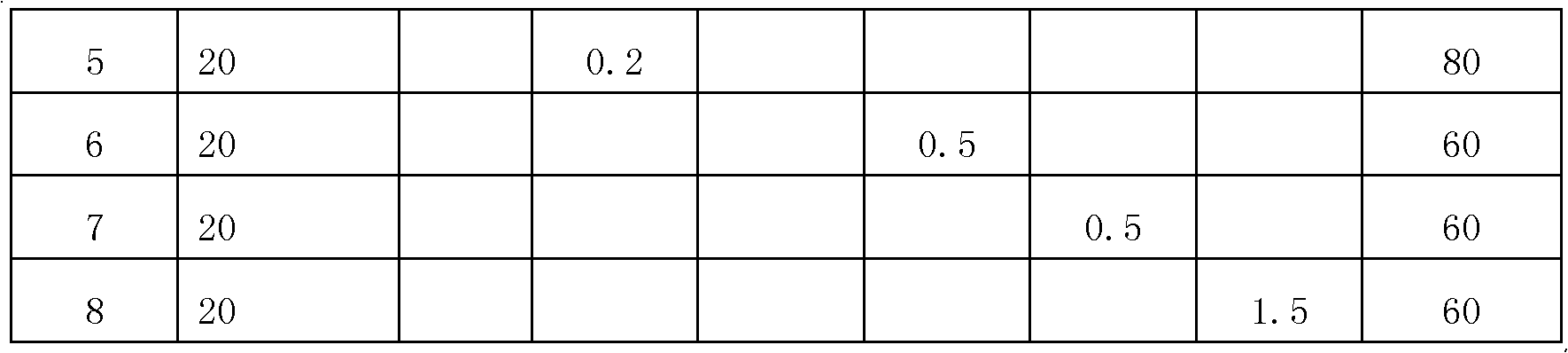

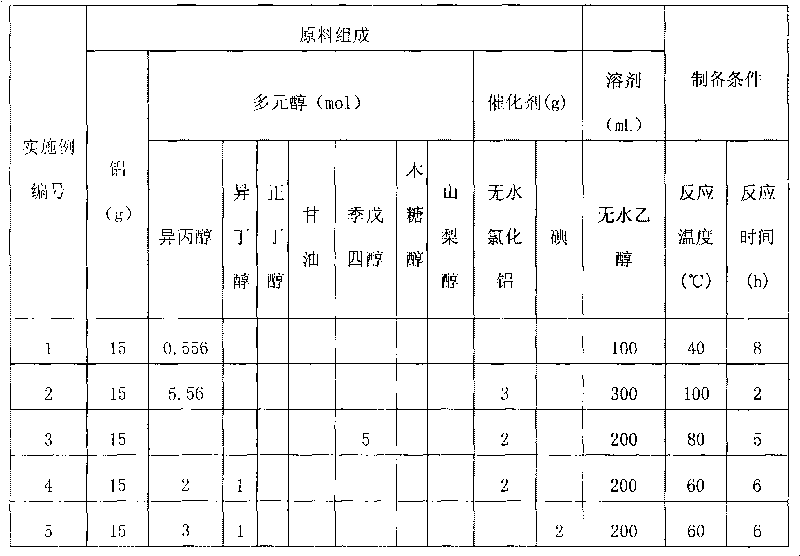

Technology of preparing aluminium oxide based continuous fibers by sol-gel process

The invention discloses technology of preparing aluminium oxide based continuous fibers by a sol-gel process, which is characterized by adding one or more polyols containing 3-6 carbon atoms into anhydrous ethanol, adding aluminum powder and a catalyst after the mixture is evenly mixed and ensuring the mixture to react under the conditions of continuous stirring and reflux condensation under certain temperature to obtain transparent aluminum alkoxide solution; adding a given quantity of silicon-containing substances and spinning assistants into the aluminum alkoxide to obtain precursor solution of aluminium oxide based fibers and concentrating the solution to obtain precursor sol of spinnable aluminium oxide based fibers; placing the concentrated sol into a liquid storage tank with a spray nozzle and spinning by a dry or wet method to obtain aluminium oxide based continuous precursor fibers containing organics; and drying and sintering the precursor fibers to obtain the aluminium oxide based fibers. The aluminium oxide based continuous fibers prepared by the technology can be used in reinforcement in the composite, further improve the heat resistance and mechanical property of the material and are widely applied in the fields of aerospace, automobile and the like.

Owner:XI AN JIAOTONG UNIV

Six-element high-entropy oxide material for lithium ion battery and preparation method

ActiveCN110556536AGuaranteed stabilityImprove cycle stabilityCell electrodesSodium-ion batteryChromium nitrate

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

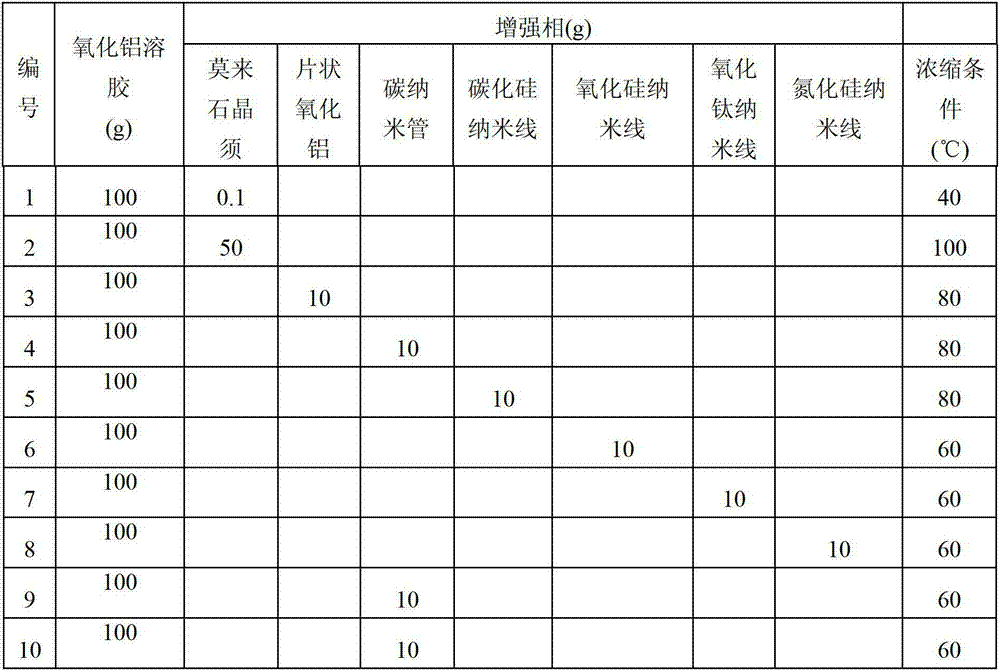

Preparation process for composite continuous ceramic fiber

The invention discloses a preparation process for a composite continuous ceramic fiber. The process is characterized in that a reinforcing material is added into precursor sol of a ceramic fiber, the reinforcing material and the precursor sol are fully mixed under stirring, an obtained composite solution is condensed to obtain spinnable precursor composite sol, the technique of plastic extrusion spinning is employed to process the condensed composite sol so as to obtain continuous fiber ceramic protofilament containing the reinforcing material and finally the protofilament is dried and sintered so as to obtain the composite continuous ceramic fiber. The ceramic fiber prepared in the invention is applicable to the fields of aerospace, automobiles, stationary and sports goods and can be used as reinforcement of a composite material.

Owner:SHAANXI UNIV OF TECH

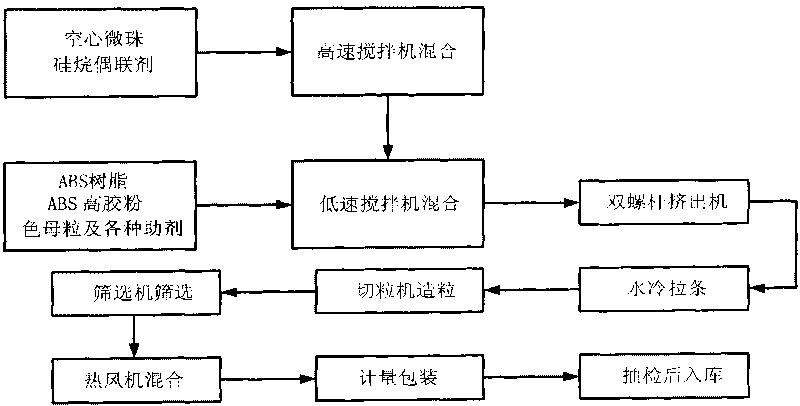

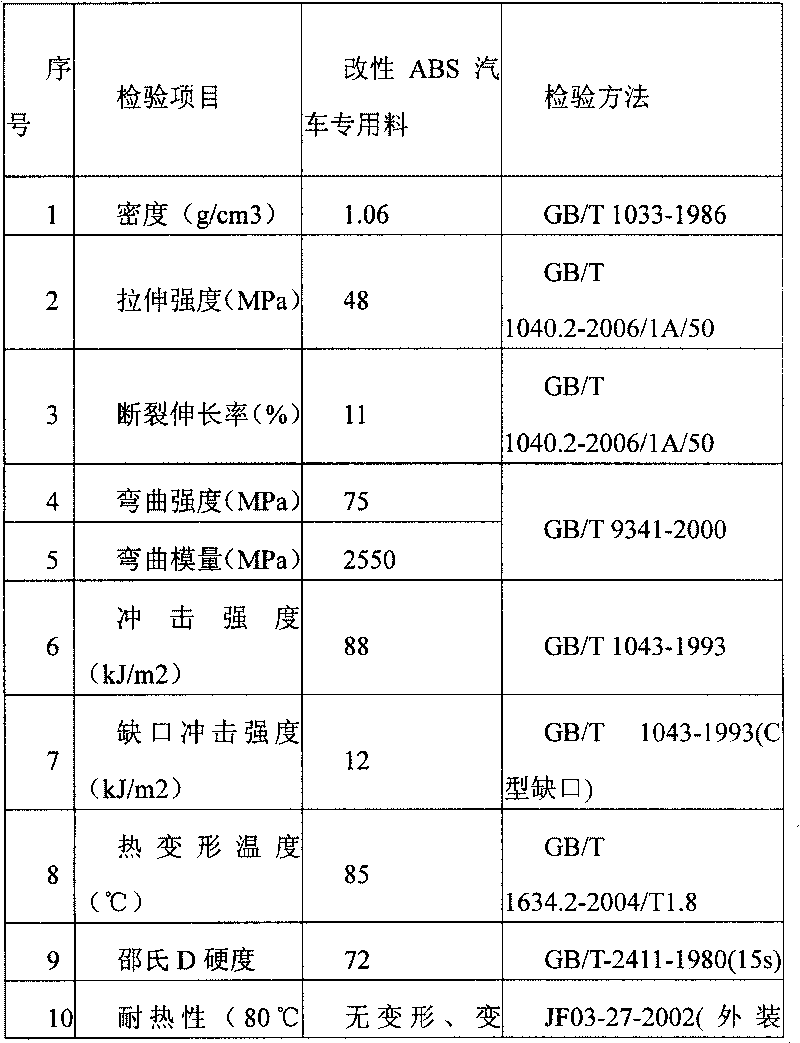

Modified ABS automobile special material and production method thereof

The invention provides a modified ABS automobile special material comprising the following components in the formula in parts by weight: 100 parts of resin matrix ABS, 5-15 parts of active filler hollow microsphere, 4-8 parts of high rubber powder ABS, 0.5-0.8 part of age resister and 2-4 parts of master batch. In the above formula composition, the matrix resin ABS is granular substance; the active filler hollow microsphere is processed by silane coupling agent KH 550; the age resister mainly comprises master antioxidant, slave antioxidant and uvioresistant agent which are all powdery substance; the color of the master batch is determined according to product requirements, and the master batch is granular substance. The invention utilizes the principle that solubility parameters are similar; other polymers and various auxiliary agents, such as age resister, flexibilizer, fillers and the like are added into the ABS material and carry out molten mechanical mixing at certain temperature so as to obtain a new material applied on lorry parts.

Owner:CHINA FIRST AUTOMOBILE

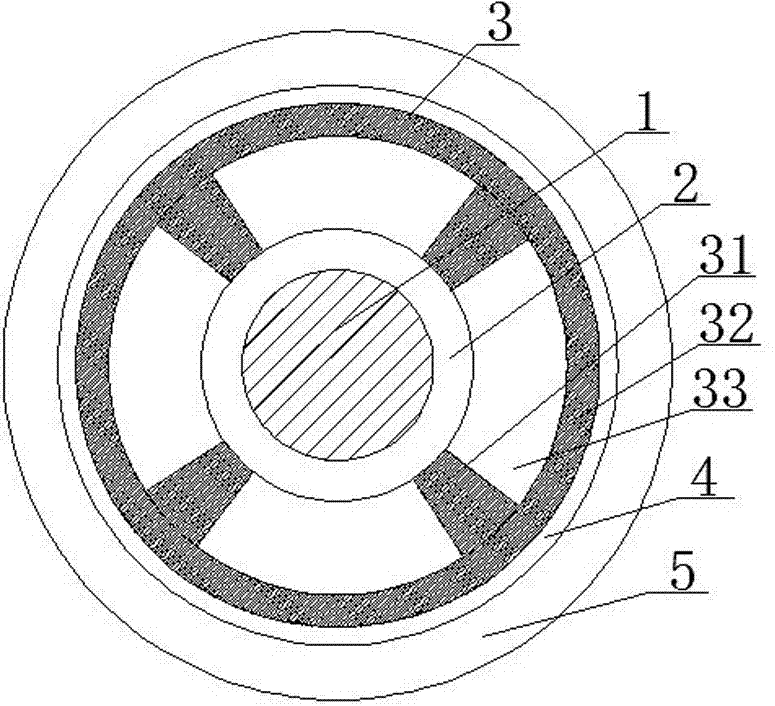

Hydrodynamic pressure suspension double-flow pump

InactiveCN103216453APlay the role of heat dissipationAchieve levitationPump componentsBlood pumpsImpellerEngineering

The invention provides a hydrodynamic pressure suspension double-flow pump, relating to an impeller ultra-small pump which has no external mechanism axis and is driven magnetically. The pump comprises two mutually separate flowing channels; each flowing channel consists of an inlet, an impeller, a pressure water chamber and an outlet; and the geometrical parameters of the flowing channels are the same or different; a stator of the pump is embedded in a pump shell, a permanent magnet is embedded in a rotor; and the stator and the permanent magnet are arranged opposite along a radial direction; a radial gap is formed between the internal surface of the pump shell and the external surface of the rotor, so that liquid hydrodynamic support for restricting axial movement is formed during normal operation of the pump; an axial gap is formed between the front cover plate of each impeller and the corresponding pump cover, so that liquid hydrodynamic support for restricting rotor axial movement is formed during the normal operation of the pump. In such a way, the rotor can be suspended in the pump cavity during normal operation. The pump provided by the invention can be used for meeting double-flow use requirement of different flows and pressures, and good flowing condition can be effectively and favorably formed in the internal cavity of the pump shell, and moreover, the operation reliability of the pump can be improved.

