Normally engaging/disengaging dual-purpose brake device of crane

A dual-function, crane technology, applied in the direction of hoisting device, etc., can solve the problem of large braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

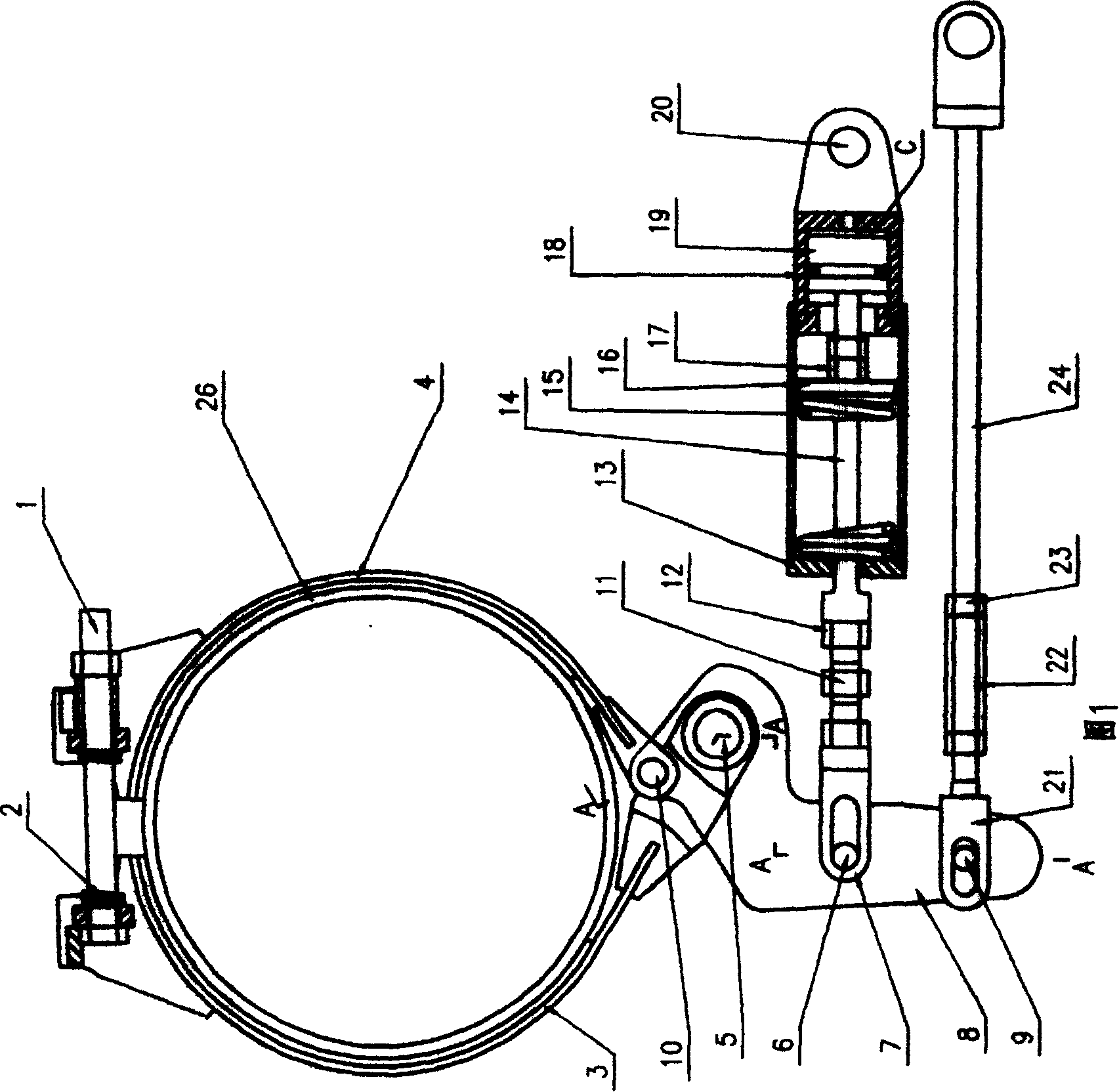

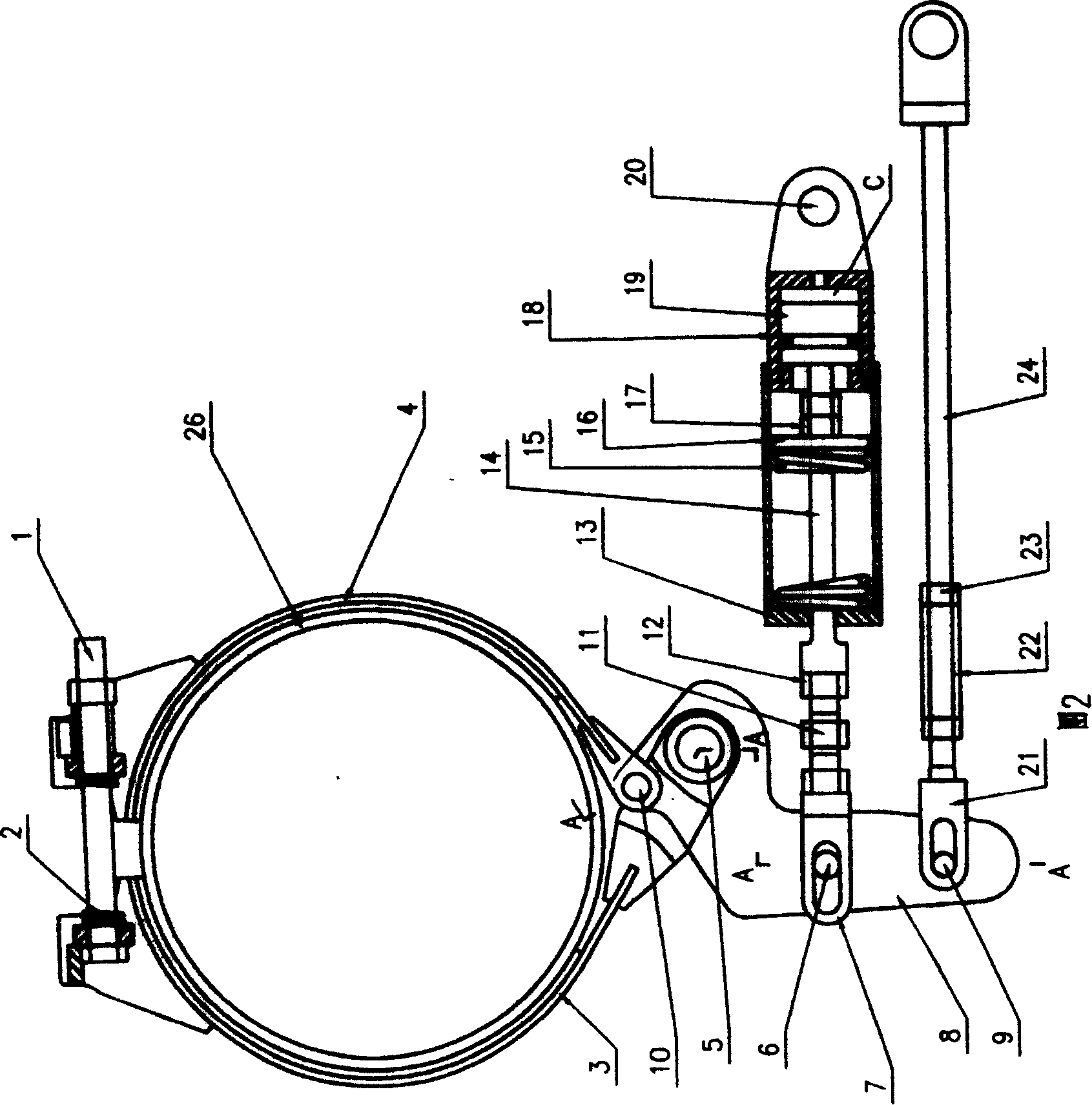

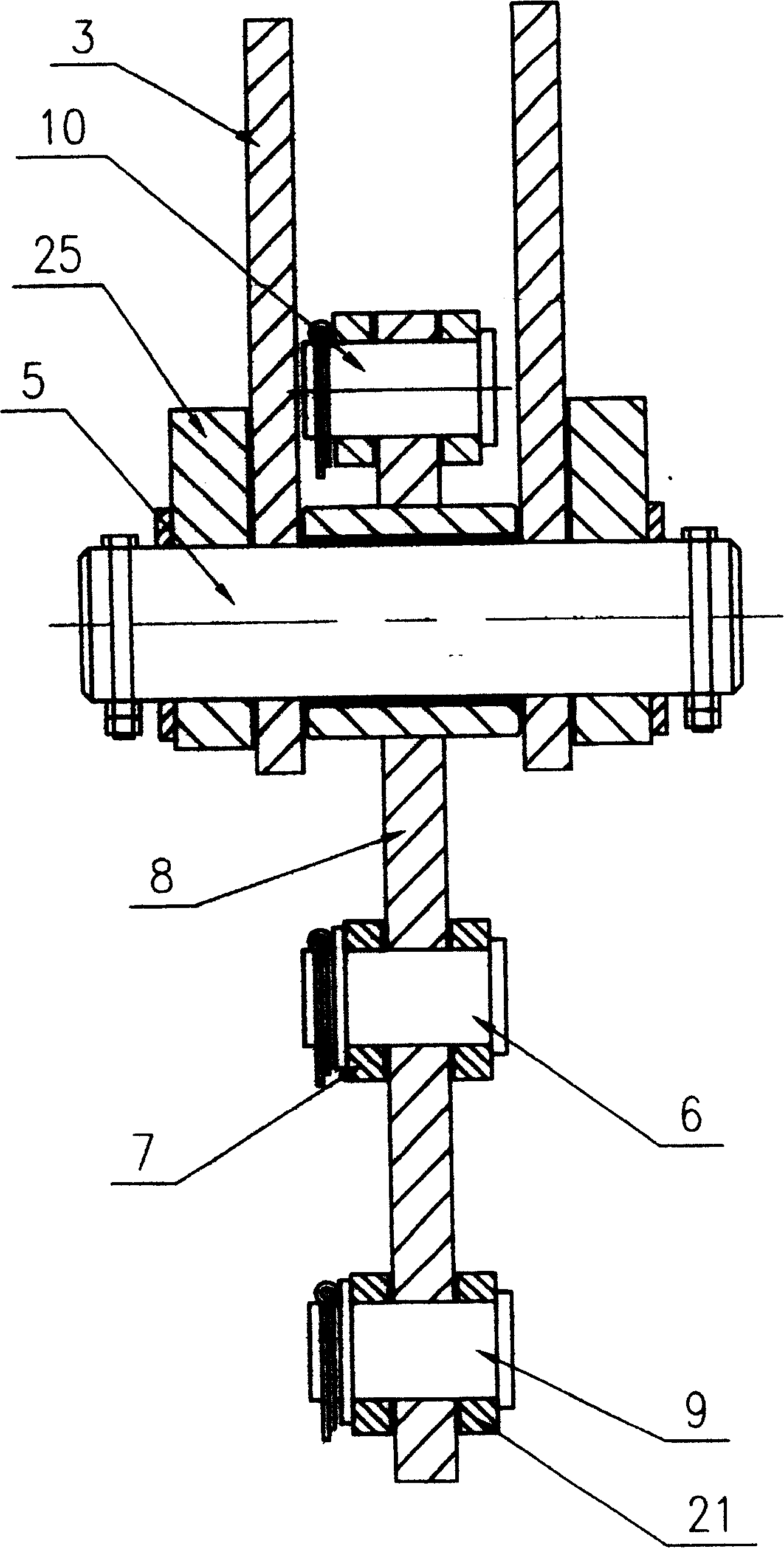

[0005] The brake band 3 and the brake band I 4 are wrapped on the reel brake drum 26, one end of the brake band 3 is fixed on the base 25 through the fixed shaft 5, and the brake band I 4 is connected with the crank arm 8 through the pin shaft II 10 , the bolt 1 and the stage clip 2 are used to connect the brake band 3 and the brake band 14, the crank arm 8 is fixed on the base 25 through the fixed shaft 5, and the oil cylinder 18 is fixed on the bracket 13 and fixed on the machine through the fixed shaft 20. On the seat 25, the left end of the brake spring 15 is pushed against the bracket 13, and the right end transmits the spring force to the tappet 14 through the baffle plate 16, and the left end of the tappet 14 is connected with the ear plate 7 through the adjusting bolt 11, and the ear plate 7 passes through the pin 6 is connected with crank arm 8. Ear plate 7 is an elongated hole. Working process of the present invention: pin shaft, lug plate, crank arm, pin shaft I, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com