Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Dense pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

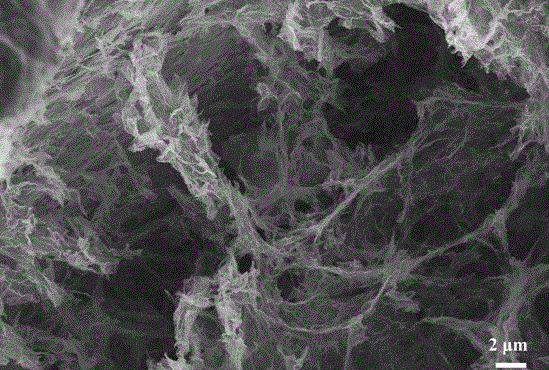

Preparation method of three-dimensional graphene

ActiveCN105523546AQuality improvementLarge specific surface areaGrapheneHigh densityAqueous solution

The invention belongs to the technical field of preparation of graphene and in particular discloses a preparation method of three-dimensional graphene. The method comprises the following steps: dispersing graphene oxide to obtain a graphene oxide aqueous solution; soaking three-dimensional foams into a graphene oxide solution and obtaining three-dimensional metal foams with graphene aerogels loaded in pores via a physical or chemical method; taking the three-dimensional metal foams with graphene aerogels loaded in pores as templates to obtain substrate-containing three-dimensional graphene via a chemical vapor deposition method; and etching and washing to obtain the three-dimensional graphene. The preparation method of the three-dimensional graphene is simple in process and is capable of preparing high-quality and high-density three-dimensional graphene and laying the foundation of the application of the three-dimensional graphene for the fields of catalysis, energy storage, heat conduction and adsorption.

Owner:FUDAN UNIV

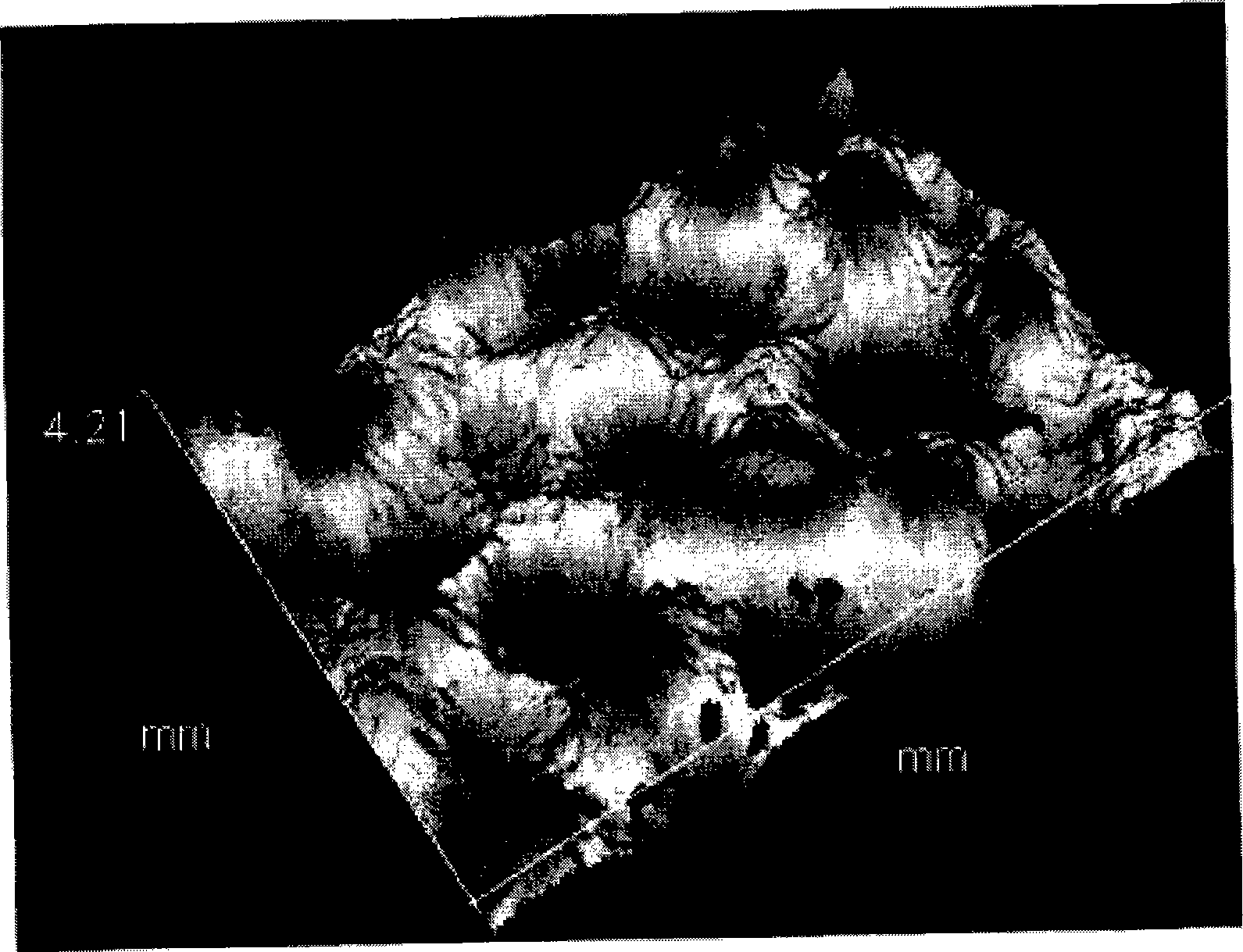

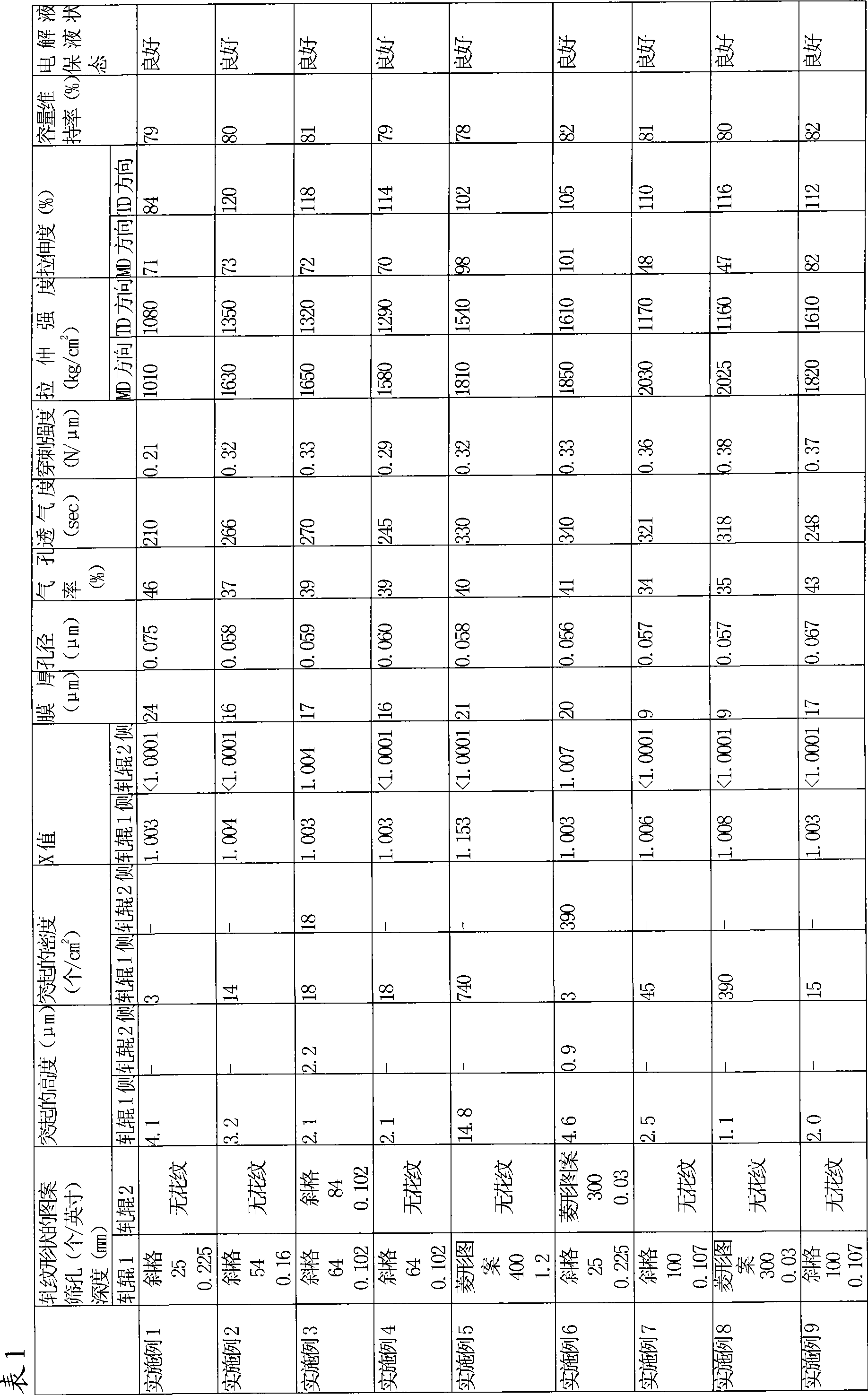

Polyolefin microporous membrane

ActiveCN101535386AAvoid compressionAvoid destructionSolid electrolytesCell seperators/membranes/diaphragms/spacersPolyolefinPolymer science

A polyolefin microporous membrane, which has a thickness of 1-100[mu]m, a pore diameter of 0.01-1[mu]m and a protrusion having a height of 0.5-30[mu]m arranged by embossing at least on one surface, is provided. A method for manufacturing the membrane and a battery separator made of the membrane are also provided.