Owner:TSINGHUA UNIV

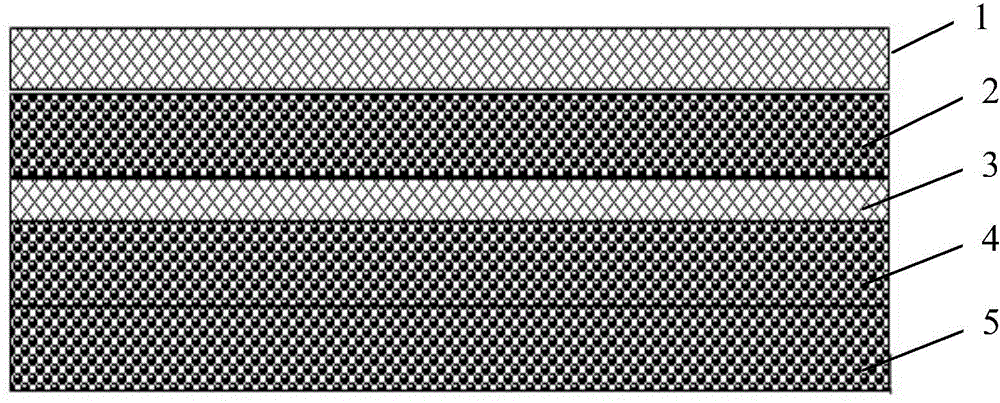

Flexible cable used for new energy automobile

ActiveCN107039117AImprove eliminationMeet special use requirementsRubber insulatorsInsulated cablesInsulation layerElectrical conductor

The invention discloses a flexible cable used for a new energy automobile. The cable comprises a conductor and an insulation layer used for wrapping the conductor. The outer part of the insulation layer is provided with a cooling layer in a wrapped manner, and at least one cooling medium channel extended along the length direction of the insulation layer is disposed in the cooling layer, and is used to introduce the cooling medium for the cooling and the heat dissipation of the insulation layer. Heat energy radiated by the insulation layer outwardly is effectively, reliably, quickly, and greatly eliminated by the cooling medium, and then the heat energy radiated on the outer part of the cooling layer is reasonable, controllable, and safe, and then the special use requirement of the new energy automobile is satisfied. The flexible cable is in service and operated reliably, safely, and stably in various severe environments, and has advantages of simple structure, convenient forming, small forming difficulty, low forming costs, compact structure, good flexibility, excellent heat dissipation effect, high flame resistant performance, high reliability, good safety performance, and strong practicability.

Owner:TBEA DEYANG CABLE CO LTD

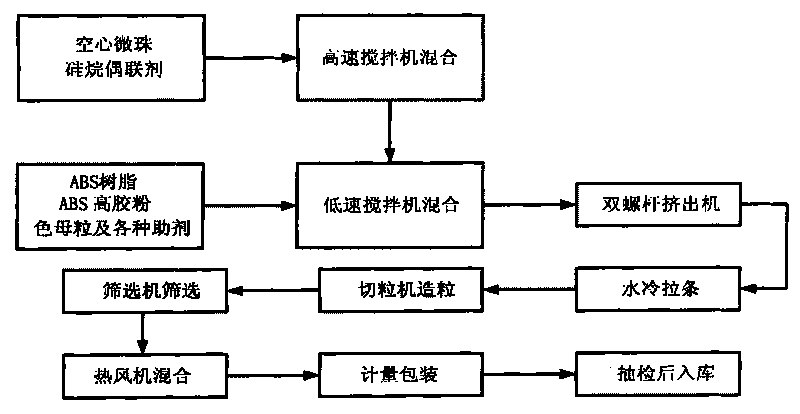

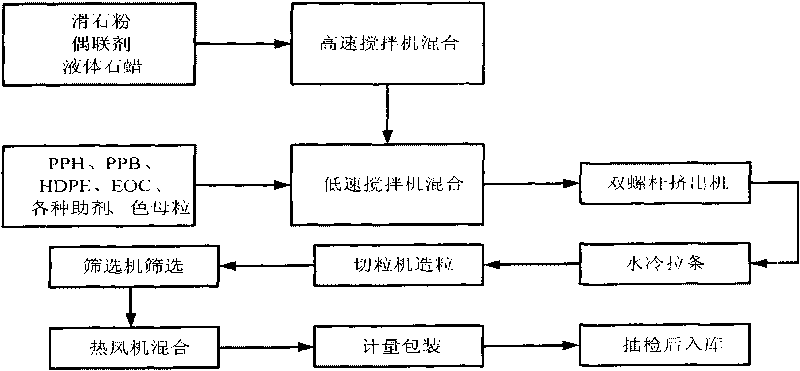

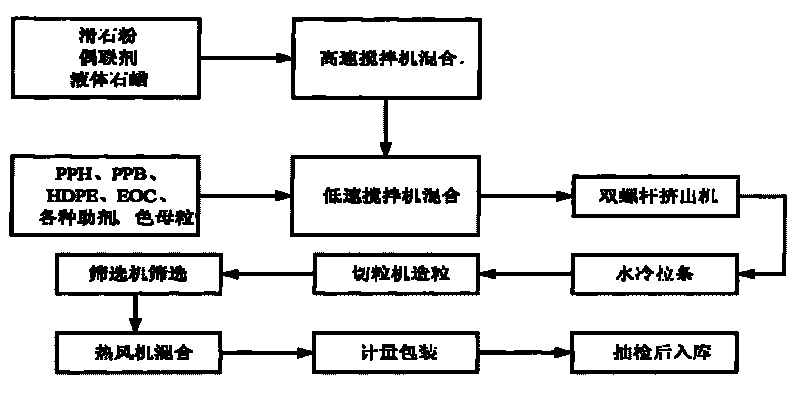

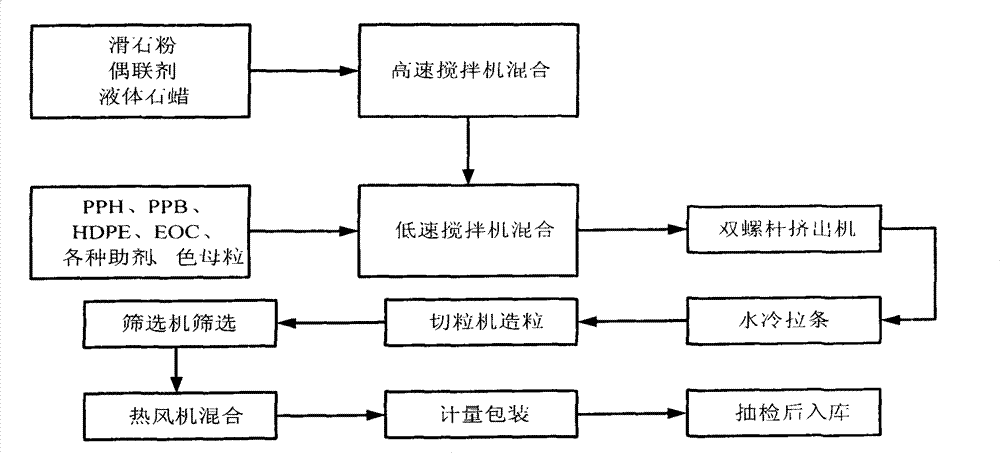

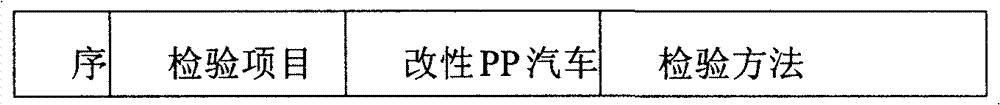

Modified PP automobile special material and production method thereof

The invention discloses a modified PP (polypropylene) automobile special material which comprises the formula of resin matrixes PPH and PPB, reinforcing filler talcum powder, high-density polyethylene HDPE, toughening agent EOC, age resister, compatilizer and master batch according to the parts by weight: 5-10 pats of PPH (homo polypropylene), 90-95 parts of PPB (co-polypropylene), 20-40 parts ofactive talcum powder or talc grain, 5-10 parts of HDPE (high-density polyethylene), 2-8 parts of EOC (flexibilizer), 0.3-0.6 part of age resister, 2-8 parts of PP-g-MA (compatilizer) and 2-4 parts of master batch. In the above formula, the sum of PPH (homo polypropylene) and PPB (co-polypropylene) is equal to 100 parts, and the PPH (homo polypropylene) and PPB (co-polypropylene) are both granular substance; the active talcum powder or talc grain is processed by silane coupling agent, and liquid paraffin is added; the age resister mainly comprises master antioxidant, slave antioxidant and uvioresistant agent which are all powdery substance; the color of the master batch is determined according to product requirements, and the master batch is granular substance. The invention utilizes the principle that solubility parameters are similar; other polymers and various auxiliary agents, such as age resister, compatilizer, flexibilizer, fillers and the like are added into the PP material and carry out molten mechanical mixing at certain temperature so as to obtain a new material applied on lorry parts.

Owner:CHINA FIRST AUTOMOBILE

Alpha-aluminium oxide powder for low glass powder

InactiveCN1587055ARealize localizationLow costAluminium oxide/hydroxide preparationTunnel kilnGranularity

The alpha-alumina powder specially for low glass powder is prepared with industrial alumina of granularity 200-250 mesh 90-95 wt%, high whiteness superfine aluminum hydroxide of whiteness Y higher than 95 % and granularity higher than 1000 mesh 3-8 wt%, AlF3 of granularity 200-250 mesh 0.5-2 wt%, NH4F of granularity 200-250 mesh 0.5-2 wt% and BaF2 of granularity 200-250 mesh 0.3-1 wt%, and through mixing; calcining in tunnel kiln the mixture at 1550-1650 deg.c via maintaining the temperature for 6-10 hr; sorting to grade, grinding in ball mill, grinding in stirring mill; grading in hydraulic vortex grading machine, surface treating in HCl solution and stoving. The present invention has the advantages of low cost and mass production.

Owner:马淑云

Ladder winding method for transformer type sensor coil

InactiveCN102522194AMeet special use requirementsUsing electrical meansCoils manufactureCopper wireCotton thread

The invention provides a ladder winding method for a transformer type sensor coil. The ladder winding method comprises the following steps of: wrapping the outer surface of a framework winding region for two circles by using non-alkali glass fiber cloth dipped with insulating varnish; then drying; flatly winding an enamel round copper wire at the framework winding region, and brushing the insulating varnish once when one layer of the enamel round copper wire is wound; after the layers of the specified number are flatly wound, continuously winding the enamel round copper wire in a specified region according to requirements, and brushing the insulating varnish once when one layer of the enamel round copper wire is wound; after the winding is completed, wrapping the coil for two circles by using a polytetrafluoroethylene film; then wrapping the coil for two circles by using the non-alkali glass fiber cloth; then binding by using cotton threads; and finally drying. After a sensor is assembled by using the coil wound by the invention, the sensor is mounted on a spout afterburner fuel regulator and is used for completing test run and check test run together with an engine, and special use requirements of the engine can be completely satisfied.

Owner:SHAANXI BAOCHENG AVIATION INSTR

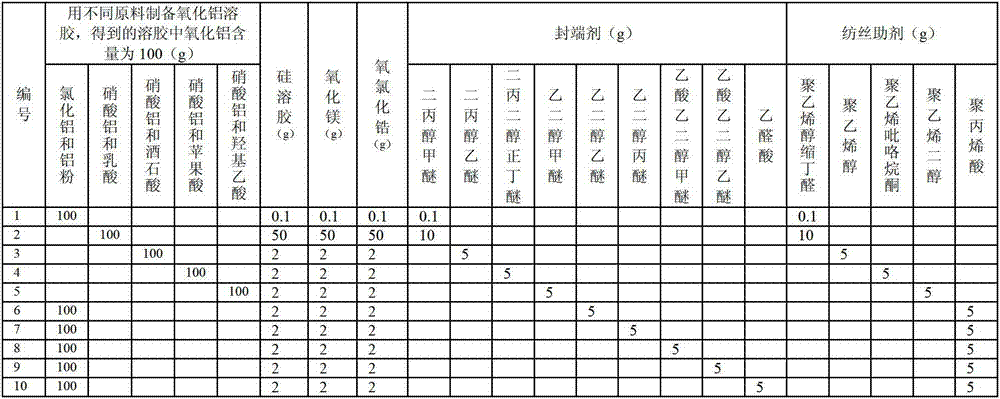

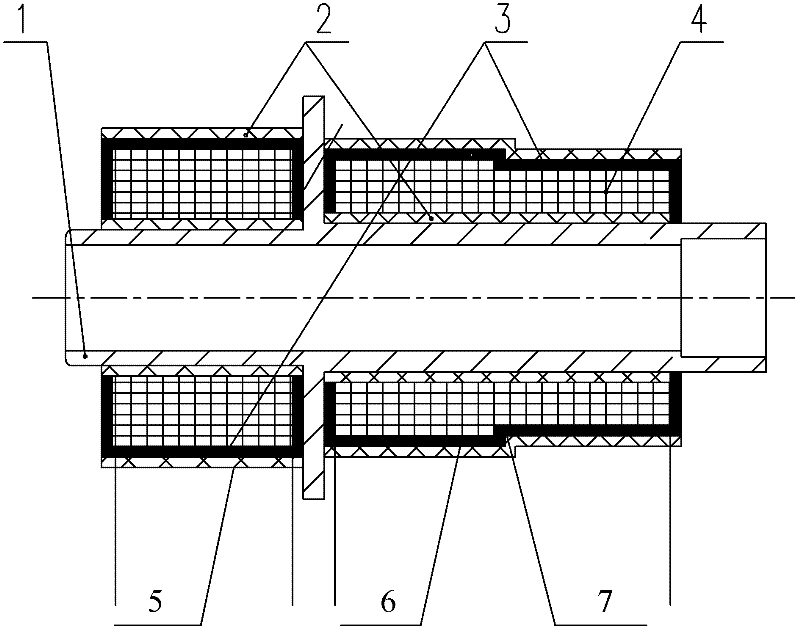

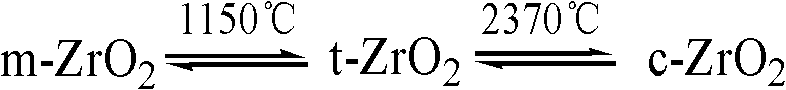

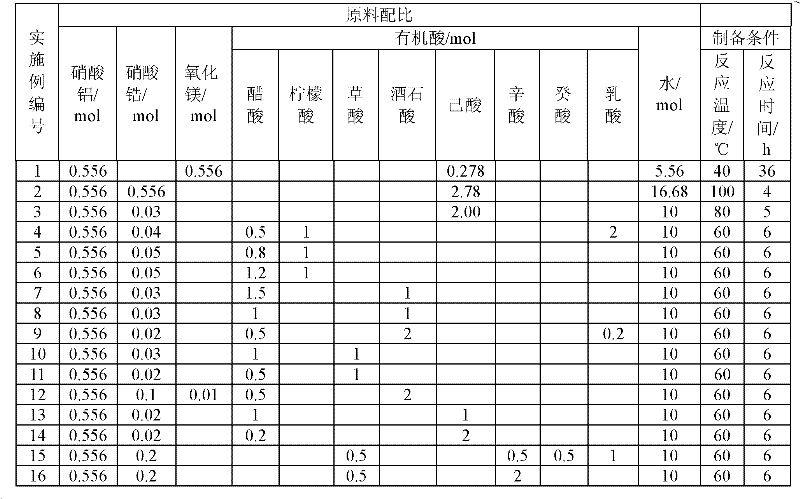

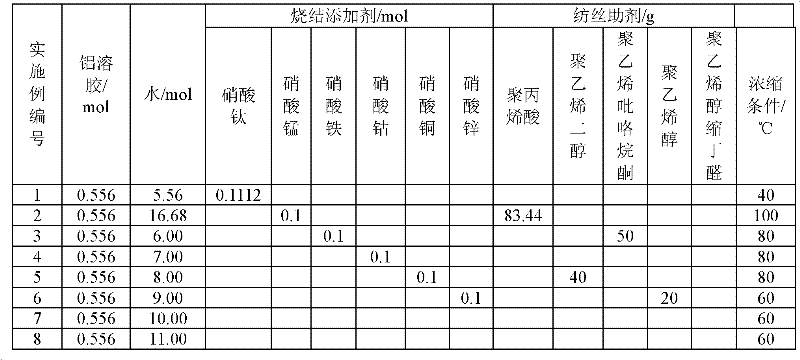

Preparation method of alumina-based composite continuous fibers

The invention discloses a preparation method of alumina-based composite continuous fibers. The preparation method comprises the following steps that 1) aluminium nitrate, zirconium nitrate, magnesium oxide and a carboxylic acid are added into water, wherein the number of carbon atoms of the carboxylic acid is in a range of 2 to 24; the mixture undergoes a reaction with stirring continuously at a certain temperature to from transparent carboxylate composite sol; 2) a certain amount of water is added into the carboxylate composite sol obtained from the step 1, and then a certain amount of a sintering additive and a certain amount of a polymer spinning additive are added into the carboxylate composite sol to produce alumina-based fiber precursor solution; 3) the alumina-based fiber precursor solution obtained from the step 2 is concentrated to form spinnable alumina-based fiber precursor sol; 4) the concentrated sol obtained from the step 3 is putted into a liquid storage tank with a spray-head and is processed through a wet spinning process or a dry spinning process to form alumina-based continuous precursor fibers containing organisms; and 5) the alumina-based continuous precursor fibers obtained from the step 4 are treated through processes of drying and sintering to from alumina-based composite fibers. The strength of the alumina-based composite continuous fibers is higher than the strength of single-phase alumina fibers. The alumina-based composite continuous fibers can be utilized for reinforcement of a composite material thereby improving the strength, the toughness and the heat-resistant performance of the composite material thus can be utilized widely for the fields of aerospace, automobiles and the like.

