A kind of marine self-protection concrete and preparation method thereof

A concrete and marine self-protection technology, which is applied in the field of marine self-protection concrete and its preparation, can solve the problem of no essential improvement in the durability of concrete, and achieve the effects of improving compactness, enhancing the ability to erode concrete, and improving water reduction.

Active Publication Date: 2022-06-03

CHINA ROAD & BRIDGE

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In marine concrete construction projects, the use of organic external protective coatings is the most commonly used technical measure to improve durability. However, the external protective coatings only build a protective layer on the concrete surface, and the durability of the interior of the concrete has not been substantially improved. Once The durability of marine concrete will be greatly challenged if the organic external protective coating is aged and damaged

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

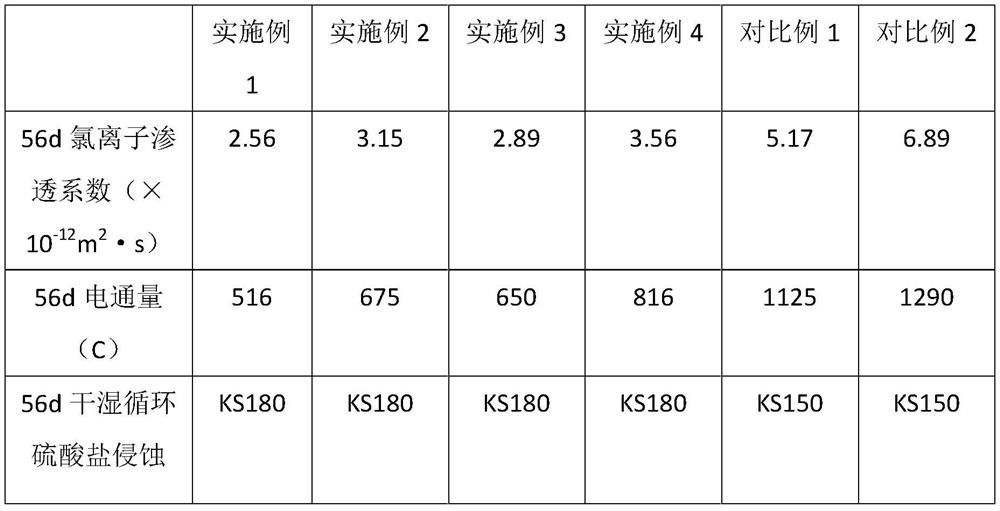

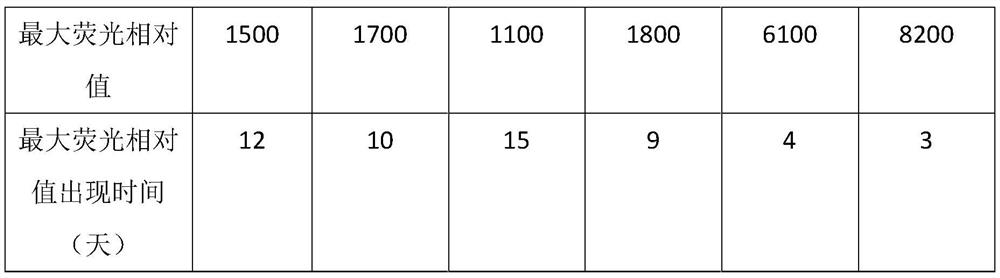

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a marine self-protective concrete and a preparation method thereof, comprising the following components, cement 200-400kg / m 3 , fly ash 80‑150kg / m 3 , mineral powder 40‑80kg / m 3 , micro silica fume 20‑40kg / m 3 , sand 650‑850kg / m 3 , gravel 900‑1100kg / m 3 , water 150‑180kg / m 3 , polycarboxylate water reducer 0.5‑1.5kg / m 3 , dense improvement material 20‑40kg / m 3 , super-hydrophobic harmful ion isolation material 10‑20kg / m 3 , anti-fouling biological corrosion agent 5‑10kg / m 3 . Adding compaction improvement materials to concrete can effectively improve the compactness of concrete after curing, which is beneficial to improve its corrosion resistance. At the same time, adding super-hydrophobic harmful ion isolation materials can isolate harmful ions in the marine environment from concrete and reduce harmful ions. The amount of corrosion damage, while the anti-fouling bio-corrosion agent added to avoid bio-corrosion caused by the marine environment, improve the overall anti-corrosion performance and durability of concrete.

Description

A kind of marine self-protection concrete and preparation method thereof technical field The present invention relates to a kind of functional concrete and preparation method thereof, relate in particular to a kind of marine engineering suitable for marine engineering environment Self-protection concrete and preparation method thereof. Background technique The durability of marine concrete is a problem that people are generally concerned about in the past half century, due to the complexity of the marine environment. Diversity, such as seawater immersion, wave scouring and the intervention of various rot ions, etc. The problem is becoming more and more prominent, seriously endangering the safety and durability of engineering facilities. Therefore, the anti-corrosion problem of marine concrete structures issue is gradually gaining attention. In marine concrete construction projects, the use of organic exterior protective coatings is the most commonly used to improve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/04C04B18/08C04B18/14C04B20/02C04B20/04C04B14/28C04B14/16C04B14/04C04B24/22C04B103/67C04B111/24C04B111/20

CPCC04B28/04C04B18/08C04B18/141C04B18/146C04B20/023C04B20/04C04B14/28C04B14/16C04B14/047C04B40/0046C04B2103/67C04B2111/24C04B2111/2092C04B14/06C04B14/02C04B2103/302C04B22/142C04B22/04C04B24/20C04B24/226C04B24/00Y02W30/91

Inventor 冯云龙夏京亮孟广成肖瑶王晶周永祥许贺程晓来

Owner CHINA ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com