Owner:ASAHI KASEI KK

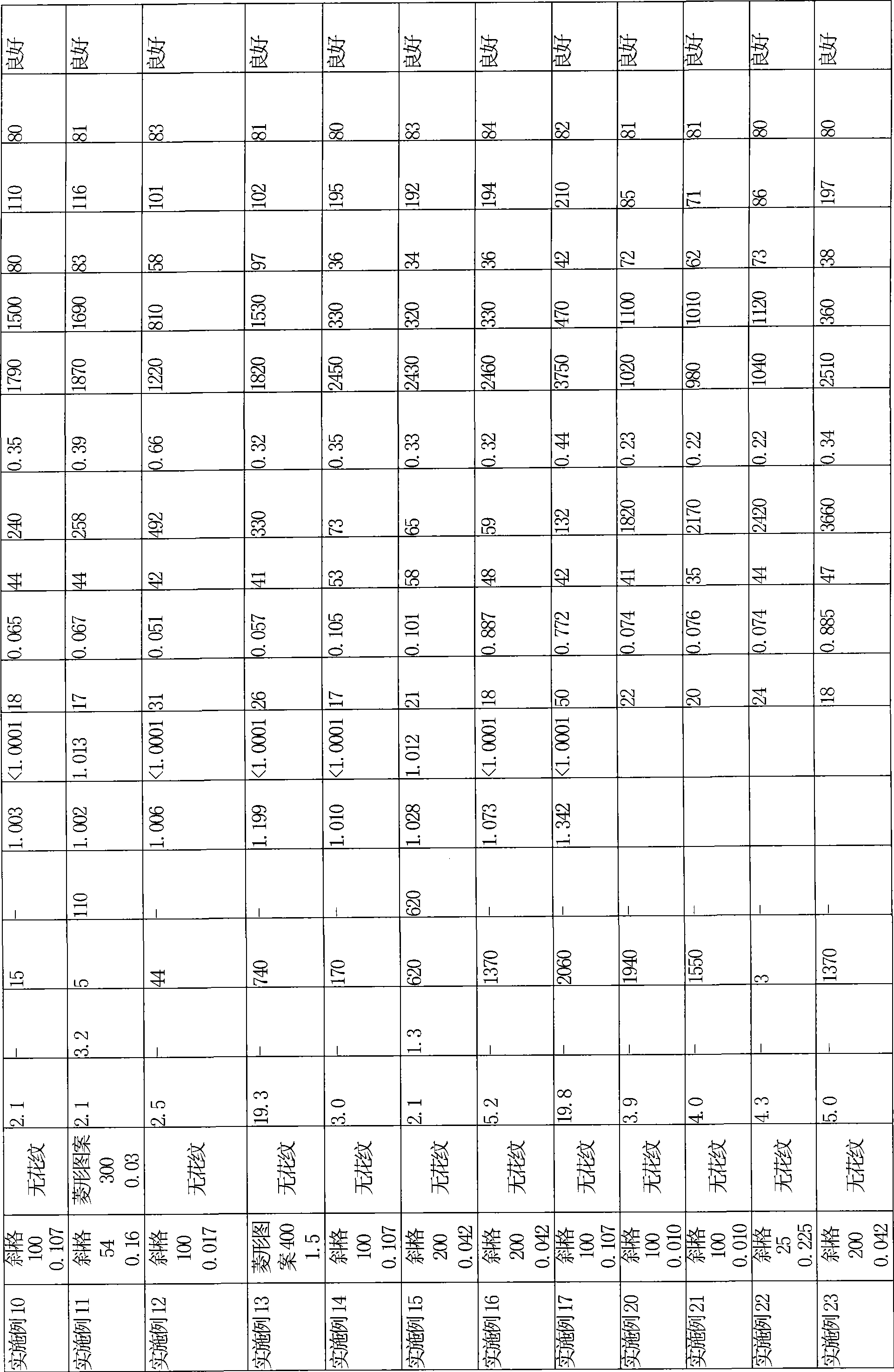

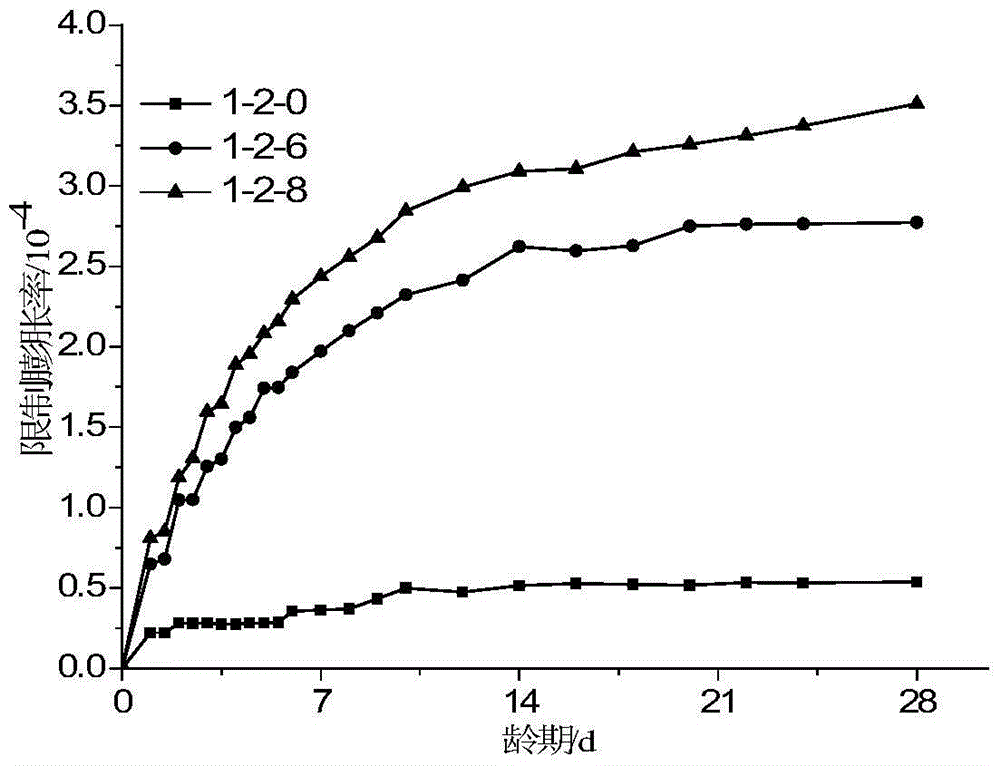

Efficient expansion clinker for cement concrete, preparation method of efficient expansion clinker and application of efficient expansion clinker

ActiveCN105712642AHigh expansion efficiencyHigh strengthCement productionFerric hydroxideMechanical property

The invention relates to efficient expansion clinker for cement concrete, a preparation method of the efficient expansion clinker and application of the efficient expansion clinker. The efficient expansion clinker is composed of, by weight, 30-60wt% of f-CaO, 5-40wt% of Fe2O3, 3-10wt% of C2S, 2-10wt% of C4AF, 3-15wt% of SiO2, 3-12wt% of Fe and 1-8wt% of C4A3S. The preparation method of the efficient expansion clinker includes: grinding 60-80wt% of limestone, 15-30wt% of pyrite cinders and 5-10wt% of rice husk ash, and well mixing to obtain raw materials; calcining the raw materials for 30-120min at the temperature of 1100-1350 DEG C to obtain the efficient expansion clinker. The expansion clinker can be mixed with dispersive carriers (such as blast furnace slag and copper slag) to form an efficient expanding agent for cement concrete. The expansion clinker and the expanding agent integrate three expanding sources including calcium hydroxide, ferric hydroxide and ettringite and are greatly promoted in expanding performance as compared with an ettringite type expanding agent with a single expanding source; due to a hydraulic binder component, later-stage mechanical properties of the cement concrete can be enhanced to some extent.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Porous covalent triazine framework hollow microsphere as well as preparation method and application thereof

ActiveCN109627250ADense pore structureStable structureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemistryHydrogen production rate

The invention belongs to the technical field of photocatalytic application of new materials, and particularly relates to a porous covalent triazine framework hollow microsphere as well as a preparation method and application thereof, a hard template stepwise polycondensation method is adopted to prepare the porous covalent triazine framework hollow microsphere with stable structure, low collapse rate and independent hollow structure, the porous covalent triazine framework hollow microsphere has excellent photocatalytic hydrogen production performance when being applied to visible light catalytic hydrogen production, thereby solving the technical problems that the covalent triazine framework hollow microsphere is not an independent hollow structure and the hydrogen production rate is poor in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

