Weft-knitted multi-layer warp-inserted and weft-inserted tubular fabric as well as knitting method and special circular weft knitting machine thereof

A tubular fabric, circular weft machine technology, applied in weft knitting, textiles, papermaking, knitting, etc., can solve the problems of few layers of interposed warp and weft yarns, uneven fabric structure, and small number of weft yarns, and achieves flexible design. , The effect of good weaving performance and high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

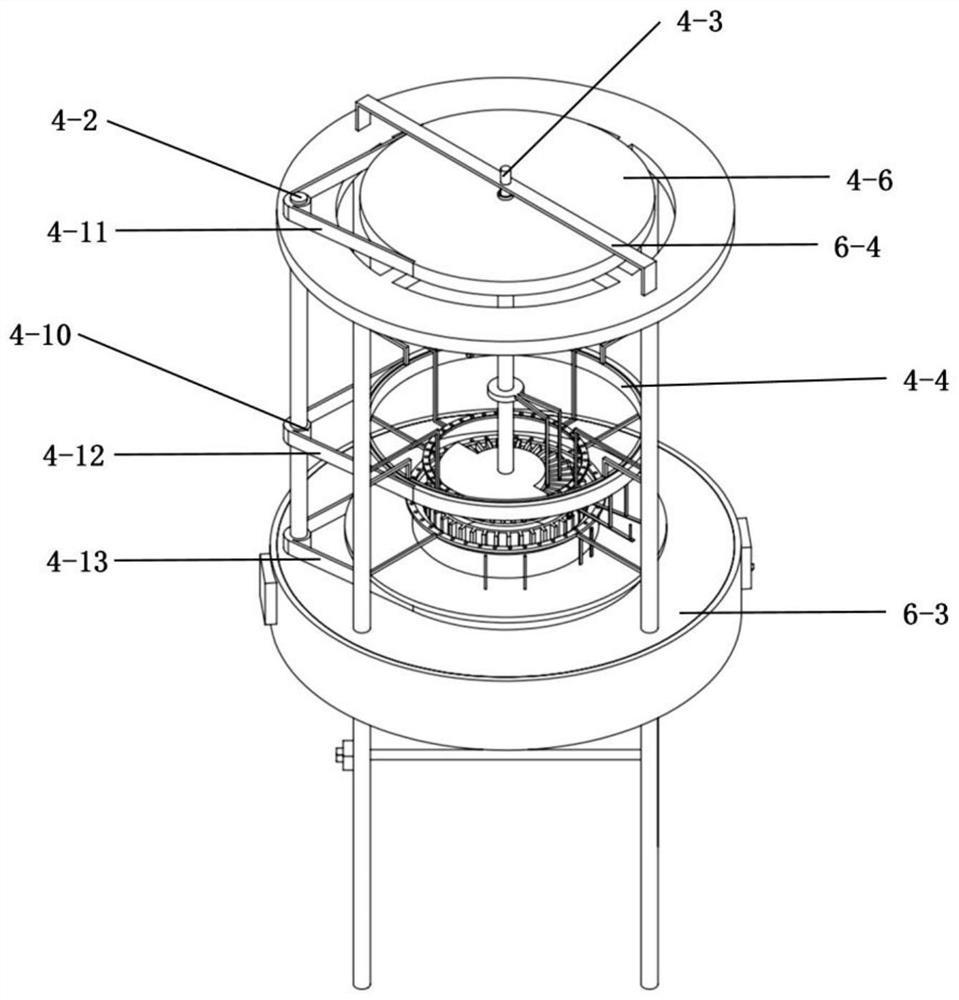

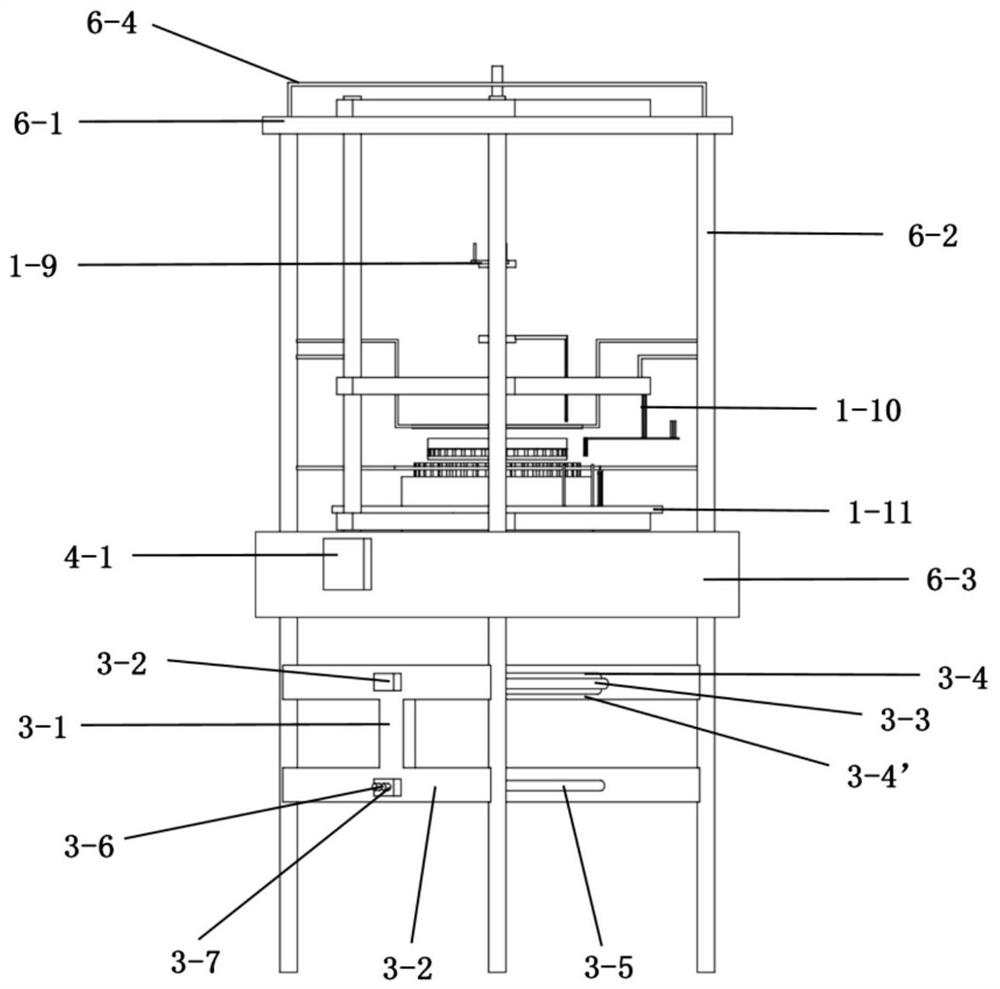

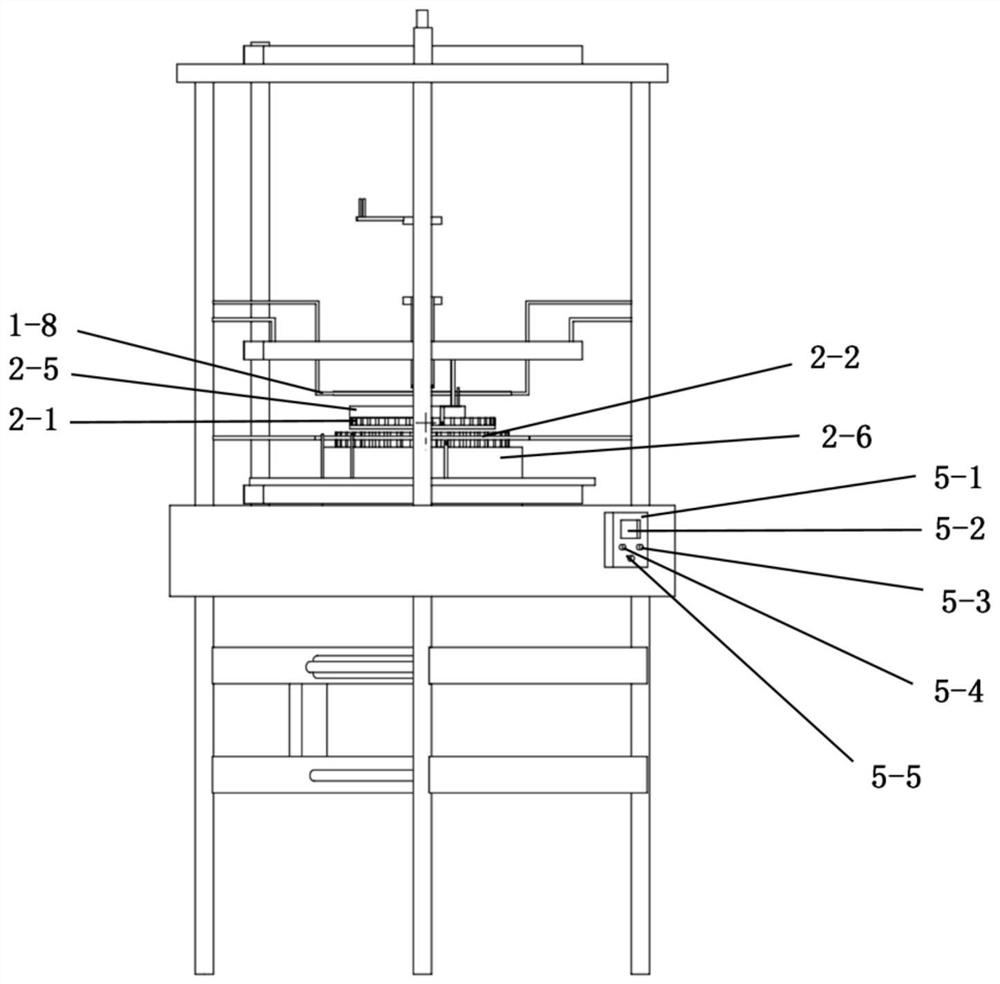

[0061] A circular weft knitting machine for weft-knitting multi-layer warp-lined and weft-lined tubular fabrics, such as Figure 1-Figure 6 As shown, it includes a yarn feeding mechanism 1, a weaving mechanism 2, a pulling and winding mechanism 3, a transmission mechanism 4, a control mechanism 5, a frame 6, and auxiliary devices;

[0062] Yarn feeding mechanism 1: weaving yarn guide 1-1, rib front plating yarn guide 1-2, rib back plating yarn guide 1-3, the first set of weft insertion yarn guide 1-4, the second The first group of interlining weft yarn guides 1-5, the third