Owner:SHAANXI UNIV OF TECH

Auxiliary electric motor special for wind power, bearing grease adding method of electric motor and wind power unit

InactiveCN105757129AImprove reliabilityReduce maintenance burdenShaftsLubrication elementsAutomotive engineeringElectricity

The invention discloses an auxiliary electric motor special for wind power.The auxiliary electric motor comprises a rotating shaft, a bearing, an external bearing cover, an end cover and an internal bearing cover; the bearing is installed on the rotating shaft in a sleeving mode, the internal bearing cover and the external bearing cover are arranged on the inner side and the outer side of the bearing respectively, and the end cover is installed on the external circle of the bearing in a sleeving mode; a grease storage space containing a grease adding channel and a grease discharging channel is formed by the external bearing cover, the end cover and the internal bearing cover in an enclosing mode.The invention further discloses a bearing grease adding method of the auxiliary electric motor special for the wind power.When lubricating grease is initially loaded and the lubricating grease is added again in a wind field, grease adding is conducted when the electric motor rotates.The invention further discloses a wind power unit containing the auxiliary electric motor special for the wind power.By means of the auxiliary electric motor special for the wind power, the bearing grease adding method of the electric motor and the wind power unit, the use requirements of the wind-power auxiliary electric motor on the long guarantee period and high reliability are guaranteed, the special use requirement in the wind field is met, and the auxiliary electric motor special for the wind power is suitable for application and popularization.

Owner:BEIJING GENERATOR MECHANICAL & ELECTRICAL TECH

Double pressure unloading valve

PendingCN108087364AAdaptableWide range of pressure regulationServomotor componentsEngineeringHigh pressure

The invention discloses a double pressure unloading valve and relates to the technical field of hydraulic pressure. The double pressure unloading valve includes a main valve, a low pressure control pilot valve, and a high pressure control pilot valve. The main valve comprises a main valve core and a one-way valve; the low pressure control pilot valve comprises a differential motion sliding valve core, a differential motion sliding valve sleeve, a ball valve core, and a low pressure pressure-regulating spring; the high pressure control pilot valve comprises a high pressure control sliding valvecore and a high pressure pressure-regulating spring; two ends of the differential motion sliding valve core have different diameters; and the differential motion sliding valve core is separately matched with the differential motion sliding valve sleeve, a low pressure control valve body, and the ball valve core to form three cavities and three pressure bearing areas. The double pressure unloadingvalve solves the problem that a commonly used unloading valve cannot set the high pressure and the low pressure separately, a pressure detecting element or an electric control element is not requiredto be introduced, and the reliability is further improved; and compared with the traditional unloading valve, the double pressure unloading valve has higher adaptability and wider pressure-regulationrange, better energy-saving effect can be achieved, and special requirements for use can be met.

Owner:番禺珠江钢管(珠海)有限公司

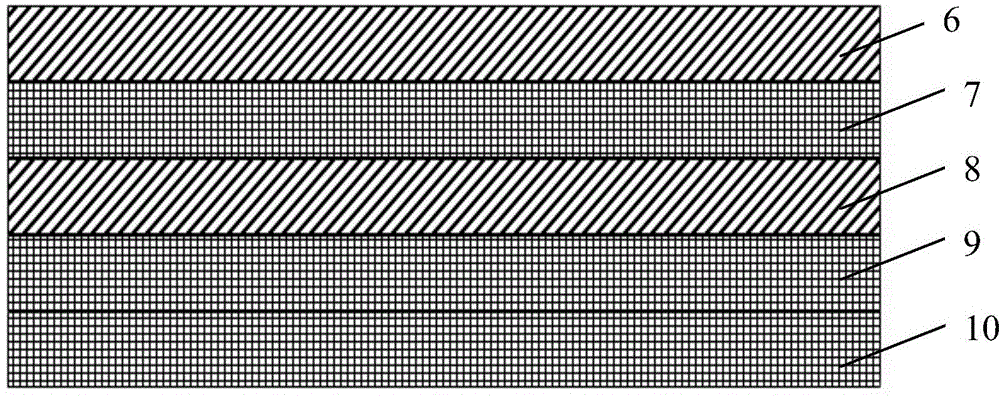

High-efficient low-cost electromagnetic shielding film and manufacturing method thereof

InactiveCN104883865ALow costGood continuityMagnetic/electric field screeningSynthetic resin layered productsElastomerElectrical resistance and conductance

The invention discloses a high-efficient low-cost electromagnetic shielding film and a manufacturing method thereof. The electromagnetic shielding film comprises: a support film layer, an ink layer coating the support film layer, and an electrical conductive adhesive layer coating the ink layer. The electromagnetic shielding film allows a simple and easy manufacture process, and can be directly produced through a conventional FPC manufacturing procedure, such as drilling and punching. The manufacturing procedure is greatly shortened; the production efficiency is improved; and the production cost is reduced. The electrical conductive adhesive layer permits the electromagnetic shielding film of excellent conductive performance, and the conductive resistance may reach 0.3 omega in an electrode of 1 cm and a bore with a diameter of 0.5 mm. The ink layer possesses excellent insulativity and frame resistance and can reach the UL94VTM-0 effect. Furthermore, rubber elastomer can be added in each layer and enables the whole electromagnetic shielding film to possess relatively high flexibility, and a special use requirement of a flexible circuit board material is satisfied.

Owner:SUZHOU CHENGBANG DALI MATERIAL TECH

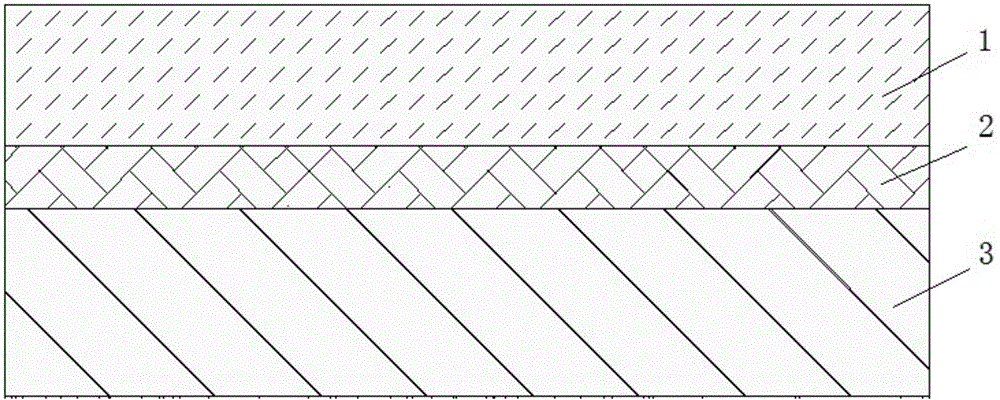

Periscopic type panoramic image imaging device and system

InactiveCN108900748AWide Field of View Pitch AngleMeet special use requirementsTelevision system detailsColor television detailsCamera lensLight sensing

The invention belongs to the technical field of lens imaging and discloses a periscopic type panoramic image imaging device and system. The periscopic type panoramic image imaging device comprises a barrel body, wherein the barrel body is internally provided with a light-sensing element for receiving a light signal reflected by a photographed object; the barrel body is internally further providedwith a camera lens assembly which is used for projecting the light signal of the photographed object to the light-sensing element; a semi-oval-shaped reflection mirror for reflecting the light signalof the photographed object at the periphery into the camera lens assembly is arranged above the barrel body; the bottom of the reflection mirror is of a sharp end shape. According to the periscopic type panoramic image imaging device and system, 360-degree panoramic information at the periphery can be obtained by adopting the reflection mirror, and the bottom of the reflection mirror is of the sharp end shape, so that a relatively wide view-field pitch angle can be obtained and the device has a 360-degree panoramic photographing function; meanwhile the periscopic type panoramic image imaging device has the relatively wide view-field pitch angle and meets special utilization requirements.

Owner:陈俊瑞

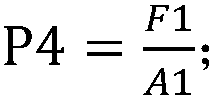

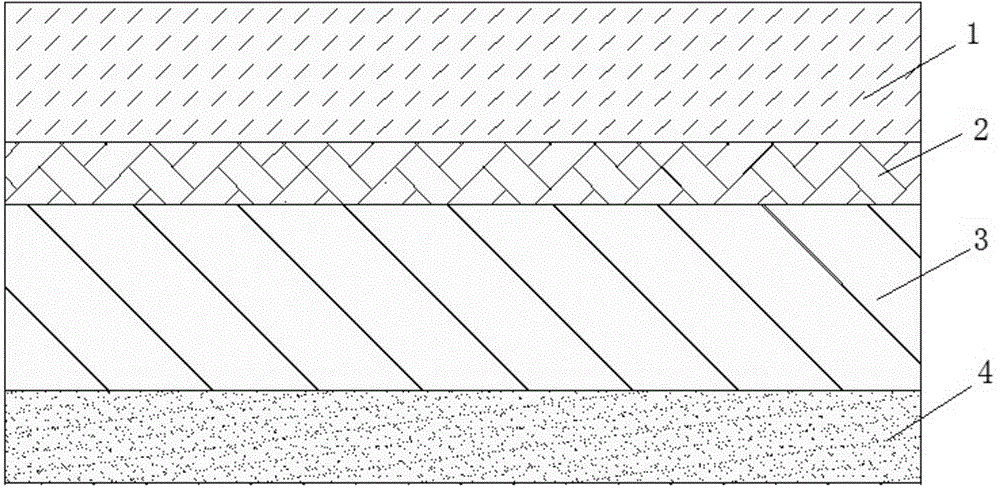

Foam composite pad base material

InactiveCN103978758AStable supportEffective distributionSynthetic resin layered productsRubber layered productsEnergy absorptionHardness

The invention provides a foam composite pad base material, which is characterized by comprising an opening foaming layer and a closed foaming layer stacked together; the opening foaming layer is a layer or multiple stacked layers, and the closed foaming layer is a layer or multiple laminated layers. The layers are firmly bonded together through an adhesive or thermal compounding. The base material provided by the invention has the energy absorption, flexibility and slow resilience of the opening foaming layer and the stability and support property of the closed foaming, is alternate hardness with softness, and comfortable and practical, and can be used as a base material for sport cushion, mattress and various leisure pads.

Owner:天津市润生塑胶制品有限公司

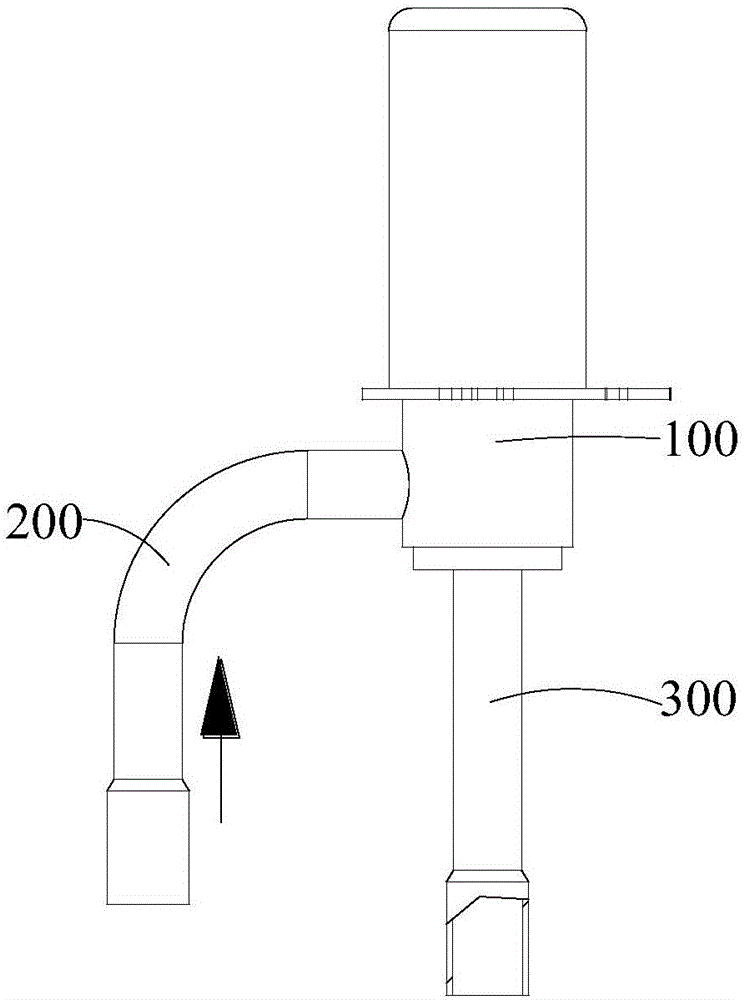

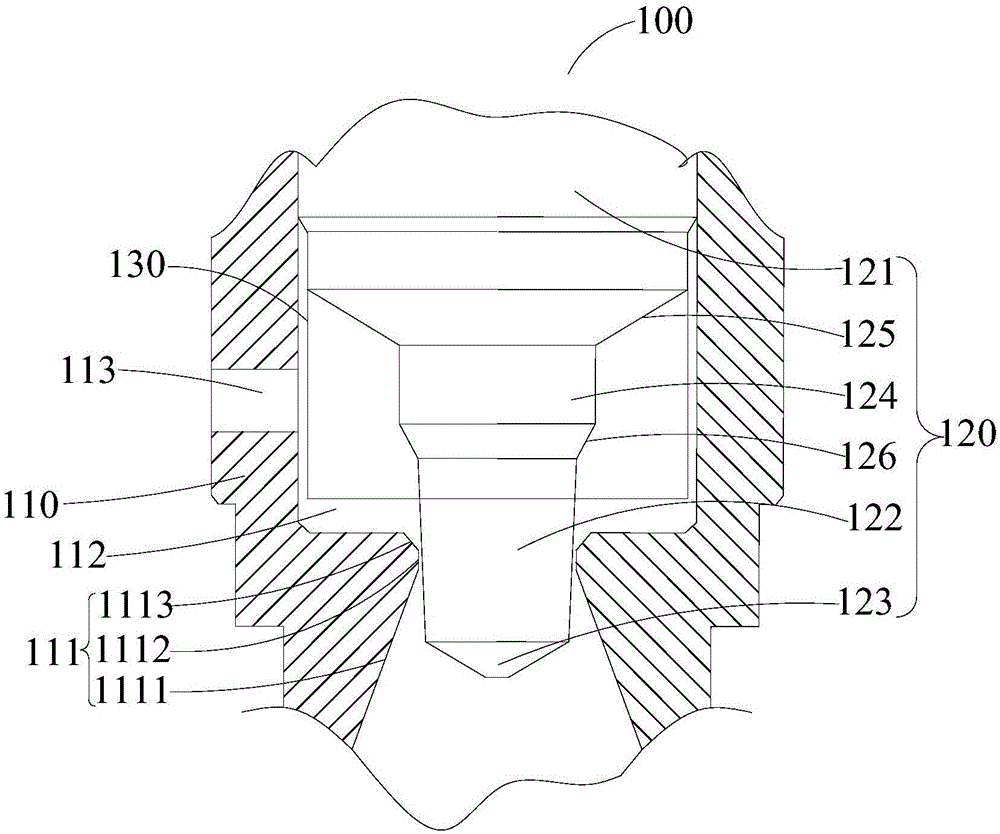

Air conditioner and electronic expansion valve of air conditioner

InactiveCN106369893ASimple structural designPrecise flow controlMechanical apparatusEfficient regulation technologiesEngineeringElectronic expansion valve