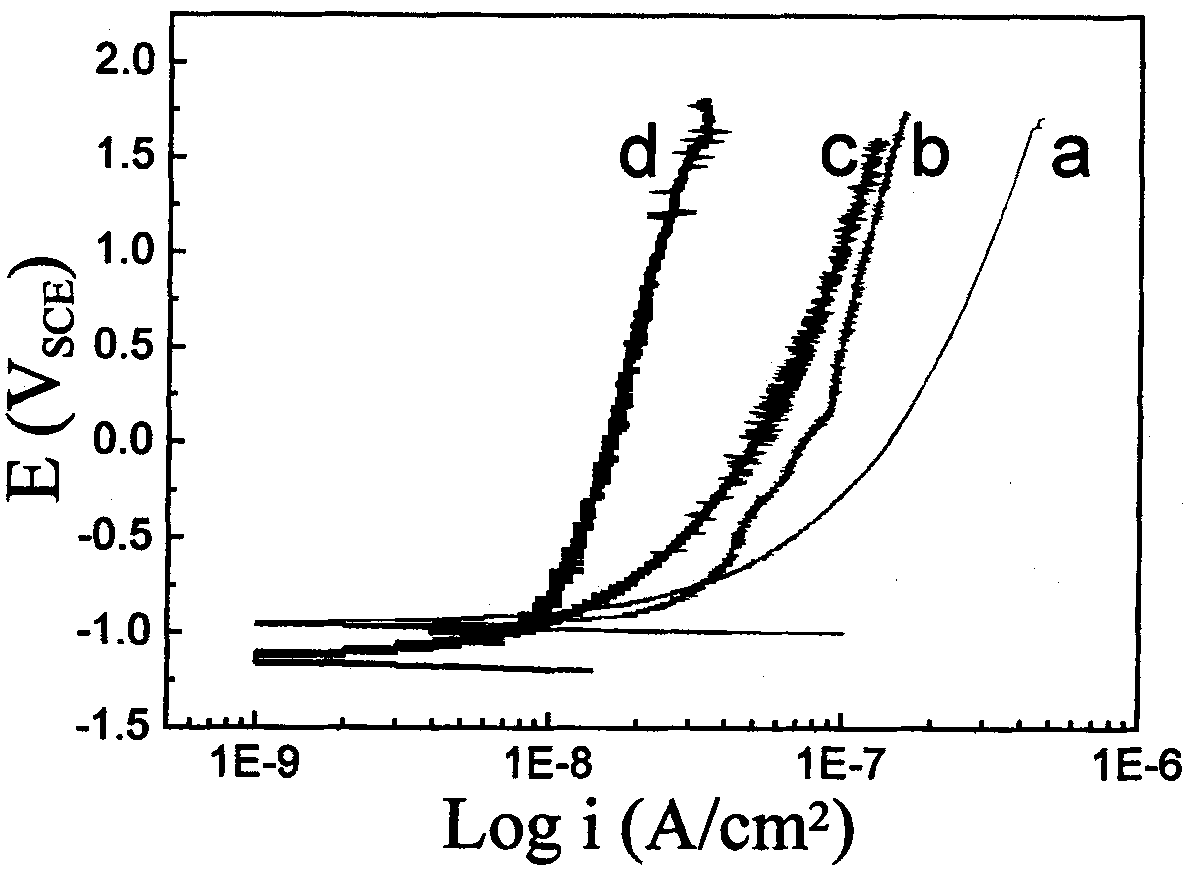

Preparation method for nitrite intercalation hydrotalcite material modified reinforcing steel bar epoxy resin coating

ActiveCN108659676AImprove compatibilityImprove bonding propertiesAnti-corrosive paintsEpoxy resin coatingsIonRebar

The invention discloses a preparation method for a nitrite intercalation hydrotalcite material modified reinforcing steel bar epoxy resin coating. The preparation method is characterized by comprisingthe following steps: adding a nitrite intercalation hydrotalcite material and silane into a silane organic mixed solution at a certain ratio, after water bath magnetic stirring is subjected to separation processing, washing with the mixed solution of ethyl alcohol and deionized water until pH (Potential of Hydrogen) is neutral, and carrying out vacuum drying to obtain a drying object; grinding the drying object to obtain fine powder, adding the fine powder into normal butanol organic solvent, carrying out ultrasonic dispersion to prepare organic solvent dispersion object solution; adding epoxy resin into the organic solvent dispersion object solution to carry out ultrasonic dispersion; adding a polyamide curing agent, carrying out even dispersion, and carrying out vacuum drying. Accordingto the preparation method, the pore structure of the epoxy resin can be compact, and the permeation intrusion of chloridions is hindered to avoid the corrosion of chloridions on reinforcing steel bar. Therefore, the coating material has multifunctionality and intellectuality, and the corrosive protection ability of the epoxy resin coating for the reinforcing steel bar is greatly improved.

Owner:HOHAI UNIV

Temperature-sensistive chitosan/polyvinyl alcohol gel, and its preparing method

InactiveCN1978498AGood biocompatibilityPromote degradationPharmaceutical non-active ingredientsProsthesisSodium bicarbonateCentrifugation

This invention discloses a temperature-sensitive chitosan / polyvinyl alcohol gel and its preparation method. The chitosan / polyvinyl alcohol gel is a physical mixed gel and its effective components include chitosan and polyvinyl alcohol. The gel formation time is different according the different ratio of chitosan and polyvinyl alcohol. The preparation method is: dissolve the chitosan into hydrochloric acid completely within ice-bath, put the sodium acid carbonate into polyvinyl alcohol and then put the solution in ice-bath. Keep stirring and within ice-bath, the solution of sodium acid carbonate polyvinyl alcohol drops slowly into chitosan hydrochloric acid solution and make sure that there is no residue in the solution. After removing bubble by centrifugation, the gel was obtained. This temperature-sensitive gel is liquid stage when the temperature is low, and the gel can be formed at the body temperature. So the gel can be injected into material. The preparation method in this invention is technical security, simple and effective. The gel is fit to carry the sensitive medicament and the slow-release effect is good.

Owner:WUHAN UNIV

Preparation method of catalyst for oxidative hydrogenation of propane

ActiveCN103769136APhysical properties (lower than surfaceLow pore volumeHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidResource utilization

The invention discloses a preparation method of a catalyst for oxidative hydrogenation of propane. The method comprises the following steps: grinding waste residual oil desulfurization catalysts into powder, adding a strong inorganic acid into the powder, filtering, adding an organic acid into the filtrate, then adding pseudo-boehmite, stirring the solution and heating at the same time until the solution is totally evaporated so as to obtain a solid substance, and then subjecting the solid substance to processes of drying, burning, and forming so as to obtain the catalyst for oxidative hydrogenation of propane. The preparation method fully utilizes the waste residual oil hydro-desulfurization catalysts, improves the resource utilization rate, and greatly reduces the cost; furthermore, the obtained catalyst has a large specific surface area, the active metal is highly dispersed on the catalyst surface, thus the utilization rate of active metal is improved, so the catalytic activity and selectivity of the catalyst are both improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified double-liquid paste injection material

The invention discloses a modified double-liquid paste injection material and relates to soft stratum reinforcement of underground construction and anti-seepage water plugging paste injection. The modified double-liquid paste injection material comprises a liquid A and a liquid B, wherein the liquid A is sodium silicate which has a modus of 2.0-3.5 and a baume degree of 20-45Be'; the liquid B is modified cement slurry which consists of the following components in parts by weight: 500-900 parts of cement, 50-200 parts of zeolite powder, 50-300 parts of ore slag powder, 0-50 parts of phosphoricacid, 1-10 parts of a naphthalene water reducer and 700-1500 parts of water; when being used, the liquid A and the liquid B are uniformly mixed in a volume ratio of (0.5-1.5):1, and the modified double-liquid paste injection material is prepared. As a part of cement is replaced by the zeolite powder and the ore slag powder to react with the sodium silicate, the zeolite powder is of a micro porousstructure and is capable of improving the peaceability and the stability of the cement slurry, water energy adsorbed into pores of the zeolite powder can be released at a later hydration reaction stage, then a solid can be sufficiently hydrated, and the compactness and the strength can be improved.

Owner:建发合诚工程咨询股份有限公司

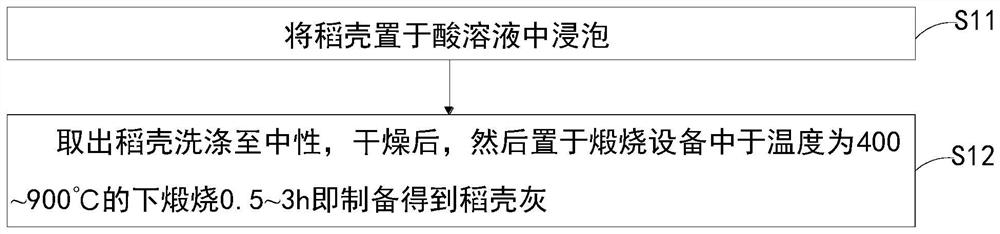

Rice hull ash and preparation method thereof, rice hull ash geopolymer and preparation method thereof

InactiveCN111995272AReduce crystallization susceptibilityLarge specific surface areaCement productionGeopolymerResidual carbon

