Inorganic nano polymer modified high-strength plastic and preparation method thereof

A high-strength plastic and inorganic nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as stress defects, cracks in materials, compatibility defects, etc., and achieve mechanical Improved performance and wear resistance, enhanced effect of external force, and easy-to-control response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

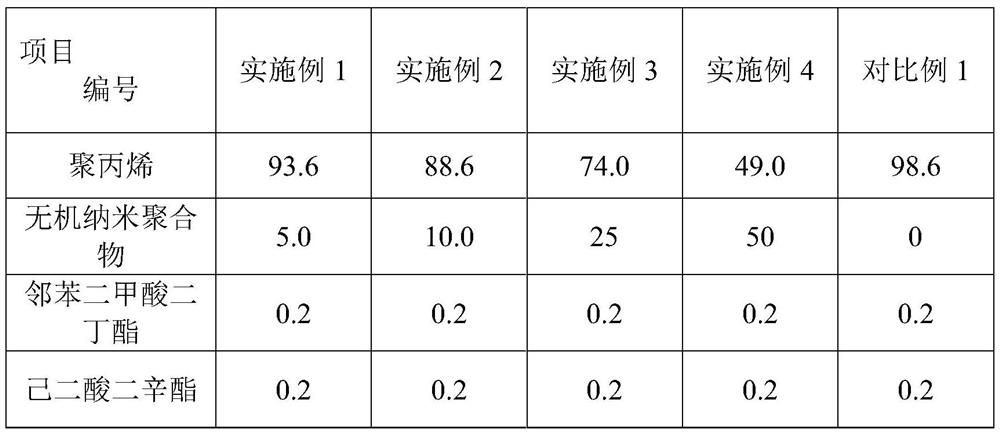

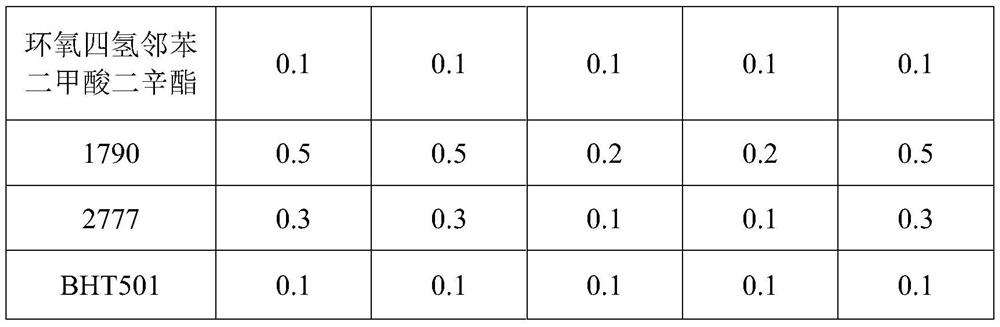

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments.

[0034] 1. The embodiment of the present invention provides an inorganic nanopolymer modified high wear-resistant rubber.

[0035] (1) Preparation of inorganic nanopolymers

[0036] S1: Take 10 parts of methyltriethoxysilane at room temperature, add 2 parts of lauric acid soap and stir for 30 minutes to form a silane mixture;

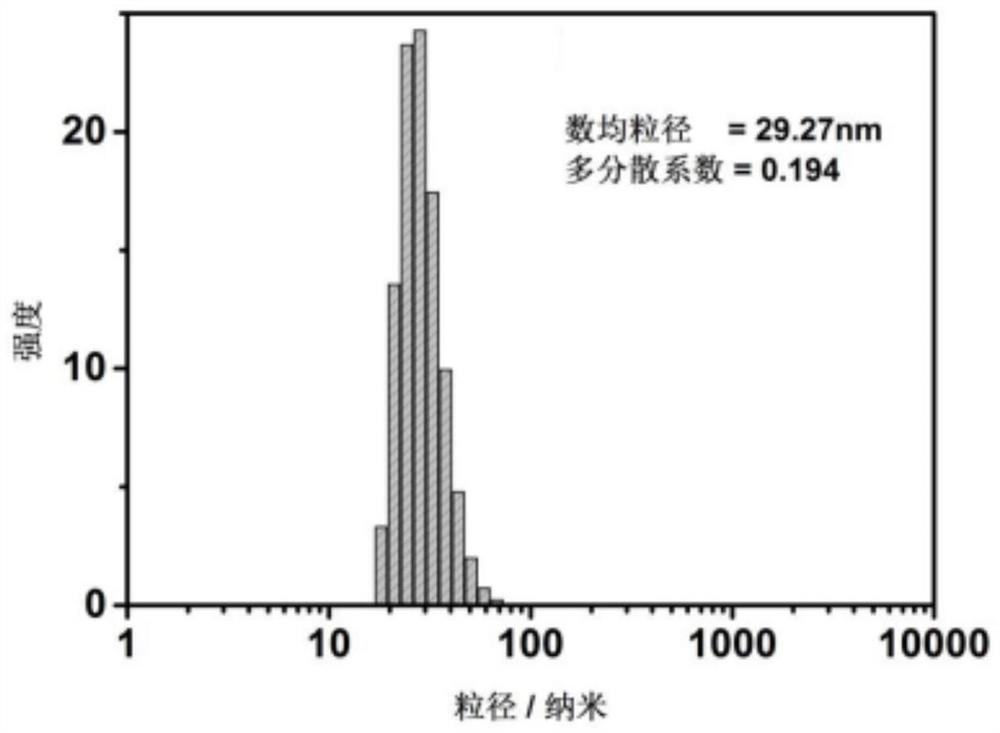

[0037]S2: Stir 70 parts of 20nm-grade acidic silica sol, 1 part of acetic acid, and 0.5 part of phenothiazine evenly, and then gradually add them dropwise to the silane mixture. The dropwise addition is completed within 10 minutes. After stirring for 30 minutes, heat up to 80°C for 1 hour. ;

[0038] S3: Add 16.5 parts of methanol, stir for 30 minutes, stop stirring after raising the temperature to 80°C, and keep it for 24 hours;

[0039] S4: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com