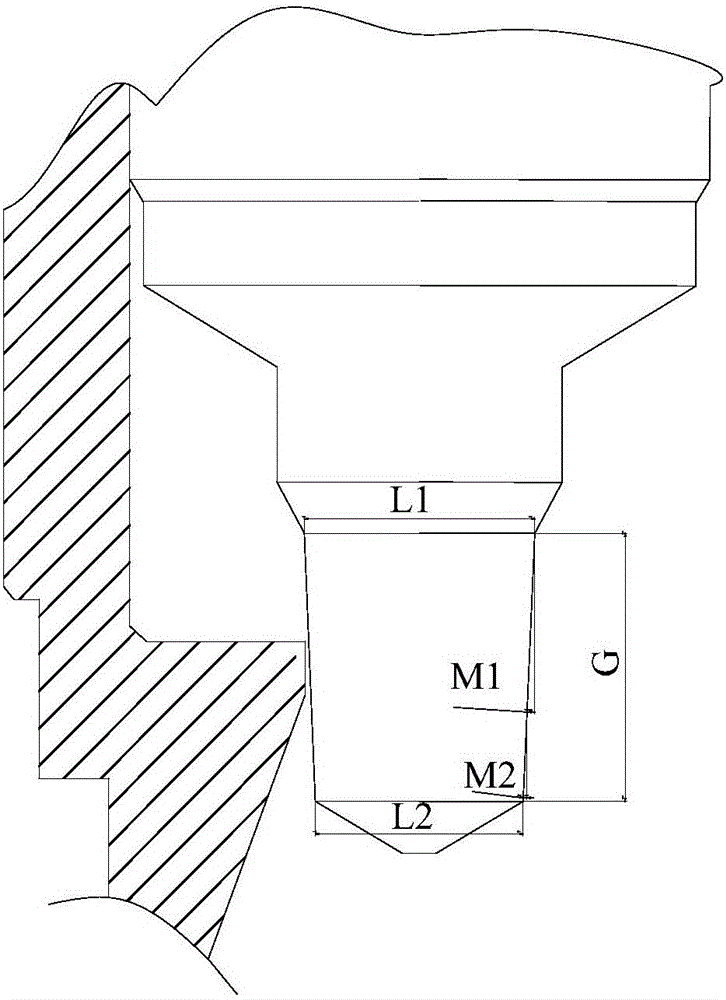

The invention further provides an electronic expansion valve. The electronic expansion valve comprises a valve element base and a valve needle. The valve element base is further provided with a valve opening. The valve needle comprises an adjusting part used for adjusting the movement of the valve needle and a throttling part used for adjusting flow of the valve opening. The throttling part is arranged in a circular truncated cone shape, and the diameter of the end, close to the adjusting part, of the throttling part is larger than the diameter of the end, away from the adjusting part, of the throttling part. Through the movement of the throttling part in the circular truncated cone shape in the valve opening, flow adjustment on the electronic expansion valve is achieved, the problem that a current electronic expansion valve cannot meet the requirements for large flow and proper flow of a refrigerant is effectively solved, and the electronic expansion valve can provide the ultra-large-flow refrigerant behind a turning point through the throttling part; and the proper flow of the refrigerant can be provided before the turning point through the throttling part, the using performance of the electronic expansion valve is improved, and running reliability of an air conditioner is guaranteed accordingly. The invention further provides the air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

Water high light wearable intaglio ink and preparing method thereof

ActiveCN100575433CStrong color loading capacityFine inkInksOther printing apparatusWater basedHigh concentration

Owner:浙江永在油墨有限公司

Technology for preparing cordierite-based continuous fiber by using sol-gel method

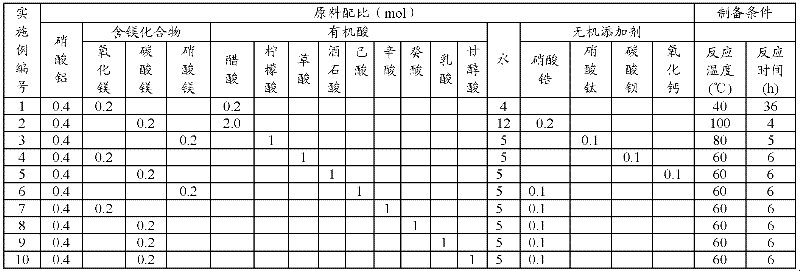

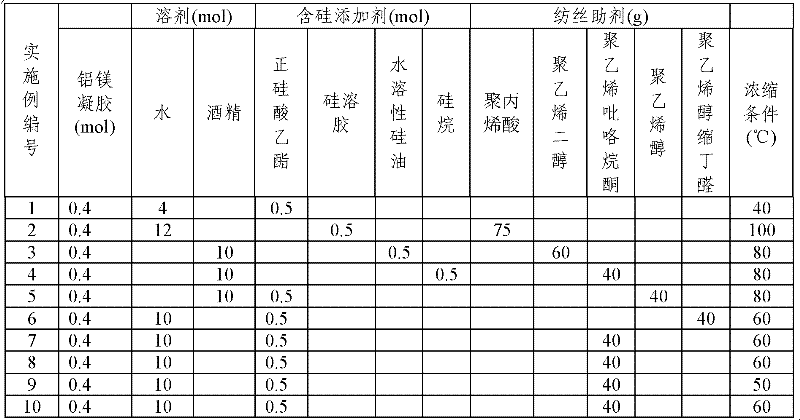

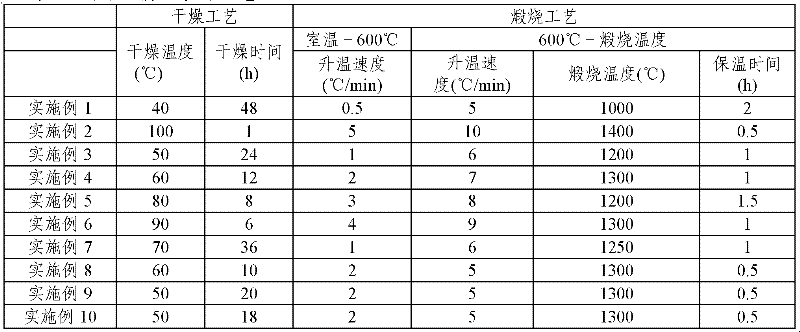

The invention discloses a technology for preparing cordierite-based continuous fiber by using a sol-gel method. According to the invention, aluminum nitrate, a magnesium-containing compound, organic acid and an inorganic additive are added to water, such that a mixed solution is formed; the mixed solution is subject to a reaction with continuous stirring under a certain temperature, such that an aluminum-magnesium gel is obtained; a certain amount of a solvent is added to the aluminum-magnesium gel, and a certain amount of a silicon-containing additive and a high-polymer spin finish aid are added to the mixture, such that a cordierite-based fiber precursor solution is obtained; the solution is condensed, such that a spinnable cordierite-based fiber precursor sol is obtained; a dry spinning method or a wet spinning method is adopted, and cordierite-based continuous fiber protofilaments containing organics are obtained; and the protofilaments are dried and sintered, such that cordierite-based continuous fiber is obtained. The cordierite-based continuous fiber can be used as reinforcement in a composite material for improving the strength and the toughness of the material, and for improving the thermal resistance of the material. The cordierite-based continuous fiber can be widely applied in fields of aeronautics and astronautics, automobiles, and industrial kilns.