The invention provides rice hull ash, a preparation method of the rice hull ash, a rice hull ash geopolymer and a preparation method of the rice hull ash geopolymer. The preparation method of the ricehull ash comprises the following steps: soaking rice hulls in an acid solution; taking out the rice husks, washing the rice husks to be neutral, drying the rice husks, and calcining the rice husks incalcining equipment at the temperature of 400-900 DEG C for 0.5-3 hours to obtain the rice husk ash. The invention discloses the preparation method of rice hull ash, K and other impurities hinderingrice hull combustion are removed through soaking treatment in an acid solution, the specific surface area of the rice hull ash is increased, the specific surface area is larger, the surface energy islarger, more active SiO2 is exposed, the volcanic ash activity of the rice hull ash is remarkably improved, and the content of silicon dioxide in the rice hull is remarkably increased and can reach 99.5% or above to the maximum. The rice husks are subjected to high-temperature calcination treatment, so that the content of crystalline silicon dioxide can be obviously reduced, the generation of amorphous silicon dioxide is promoted, the chemical activity is improved, and meanwhile, residual carbon is reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

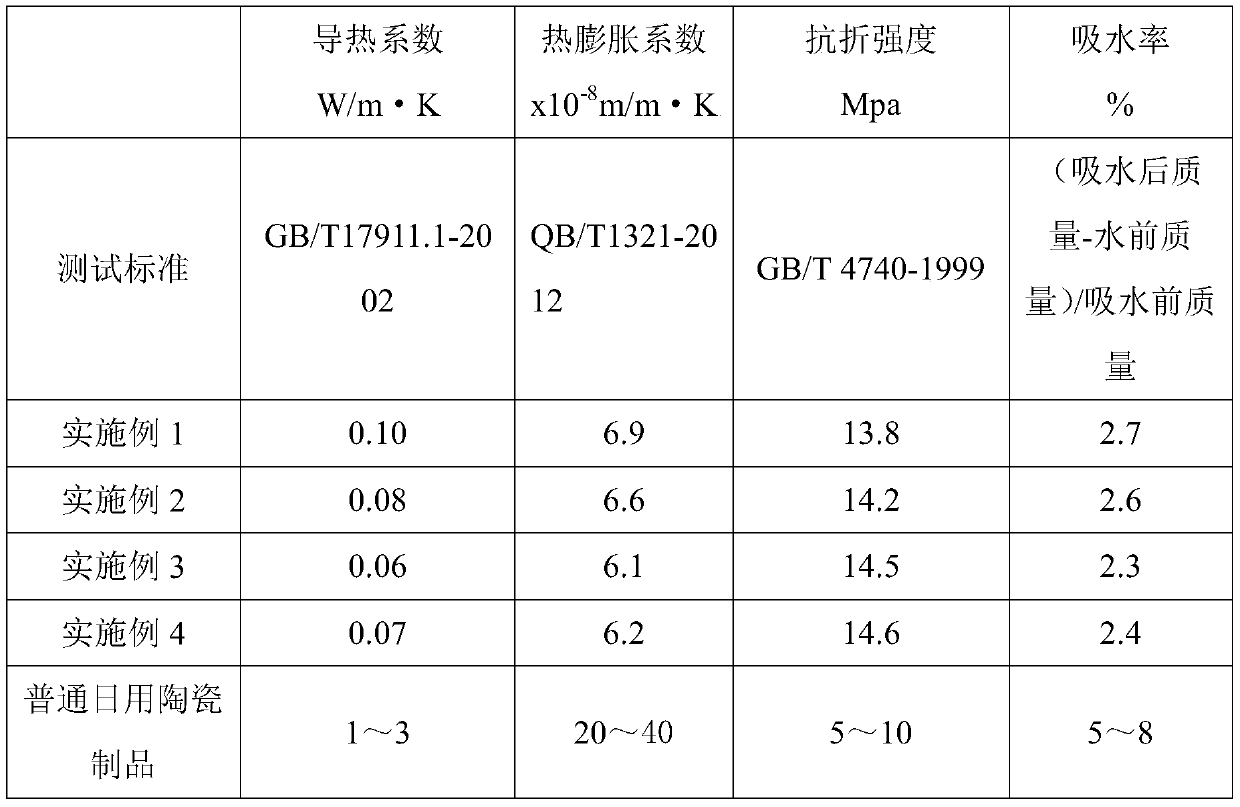

Anti-scald domestic ceramic product and preparation method thereof

InactiveCN111302829ALow thermal conductivityGood anti-scald effectCeramicwareClaywaresThermal dilatationBreaking strength

The invention discloses an anti-scald domestic ceramic product and a preparation method thereof. The anti-scald domestic ceramic product is prepared from the following raw materials in parts by weight: 30-37 parts of albite, 22-26 parts of calcite, 40-50 parts of aluminum bentonite, 5-7 parts of aluminum oxide, 12-15 parts of quartz, 8-11 parts of wollastonite whiskers, 14-17 parts of aluminum silicate, 5-7 parts of sodium silicate, 1.2-1.6 parts of a water reducing agent, 2.4-3.4 parts of a foaming agent, 1.4-1.7 parts of a foam stabilizer and 3-4 parts of a dispersing agent. The anti-scald domestic ceramic product is low in heat conductivity coefficient and good in anti-scald effect; the product is small in thermal expansion coefficient, good in heat resistance, high in breaking strength, good in mechanical property and long in service life; the water absorption is low; in addition, the anti-scald domestic ceramic product provided by the invention has a compact pore structure inside,and is light in weight, good in heat insulation performance, good in anti-scald effect and good in comprehensive performance.

Owner:FUJIAN WILL CERAMIC CO LTD

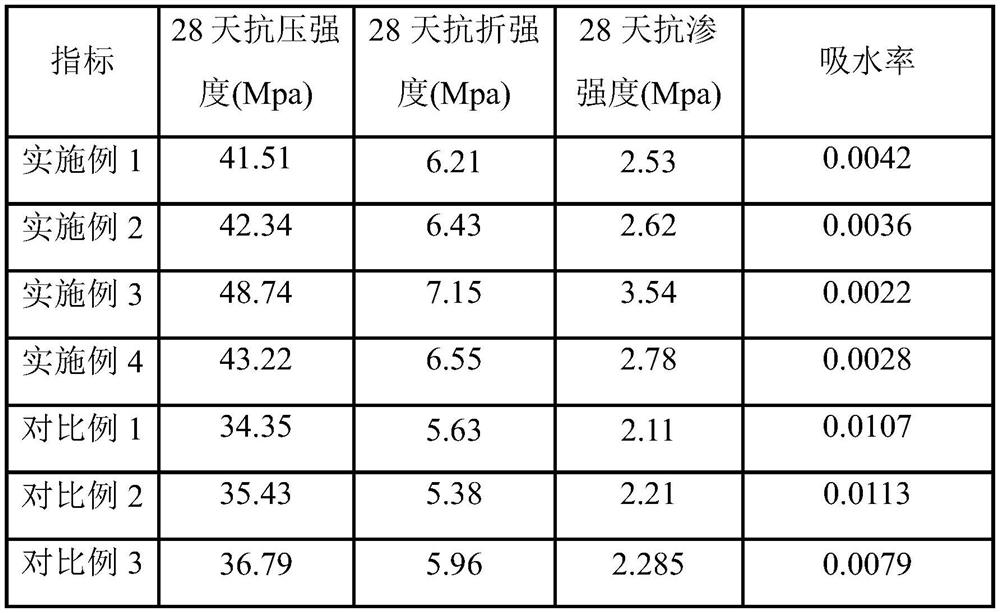

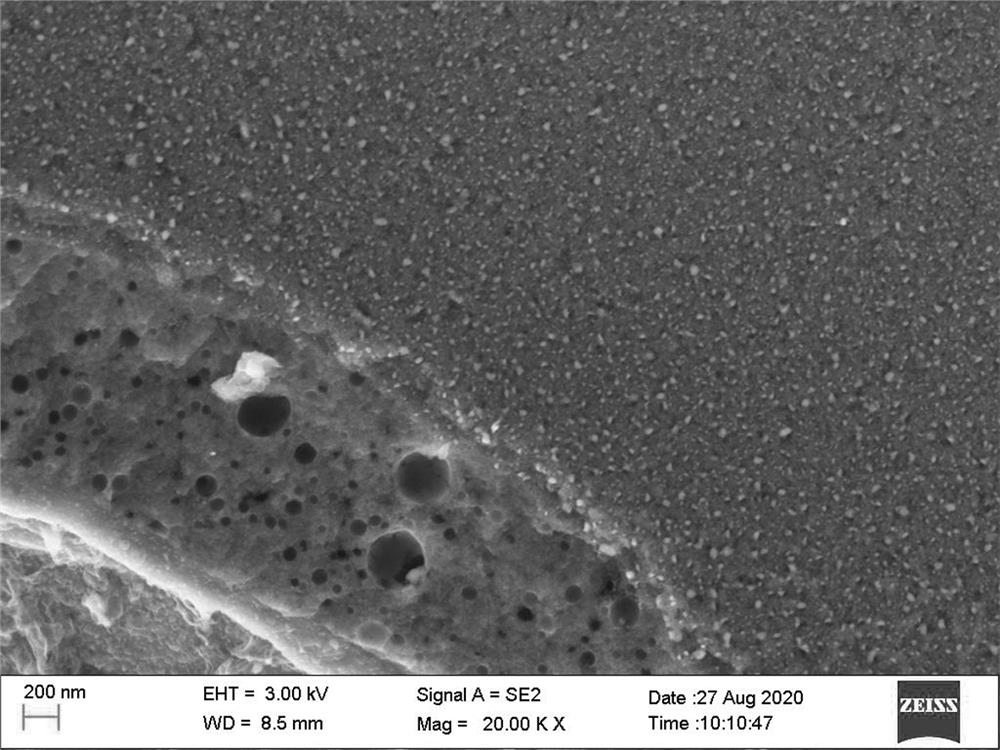

Nano SiO2 high-strength waterproof impermeable mortar and preparation method thereof

InactiveCN112661461AImprove waterproof and anti-seepage performanceHigh strengthHydration reactionNano sio2

The invention provides nano SiO2 high-strength waterproof impermeable mortar and a preparation method thereof. The waterproof impermeable mortar is prepared from the following raw materials: cement, water, sand, fly ash, nano SiO2 dispersion liquid and the like. By adding other active materials such as the nano SiO2, the polypropylene fibers and the early strength agent, the cement-based material can be brought into pores inside the cement-based material under the carrying action of water, particularly capillary pores with small sizes, to absorb water and expand, so that a filling effect is achieved. Besides, nano SiO2 can participate in and promote hydration reaction, and produced fine and regular hydrated crystalline substances are attached to the peripheries of pores, so that the microstructure is densified, a dense impermeable area is formed in the deep position of the interior of the cement-based material, and the waterproof and impermeable performance of the cement-based material is greatly improved. The added nano SiO2 can improve the microstructure of the cement-based material and inhibit the generation of cracks, so that the strength, seepage resistance and durability of the cement-based material are improved.

