Preparation method of three-dimensional graphene

A technology of graphene and graphene solution, which is applied in the direction of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of restricting macro-scale preparation applications, low volume density and specific surface area, high resistance and thermal resistance, etc., to achieve Broad application prospects, large specific surface area, and dense pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

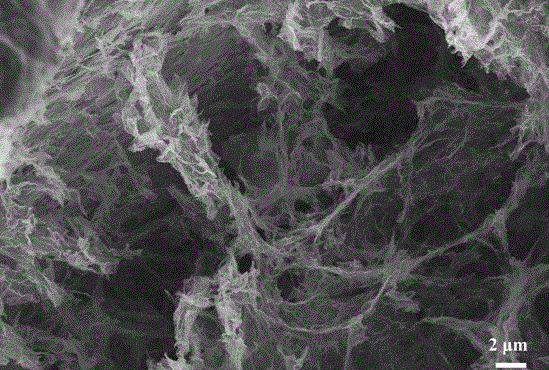

[0026] First, the modified Hummers method was used to prepare graphene oxide, and a 5 mg / mL graphene oxide aqueous solution was prepared by mechanical stirring and ultrasound, and poured into an autoclave. The cleaned nickel foam was immersed in the graphene oxide solution. The reactor containing the nickel foam and the graphene oxide solution was left to react at 180° C. for 12 hours to obtain the nickel foam loaded with graphene hydrogel in the pores. The nickel foam loaded with graphene hydrogel was freeze-dried for 3 days to obtain the nickel foam loaded with graphene aerogel ( figure 2 , image 3 ). Take this as a template, put it into a quartz tube, and evacuate it to 5×10 -3 Torr, backfilled with 200 sccm hydrogen and 500 sccm argon to atmospheric pressure. Heat the tube furnace to 1000°C, and anneal at 1000°C for 30 minutes. 10 sccm of methane gas was introduced to grow for 20 minutes. After the growth was over, the samples were taken out after the furnace was c...

Embodiment 2

[0028] First, graphene oxide was prepared by the modified Hummers method, and a 10 mg / mL graphene oxide aqueous solution was prepared by mechanical stirring and ultrasound. According to graphene oxide: ascorbic acid mass ratio is 1:3, adds ascorbic acid to graphene oxide aqueous solution. The cleaned nickel foam was immersed in the graphene oxide / ascorbic acid solution. The graphene oxide / ascorbic acid solution impregnated with nickel foam was left to react at 90° C. for 3 hours to obtain the nickel foam loaded with graphene hydrogel in the pores. The nickel foam loaded with graphene hydrogel was freeze-dried for 3 days to obtain the nickel foam loaded with graphene aerogel. Take this as a template, put it into a quartz tube, and evacuate it to 5×10 -3 Torr, backfilled with 200 sccm hydrogen and 500 sccm argon to atmospheric pressure. Heat the tube furnace to 1000°C, and anneal at 1000°C for 30 minutes. 10 sccm of methane gas was introduced to grow for 20 minutes. After t...

Embodiment 3

[0030] First, graphene oxide was prepared by the modified Hummers method, and a 10 mg / mL graphene oxide aqueous solution was prepared by mechanical stirring and ultrasound. The cleaned nickel foam was immersed in graphene oxide solution, and the graphene oxide solution impregnated with nickel foam was directly freeze-dried for 3 days to obtain nickel foam loaded with graphene airgel. Take this as a template, put it into a quartz tube, and evacuate it to 5×10 -3 Torr, backfilled with 200 sccm hydrogen and 500 sccm argon to atmospheric pressure. The tube furnace was heated to 1000°C at a rate of 2°C / min, and annealed at 1000°C for 30 minutes. Bubble 50 sccm hydrogen / 100 sccm argon into ethanol, use the introduced ethanol vapor as carbon source, and grow for 30 minutes. After the growth was over, the samples were taken out after the furnace was cooled to room temperature. A 4% PMMA anisole solution was added dropwise to the sample surface, followed by curing on a hot stage at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com