Owner:SHAANXI UNIV OF TECH

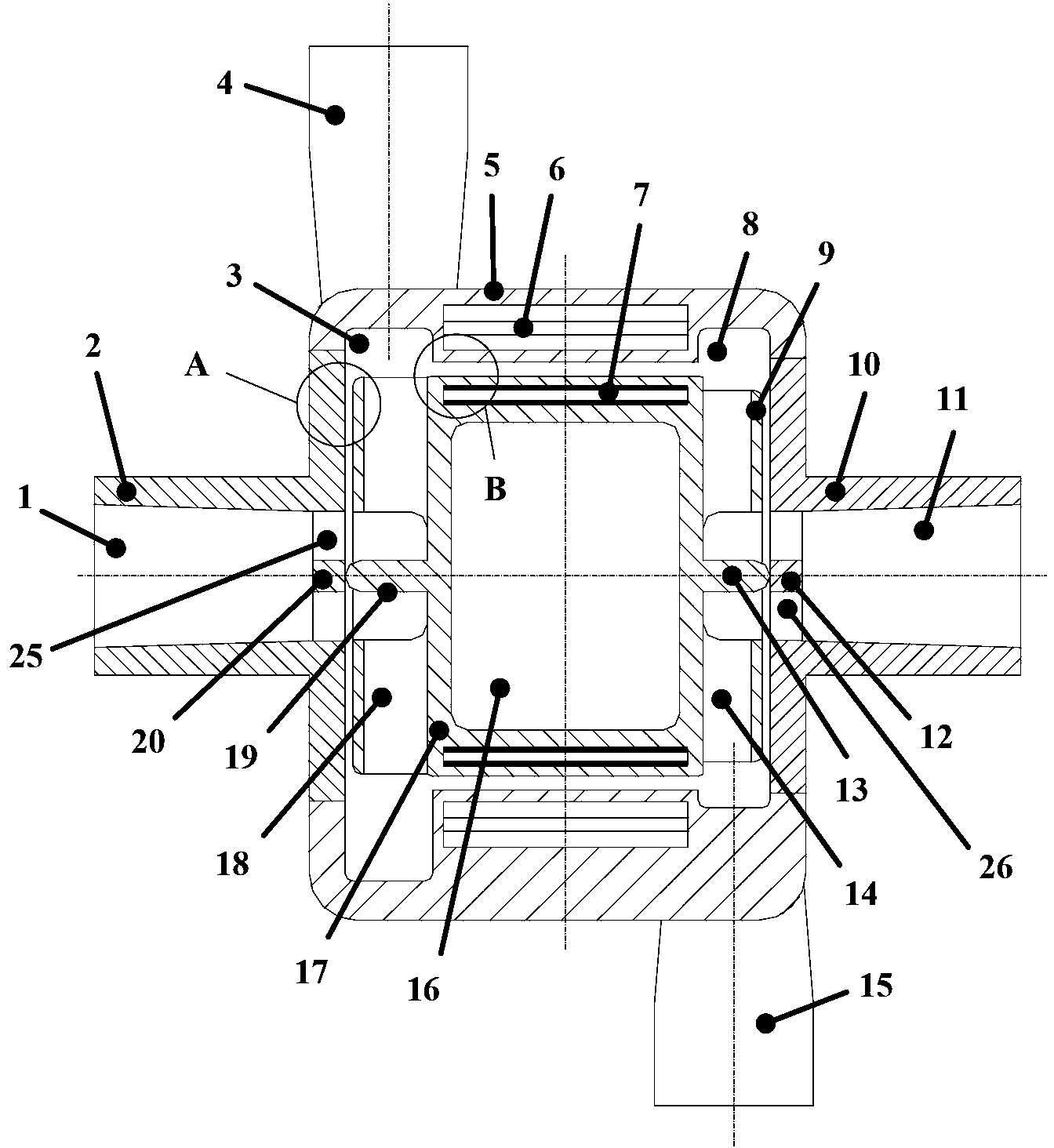

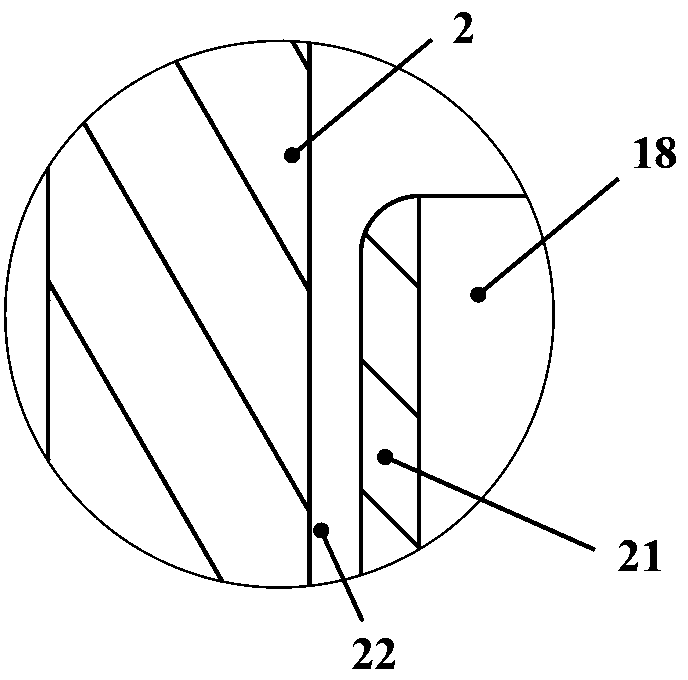

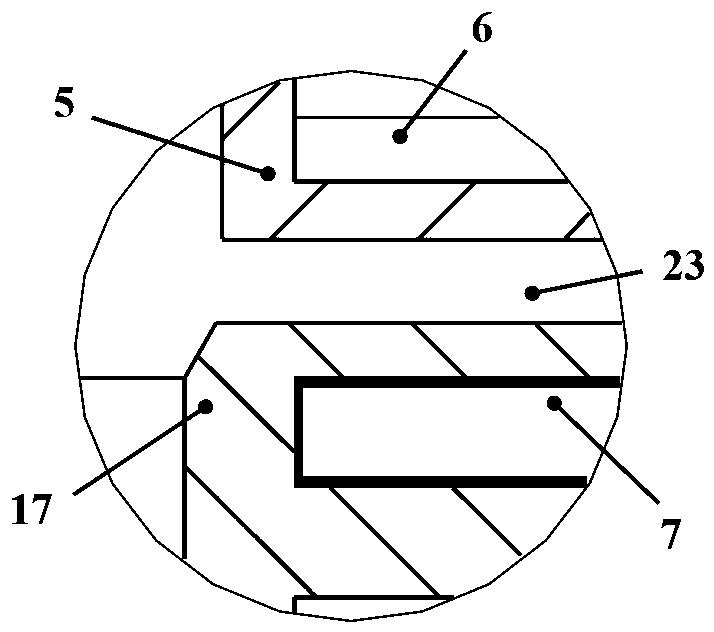

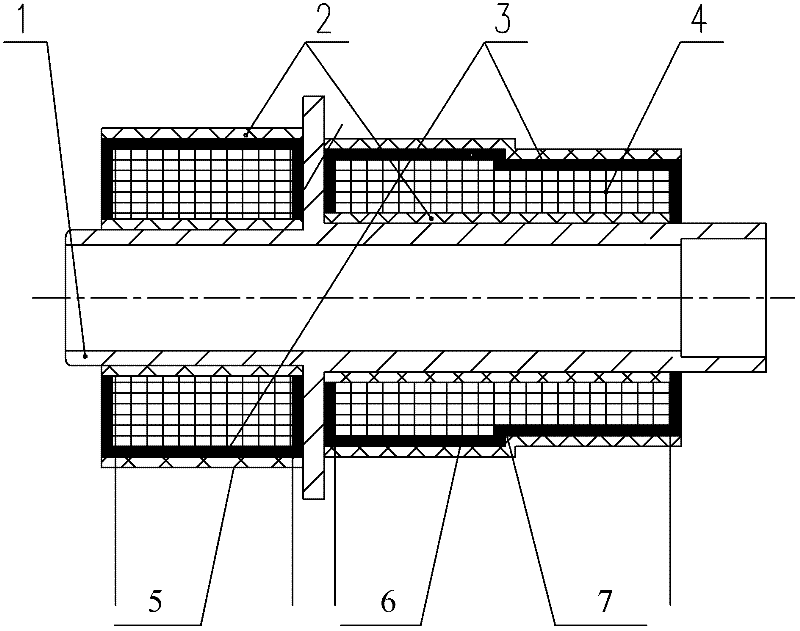

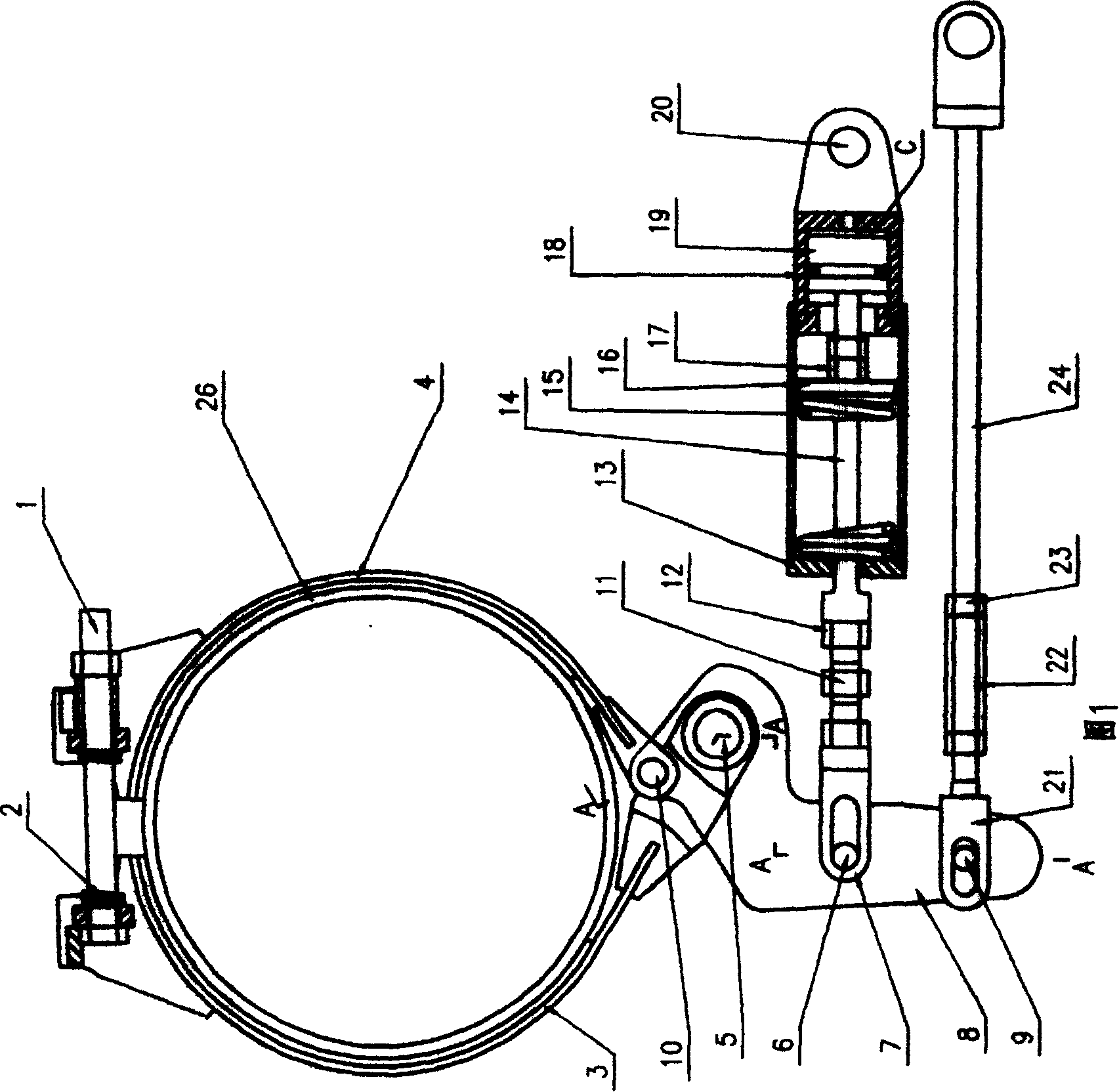

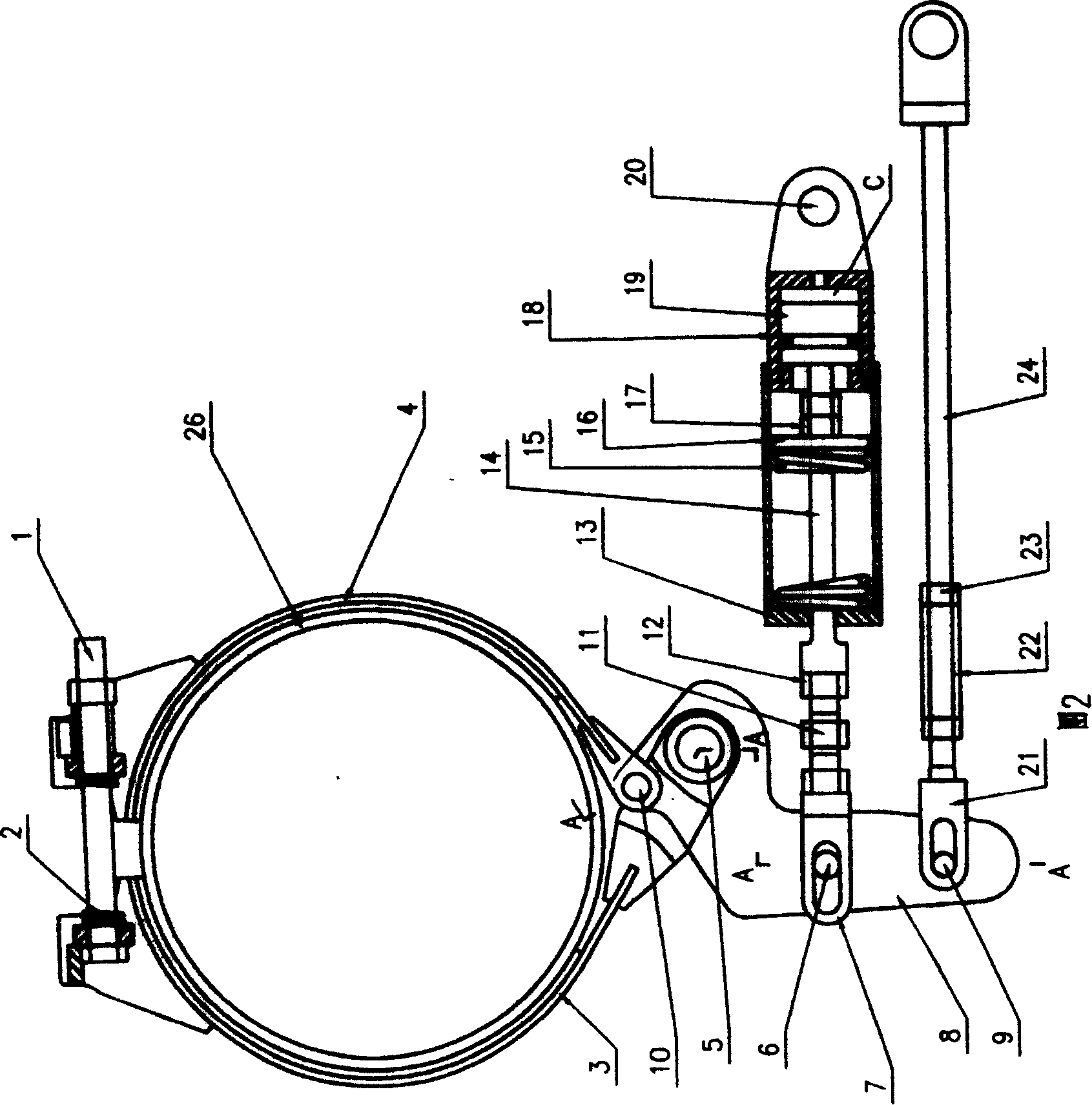

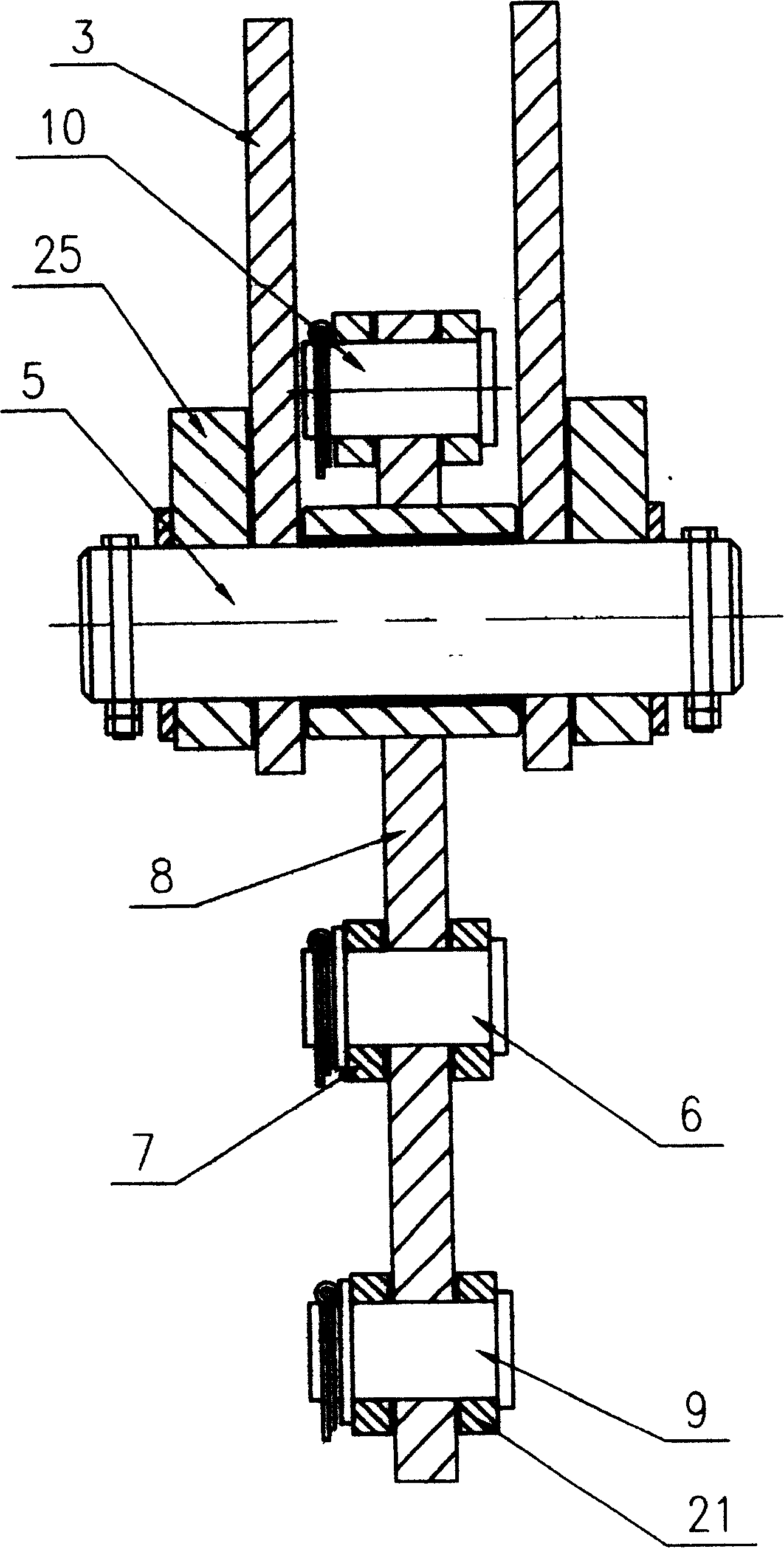

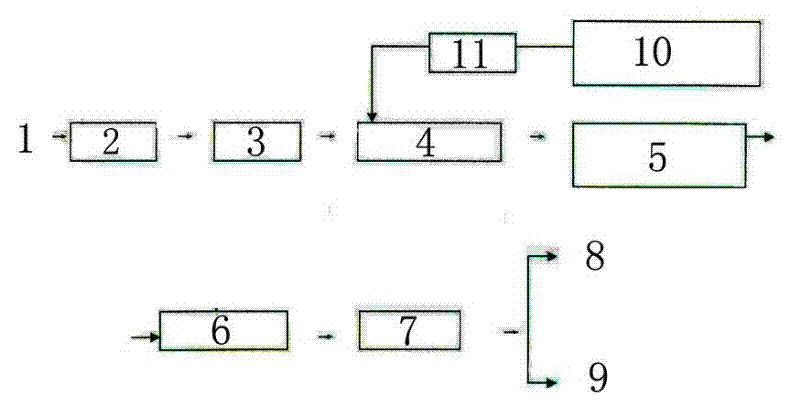

Normally engaging/disengaging dual-purpose brake device of crane

The invention discloses a crane brake, with open-close functions. It is characterized in that: the brake belts (3, 4) are coiled on the drum brake (26); one end of brake belt (3) via fixed axle (5) is fixed on the base (25); the brake belt (4) via pin (10) is connected to the bended arm (8); the bolt (1) and compress spring (2) are used to connect the brake belt (3) and the brake belt (4); the bended arm (8) via fixed axle (5) is fixed on the base (25); the cylinder (18) is fixed on the bracket (13) and via fixed axle (20) fixed on the base 925); the left end of brake spring (15) is supported on the bracket (13), while the right end via baffle plate (16) transforms the spring force to the support rod (14); the left end of support rod (14) via adjusting bolt (11) is connected to the ear plate (7); the ear plate (7) via pin (6) is connected to the bended arm (8). The invention has the advantages of simple structure, lower cost, high safety, and open-close function.

Owner:哈尔滨工程机械制造有限责任公司

Impact-resistant modified polyvinyl chloride (PVC-M) pipe material for coal mine

The invention provides an impact-resistant modified polyvinyl chloride (PVC-M) pipe material for a coal mine. The pipe material is prepared by adding a nanoscale antistatic reinforcing and tougheningmaterial and a flame-resistant material. The impact-resistant modified polyvinyl chloride (PVC-M) pipe material for the coal mine has the advantages that by fully utilizing the advantages of high strength, low cost, convenient material taking and easy processing, the electrical conductivity of nanoscale conductive carbon black and the synergistic flame-retardant smoke suppression effect of tricresyl phosphate or aluminum hydroxide and cooperating with the toughening and reinforcing material, the pipe material achieves the purpose of the safe use in the field of coal mine medium conveying and has an antistatic function, and the antistatic capacity of a pipeline is improved, so that the pipeline is suitable for the application of an underground system of the coal mine; the pipe material hasantistatic, flame-resistant, inner pressure-resistant and impact-resistant properties, compared with a traditional plastic pipeline, the pipeline is more durable and safer, and especially suitable forthe work environment, flame retardance, impact resistance and other fields which have requirements for the anti-static electricity, the use safety can be effectively improved, and the possibility ofthe safety accident injury caused by pipe bursting and air leakage due to accidental damage is reduced.