Owner:YANCHENG INST OF TECH

Limestone flour mineral composite agent

The invention provides a limestone flour mineral composite agent. The limestone flour mineral composite agent is prepared from the following raw materials in parts by weight: 30 to 80 parts of limestone flour, 10 to 30 parts of slag powder, 5 to 10 parts of magnesia powder, 3 to 8 parts of nitrate, 20 to 50 parts of gypsum powder and 5 to 15 parts of triethanolamine. According to the composite agent, the early strength and long-term strength of concrete can be improved, the early hydration of cement is promoted due to the limestone flour, and moreover, the triethanolamine is also beneficial for the development on the early strength of concrete; the durability of concrete is improved, the porosity of concrete can be effectively reduced due to combined addition of the limestone flour and mineral powder, so that the pore structure is refined, the pore structure is improved, the chloride ion diffusion coefficient of concrete can be effectively reduced, and moreover, the triethanolamine enables a cement hydration product to be compact in structure. The composite agent is simple in preparation technology and low in cost, and is applicable for large-scale industrial production.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Method for preparing carbon molecular sieve based on petroleum coke

InactiveCN108467035AReduce volume shrinkage effectHigh strengthCarbon compoundsChemical industryCarbonization

The invention belongs to the technical field of chemical industry production, and particularly relates to a method for preparing a carbon molecular sieve based on petroleum coke. The preparation method includes the following steps of: mixing and grinding petroleum coke and nano-silica, carrying out carbonization, excitation and carbon deposit to obtain the carbon molecular sieve. According to theinvention, nano-silica is doped in petroleum coke and formed of silicon carbide filled in the petroleum coke pore structure during high temperature treatment, so that the obtained carbon molecular sieve has higher strength; meanwhile, the filling of the nano silica can also generate carbon monoxide gas in the process of being reduced by carbon, and can reduce the pore shrinkage of the petroleum coke caused by polycondensation during the releasing process, thereby ensuring that the obtained carbon molecular sieve has a more dense pore structure.

Owner:ANHUI HAIDE PETROCHEM

Aluminum or aluminium alloy oxide precursor anodic oxidation method

InactiveCN101928973ASimple processing methodProcess stabilitySurface reaction electrolytic coatingRare-earth elementElectrochemical anodization

The invention relates to an aluminum or aluminium alloy oxide precursor anodic oxidation method which adopts Ni (NO3)2 solution of rare earth salt for chemical pretreatment to form Ni-Al double-hydroxy metal oxide on the surface of aluminum, and leads a rare earth composite anodic oxidation film to be formed on the surface of aluminum or aluminium alloy through electrochemical anodic oxidation treatment. As the composite anodic oxidation film with rare-earth elements is introduced, the invention has more compact structure, and remarkably improves the surface hardness and the corrosion resistance of the material.

Owner:BEIJING UNIV OF CHEM TECH

Concrete modifier

The invention discloses a concrete modifier. The concrete modifier is prepared from the following raw materials in parts by mass: 100 to 150 parts of superfine slag powder, 30 to 50 parts of wood powder, 20 to 40 parts of sodium silicate, 20 to 40 parts of diatomite, 10 to 20 parts of hydroxyethyl cellulose, 5 to 15 parts of silicon oil and 5 to 10 parts of super absorbent polymer. The concrete modifier disclosed by the invention has the advantages of low cost and convenience in use; the concrete modifier is directly added in the process of adding water into concrete raw materials for stirring; the pore structure of concrete can be compacted, the slump and expansion of the concrete are improved, and the structural strength of the concrete is improved; and in addition, the water-retaining property of the concrete is improved and the curing period of the concrete is shortened.

Owner:SUZHOU TANGSHI JIANHUA CONCRETE PILE

A kind of preparation method of three-dimensional graphene

ActiveCN105523546BQuality improvementLarge specific surface areaGrapheneHigh densityAqueous solution

The invention belongs to the technical field of preparation of graphene and in particular discloses a preparation method of three-dimensional graphene. The method comprises the following steps: dispersing graphene oxide to obtain a graphene oxide aqueous solution; soaking three-dimensional foams into a graphene oxide solution and obtaining three-dimensional metal foams with graphene aerogels loaded in pores via a physical or chemical method; taking the three-dimensional metal foams with graphene aerogels loaded in pores as templates to obtain substrate-containing three-dimensional graphene via a chemical vapor deposition method; and etching and washing to obtain the three-dimensional graphene. The preparation method of the three-dimensional graphene is simple in process and is capable of preparing high-quality and high-density three-dimensional graphene and laying the foundation of the application of the three-dimensional graphene for the fields of catalysis, energy storage, heat conduction and adsorption.

Owner:FUDAN UNIV

Preparation method of hydrophobic porous carbon material

ActiveCN112408360AAvoid wastingAvoid it happening againCarbon preparation/purificationPotassium persulfateOXALIC ACID DIHYDRATE

The invention relates to a preparation method of a hydrophobic porous carbon material, which belongs to the field of carbon materials, and is characterized by comprising the following steps: pre-emulsifying raw materials organic silicon, styrene, acrylate, an emulsifier and deionized water, dropwisely adding potassium peroxodisulfate to perform emulsion polymerization to obtain styrene-acrylic latex SSAL, and blending the SSAL with an oxalic acid solution to obtain a resin matrix PSO; and carbonizing PSO at high temperature to obtain a hydrophobic porous carbon material. According to the method, oxalic acid is used as an activating agent, and a specific adding step is matched, so that the pore-forming effect is guaranteed, and meanwhile, energy waste and waste liquid generation are avoided.