group of weft interlining yarn guides 1-6, the first group of interlining warp yarn guide discs 1-7, the second group of interlining warp yarn guide discs 1-8, dial creel 1-9, intermediate creel 1-10, needle cylinder creel 1-11, dial yarn guide frame 1-12. The bobbins of the first group of inserted weft yarns 12, rib front plating 8 and their yarn guides 1-4, 1-2 are arranged sequentially on the cylinder c...

Embodiment 2

[0074] A kind of method utilizing the circular weft machine described in embodiment 1 to weave weft-knitted multi-layer warp-lined and weft-lined tubular fabrics, such as Figure 9 shown, including the following steps:

[0075] (1) Starting position: dial 2-1 and cylinder 2-2 have just completed the knitting process of the previous cycle, and dial needle 2-3 and cylinder needle 2-4 are at the innermost and lowest positions respectively ;

[0076] (2) Knitting back: the dial cam seat 2-5 and the needle cylinder cam seat 2-6 rotate synchronously, driving the dial cam and the needle cylinder cam to rotate synchronously, and the needle disc knitting needles 2-3 and the cylinder knitting needles 2-4 Under the action of the needle triangle on the dial and the needle cylinder, respectively, move from the initial position to the outermost and the highest position, the old loops on the dial knitting needles and cylinder knitting needles (old rib loops and plating yarns) Circle) 7-1',...

Embodiment 3

[0082] The weft-knitted multi-layer warp-lined and weft-lined tubular fabric prepared by a method of embodiment 2, such as Figure 8 to Figure 11 Shown:

[0083] The weft-knitted multi-layer warp-lined and weft-lined tubular fabric structure has a binding system of 1+1 rib weave 7, including rib front loops 7-1 and rib reverse loops 7-2, and rib front loops 7-1 and rib reverse loops. The stitches 7-2 are connected by adjacent rib stitch sinkers 7-7 of each course. Rib front plating 8 is lined in front of the rib front coil 7-1, the front of the fabric shows rib front plating 8, rib front plating sinker arc 8-3 connects two adjacent rib front coils 7-1; rib reverse plating 9 Lined into the back of the rib back stitch 7-2, the back of the fabric shows the rib back plating 9, and the rib back plating sinker arc 9-3 connects two adjacent rib back stitches 7-2. The first group of interlining warp yarns 10 is lined between two adjacent rib front coil posts 7-3, and the second grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com