Owner:宁夏青龙塑料管材有限公司

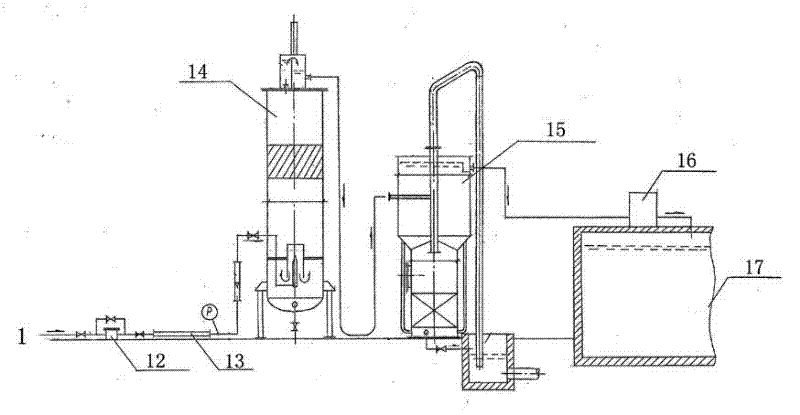

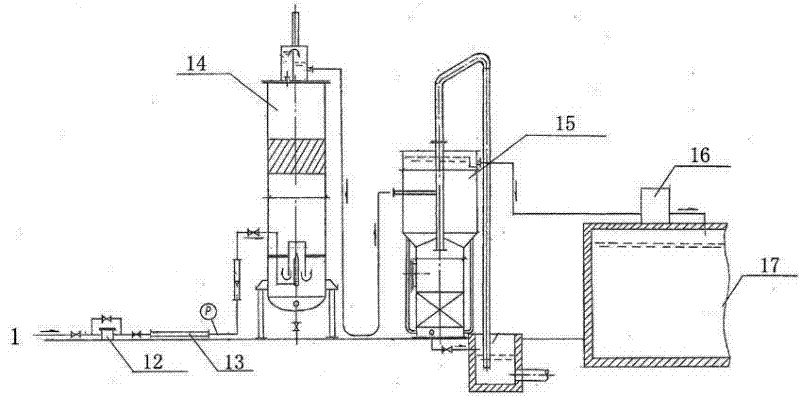

Method for performing purification treatment to surface raw water and water purifying device

InactiveCN102390900AMeet special use requirementsCompact structureMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processFlocculationAluminium sulfate

The invention relates to a method for performing purification treatment to surface raw water and a water purifying device. The method comprises the step of performing rough filtration, medicine-adding blended disinfection, flocculation precipitation, and valvedless filtration to the surface raw water with a turbidity lower than 1500mg / l, to get purified water reaching domestic water standards. The water purifying device mainly comprises a rough filter, a medicine-adding blender, a flocculation precipitator, and a valvedless filter group, wherein the medicine-adding blender is connected to the rear part of the rough filter and connected with a medicine adding device for allocating disinfection water agent through a dosing pump or a valve; the rear part of the medicine-adding blender is connected with the flocculation precipitator and the valvedless filter; the flocculation precipitator comprises a lower part for flocculation reaction and an upper part for inclined pipe precipitation; and the flocculation reaction adopts powdery aluminium chlorohydroxide or aluminium sulphate as flocculation reactant. The invention has the advantages of compact and reasonable structure, operation convenience, running stability, good treatment effect, low construction cost, lower running cost, etc., and can basically meet special use requirements of countryside and small and medium enterprises.

Owner:浙江弗莱德环境科技股份有限公司

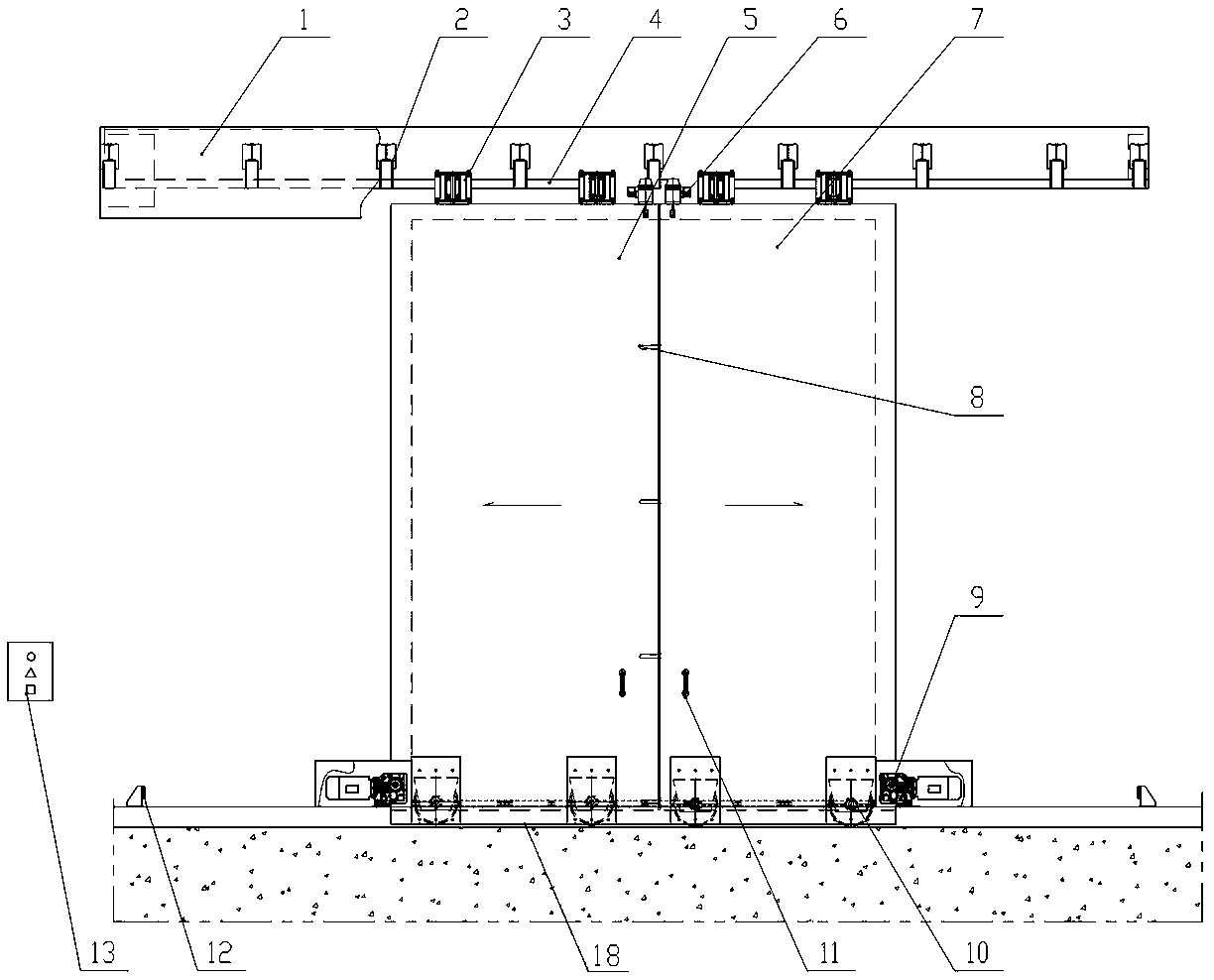

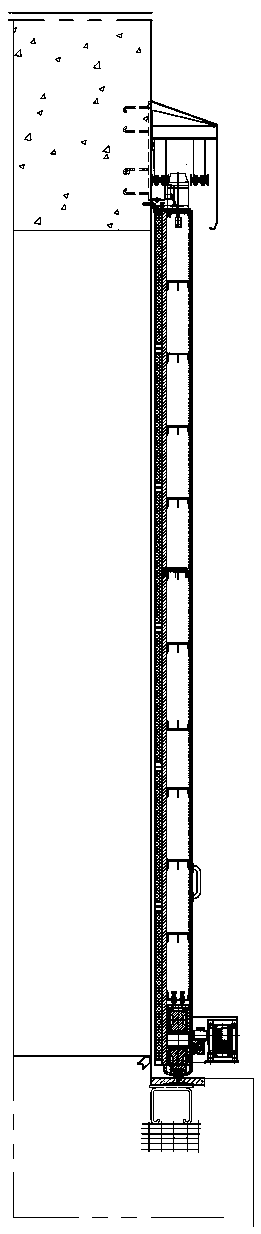

Protective door with function of resisting impact of small aircrafts

PendingCN109914990AImpact resistanceRealize anti-theft functionRadiation protectionFireproof doorsElectromagnetic lockDrive motor

The invention discloses a protective door with a function of resisting the impact of small aircrafts. The protective door comprises a left side door and a right side door; the bottoms of the left sidedoor and the right side door roll on a lower guide rail respectively by means of two travelling wheels; the tops of the left side door and the right side door roll on an upper guide rail respectivelyby means of two upper guide wheels; the left side door and the right side door are respectively provided with drive motors used for driving the travelling wheels to rotate; two electromagnetic locksare arranged on the wall above a middle door seam when the left side door and the right side door are in a closed state; lock holes, corresponding to the two electromagnetic locks, are respectively formed in the tops of the left side door and the right side door; an enhancement structure is arranged between the opposite sides of the left side door and the right side door. The whole structural strength of the protective door is improved, and the protection intensity of the protective door is especially improved when the protective door is closed; the protective door has the functions of resisting the impact of the small aircrafts, resisting the wind pressure of tornado, and defending flying projectiles of the tornado, thus meeting the special use requirements of a nuclear power plant for the protective door.

Owner:JIANGSU LONGTENG DOOR IND

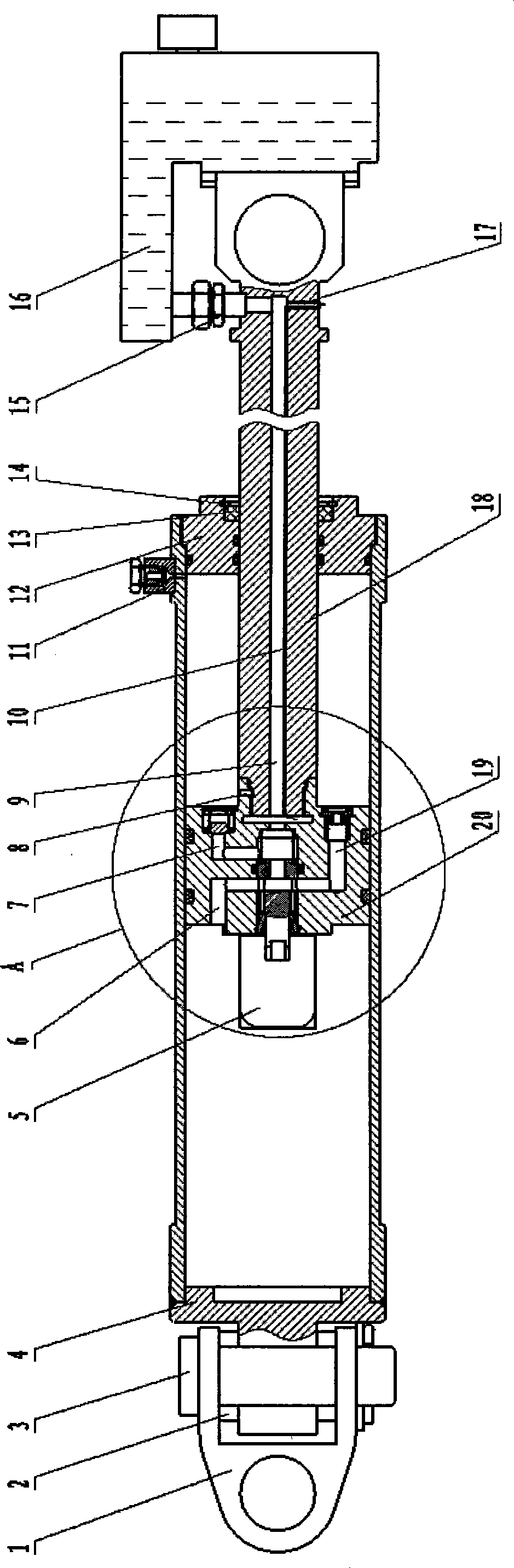

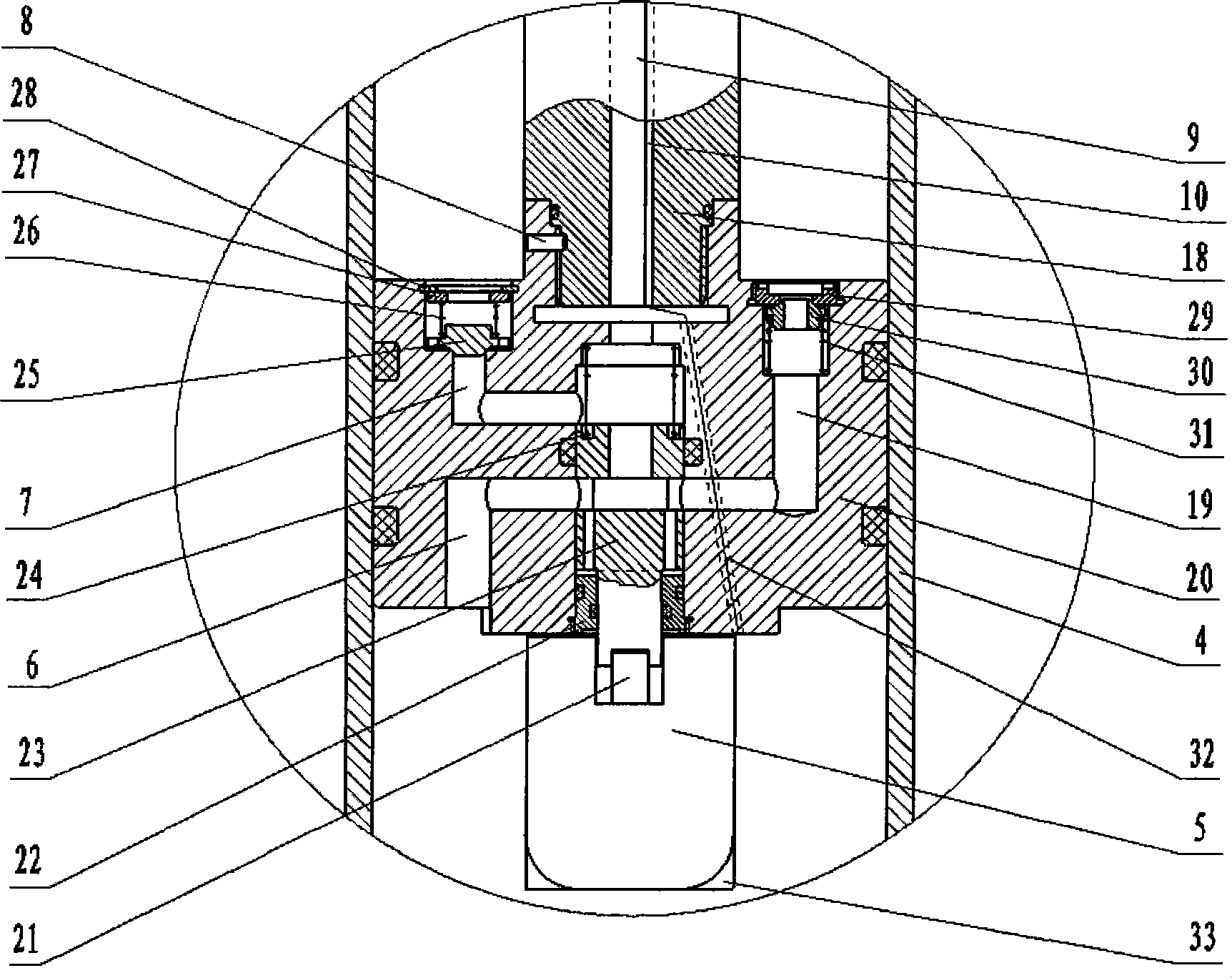

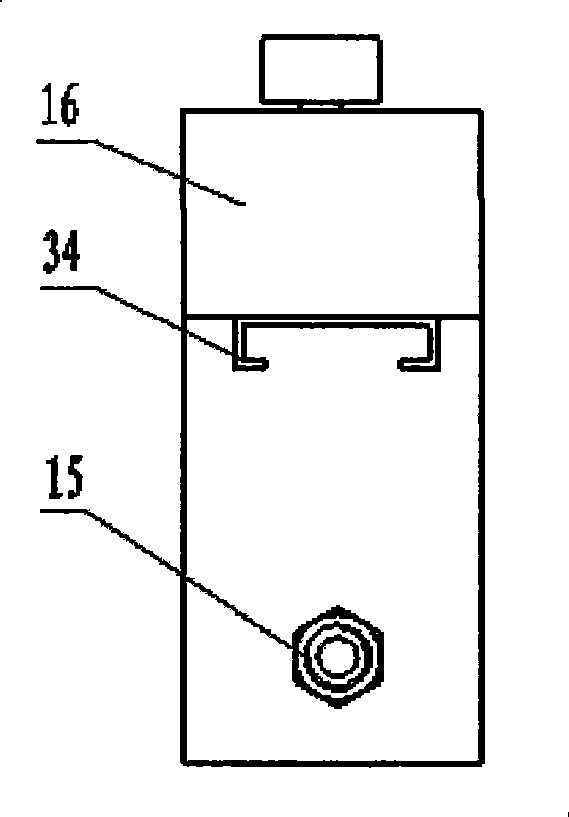

Vibration-damping and locking integrating device of chassis suspension fork of vehicle