Owner:山东利特纳米技术有限公司

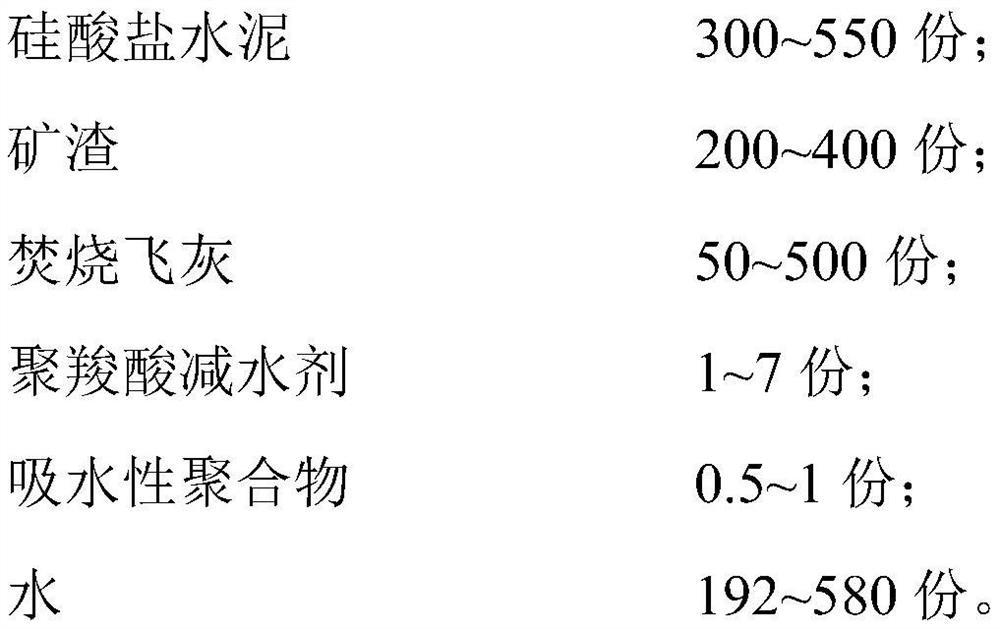

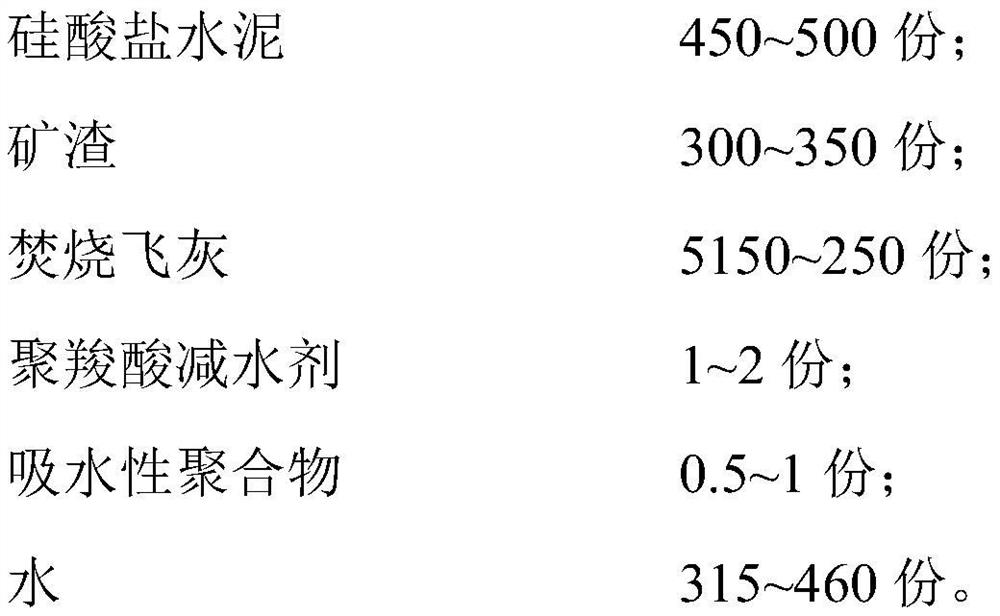

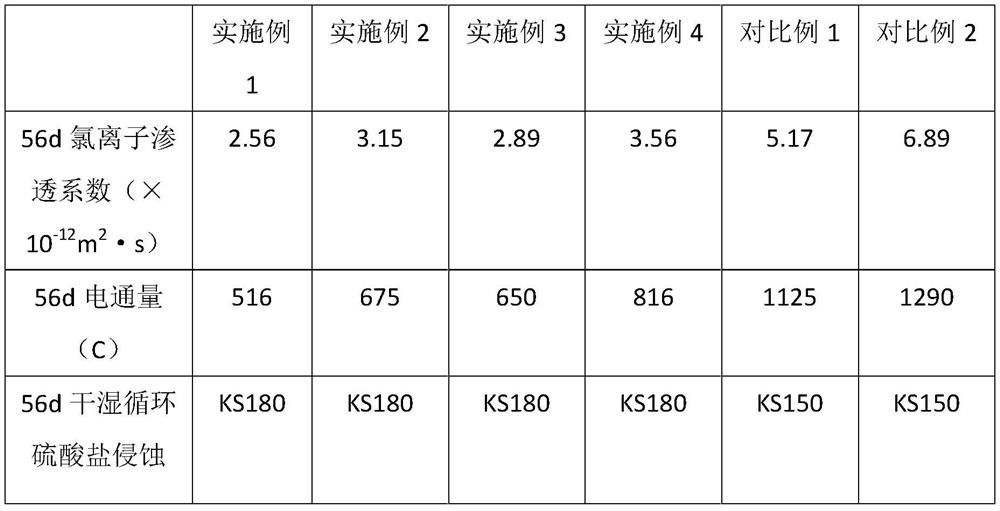

Cement-based modified composite material and preparation method thereof

The invention provides a cement-based modified composite material. The cement-based modified composite material comprises the following components in parts by weight: 300-550 parts of Portland cement;200-400 parts of slag; 50-500 parts of incineration fly ash; 1-7 parts of a polycarboxylate superplasticizer; 0.5-1 part of a water-absorbing polymer; and 192-580 parts of water; according to the cement-based modified composite material, Portland cement, slag and incineration fly ash are used as main components and cooperate with a water-absorbing polymer and a polycarboxylate superplasticizer, so that heavy metal ions are effectively absorbed into the water-absorbing polymer and retained in the water-absorbing polymer, the curing effect is achieved, and meanwhile, the leaching process of theheavy metal ions is slowed down; the precipitation concentration of heavy metals in the composite material is greatly reduced by the water-absorbing polymer, and the performance of the molecular structure of the cement-based modified composite material is improved, so that the cement-based modified composite material reaches the use standard of building materials.

Owner:SHENZHEN UNIV

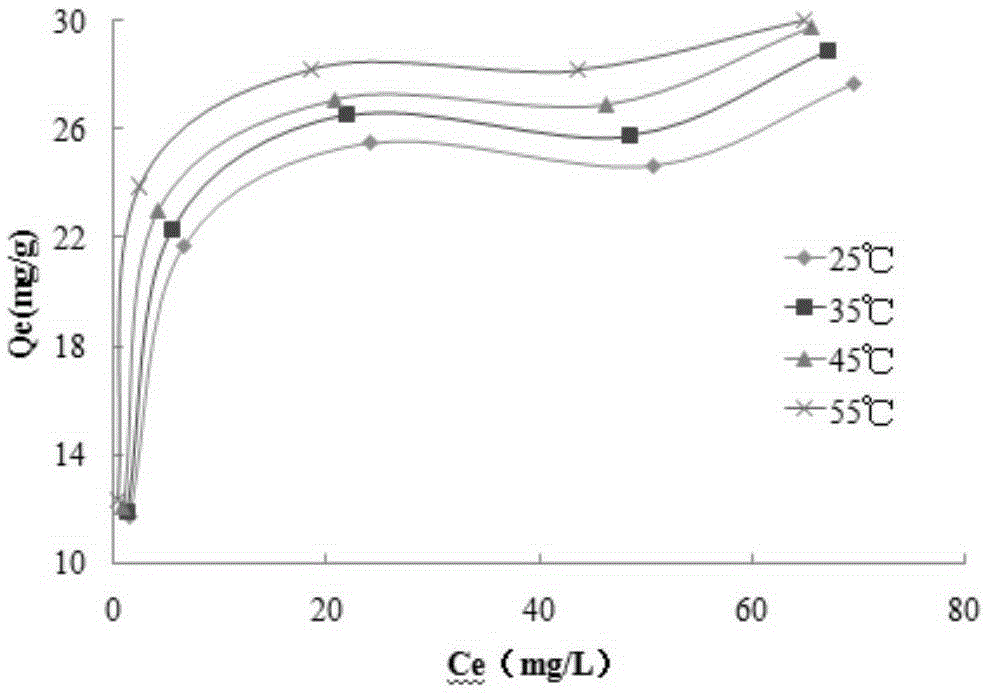

Method for enriching micro sliver irons by utilizing melamine modified urea resin

InactiveCN106563289ARich pore structureDense pore structureSolid sorbent liquid separationX/gamma/cosmic radiation measurmentSites treatmentSorbent

The invention discloses a method for enriching micro sliver irons by utilizing melamine modified urea resin. The method is characterized in that melamine modified urea resin is taken as an adsorbent; and a constant-temperature oscillation method is adopted to adsorb silver ions in a silver ion containing solution. According to the method disclosed by the invention, melamine modified urea resin raw material is cheap and easily available; the preparation method is simple; selectivity on sliver ions is high; melamine modified urea resin is utilized to adsorb silver irons and 110 mAg of radioactive isotope thereof in a water body, so that 110 mAg field measurement needs of efflux of a nuclear power station can be met, especially, quick field measurement needs under an emergency situation are met; and meanwhile, a sample treated on site is convenient to transport, and an application prospect is wide.

Owner:NANJING UNIV OF SCI & TECH

Soil conditioner, and preparation method and use method thereof

InactiveCN113024326AImprove breathabilitySolve compactionOrganic fertilisersFertilizer mixturesSoil scienceEnvironmental engineering

The invention provides a soil conditioner, and a preparation method and a use method thereof, and relates to the technical field of soil improvement. According to the soil conditioner, glass and food waste are sintered and mixed to prepare a material with a compact porous structure, and when the soil conditioner is applied to soil, not only can moisture be effectively locked, but also the air permeability of the soil can be enhanced, so that the problem of soil hardening is effectively solved. In addition, the invention further provides the preparation method of the soil conditioner, the soil conditioner with the good improvement effect can be simply and rapidly prepared through the method, operability is high, intelligent automatic production is easy to achieve, and practicability is high. Besides, the invention further provides the use method of the soil conditioner, namely, the soil conditioner and an organic fertilizer are mixed and applied according to the proportion of (0.3-0.8): 1, so that the utilization rate of the soil conditioner can be increased, the situation of incompatibility of the mixing proportion can be avoided, and the problem of soil hardening can be better solved.

Owner:杨凌亿能碳生物肥研发集团有限公司

Injectable temperature-sensitive chitosan/methyl cellulose gel and its preparation process

InactiveCN100522247CDense pore structureHigh mechanical strengthPharmaceutical non-active ingredientsProsthesisCelluloseMethyl cellulose

The invention discloses an injectable thermosensitive chitosan / methylcellulose blend gel and a preparation method thereof. The gel is a physical gel, and its effective composition includes chitosan and methyl cellulose, and the weight percentages of the two are 0.25-2% and 0.25-5% respectively. The preparation method is to dissolve chitosan in an acid solution to obtain a 0.5-4wt% chitosan acid solution, and place it in an ice bath; dissolve the alkaline salt in a 0.5-10wt% methylcellulose solution, and Place in an ice bath; then slowly drop the methylcellulose salt solution into the chitosan acid solution under constant stirring to keep the solution free from turbidity, stir until the two are fully mixed, and centrifuge to remove air bubbles, then place the blended solution The gel is formed at the gel temperature. This new type of injectable temperature-sensitive gel has simple and mild preparation conditions, can avoid organic chemical reagents and other harmful substances, is suitable for the delivery of sensitive macromolecules such as protein drugs, and can also be used as an injectable medical material and tissue engineering scaffold materials.

Owner:WUHAN UNIV

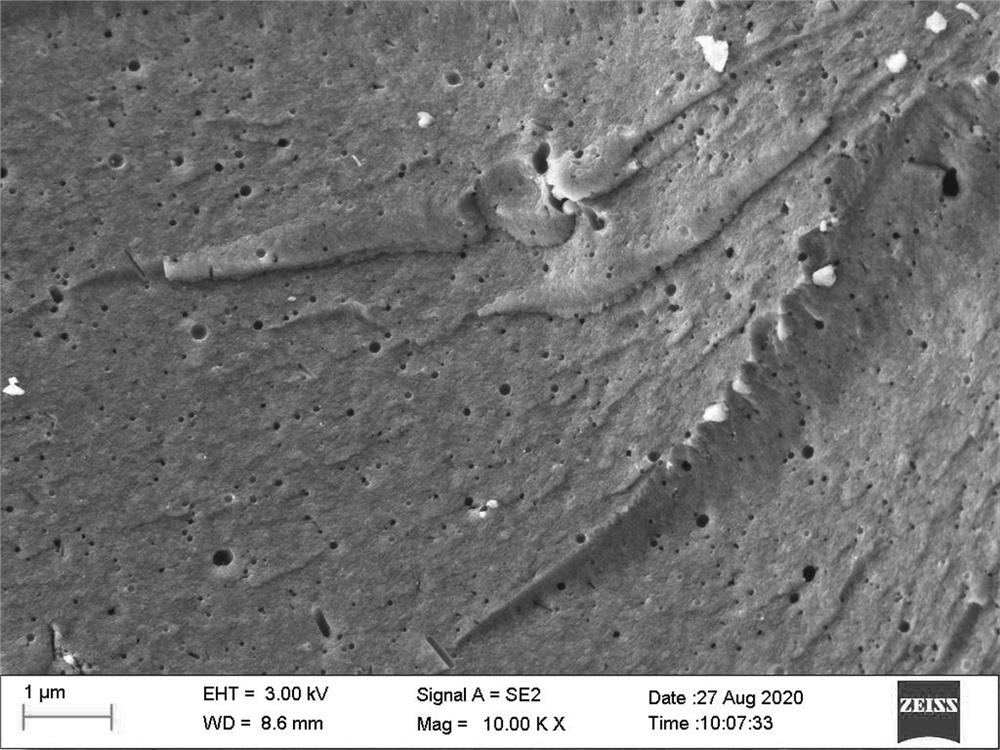

A kind of marine self-protection concrete and preparation method thereof

ActiveCN113548849BDense pore structureImprove compactnessSolid waste managementSuperplasticizerCarboxylic acid

The invention relates to a marine self-protective concrete and a preparation method thereof, comprising the following components, cement 200-400kg / m 3 , fly ash 80‑150kg / m 3 , mineral powder 40‑80kg / m 3 , micro silica fume 20‑40kg / m 3 , sand 650‑850kg / m 3 , gravel 900‑1100kg / m 3 , water 150‑180kg / m 3 , polycarboxylate water reducer 0.5‑1.5kg / m 3 , dense improvement material 20‑40kg / m 3 , super-hydrophobic harmful ion isolation material 10‑20kg / m 3 , anti-fouling biological corrosion agent 5‑10kg / m 3 . Adding compaction improvement materials to concrete can effectively improve the compactness of concrete after curing, which is beneficial to improve its corrosion resistance. At the same time, adding super-hydrophobic harmful ion isolation materials can isolate harmful ions in the marine environment from concrete and reduce harmful ions. The amount of corrosion damage, while the anti-fouling bio-corrosion agent added to avoid bio-corrosion caused by the marine environment, improve the overall anti-corrosion performance and durability of concrete.

Owner:CHINA ROAD & BRIDGE

Temperature-sensistive chitosan/polyvinyl alcohol gel, and preparing method thereof

InactiveCN100509923CGood biocompatibilityPromote degradationPharmaceutical non-active ingredientsProsthesisSodium bicarbonateTemperature sensitive

The invention discloses a temperature-sensitive chitosan / polyvinyl alcohol gel and a preparation method thereof. This chitosan / polyvinyl alcohol gel is a physical blend gel, and the effective components constituting the gel include chitosan and polyvinyl alcohol, and the gel temperature varies according to the proportioning ratio between chitosan and polyvinyl alcohol. different. Its preparation method is to dissolve chitosan completely in hydrochloric acid solution, and place it in an ice bath; add sodium bicarbonate solution to polyvinyl alcohol solution, and place it in an ice bath; Slowly drop the sodium bicarbonate polyvinyl alcohol solution into the chitosan hydrochloric acid solution to keep the solution free of turbidity, centrifuge to remove air bubbles, and place it at the gel temperature for a period of time to obtain a gel. This temperature-sensitive gel is liquid at low temperature and can form a gel at human body temperature. It can be used as an injection implant material. The preparation method is safe, simple and effective, and meets environmental protection requirements. It is suitable for the delivery of sensitive drugs. Release effect is good.

Owner:WUHAN UNIV

Preparation method of epoxy resin coating on reinforced steel modified by nitrite intercalation hydrotalcite material

ActiveCN108659676BImprove adsorption capacityGood compatibilityAnti-corrosive paintsEpoxy resin coatingsPolyamideOrganosolv

The invention discloses a preparation method for a nitrite intercalation hydrotalcite material modified reinforcing steel bar epoxy resin coating. The preparation method is characterized by comprisingthe following steps: adding a nitrite intercalation hydrotalcite material and silane into a silane organic mixed solution at a certain ratio, after water bath magnetic stirring is subjected to separation processing, washing with the mixed solution of ethyl alcohol and deionized water until pH (Potential of Hydrogen) is neutral, and carrying out vacuum drying to obtain a drying object; grinding the drying object to obtain fine powder, adding the fine powder into normal butanol organic solvent, carrying out ultrasonic dispersion to prepare organic solvent dispersion object solution; adding epoxy resin into the organic solvent dispersion object solution to carry out ultrasonic dispersion; adding a polyamide curing agent, carrying out even dispersion, and carrying out vacuum drying. Accordingto the preparation method, the pore structure of the epoxy resin can be compact, and the permeation intrusion of chloridions is hindered to avoid the corrosion of chloridions on reinforcing steel bar. Therefore, the coating material has multifunctionality and intellectuality, and the corrosive protection ability of the epoxy resin coating for the reinforcing steel bar is greatly improved.

Owner:HOHAI UNIV

Anti-cracking alkali slag recycled concrete and preparation method thereof

The invention discloses anti-cracking alkali slag recycled concrete and a preparation method thereof. According to the invention, sodium sulfate, sodium silicate and cement are used as composite excitants, such that advantages of cracking resistance, good strength, and the like are provided. The recycled coarse aggregate with the saturated surface dry can return water to achieve an internal curing effect, so that the shrinkage of the material is reduced, and the anti-cracking performance is improved; magnesium oxide is adopted to compensate shrinkage of the alkali slag concrete, and cracking is further reduced; by adopting the PTB emulsion, the development of micro-cracks in the material can be inhibited, and the waterproof performance and the workability are relatively good; and the used slag and recycled aggregate are wastes which are recycled, so that garbage landfill can be reduced, and environmental management and protection are facilitated. The anti-cracking alkali slag recycled concrete has good economic, social and environment-friendly benefits and is suitable for large-scale popularization and application.

Owner:FUJIAN AGRI & FORESTRY UNIV

Low-shrinkage anti-cracking concrete

The invention discloses low-shrinkage anti-cracking concrete, and belongs to the technical field of building materials, the low-shrinkage anti-cracking concrete is characterized in that the concrete comprises, by weight, 580-610 parts of a cementing material, 780-880 parts of machine-made sand, 900-940 parts of gravel, 25-35 parts of an additive and 130-160 parts of water, the cementing material comprises cement, fly ash, mineral powder and slag, and according to the weight ratio, the cementing material comprises the cement, the fly ash, the mineral powder and the slag. The ratio of the cement to the fly ash to the mineral powder to the slag is 5: (1.6-2.1): (1.2-1.7): (0.9-1.3), so that the effect of reducing the shrinkage rate of the concrete is achieved.

Owner:山西利鑫泰混凝土有限公司

Preparation method of hydrophobic porous carbon material

ActiveCN112408360BAvoid wastingAvoid it happening againCarbon preparation/purificationPotassium persulfateOXALIC ACID DIHYDRATE

The invention relates to a preparation method of a hydrophobic porous carbon material, which belongs to the field of carbon materials, and is characterized in that firstly, the raw materials organosilicon, styrene, acrylate, emulsifier and deionized water are pre-emulsified, and then potassium persulfate is added dropwise Emulsion polymerization is carried out to obtain SSAL latex SSAL, and then the SSAL is blended with oxalic acid solution to obtain a resin matrix PSO, and the PSO is carbonized at a high temperature to obtain a hydrophobic porous carbon material; the present invention uses oxalic acid as an activator, with specific addition steps, The purpose is to ensure the pore-forming effect while avoiding the waste of energy and the generation of waste liquid.