InactiveCN101519026ASimple working processCompact structureResilient suspensionsHeavy dutyRolling chassis

The invention relates to a vibration-damping and locking integrating device of a chassis suspension fork of a vehicle, in particular to a vibration-damping and locking device of a chassis suspension fork of a vehicle. The vibration-damping and locking device mainly comprises a piston rod, a cylinder, a piston, a lock valve, a DC electromagnet, an oil tank, and the like. The device is arranged between a vehicle body and an axle, has the characteristics of compact structure, less space occupation, convenient installation, high sensitivity and reliability, low cost, and the like, can complete the bilateral rigid locking and vibration damping of the chassis suspension fork of a vehicle and can adapt to the severe atmosphere of a vehicle chassis. The device can be widely used as a vibration-damping and locking device of the chassis suspension forks of various vehicles, is suitable for vehicles with compact structural space, and particularly suitable for being used as the vibration-damping and locking devices of the chassis suspension forks of special vehicles, special purpose vehicles and heavy-duty vehicles, thereby satisfying the special use requirements of the vehicles.

Owner:CHONGQING UNIV +1

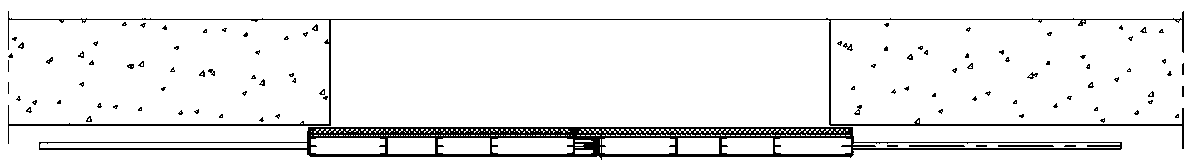

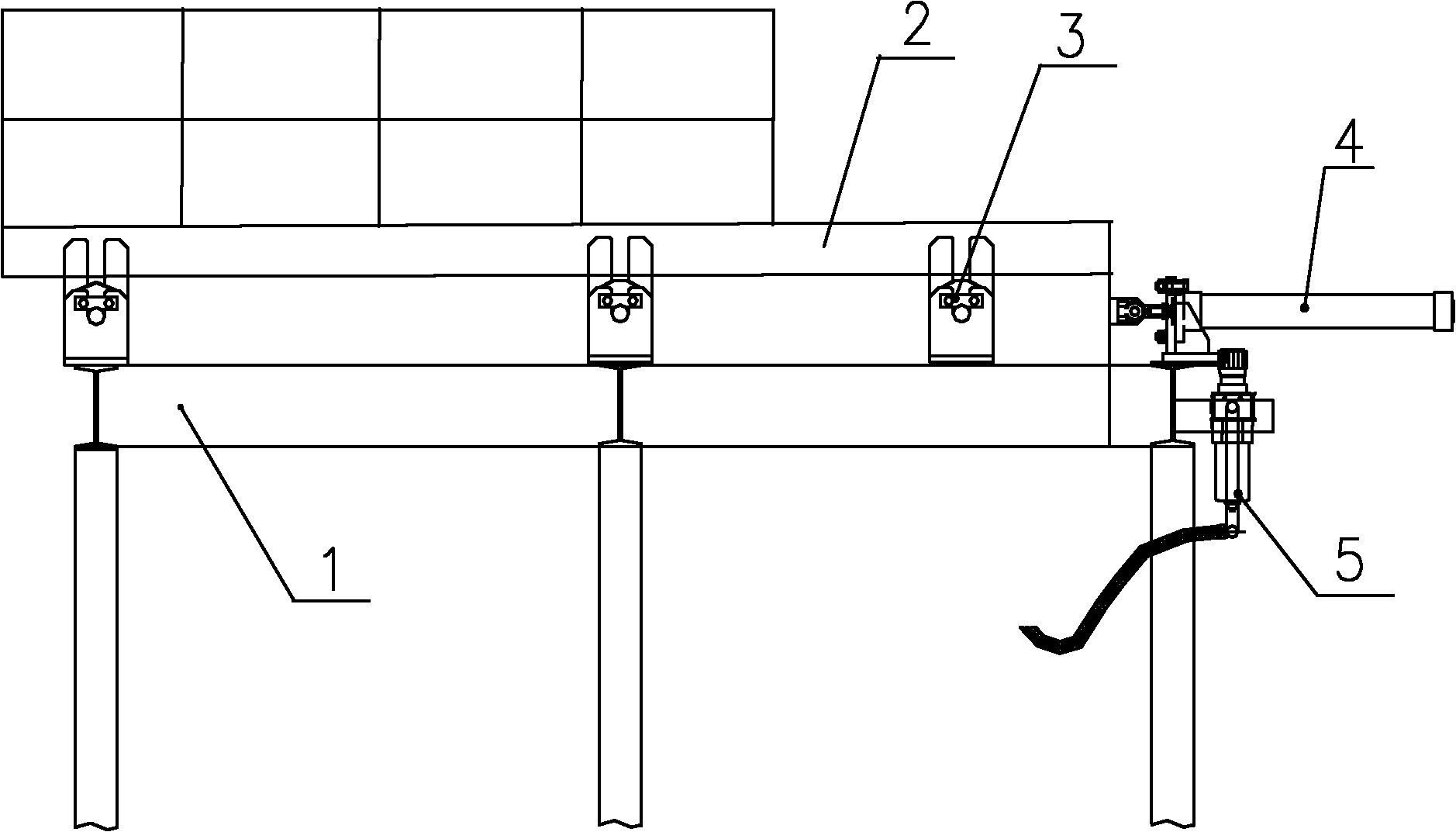

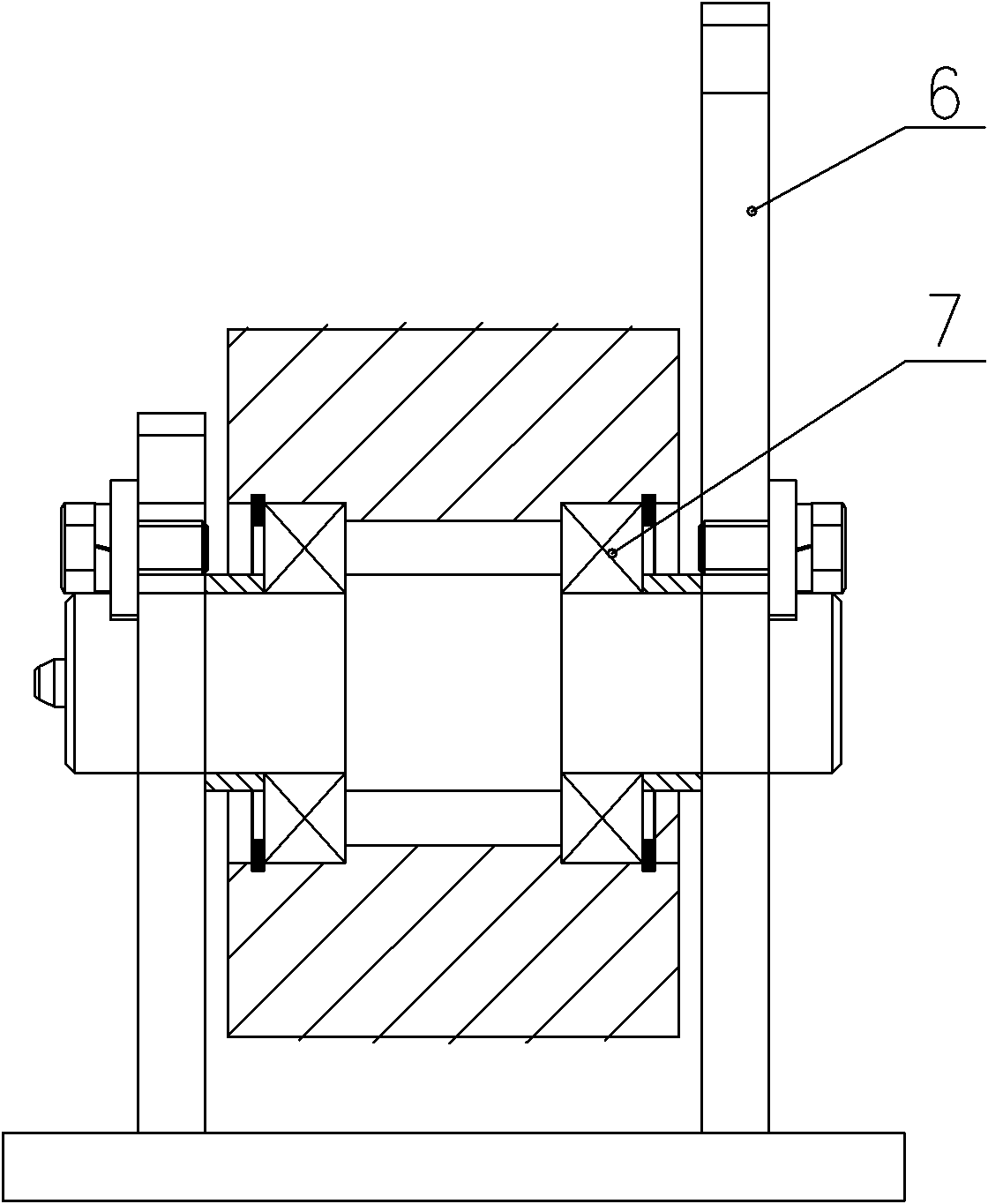

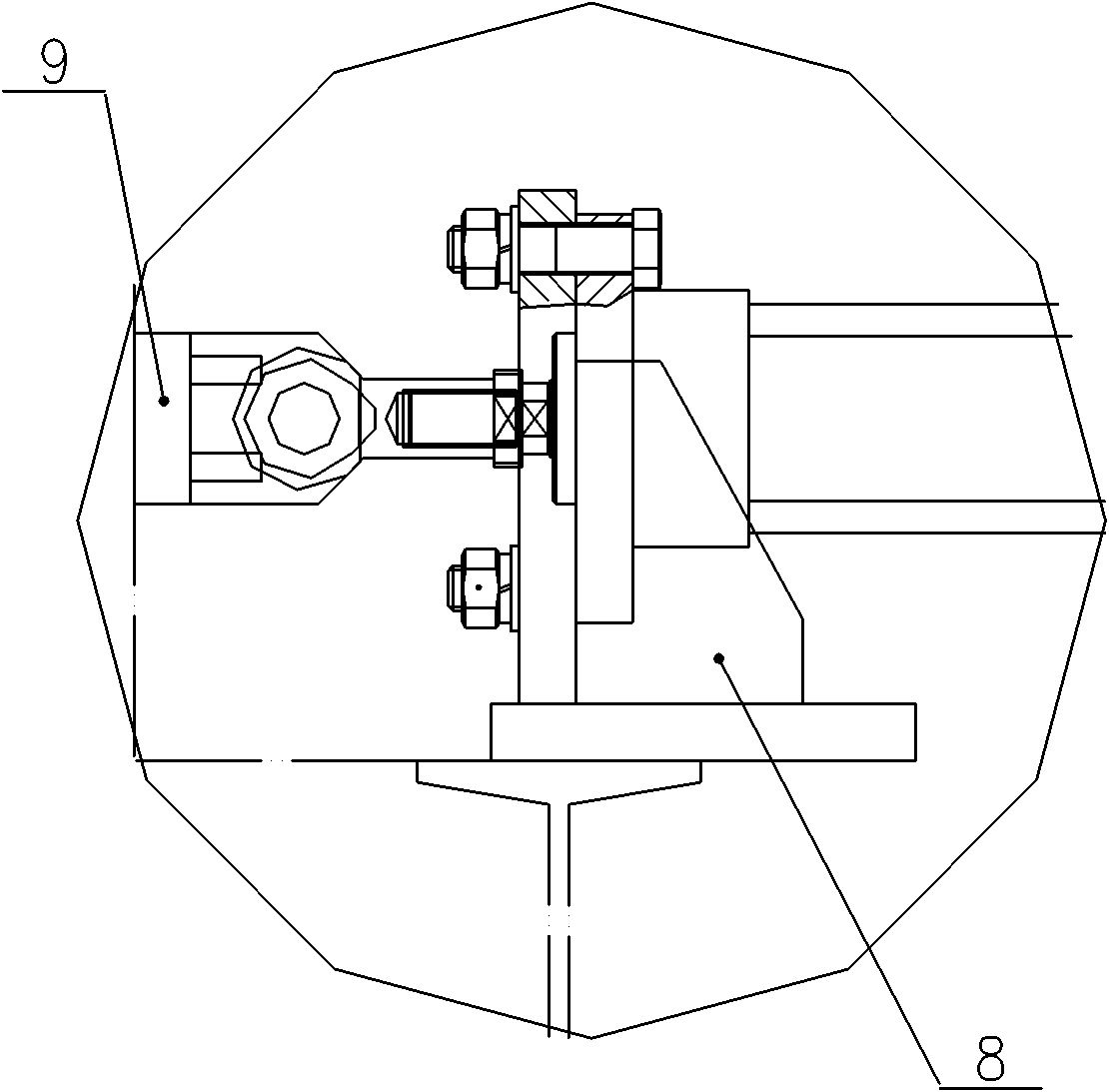

Movable operation platform for installing hydraulic cylinder of ladle slide gate

ActiveCN102069184AMeet special use requirementsGuaranteed uptimeMelt-holding vesselsHydraulic cylinderEngineering

The invention relates to a movable operation platform which mainly comprises a fixed platform (1), a movable platform (2) and a pneumatic system, wherein the pneumatic system is used for driving the movable platform (2) to move forward or backward, the bottom of the movable platform (2) is provided with a roller wheel (3) and a positioning hook, the movable platform is movably supported on the fixed platform (1) by the roller wheel (3), and when the movable platform (2) moves to a finishing point on the fixed platform (1), the movable platform (2) is hooked to the bottom of the fixed platform(1) by the positioning hook so as to prevent the movable platform (2) from tilting. The movable operation platform provided by the invention is reliable in operation, and can satisfy the convenience requirements for installing a hydraulic cylinder of a slide gate and replacing fault ladles, therefore, the movable operation platform has a good application prospect in installing the hydraulic cylinder of the movable gate of a continuous casting machine and replacing the fault ladles.