Owner:山东利特纳米技术有限公司

Preparation method for abrasion resistant alloy material

The invention relates to a preparation method for an abrasion resistant alloy material and belongs to the technical field of abrasion resistant material industry. Tungsten powder is placed in a stainless steel ball mill tank to be ball-milled and sieved, and thus processed tungsten powder is obtained; obsidian, pitchstone and perlite are used as raw materials, the raw materials are washed throughclean water, then ball-milled and sieved, and thus mixed ball-milled powder is obtained; the processed tungsten powder and the ball-milled powder are mixed according to the mass ratio and stirred continuously, then a powder mixture and steel ingot melted liquid are continuously stirred and mixed, and thus a mixture is obtained; and prepared mixed melted liquid is taken out and cast in a block-shaped mould, isothermal annealing is conducted, and thus the abrasion resistant alloy material is obtained.

Owner:NOTTING CHANGZHOU PRECISION MACHINERY

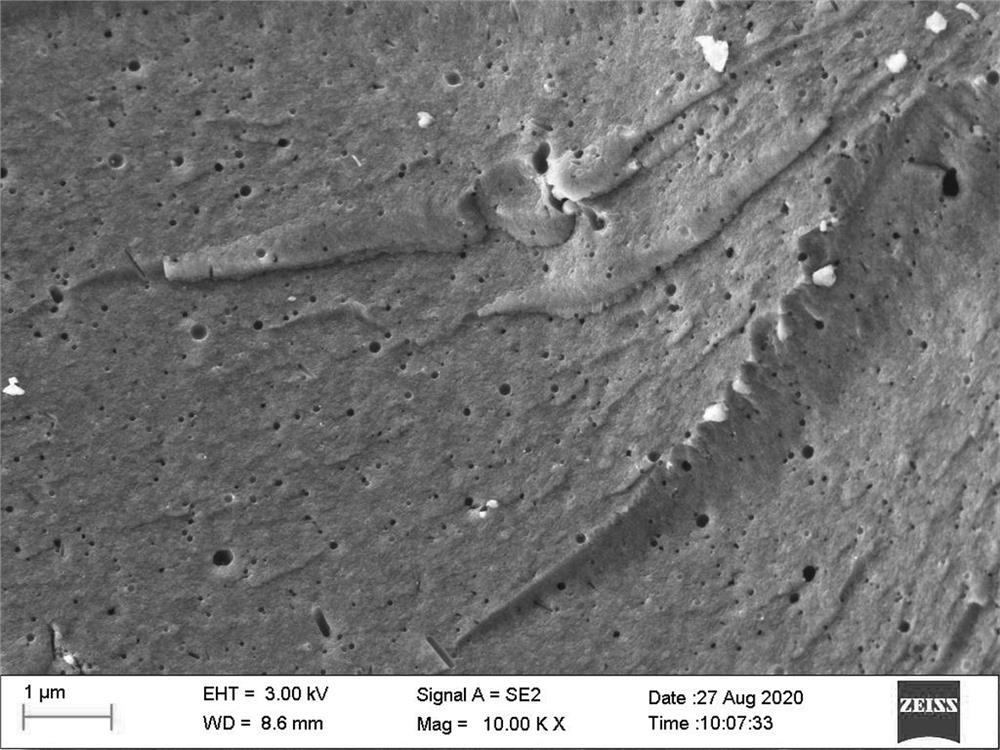

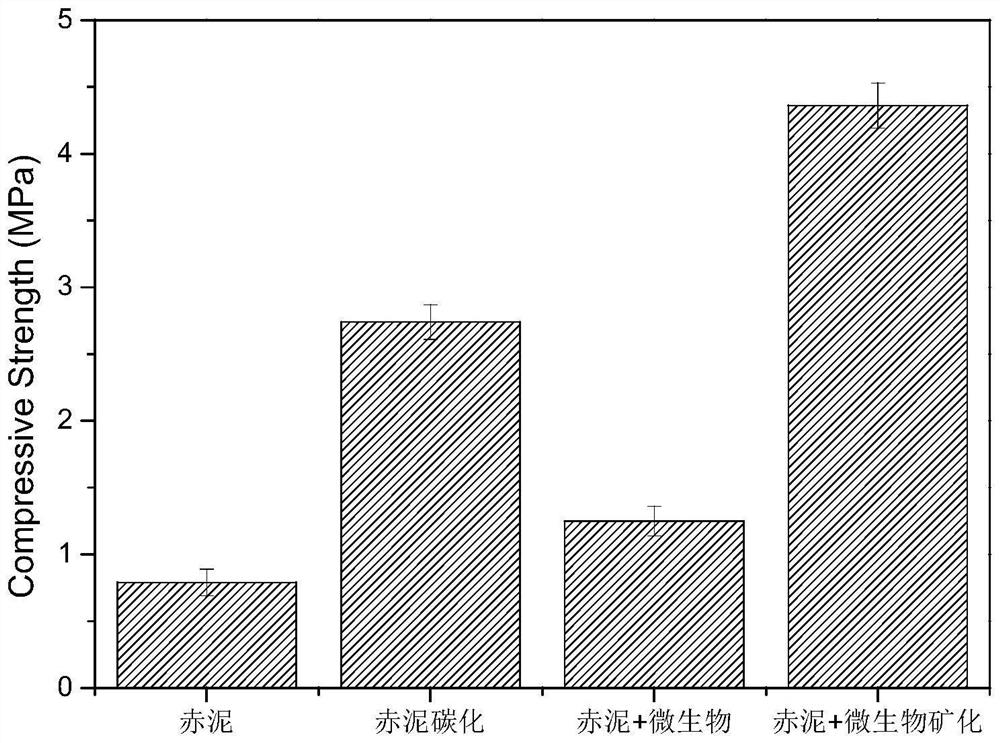

Method for preparing red mud building material product based on compound microorganism technology

The invention discloses a method for preparing a red mud building material product based on a compound microorganism technology, and belongs to the field of red mud building material products. The method solves the pollution problem of red mud, and comprises the following steps: mixing red mud and steel slag according to a mass ratio of 1: 1-3: 1 to obtain a composite cementing material; bacillus mucilaginosus, bacillus subtilis and bacillus aceticus are mixed according to the mass ratio of 1: 1: 1-3: 1: 1, and a compound microorganism is obtained; fully mixing the composite cementing material, water, sand and composite microorganisms, uniformly stirring to obtain slurry, pouring the slurry into a mold, vibrating and molding to obtain a test piece; curing and demolding the test piece to obtain a sample, and sequentially performing standard curing and carbonization curing on the sample to obtain the red mud building material product. The method can be used for preparing red mud building material products.

Owner:SHANDONG HONGYI TECH +1

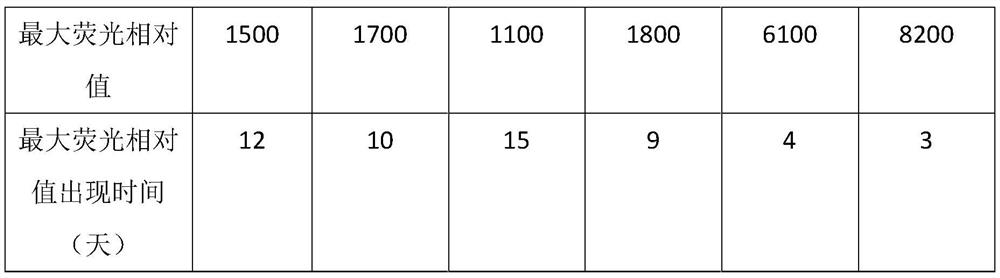

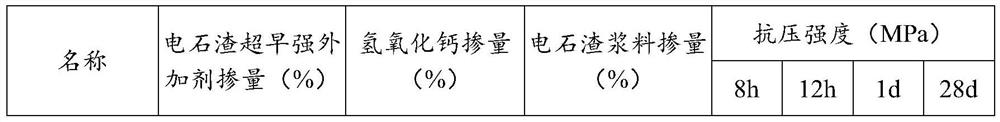

A kind of preparation method and application of calcium carbide slag super early strength admixture

The invention discloses a preparation method and application of a calcium carbide slag super early strength admixture. The preparation method comprises: (1) taking 20-60 parts by mass of carbide slag and 0.5-1 part by mass of a dispersant, adding 80-160 parts by mass (2) Add grinding aid with a solid content of calcium carbide slag of 0.5‰ to 1.5‰ in the calcium carbide slag slurry, and calcium carbide slag solid content in the calcium carbide slag slurry. The plasticizer with a content of 5-25‰ and 300-400 parts by mass of grinding medium are ground in a wet mill, and the grinding medium is screened to obtain calcium carbide slag ultra-fine slurry; (3) Add anti-agglomeration to the calcium carbide slag ultra-fine slurry to stabilize The agent is stirred to obtain calcium carbide slag super early strength admixture. The method of the invention has the advantages of simple process, low energy consumption and low cost. The prepared calcium carbide slag super-early strength admixture is added to the cement cementitious material, which can significantly enhance the early strength of the cement cementitious material, and the strength does not shrink in the later stage, thereby increasing the calcium carbide slag product. added value.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com