Owner:WISDRI ENG & RES INC LTD

Modified PP automobile special material and production method thereof

The invention discloses a modified PP (polypropylene) automobile special material which comprises the formula of resin matrixes PPH and PPB, reinforcing filler talcum powder, high-density polyethylene HDPE, toughening agent EOC, age resister, compatilizer and master batch according to the parts by weight: 5-10 pats of PPH (homo polypropylene), 90-95 parts of PPB (co-polypropylene), 20-40 parts ofactive talcum powder or talc grain, 5-10 parts of HDPE (high-density polyethylene), 2-8 parts of EOC (flexibilizer), 0.3-0.6 part of age resister, 2-8 parts of PP-g-MA (compatilizer) and 2-4 parts of master batch. In the above formula, the sum of PPH (homo polypropylene) and PPB (co-polypropylene) is equal to 100 parts, and the PPH (homo polypropylene) and PPB (co-polypropylene) are both granular substance; the active talcum powder or talc grain is processed by silane coupling agent, and liquid paraffin is added; the age resister mainly comprises master antioxidant, slave antioxidant and uvioresistant agent which are all powdery substance; the color of the master batch is determined according to product requirements, and the master batch is granular substance. The invention utilizes the principle that solubility parameters are similar; other polymers and various auxiliary agents, such as age resister, compatilizer, flexibilizer, fillers and the like are added into the PP material and carry out molten mechanical mixing at certain temperature so as to obtain a new material applied on lorry parts.

Owner:CHINA FIRST AUTOMOBILE

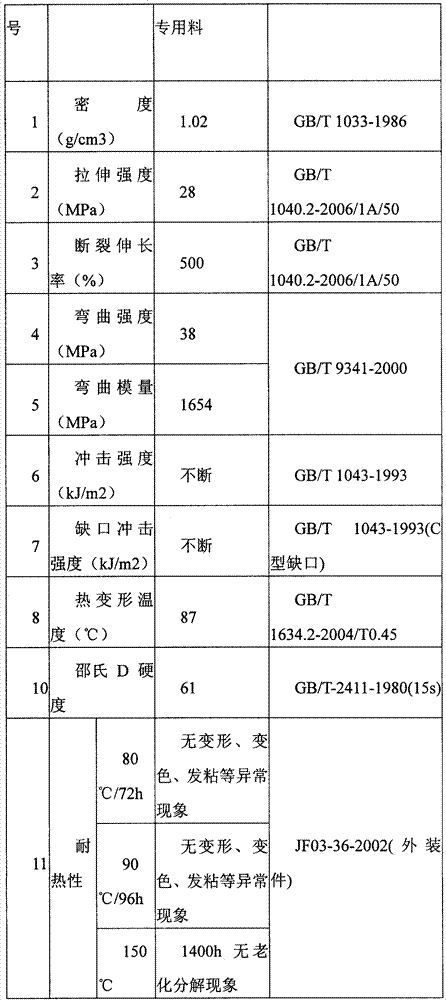

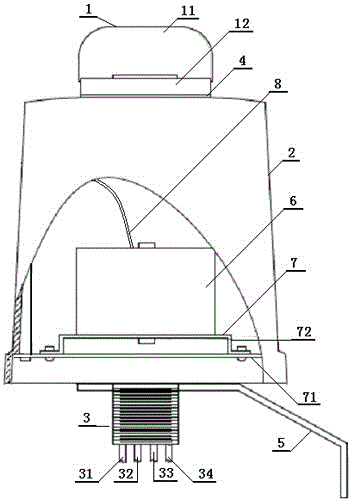

High-power photoelectric controller

ActiveCN105163438ASimple and scientific structureReduce the number of settingsElectric light circuit arrangementAutomatic controlLoad capacity

The invention relates to a high-power photoelectric controller. The high-power photoelectric controller comprises a shell, an electronic type optical controller, an optical controller base, a high-power relay and an electric connection socket, wherein a power supply input interface, a grounding interface and a control output interface are arranged on the optical controller base; and a power supply input and control output connection interface is arranged on the electric connection socket. Because the high-power relay is additionally arranged between the control output end and the load end of the existing electronic type optical controller, the optical controller has several times of, even more than several tenfold of, load capacity of the conventional electronic type optical controller; therefore, facilities are simplified easily; the arrangement cost is reduced easily; simultaneously, the high-power photoelectric controller has the load capacity of single-contact turnover output control and double-contact alternative output control; therefore, the special use requirement that continuous works of loads are automatically controlled by the photoelectric controller can be realized through a method for alternatively controlling double loads to work alternatively; the high-power photoelectric controller has the characteristics of being high in load capacity, wide in application range and convenient to use; the high-power photoelectric controller is a major innovation of the existing electronic type optical controller; and thus, the high-power photoelectric controller has high practicability.

Owner:上海西艾爱电子有限公司

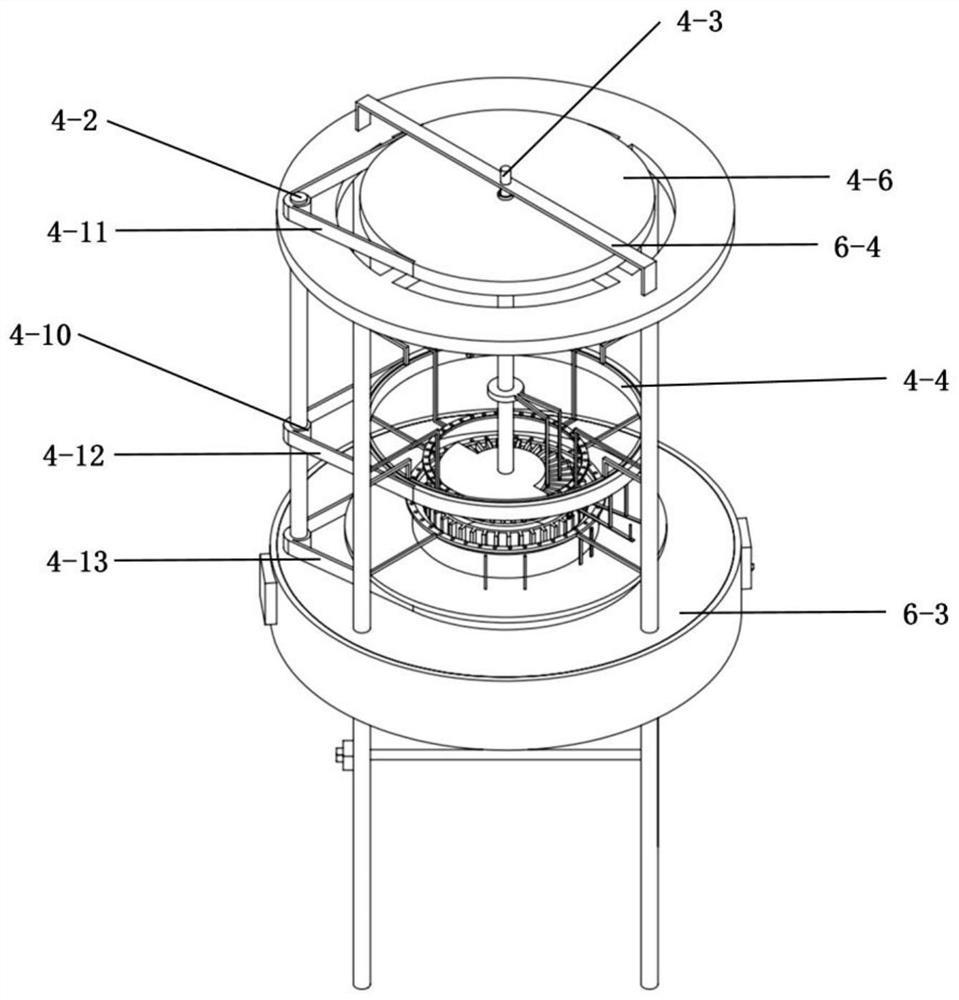

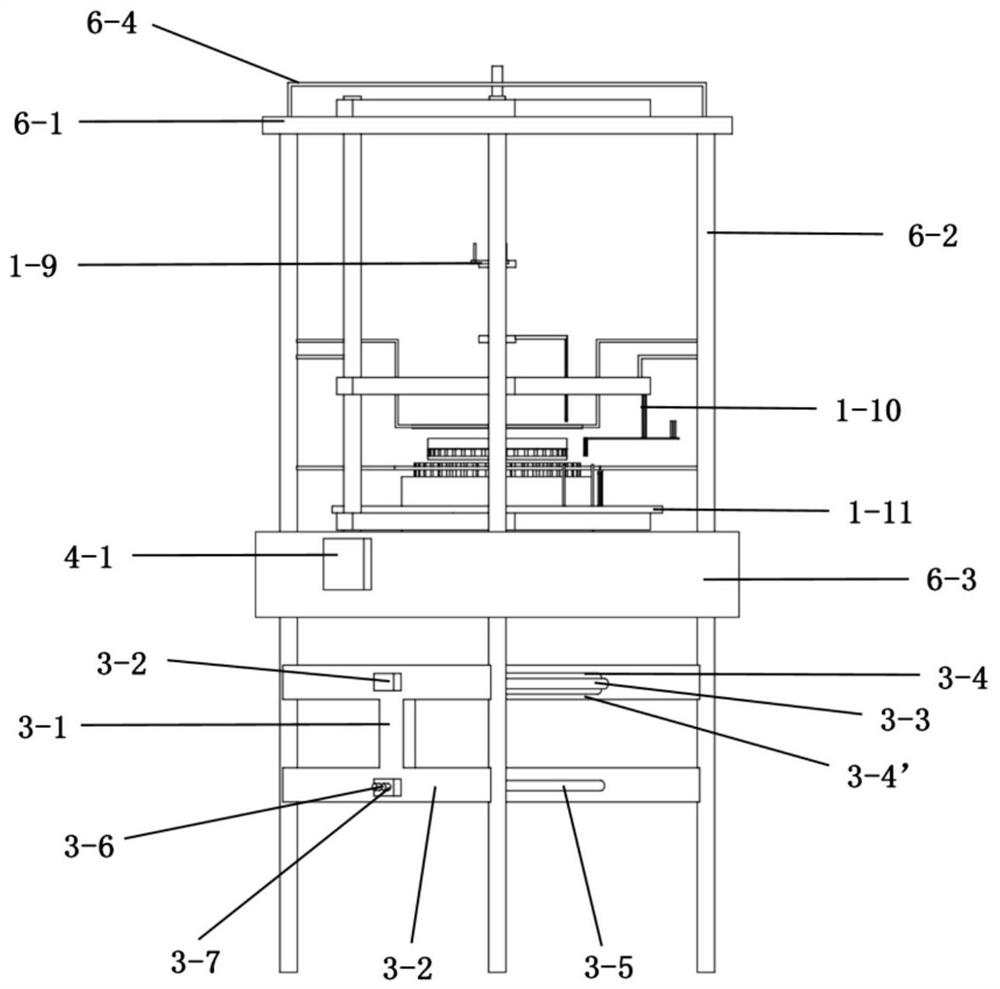

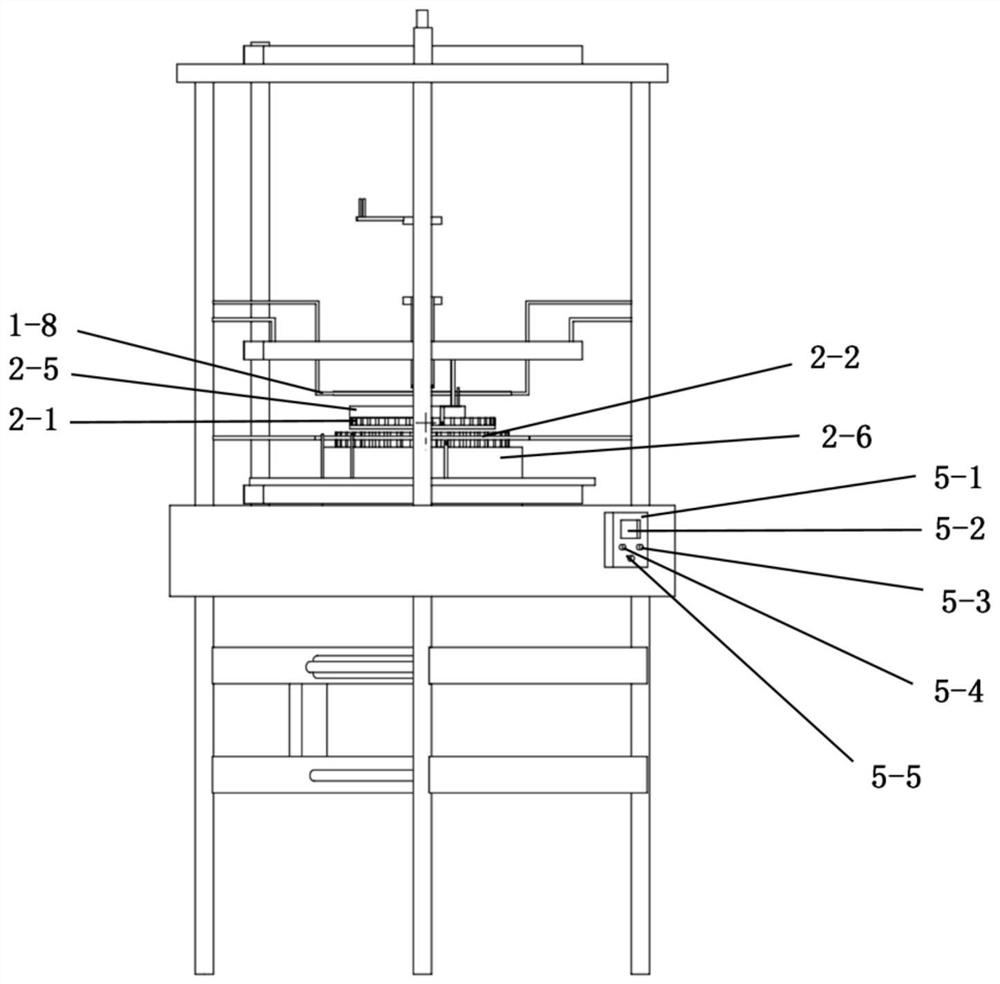

Weft-knitted multi-layer warp-inserted and weft-inserted tubular fabric as well as knitting method and special circular weft knitting machine thereof

ActiveCN113186638AFlexible designImprove structural stabilityWeft knittingStructural engineeringWeft yarn

The invention discloses a weft-knitted multi-layer warp-inserted and weft-inserted tubular fabric as well as a knitting method and special circular weft knitting machine thereof, and belongs to the field of spinning. The circular weft knitting machine comprises a yarn feeding mechanism, a knitting mechanism, a traction and winding mechanism, a transmission mechanism, a control mechanism, a rack and an auxiliary device, wherein the yarn feeding mechanism comprises yarn guides and creels of rib knitting yarns, rib front plaiting yarns, rib back plaiting yarns, a first group of weft insertion yarns, a second group of weft insertion yarns and a third group of weft insertion yarns, a first group of warp insertion yarn guide discs, a second group of warp insertion yarn guide discs and a warp insertion yarn creel; and the transmission mechanism comprises a main transmission shaft, a dial fixed shaft, a middle fixed shaft, a needle cylinder fixed shaft, a dial large gear, a dial fixed shaft sleeve, a middle fixed shaft sleeve, a needle cylinder fixed shaft sleeve, a main transmission shaft sleeve, a dial belt pulley, a middle belt pulley, a needle cylinder belt pulley and the like. According to the invention, the tubular fabric inserted with two layers of warp yarns and three layers of weft yarns can be woven, and the problems that the number of layers of the warp yarns and the weft yarns inserted in the weft-knitted warp-lined and weft-lined tubular fabric is small and the thickness is small are solved.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com